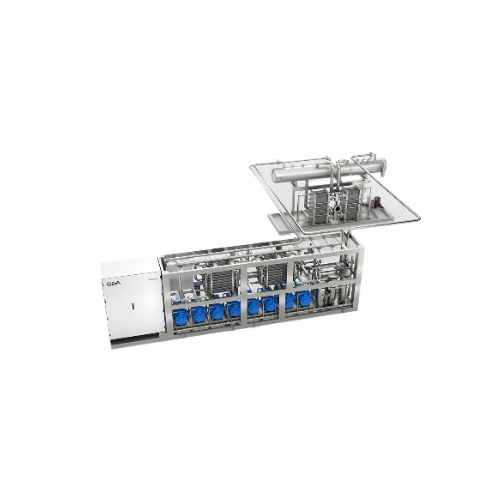

Heat pump solution for spray dryers

Enhance your spray drying efficiency and sustainability with an innovative heat pump system that recycles waste energy and significantly reduces reliance on fossil fuels, enabling substantial energy and emissions savings.

Reduces Energy Use and Emissions in Spray Drying

The GEA AddCool Heat Pump for Spray Dryers revolutionizes energy efficiency in the spray drying process by utilizing waste energy recovery, air heating, and cooling integration. Designed for industries such as food, dairy, and pharmaceuticals, it dramatically reduces fossil fuel dependency and CO2 emissions. Capable of decreasing energy consumption by up to 49%, it supports continuous, automated operations at high temperatures without altering the existing production process. Engineered for seamless retrofit into current systems, it maintains powder quality while providing additional cooling capacity for other plant operations. Validated by TÜV, the AddCool system complies with ISO 14021 standards. GEA offers engineering support and service options to ensure optimal long-term performance.

Benefits

- Reduces carbon footprint by 50-80%, minimizing environmental impact.

- Lowers primary energy consumption by up to 49%, optimizing operational costs.

- Enables easy retrofitting with no production downtime during maintenance.

- Enhances sustainability with electricity-driven high-temperature heating and cooling.

- Integrates seamlessly with existing spray drying processes and equipment.

- Applications

- New food, Chemical powders, Nutritional formula, Food powder, Pharmaceutical powders, Plant-based milk, Dairy products

- End products

- Coffee creamer, Infant formula, Dairy alternatives, Vitamin supplements, Chemical additives, Whey powder, Milk powder, Plant-based protein powder, Pharmaceutical excipients

- Steps before

- Heating, Energy generation, Pre-processing

- Steps after

- Packing, Storage, Cooling

- Input ingredients

- waste energy, external air, liquids for spray drying

- Output ingredients

- hot air, stable powders, coarse agglomerated powders, free-flowing powders, dustless powders

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Heat Reduction Efficiency

- Up to 49%

- Carbon Footprint Reduction

- 50-80%

- Energy Source

- Electricity

- Energy Consumption

- Reduced by up to 49%

- Integration Type

- Retrofit into existing plants

- Operational Downtime

- Minimal during maintenance

- Working Mechanism

- Heat Pump

- Energy Source

- Electricity

- Integration Capabilities

- Easy Retrofit

- Automation Level

- Manual / PLC

- Waste Heat Utilization

- Reclaimed Energies

- Maintenance Impact

- Minimal Downtime

- Cooling Capacity

- Added Cooling

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- Compact design, adjustable setup

- Heat Pump Configuration

- Integrated with existing system

- Adaptability

- Easily retrofitted to existing plants

- Installation Flexibility

- Does not alter existing spray dryer operation

- Cooling,Heating Capabilities

- High-temperature heating and low-temperature cooling

- Control Panel Type

- PLