Making Milk Powder

Find innovative production technology for making milk powder and connect directly with world-leading specialists

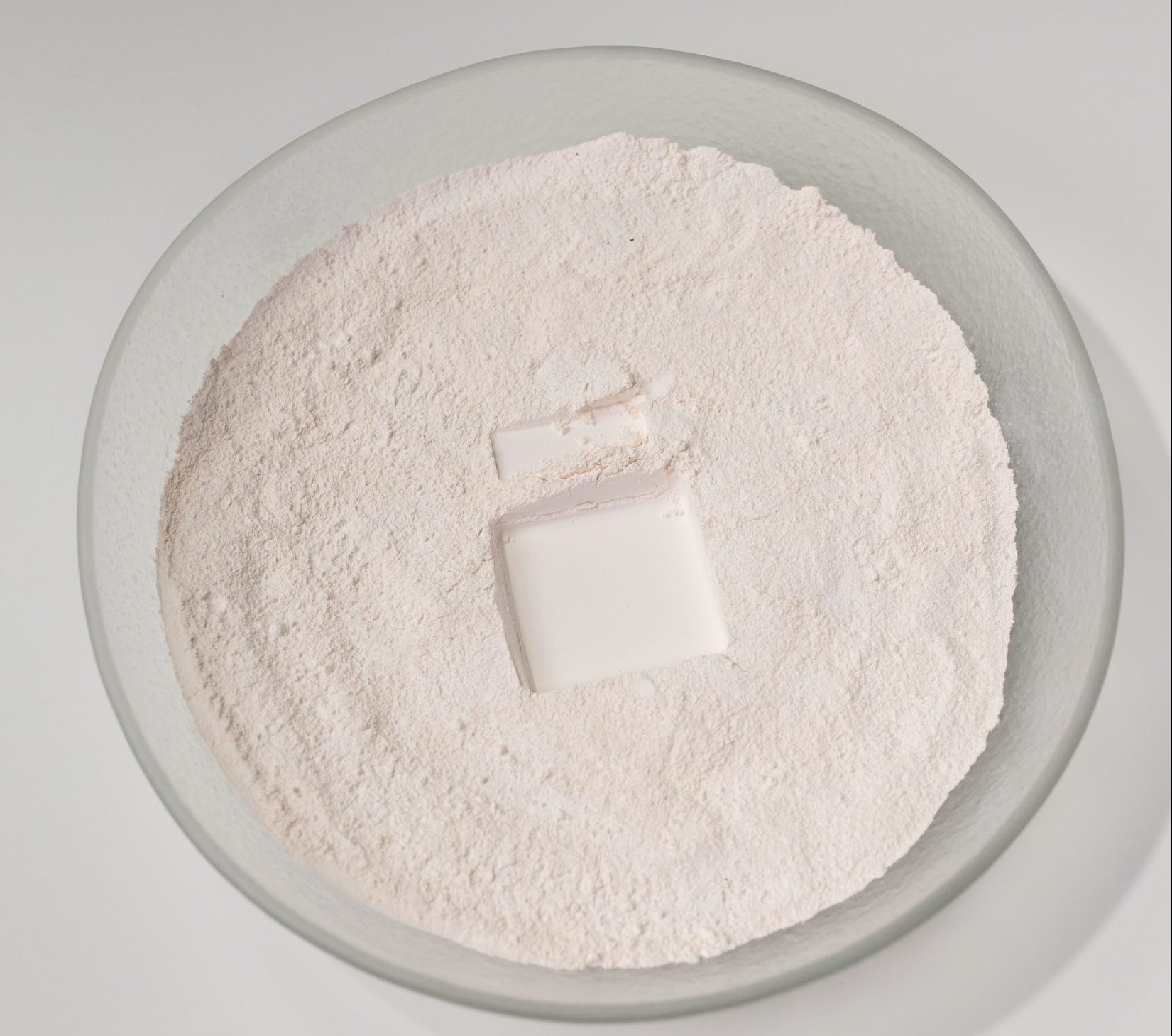

Basically, to make milk powder, you need to remove the water content from the liquid milk and turn it into powder. How to do it? After pasteurizing and homogenizing the milk, milk’s water content is removed through filtration, evaporation, and drying. You have then to cool and sieve it before filling the containers. Here's how you get milk powder.

Select your milk powder process

Tell us about your production challenge

Milk powder processing – From liquid to powder

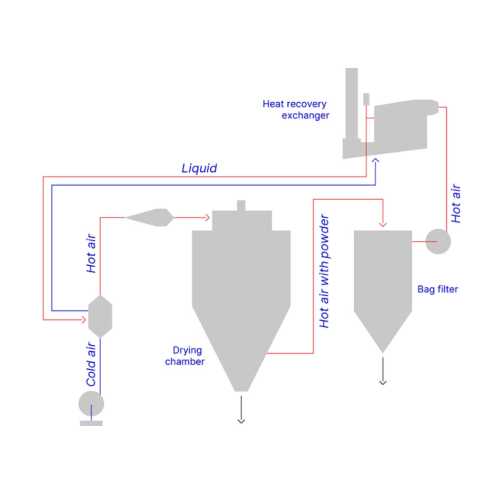

Milk is 87% water. The idea of turning raw milk from liquid to powder form relies heavily on removing water content from milk. This involves three processes: filtration, evaporation, and drying

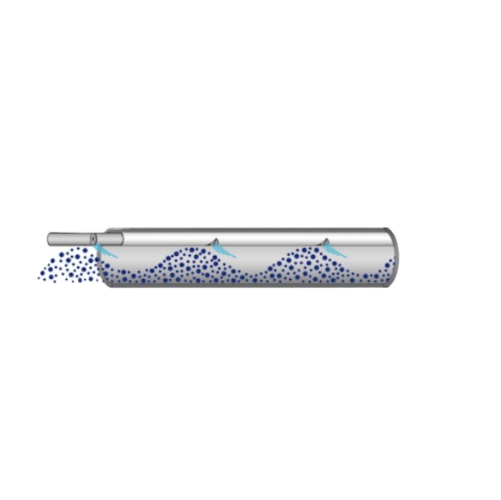

In filtration, milk passes through filters that have special membranes that let water pass through. This stage removes about 60 percent of the water content. The filtered milk then goes through the evaporator which heats it to remove an additional 25% water content. And finally, the processed milk goes to the dryer, in which it is injected at high pressure in a chamber with hot air that rapidly removes the remaining moisture. At this point, the fluidized bed dryer cools the milk powder and after sieving it, it goes to a filling machine for packaging.

Powdered milk in other food production and applications

Powdered milk has more applications than you might think; from infant formula to chocolates and other baked goods like sweets and desserts, you can use milk powder as a flavoring or to create a creamy texture in some food recipes. Using it as an ingredient, you can create condensed milk, evaporated milk, coffee creamer, whipped toppings, yoghurts, cottage cheese, pastries, cookies, etc. This solid form of concentrated milk is widely used in homemade applications as well as in the baking industry.

Did you know that it can also be used to create a facial mask and other soothing skin treatments? Scoop a bowl of milk powder and add enough water to make a thick paste. With clean hands, apply the paste to your face. Let it dry, then rinse it off for soft smooth skin. It can also soothe insect bites and other skin irritations.

Storage and shelf life that makes the difference

Milk powder is known to have a longer shelf life than liquid milk. That’s because, for microorganisms to grow, a minimum amount of water in an environment is necessary. Since liquid milk has more water, it will have more microbial growth. During milk powder processing, dehydration processes remove the water content, so powdered milk will have less microbial growth. Actually, if stored properly, milk powder has a shelf life of more than one year.

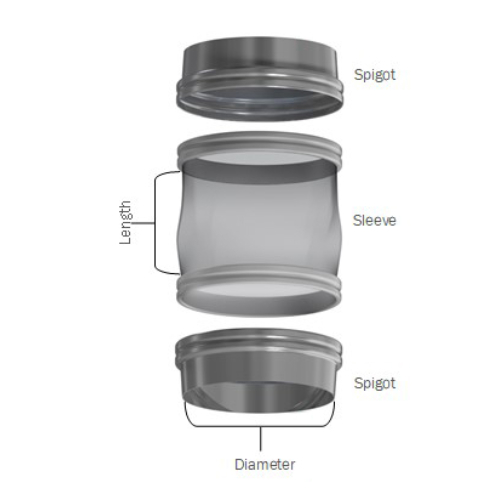

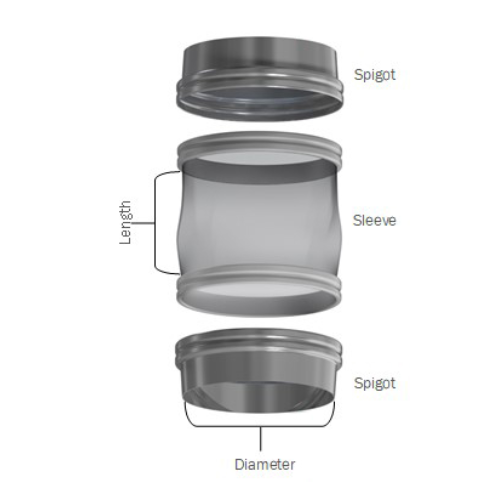

Choosing cans for packaging infant milk powder

Packaging of milk powder comes in different types of containers. You can choose between pouches or cans depending on the application. For example, infant milk powder is packed in cans.

The cans are mostly filled with nitrogen to minimize the amount of oxygen inside. This helps prolong shelf life as excessive oxygen can deteriorate the quality of milk powder. After filling, the seaming machine uses two layers for sealing. Inner layer completely seals the milk powder by metal foil or lid, and the outer layer is a plastic cover.

Processing steps involved in milk powder making

Which milk powder technology do you need?

Milk and whey skimming centrifuge

Enhance your dairy processing with advanced centrifuge technology, optimizing milk and wh...

Bacteria removal separators for milk and whey

Optimize your dairy production by effectively removing bacteria and spores f...

Inline powder analysis system

Ensure optimal powder quality with real-time measurement of moisture, density, and contaminant...

Spray dryer performance optimization system

Achieve unparalleled spray drying efficiency with real-time monitoring and con...

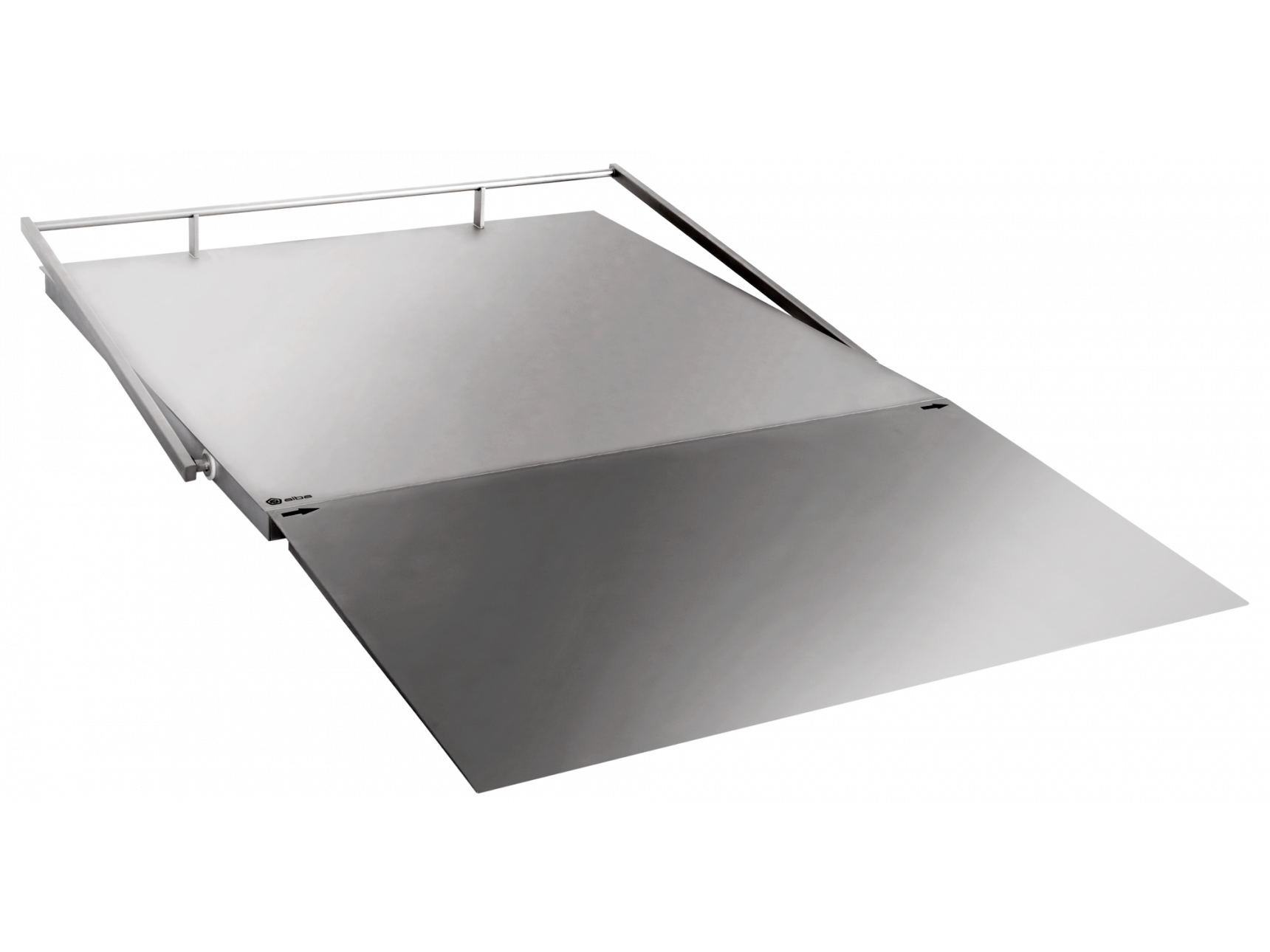

Sanitary cover for visual inspection

Ensure optimal hygiene and easy access in your production line with a transparent cove...

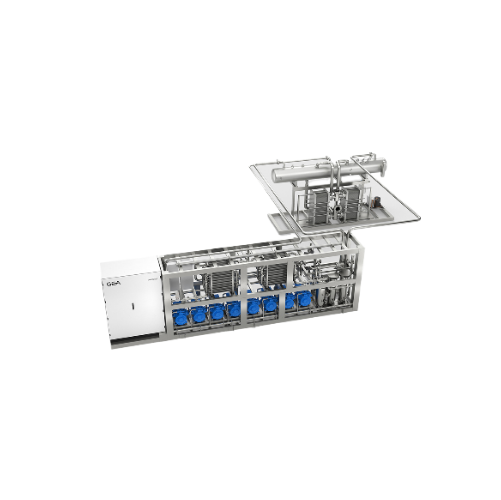

Milk evaporator for dairy industry

Optimize your liquid food production with precise control over evaporation processes, en...

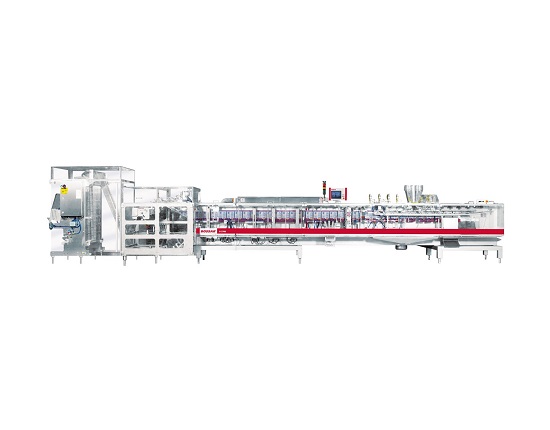

Complete milk processing lines

Optimize liquid product quality with a comprehensive processing line that integrates pasteuri...

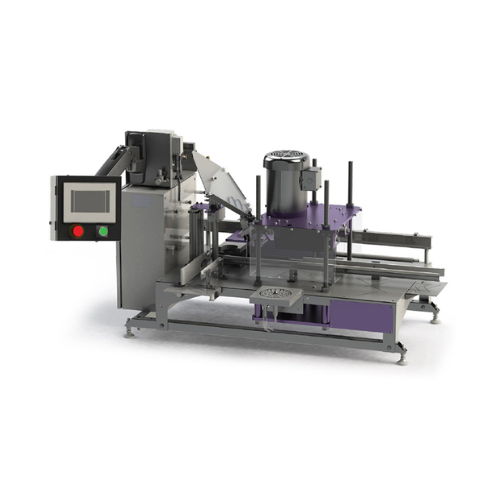

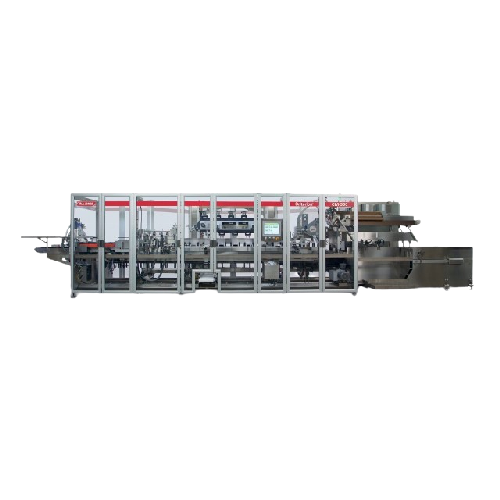

Medium-speed end load cartoner for food and beverage packaging

Streamline your packaging line with versatile cartoning c...

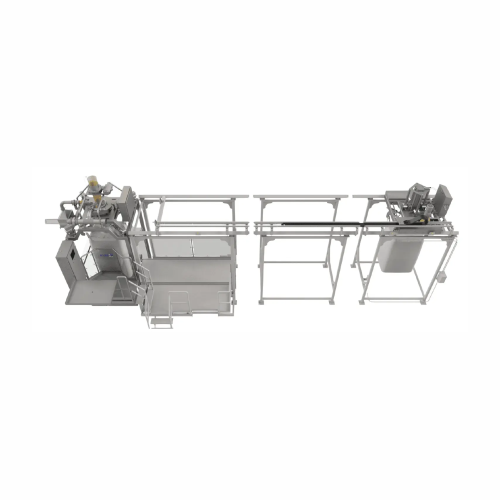

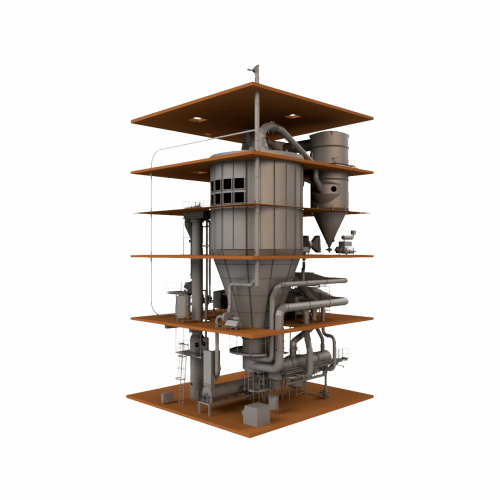

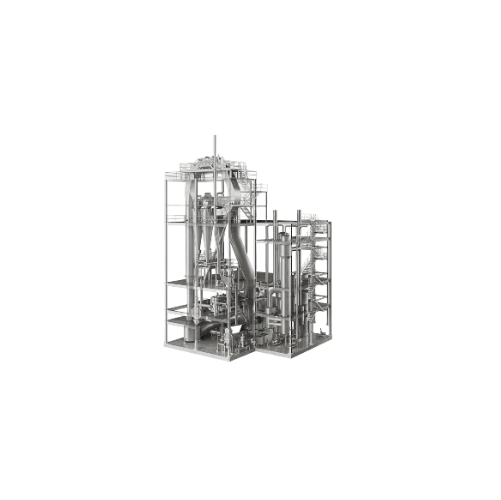

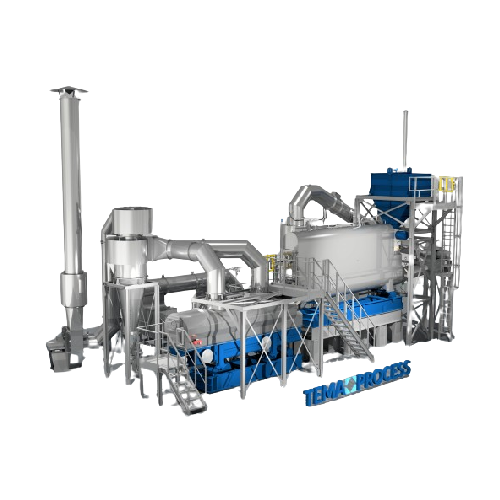

Milk powder processing plant

Achieve precise powder formulations with our state-of-the-art milk powder processing plant, ide...

Condensing unit for ice storage tanks

Enhance the longevity and quality of your dairy and cold storage products with a robu...

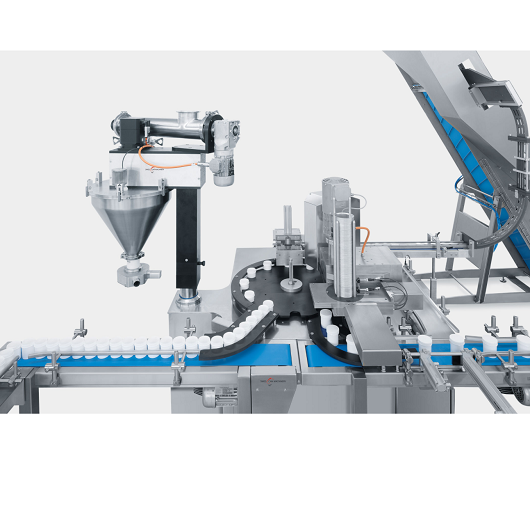

Automated milk dosing system for dairy production

Ensure precise milk allocation for diverse cheese types with this robus...

Milk receiving and storage units for dairy operations

Streamline your dairy processing with equipment designed to efficie...

Mechanical conveyors for powder transport

Optimize your powder and granule handling with precise, customizable conveying s...

Magnetic separators for metal contaminant removal in powder processing

Ensure product purity and safety by effectively ...

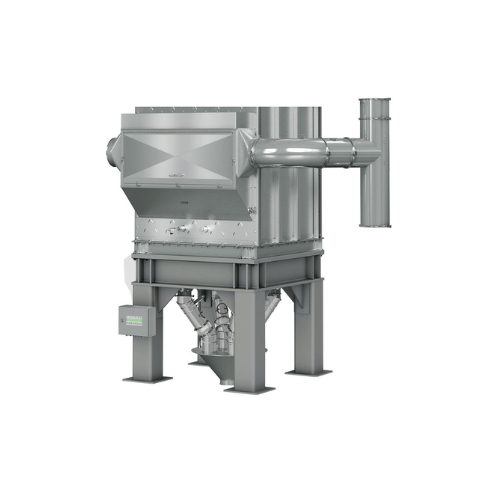

Air filtration system for dairy and food powder processing

Optimize powder processing with advanced air filtration, ensu...

Powder sifters for industrial applications

Optimize powder consistency and enhance production flow with advanced sifting t...

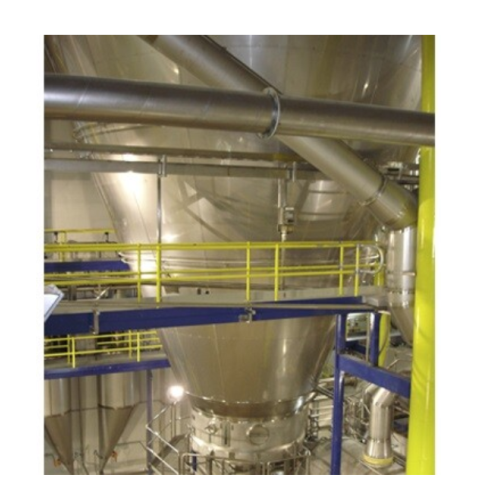

Storage silos and hoppers for food and dairy industries

Ensure optimal powder storage with solutions that enhance space e...

Powder unloading systems for food and dairy applications

Streamline your powder handling with customizable unloading syst...

Flexible connector for bulk powder manufacturing

Eliminate leakage and enhance hygiene in your powder processing with a sn...

Flexible connector system for bulk powder processing

Eliminate leaks and enhance hygiene in your powder processing line w...

Powder and liquid mixing system for food and life sciences

Achieve rapid and homogeneous dissolution of large quantities...

Box weight checkweigher for bulk bag-in-box applications

Ensure precise weight control in bulk packaging lines with this ...

Industrial Xl bag sealer for large pallet containers

Eliminate manual handling and ensure perfect seals for bulk packagin...

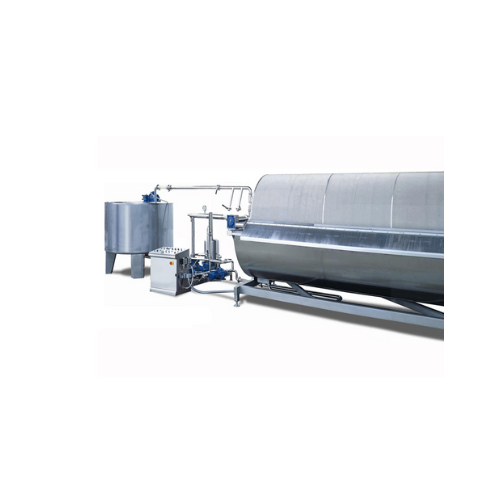

Cip system for wine, grape juice, oil, and dairy

Ensure optimal hygiene and operational efficiency in processing lines wit...

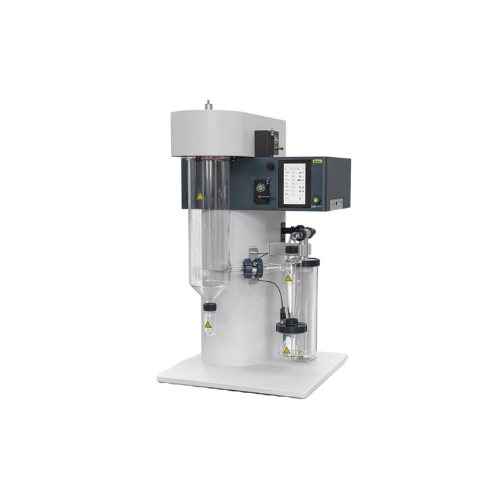

Pilot scale spray dryer for product development

Achieve precise moisture levels and product consistency in development env...

High infeed palletizer for varied product types

Optimize your production line with high infeed palletizers, ensuring seaml...

Energy-efficient impact classifier for superfine grinding

Achieve precise superfine grinding with energy efficiency, per...

Industrial metal detector for food production lines

Ensure product safety and compliance by seamlessly detecting metal co...

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

Vacuum paddle dryer for laboratory use

Achieve precise temperature and moisture control in your batches with this vacuum sh...

High-shear inline mixer for lump-free products

Achieve consistent texture and prevent clumping in liquid and powder blends...

Jars and bottles rinsing solution

Ensure impeccable hygiene and particle-free cleanliness for your jars and bottles by inte...

Dense phase vacuum conveying for fragile powders

Efficiently convey fragile powders without compromising their integrity, ...

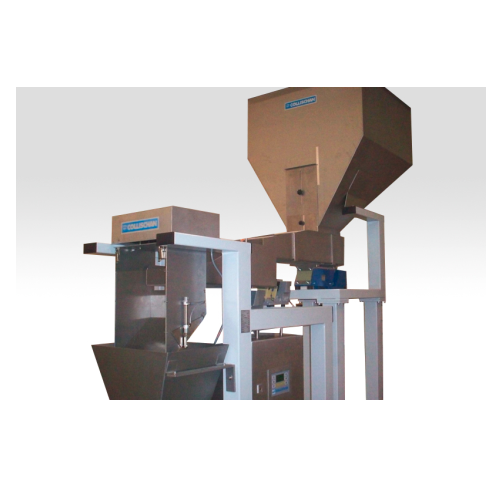

25kg automatic dry powder packaging system

Optimize your packaging line efficiency with precise, high-speed handling for 2...

25kg powder packaging system for sanitary applications

Achieve high accuracy and hygiene in powder packaging with a syste...

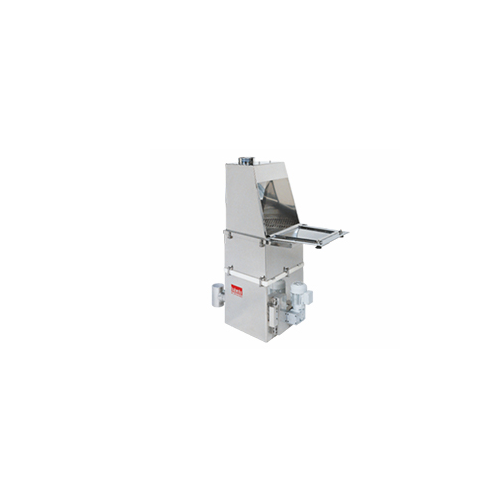

Bag break station for pneumatic conveying systems

Efficiently manage powder feeding and dust control in your production l...

Sanitary bulk bag filling system

Streamline your powder handling process with a system designed to improve stability and acc...

Bulk bag filler with integrated palletizing system

Optimize your powder packaging with a seamless system that fills and a...

Sanitary bulk bag unloader for powdered products

Efficiently manage powder discharge with enhanced dust control and stream...

Ultrapure water demineralizer for critical boilers

Achieve high-purity water production with minimal chemical usage and a...

Advanced hollow fiber membrane for wastewater treatment

Tackle high solid challenges in water treatment with robust ultra...

Permeate drying system for dairy applications

Optimize your dairy production with efficient permeate drying, delivering hi...

Tall form bustle dryer for dairy and food products

Experience efficient drying and precise moisture control with this inn...

Lactose crystallizing evaporator

Optimize lactose yield and crystal size control in continuous processing, enhancing product...

Sorting system for blueberries

Streamline diverse food processing tasks by efficiently conveying, processing, and sorting pr...

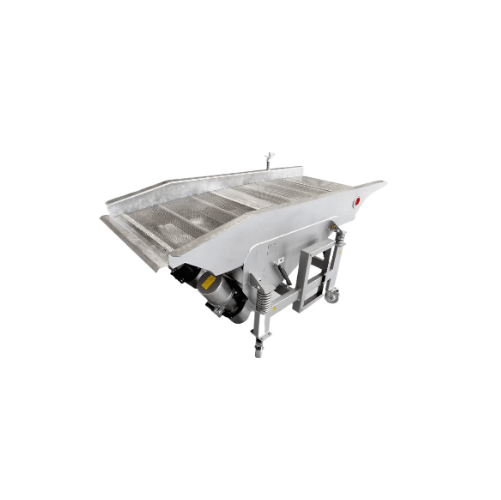

Vibratory conveyor for efficient bulk material transportation

Optimize your processing line with robust vibratory convey...

Vibrating control screeners for high volume screening and sifting

Ensure precise material separation with a solution de...

Double cone blender for fragile and abrasive material

Achieve homogeneous blends of fragile materials while minimizing da...

Tumbler screener for multi-deck screening in powders and granules

Achieve precise separation and de-dusting of powders ...

Industrial silos for powdered and granulated products

Optimize your storage and material flow for powdered and granulated...

Big bag unloading station for solid materials

Streamline your production line by efficiently handling and dosing bulk soli...

Big bag unloading station for solids handling

Optimize bulk solid ingredient handling with this station, designed to strea...

Double cone blender for homogeneous solid-solid mixtures

Need uniform blending for complex solid mixtures with diverse de...

Industrial sieving solution for solid materials

Effortlessly separate impurities and adjust particle size for optimal prod...

Industrial v-type solids blender for homogeneous mixture

Achieve precise blending of diverse powders and solids using the...

Vacuum rotary filter for liquid filtration

Enhance your production line’s efficiency with precise filtration, ensuri...

Powder blender for liquid mixing applications

Optimize your process with a compact blender designed to efficiently dissolv...

Powder liquid blender for food processing

Achieve seamless integration of solids into liquids with precision-engineered bl...

Cip cleaning system for dairy industries

Ensure hygienic operation with this system, designed to maintain optimal cleanline...

Powder liquid mixer for pectins and starches

Struggling with clumpy, undissolved granules in your mixtures? This innovativ...

Industrial powder grinder

Achieve precise particle size reduction and classification with advanced equipment designed for co...

Powder mixing systems

Optimize your production line with precision powder mixing systems that ensure uniformity, enhance prod...

Choppers and disintegrators for industrial size reduction

Enhance your production efficiency by mastering size reduction...

Drying systems for powders and bulk solids

Enhance your production line with precise control of moisture content in powder...

Cip/sip cleaning for solids processing systems

Ensure seamless transitions and maintain hygienic production environments w...

Continuous powder agglomeration system

Enhance product solubility and flowability while minimizing energy consumption with ...

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

Industrial granulator for high-throughput plastic recycling

Facing challenges in efficiently recycling high-volume plast...

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Ball mill for dry comminution of hard materials

Achieve ultrafine particle sizes and precise material breakdown with this ...

Air jet sieve for particle size analysis

Achieve precise particle size distribution effortlessly for your powders, ensuring...

Horizontal vacuum paddle dryer for sensitive pharmaceutical ingredients

Achieve precise drying and mixing of sensitive ...

Vacuum drying solution for filter cake or viscous materials

When faced with the challenge of drying filter cake or trans...

Industrial metal detector for gravity feed applications

Ensure the purity of your products by detecting and removing both...

Stationary entry packaging system for valve bags

Optimize your packaging workflow with a high-speed, modular filling syste...

Over-driven conical mills for precise particle size reduction

Achieve consistent particle size reduction with minimal he...

High capacity production milling for bulk materials

Optimize your production with our high-capacity milling solution, des...

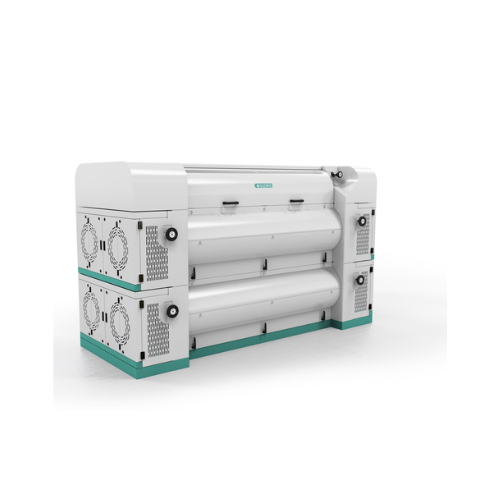

Chocolate refiner and conche solution

Elevate your chocolate production with a versatile solution that seamlessly integrate...

Industrial melting unit for chocolate and powders

Enhance your production efficiency by seamlessly melting and homogenizi...

Stainless steel chocolate tank for storage and processing

Efficiently control temperature and consistency for chocolate ...

Spouted bed processing for food, feed, and fine chemicals

Tackle the challenge of processing temperature-sensitive and s...

Sampling valve for secure sample extraction

Ensure product quality by safely extracting representative samples without hal...

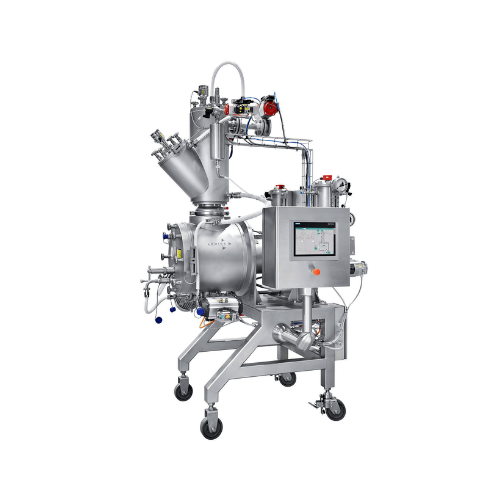

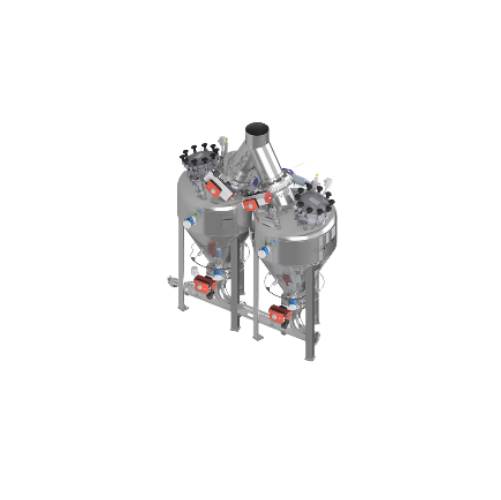

Fermenter for microbial fermentation processes

Optimize your fermentation and biopharmaceutical production with stainless ...

Conical powder mixer for uniform powder blending

Achieve consistent powder blending while preserving the integrity of deli...

Ultraclean aseptic storage tanks for hygienic liquid food

Ensure your liquid products remain uncontaminated and maintain...

Automated cleaning in place (cip) systems for beverage processing

Optimize your production with automated CIP systems t...

Industrial vibrating sifters for granular material separation

Achieve precise particle separation and ensure product pur...

Vibration transport system for hygienic conveying of bulk goods

Optimize your production line with efficient and hygieni...

Industrial mixer for batch granules or grains

Achieve precise mixing with seamless integration of heating, sterilization, ...

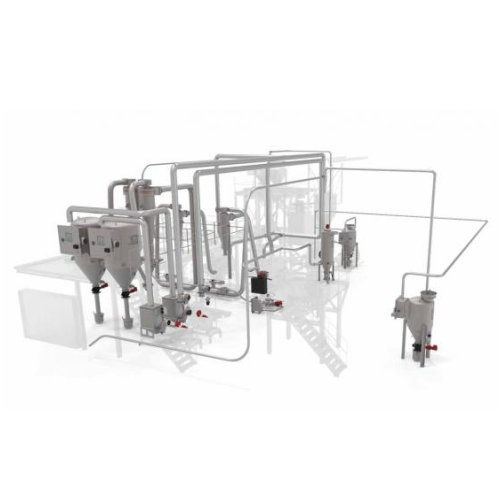

Industrial pneumatic conveying system for powders and granulates

Achieve hygienic and dust-free transport of powders and...

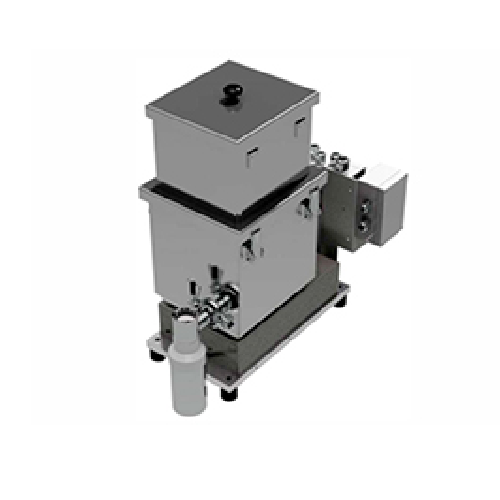

Micro dosing system for precise powder weighing

Achieve unparalleled dosing accuracy in your production line with a system...

Modular big bag unloading station for various materials

For hassle-free handling of bulk materials, this modular solution...

Industrial centrifugal sifter for solid particulate materials

Quickly and accurately sift a wide range of powders and gr...

Extraction plant for natural essences and active ingredients

Optimize your extraction processes with a versatile system ...

Thermal process plants for liquid treatment

Achieve precision thermal processing with systems designed to optimize the hea...

Lactose pneumatic conveying solution

Eliminate frequent production halts due to lactose buildup with our conveying solution...

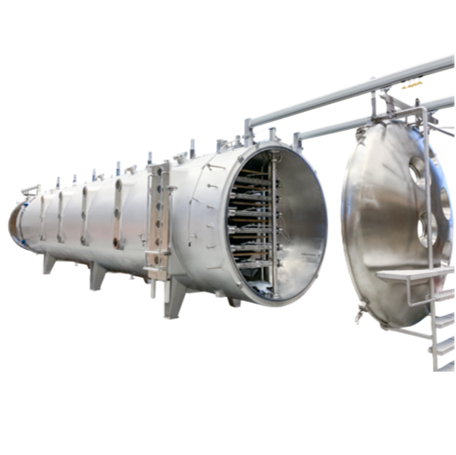

Industrial freeze dryer for large scale food processing

Optimize moisture removal for high-quality food preservation and ...

Industrial low temperature freeze dryer for high sugar or acid content products

For processing challenging high sugar ...

Weigh filler for bulk quantities 2-20kg

Optimizing your filling process with precision, this equipment handles bulk quantit...

Powder addition system for oils and fats

Efficiently integrate powdered additives into your liquid processes with our hygie...

Precision size grader for tomatoes and round fruits

Ensure precise grading and sorting of tomatoes and round fruits to op...

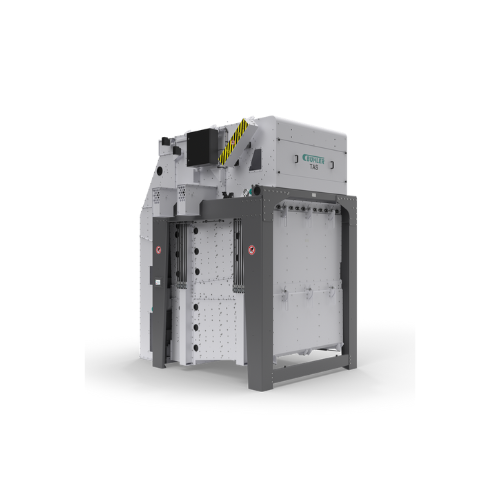

Grain separator for impurity removal in milling

Optimize grain cleaning with a high-performance separator designed to effi...

Grain cleaning system for high-quality processing

Optimize your grain processing with a versatile cleaning system designe...

Automatic rice whitening solution

Need consistent rice whiteness and bran removal without manual intervention? This high-sp...

Batch mixer for animal feed

Streamline your mixing process with a high-speed batch mixer that delivers up to 20 mixing cycle...

Optical sorter for grains, seeds, and plastics

Enhance sorting efficiency with cutting-edge optical technology that distin...

Laboratory plansifter for particle-size distribution

Optimize your grain milling and brewing operations with precise part...

Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal tr...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Cracking mill for oilseeds and feed

Enhance your production efficiency with a cracking mill that optimizes throughput and m...

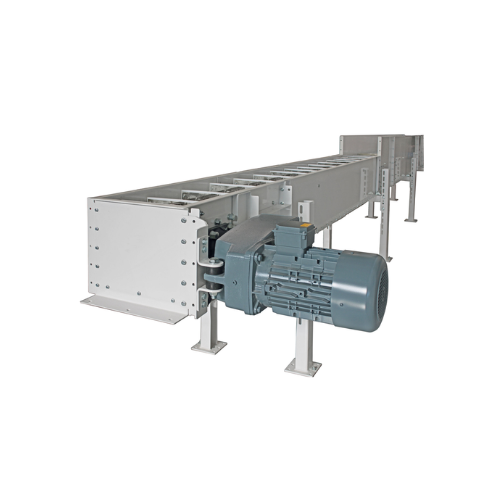

Chain conveyor for grain handling

Optimize your production line with a customizable chain conveyor that ensures efficient, ...

Laboratory spray dryer for organic solvent samples

Experience precise particle control and enhanced safety when convertin...

Protein and nitrogen analysis system for laboratories

Streamline your nitrogen and protein analysis with precision titrat...

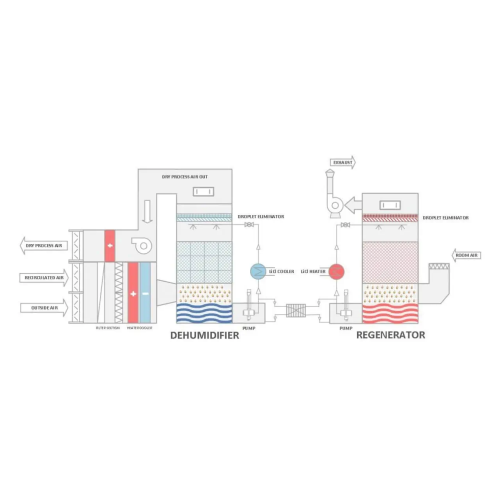

Industrial dehumidifier for continuous spray drying

Ensure stable spray drying conditions with precise humidity control, ...

Versatile steam distillation unit for laboratory applications

Achieve reliable analysis of complex samples with this ste...

Inert loop for safe organic solvent spray drying

Ensure safe handling and efficient recovery of organic solvents in spray ...

Industrial tanks for diverse applications

Efficiently manage your liquid production processes with customizable storage, m...

Standard starch viscometer for gelatinization analysis

Ensure precise gelatinization property measurement with real-time ...

Small twin screw extruder

Optimize your lab and pilot production with a versatile twin screw extruder, designed for precise ...

Lab- and pilot-scale twin screw extruders for small-scale production

Optimize extrusion techniques with lab and pilot-s...

High-speed case packer for snack bags

Optimize your packaging efficiency with a compact solution designed for seamless vert...

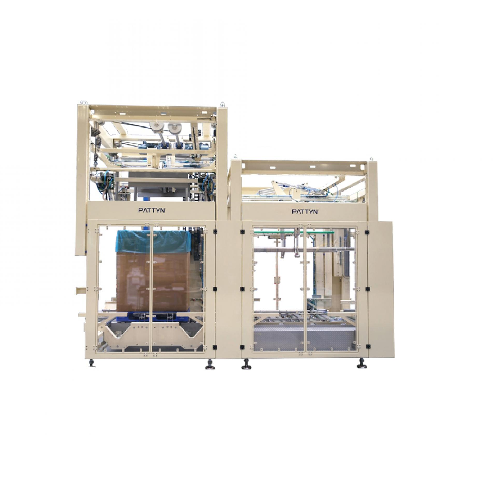

Horizontal load carton erector for food production

Enhance your production line with precise carton erecting, loading, an...

Horizontal case packing and tray loading

Enhance your packaging line efficiency with a highly adaptive system that seamless...

Tray erecting system for various tray styles

Effortlessly configure diverse tray styles with an efficient system designed ...

Industrial homogenizer for high pressure applications

Achieve consistent product texture and stability for your emulsions...

Cheese vat for diverse cheese production

Optimize your cheese production with a versatile cheese vat designed for precision...

Vertical ribbon mixer for solids and powders

Achieve rapid, uniform mixing of powders and solids while preserving particle...

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

Horizontal ribbon blender for solids and powders

Efficiently achieve uniform blending of bulk solids and powders, ensuring...

Conical screw mixer for solids and powders

Achieve precise homogenization of your solid and powder mixtures with minimal e...

Integrated pickup station for bagged products and big bags

Streamline the handling and transition of bulk materials with...

Advanced powder dosing system for continuous production

Achieve precise powder integration into your liquid processes, en...

Dust-free docking collar for containers and bins

Achieve seamless, dust-free connections between containers and processing...

Accurate dosing for powder products

Ensure precise dosing and consistent flow of bulk powders in your production line to en...

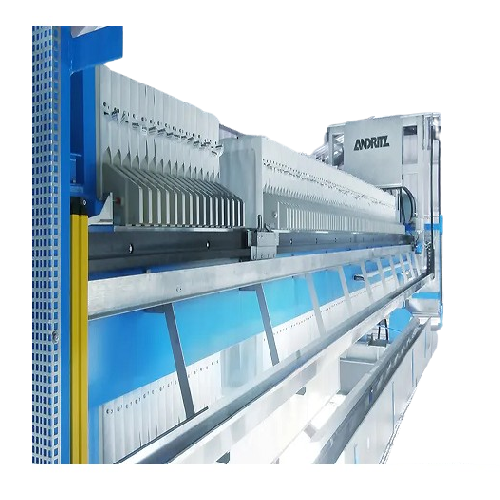

Industrial filter press for dewatering and filtration

Optimize your dewatering and filtration needs with a highly adaptab...

Volumetric filler for bags and rigid containers

Optimize precision filling of powders and granules with a versatile soluti...

Multi-fill powder filling system

Achieve precise and consistent filling for your powdered and granulated products with a mod...

Special purpose auger filling systems for diverse industries

For manufacturers handling precise dosing, our advanced aug...

In-line filling system for various container sizes

Streamline your production with versatile in-line filling solutions th...

Vertical form fill seal filling system for auger applications

Effortlessly integrate precise powder and granule filling ...

Foodec decanter centrifuge for food processing

Achieve high yields and clear liquid separation in your food processing lin...

Powder filling machine for dry products

Achieve precision and consistency in filling dry powders and granules with a versat...

In-line vacuum powder filler

Optimize your production line with precise, contamination-free filling for nutritional powders,...

Barcode reading and verification system

Ensure every container has the correct product with a cutting-edge scanning system ...

Container inspection and particulate detection system

Ensure product integrity and efficiency by accurately detecting and...

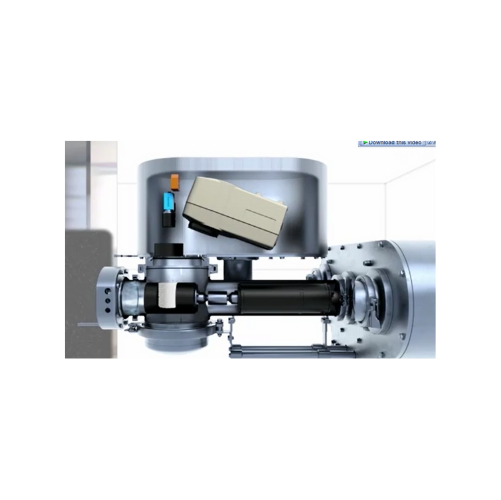

Vacuum gassing seamer for infant formula packaging

Ensure low residual oxygen levels in your powdered products with a spe...

Vacuum powder filler for dairy and pharmaceutical products

Achieve precision and maintain product integrity with a versa...

High-speed container reject system

Ensure product integrity by swiftly rejecting non-compliant containers at speeds up to 3...

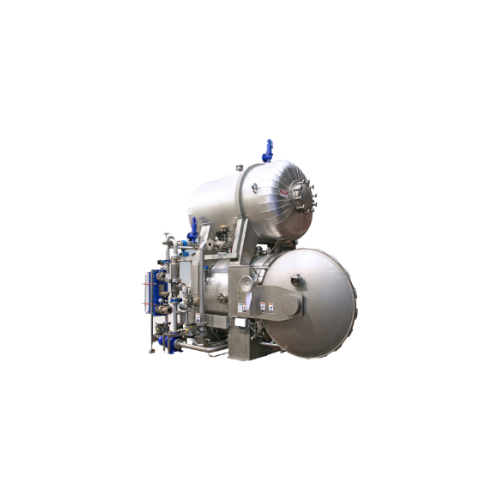

Multi-purpose laboratory sterilizer for food processing

Achieve precise thermal process design and flexibility with a ste...

High pressure pumps for viscous fluid transfer

Optimize fluid transfer with high pressure pumps designed to handle viscous...

Cyclone filter for pneumatic conveying systems

Efficiently separate and filter airborne dust in pneumatic conveying lines,...

Self-cleaning silo filter

Ensure purity and compliance by trapping dust effectively during silo loading, while maintaining c...

Square sieve for removing foreign bodies and grain sizes

Achieve precise material separation and enhance product purity w...

Industrial vibrating extractor for homogeneous product conveyance

Ensure consistent flow of dry bulk materials with a v...

Food product sifter

Ensure precise separation with vibratory sifters designed for continuous operation, delivering gentle han...

Industrial powder sifter with sanitary compliance

Optimize your powder processing with this versatile sifter, ensuring pr...

Sifter for pet food, fish feed, and animal feed

Achieve precise particle separation and enhance feed quality with this vib...

Cyclone tank for dust separation in production lines

Optimize your production line with efficient dust separation, ensuri...

Big bag emptying station for bulk product handling

Streamline your bulk material handling with a station designed to effi...

Industrial bucket elevator for efficient product conveyance

Enhance production efficiency by elevating and transferring ...

Direct discharge descender for product handling

Efficiently transport granulated materials without compromising their inte...

Finished product storage silos for industrial applications

Optimize your storage capabilities with silos that ensure saf...

Silo unloading belt for food industry

Ensure seamless flow and precise control when unloading silos with this automated bel...

Big bag emptying station for raw materials

Streamline your material handling process by efficiently lifting, emptying, and...

Big bag loading station for bulk product handling

Efficiently manage big bag handling with a system that combines hoistin...

Dense phase vacuum conveying system for powder handling

Effortlessly transport delicate powders and fragile granules with...

Lean phase pressure conveying for powder handling

Effortlessly transport and manage powdered materials with lean phase pr...

Lean phase vacuum conveying system for powder handling

Efficiently transport and separate powders and granules with preci...

25kg bag tipping station for powder discharge

Efficiently discharge and sieve 25kg bags of powder while minimizing dust em...

Rotary tube selector valve for powder conveying

Streamline your pneumatic transport system with a robust solution that div...

Auger powder sampler for industrial quality control

Ensure precise quality control by integrating an auger powder sampler...

Vacuum powder sampler for particle size distribution control

Ensure precise quality control with a vacuum powder sampler...

Bulk storage silos for food products

Ensure optimal powder storage and handling with versatile silos designed for efficient...

Powder sampling solution for dairy and food processors

Ensure precise quality control with a versatile sampling system de...

Powder spool sampler for dairy and food processors

Efficiently manage powder quality with a robust spool sampler designed...

Automatic bag slitting and emptying for powders

Streamline your powder-processing operations by seamlessly integrating bag...

Dense phase pressure conveying system

Efficiently transport high-capacity powders across long distances with precision and ...

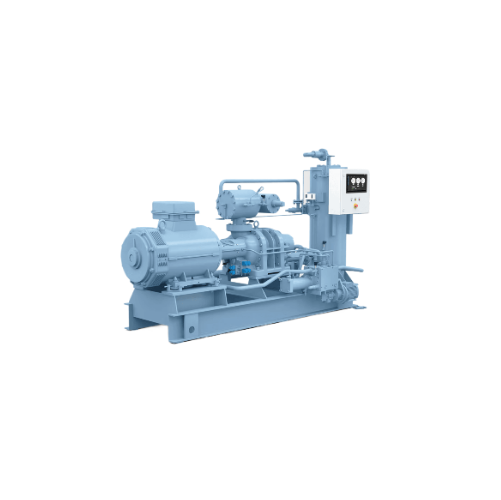

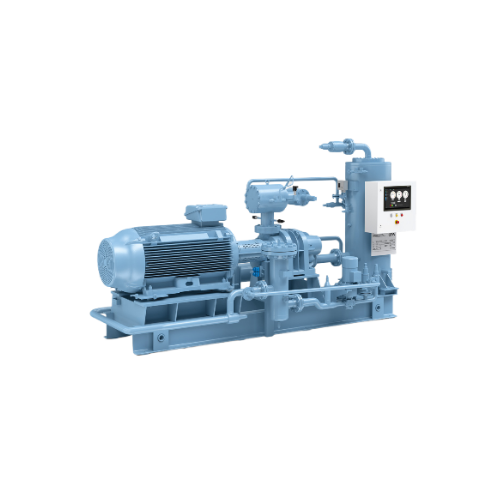

Single-stage screw compressor package

Optimize your refrigeration and heating processes with versatile packages designed to...

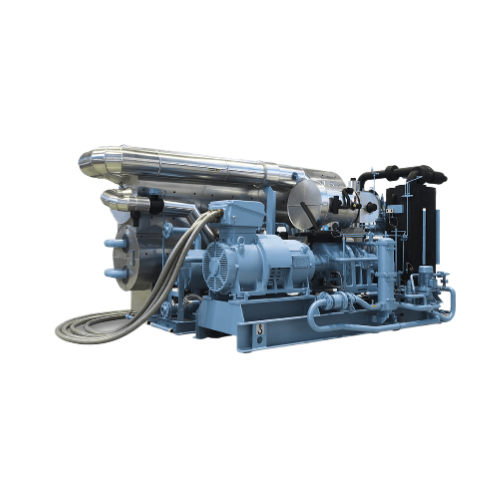

Co2 cooling and Nh3 heating solution

Achieve precision in temperature control with cutting-edge high-pressure compressor sy...

High shear powder dissolver for homogeneous products

Achieve consistent powder-liquid blends effortlessly with a compact ...

Standardization unit for cream fat or milk fat

Optimize your milk standardization process to achieve precise cream and fat...

Customized industrial heat pumps

Optimize your industrial processes with versatile heat pumps that recover and utilize waste...

Industrial ammonia heat pump for efficient heating solutions

Need reliable and efficient heating capabilities while mini...

Palletizer for high-speed pallet loading

Achieve efficient, high-speed palletizing with a system designed for seamless inte...

Low care bulk powder fillers

Optimize your production efficiency by accurately filling flexible bulk containers with dry pow...

Bag, box, and drum container handling solutions for powder products

Optimize the flow and integrity of your powder pack...

Powdered product shelf-life enhancement through inert gas packing

Extend the shelf life of sensitive powder products by...

Inline automatic powder fillers for food and nutraceuticals

Ensure precise and efficient filling of sensitive powders in...

Continuous leveler and sealer for powder packing

Enhance efficiency in powder packaging with a system that ensures precise...

Semi-automatic powder filling system for food products

Achieve precise and flexible filling for food powders and granules...

Hygienic powder filling system for low throughput

Ideal for compact production facilities, this filling system efficientl...

Automated powder bag filling system

Streamline your powder packaging operations with a fully integrated system that automat...

High care bulk powder fillers

Ensure hygienic packaging for your bulk powders with a system designed to enhance filling accu...

Dairy evaporator for nutritional formula

Enhance your dairy processing by optimizing energy efficiency and product quality ...

Dairy waste reduction with evaporator product recovery

Transform dairy processing by efficiently recovering valuable low ...

Falling film evaporator for temperature-sensitive products

Ensure consistent concentration and quality of heat-sensitive...

Multi-flash evaporators for alumina industry

Experience efficient thermal separation with enhanced heat recovery, ideal fo...

Compact plate evaporator for temperature-sensitive products

Ensure optimal heat transfer and minimal space usage with th...

Explosion protection vents for spray dryers

Optimize safety and hygiene in your spray drying operations with advanced expl...

Heat pump solution for spray dryers

Enhance your spray drying efficiency and sustainability with an innovative heat pump sy...

Concentrate heater for dairy spray dryers

Achieve precise temperature control in dairy powder production with a concentrat...

Spray dryer for nutritional and dairy powders

Achieve precise particle size and optimal drying of nutritional and dairy po...

Lab-scale spray dryer for small volume powder samples

When developing new formulations, achieving consistent powder quali...

R&d spray drying solution for small batch production

Efficiently convert liquid solutions into precise, uniform powders f...

Powder separation cyclone for food and chemical industries

Optimize your powder production with advanced cyclone technol...

Automated fines return system for food and dairy spray dryers

Enhance your spray drying process by eliminating manual in...

Bag filter for food and dairy spray dryers

Achieve cost-efficient and reliable dedusting for your spray drying processes w...

Heat recovery system for spray drying plants

Enhance your spray drying efficiency with a heat recovery system that capture...

Feed-type ring dryer for industrial drying processes

Optimize your production with a versatile drying solution designed f...

P-type ring dryer for thermally sensitive products

Optimize moisture control and prevent thermal degradation in your prod...

Clean purge system for spray dryers

Enhance safety and efficiency by preventing fire risks in spray dryers while improving ...

Spray dryer for whey and milk powders

Optimize your drying process for dense, agglomerated whey and milk powders with a spa...

Conventional spray drying for chemical industry

Achieve optimal particle size uniformity in food powders with precision at...

Co monitoring system for spray dryers

Ensure safety and prevent costly disruptions in your spray drying process by monitori...

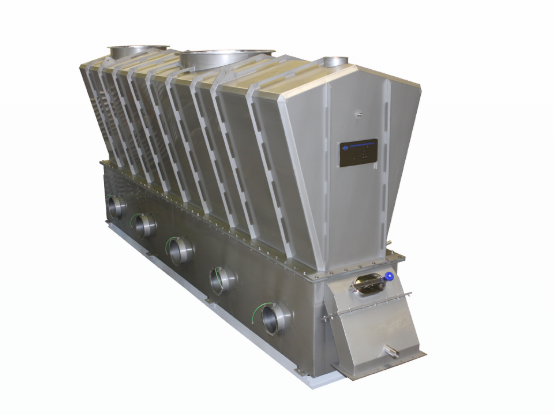

Static fluid bed dryer for powder and granular materials

Achieve optimal moisture control in powder and granular products...

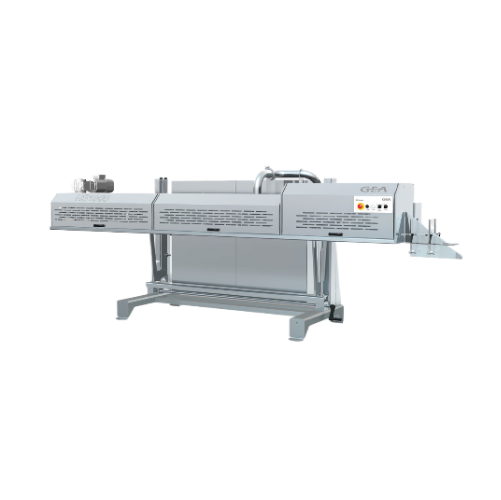

Vibrating fluid bed for final stage powder drying

Enhance powder processing precision with a vibrating fluid bed that ens...

Mvr and Tvr heated distillation system

Achieve superior energy efficiency and reduced steam consumption in your distillatio...

Spray dryer for food and dairy products

Achieve consistent drying for diverse powders and granulates with precision technol...

Ammonia chiller for industrial refrigeration

Achieve optimal energy efficiency and reduced operational costs in your cooli...

Solid-wall bowl separators for milk & whey

Achieve precise skimming and standardizing of milk and whey with this advanced ...

Single-chamber freeze dryer for liquid products

When precision drying of sensitive liquids is crucial, this single-chamber...

Industrial powder fillers for various containers

Optimize your packaging line with high-speed powder fillers that handle d...

Negative pressure filter for fine dust particles

Ensure efficient air purification and dust collection in your production ...

Industrial rotary feeder for powder and agglomerates

Achieve seamless integration in your production line with a robust s...

Pneumatic mixer for fluidizable bulk materials

Achieve uniform and gentle mixing of powdered ingredients with minimal effo...

Pta and Pet production systems

Maximize throughput while minimizing dust fines in your production of PTA and PET pellets wit...

Advanced degassing and temperature control solution for process silos

Optimize your production line with precise contro...

Dosing and conveying screw for dry bulk materials

Efficiently manage the precise dosing and conveying of dry, powder, and...

Rotary feeder for powdered bulk materials

Achieve precise control in feeding and discharging powdered materials with a rot...

Drop-through rotary valve for precise powder and granule feeding

Ensure precise material handling with this drop-through...

Rotary ball vibrators for bulk solids discharging

Ideal for enhancing material flow, this equipment efficiently handles f...

Trough screw conveyor for flour mills

Optimize your flour processing with efficient material handling, precisely designed f...

Pipe couplings for pneumatic conveying lines

Ensure a secure and quick connection for your pneumatic lines with these pipe...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Integrated conveying and weighing system for bulk materials

Achieve precise material management with a solution that sea...

Ibc docking and discharge stations

Ensure seamless material transfer with dust-free docking and effective discharge, mainta...

Continuous vacuum conveyors for material flow control

Ensure consistent material transfer and reduce downtime in your pro...

Robotic palletizing and depalletizing systems

Enhance your production efficiency by automating the repetitive and labor-in...

Milk reception unit for dairy processing

Ensure precise measurement and streamlined handling of raw milk with an engineered...

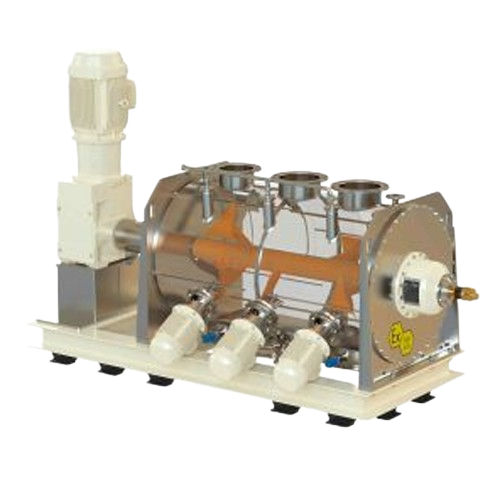

Centrifugal separators for liquid/liquid/solid separation

Achieve efficient separation and clarification for diverse app...

Instrumentation calibration services for accurate measurements

Ensure precise control over your production variables by ...

Pre-formed container filling system for multi-layer products

Efficiently handle a diverse range of products with this fl...

Twin screw feeder for dosing bulk solids

Ideal for precise bulk solids dosing, this twin screw feeder ensures consistent fl...

Gravimetric single-screw feeder for free-flowing products

Optimize your dosing precision for powders and granulates with...

Volumetric auger filler for precise powder weighing

Optimize your production line with a high-speed volumetric auger fill...

Bag tipping unit for Cip processes in powder handling

Ensure seamless powder handling and high hygiene standards in your ...

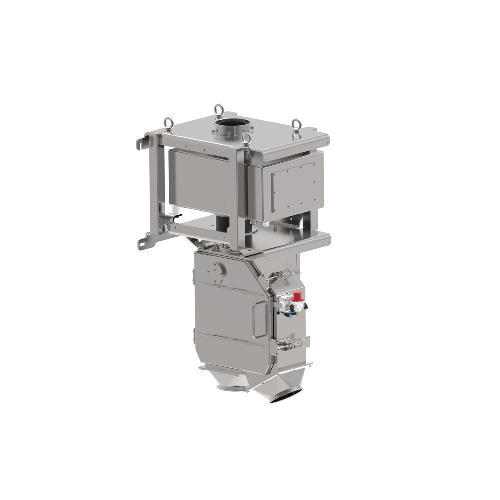

Big bag discharger for powder handling

Effortlessly discharge large bags of powdered ingredients with a modular, safe syste...

Manual bag tipping unit for powder handling

Ensure a contamination-free environment with a compact manual bag tipping unit...

Direct Uht treatment for liquid foods

Optimize aseptic production with advanced UHT technology to preserve nutritional valu...

Milk skimming separator

Achieve superior separation efficiency and reduced energy consumption in dairy processing with seamle...

Efficient dairy product separator

Achieve precise fat separation and enhance product quality while reducing energy consumpt...

Industrial bag filter for powder collection efficiency

For producers seeking to enhance powder yield while minimizing emi...

Spray dryer for heat-sensitive powders

Ensure high-quality drying of heat-sensitive powders, producing non-caking and non-h...

Spray drying system for nutritional powders

Enhance production efficiency and product quality with a versatile spray dryin...

Versatile spray dryer for dairy and plant-based powders

Achieve precise moisture control and optimal powder functionality...

Permeate powder spray dryer

Optimize permeate powder production with continuous spray drying, ensuring premium, non-caking o...

Automatic milk standardization unit

Achieve precise control over milk’s fat, protein, and solids content, reducing cr...

Air jet cleaning system for powder production

Eliminate water and chemical use while maximizing production efficiency with...

Lump breaker for dry powders and granulates

Optimize the consistency of your production line by efficiently breaking up lu...

Centrifugal sifter for food and pharmaceutical powders

Ensure consistent particle size and remove contaminants in high-sp...

Spore and bacteria removal unit for dairy products

Ensure superior quality by precisely removing spores and bacteria from...

Industrial powder mixer for food production

Enhance your production line with a high-speed batch mixer designed for precis...

Conical homogenizer for powder and granulated products

Achieve seamless homogenization of diverse powders and granulated ...

Big bag filler for granulated or powder components

Ensure precise and dust-free filling of large bags with a unit designe...

Ingredient dissolver for small batch processing

Optimize your mixing processes with a versatile dissolver designed for eff...

Tubular heat exchanger for food processing

Optimize energy consumption and ensure unparalleled food safety during heat tre...

Autonomous ingredient dissolver for high-volume dry ingredient mixing

Efficiently mix multiple high volumes of dry ingr...

Dust filter for food processing

Ensure high-quality powder production with this self-cleaning dust filter, designed to minim...

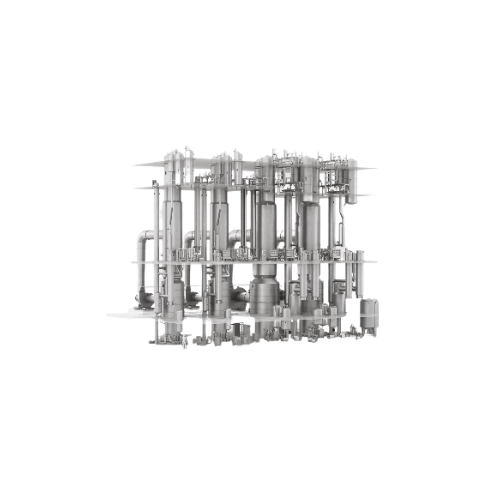

Continuous evaporator for dairy products

Enhance your production efficiency with a fully automatic evaporator designed to m...

Evaporator for dairy products

Need efficient moisture removal in diverse dairy and food applications? This falling film evap...

Powder feeder for consistent and accurate dosing

Ensure precise powder dosing with high hygiene standards to maintain prod...

Vibrating conveyor for short-distance powder transport

Achieve precise and hygienic powder conveying and dosing with this...

Aseptic tank with blending function for liquid food storage

Achieve seamless integration of aseptic buffering and in-lin...

Pneumatic conveyor for fragile powders

Handle your delicate powders with care, ensuring minimal breakdown while achieving h...

Spray dryer for nutritional powders

Ensure precise moisture control and enhance powder quality in nutritional products with...

Spray dryer for dairy, whey, and plant-based powders

Achieve precise control over powder attributes with our versatile sp...

Automated milk standardization system

Achieve precise milk fat and protein control continuously with real-time adjustments,...

Automated milk standardization unit

Achieve precise in-line standardization of milk components, ensuring optimal quality an...

Ultra-high temperature processor for premium liquid foods

Achieve superior product quality and flexibility with advanced...

High capacity milk separator with polynode technology

Achieve unprecedented milk skimming efficiency and reduced environm...

Industrial bag filter for powder collection

Optimize powder yield and maintain strict hygiene with a high-capacity filtrat...

Autonomous ingredient dissolver for high volume dry ingredient mixing

Streamline your production by seamlessly mixing d...

Batch dissolver for sugar or dextrose

Efficiently dissolve crystalline substances like sugar and dextrose with precision, e...

Ingredient dissolver for small batches

Efficiently dissolve water-soluble powders and concentrates up to 200 cP with precis...

Industrial plate heat exchanger for food processing

Ensure consistent product quality with precise temperature control an...

Tubular heat exchanger for food products

Achieve precise temperature control and energy efficiency with this innovative tub...

Low-energy evaporation system for dairy products

Enhance product quality and lower energy costs with a cutting-edge evapor...

Evaporation system for dairy products

Optimize product quality with continuous evaporation, ensuring efficient moisture rem...

Aseptic tank for blending and buffering

Optimize your production line with a secure aseptic tank that ensures precise in-li...

Filling system for gable top packages

Achieve precise, cost-effective filling with reduced energy consumption for chilled l...

Filling system for tetra brik 100 slim packages

Optimize your chilled product packaging with a high-speed filling system d...

Filling system for tetra wedge aseptic packages

Optimize your production line with a reliable filling system designed to e...

Compact aseptic filling solution for versatile production

Maximize production line efficiency with a compact filling sys...

High-speed carton filler for aseptic packaging

Maximize production efficiency with this high-speed filling solution that e...

Carton filling system for tetra brik portion packs

Achieve high-capacity portion filling with innovative electron beam st...

Cardboard packer for secondary packaging

Streamline your packaging process with a high-speed, automated cardboard packer th...

Belt dryer for large-scale continuous drying

Achieve precise moisture control and energy-efficient processing with this be...

Industrial lithium chloride dehumidifier

Efficiently control air moisture and temperature with a solution that ensures prec...

Continuous bulk fluid bed dryer

Achieve rapid and energy-efficient moisture removal across diverse materials with our advanc...

Continuous fluid bed dryers for various industrial applications

Achieve precise moisture control with fluid bed dryers, ...

Continuous fluid bed dryer for powder and granules

Enhance your production line with precise moisture control and energy ...

Vibrating fluid bed dryer for bulk materials

Ensure efficient moisture removal and thermal processing with this fluid bed ...

Automated ingredient weigher for dairy production

Optimize your batching process with precise ingredient weight managemen...

Yogurt production line

Optimize your dairy production with a comprehensive solution that seamlessly transforms milk into a di...

Dual-motion rectangular separator for pulp and paper industry

Optimize your production line with a versatile separation ...

Shear pumps for continuous on-line dispersion

Effortlessly achieve consistent shearing and mixing with versatile shear pum...

Self-cleaning separator for industrial liquid/solid separation

Optimize your production line with self-cleaning separato...

Ultrafiltration for dairy and plant-based protein concentration

Optimize your production capacity and increase yield wit...

High pressure homogenizers for dairy and pharmaceutical applications

Optimize your production line with high-pressure h...

High pressure homogenizer for dairy and food processing

Achieve uniform particle size and enhance product stability with ...

Milk pasteurizer system

Ensure your dairy and plant-based beverages achieve optimal safety and quality with precise temperatu...

Small scale continuous evaporator

Ideal for lab and small-scale production, this evaporator offers precise control for redu...

Small scale spin flash dryers for high-viscosity liquids

Optimize moisture control with cutting-edge spin flash dryers de...

Tall form dryer for producing large non-agglomerated particles

Achieve precise particle size control and optimal moistur...

Spray dryers for producing free-flowing dustless powders

Achieve consistent product quality with customizable spray dryer...

Bin activator for reliable bulk solids discharge

Ensure reliable flow and prevent compaction in your production line with ...

Volumetric feeder for flowable ingredients

Ensure consistent and precise dosing of diverse materials in your production li...

Single screw feeder with stirring agitator for powders and pellets

Ensure consistent mass flow and precise dosing with ...

Twin screw feeder with stirring agitator for poor flowing powders

Optimize your processing line with a highly adaptable...

Centrifugal atomizer for precise spray drying

Achieve precise control over particle size and moisture content with centrif...

Industrial fluid bed dryers for powder processing

Enhance moisture control and uniformity in powder products with dynamic...

Loss-in-weight feeder for flowable ingredients

Achieve precise ingredient delivery with this feeder, designed to handle a ...

Single screw loss-in-weight feeder for powders and pellets

Ensure precise dosing and mixing in continuous automated oper...

Twin screw volumetric feeder for poor flowing powders

Struggling with poor flowing or floodable powders? This twin screw ...

Vibrating tray loss-in-weight feeder for grained ingredients

Achieve precise and continuous dosing of free-flowing solid...

Weigh-belt feeder for industrial processes

Efficiently manage material flow and precision with a dependable weigh-belt fee...

Bigbag discharge station

Efficiently manage bulk material unloading with this solution, which facilitates seamless dischargin...

Single screw batch feeder with stirring agitator for powders and pellets

Ensure precise ingredient control and consiste...

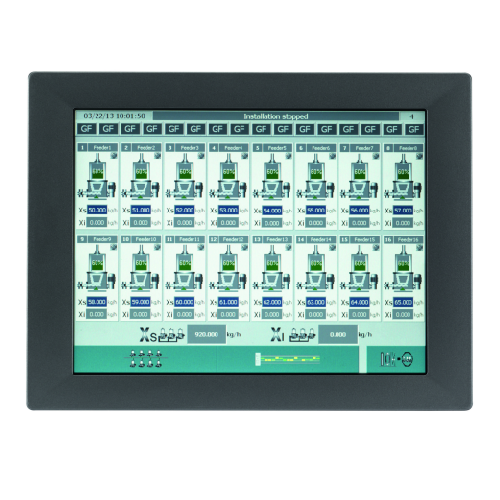

Gravimetric feeder operator interface

Efficiently manage up to 16 gravimetric feeders with a user-friendly interface, enabl...

Single feeder operator interface for gravimetric feeders

Enhance precision in your dosing operations with an intuitive to...

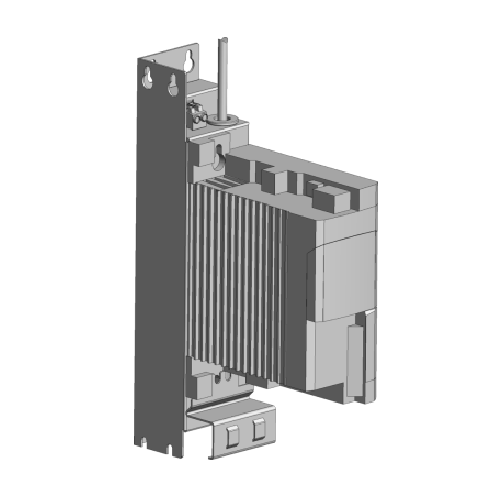

Speed controller for feeders

Ensure precise material flow by integrating this speed controller, ideal for managing both volu...

Loss-in-weight feeder for flowable particles

Ensure precise ingredient delivery with a feeder designed for high accuracy a...

Batch feeder for bulk solids processing

Achieve precise batch dosing with this advanced feeder, designed to handle a variet...

Precision batch feeder for flowable ingredients

Achieve precise ingredient control with a batch feeder designed for versat...

Microbatch dosing for precision ingredient measurement

Achieve precise ingredient dosing with our MicroBatch system, desi...

Metal detection system for powders & granules

Ensure product integrity and protect your machinery from metallic contaminan...

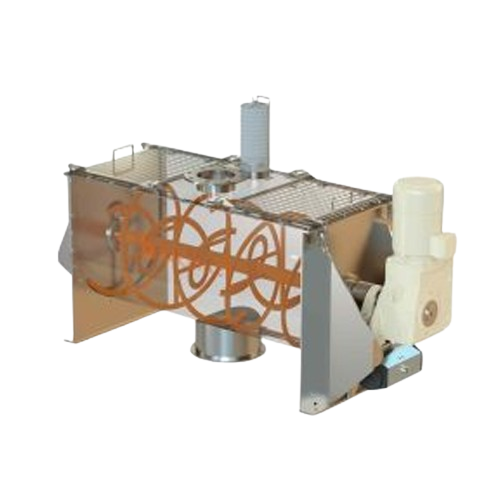

Twin shaft horizontal batch mixers for homogenous material mixing

Achieve consistent and rapid mixing of diverse materi...

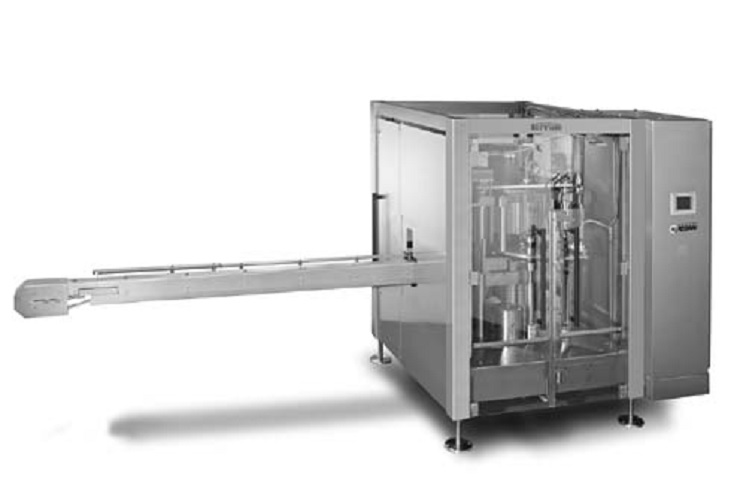

Intelligent Continuous Food Cartoner

Fully automated robotic packing solutions enable larger-scale food producers to pack a...

High-speed Cartoner For Single-Serve Products

Large-volume producers of single-serve packs, such as sugar sticks, instant ...

Vacuum and Gas Injection System for FIBCs

Products packed in large bulk bags, such as FIBCs, require vacuum pressure and a...

Automatic FIBC Sealing machine

When sealing large bags containing bulk products, a sealer must be reliable to keep the MAP s...

Sensor for Modified Atmosphere FIBCs

Every year, more than 200 million FIBCs are filled with food for storage and transport...

Modified Atmosphere Big Bags

Manufacturers requiring big bag packaging have specific sizes, shapes, and material requirement...

Pilot plant homogeniser

From food to pharma, homogenization is an essential step in the production process that provides unif...

Semi-manual can sealer

When starting out in the canned product business, you do not necessary want to invest in industrial sc...

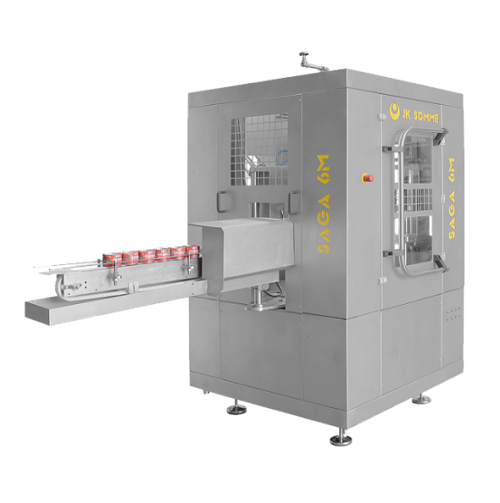

Seaming machine for infant formula cans

Packaging of food products, but especially those for babies, like infant formula, i...

Ionized air system for cleaning of baby food cans

When producing canned food products, especially those for infant...

High speed can seamer

Tin plate thickness for cans has gradually reduced over the years, which makes it a hassle to use new c...

Medium scale round can seamer

Automatic seaming of cans of craft bear can be quite the hassle with the movement from the cen...

Wraparound case packer

Packaging companies need to pay attention to personalization in shape and design in addition to the at...

Vacuum belt dryer for instant drink powders

Extracting the essential acids and compounds from fruits and plants is a compl...

Milling and drying machine for fine powders

When you need to produce ultra-fine powders, the milling and drying process em...

Flash drying grinder for powders

Drying and grinding can be an important feature when trying to process products such as raw...

Hygienic floor scale

The food and pharmaceutical industries require maintaining high levels of sanitations as well as logisti...

High pressure pilot homogenizer

Biotech and pharmaceutical development programs often require a mixing method that achieves ...

High pressure air powered laboratory homogenizer

Offering lab-scale to small pharmaceutical production scale output for in...

Entry-level high volume package seal tester

Manufactured food products need to be packed in gas-filled pouches to ensure t...

Economical Pouch Packaging Machine

The side gusset pouch is a popular packaging solution for medium formats, particularly f...

Dairy Packaging Machine

The use of sachets and pouches for powdered or shredded dairy products is an increasingly popular for...

Can filling equipment

Having separate equipment for different process steps like filling and closing, can put a brake on grow...

Tumbler sieve for classifying and dedusting granular materials

For the classification of delicate granular material, scr...

High volume particles separation sieve

For large scale production processes in the chemicals or food industries that requir...

Multifrequency sieve for separation of difficult particles

Separating particles in difficult-to-process materials for pr...

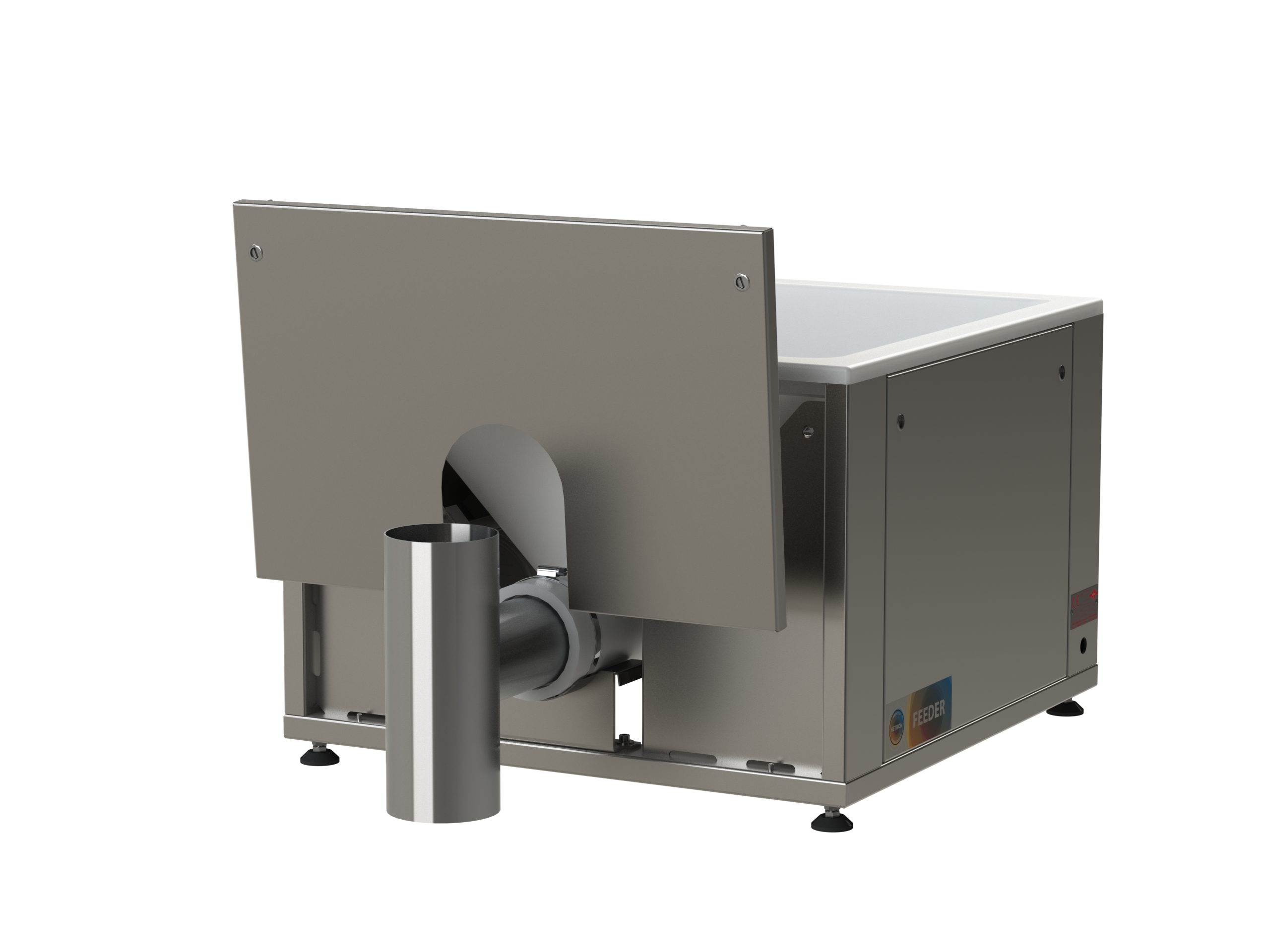

Feeder with flexible wall hopper

The varying properties of dry powder products mean that specialized feeders are required fo...

Dual channel plug diverter valve

Short switching times are often required when diverting or combining powder or granular sol...

Two-way flap type diverter valve

Routing powder, pellets or granules from a product source to two receiving points must be d...

Can seamer for food products

Flexible can seaming equipment is required to adapt for product-specific variations in food can...

High performance can seamers for the food industry

The wide variation of materials and dimensions used in the food cannin...

Hygienic floor scale with lifting device

The food and pharmaceutical industries require maintaining high levels of sanitati...

Inline batch mixer for solids and liquids

Several issues often arise when your process requires batch-wise mixing of powde...

Food vacuum conveyor

Widely used in industries where a high rating in food quality is imperative.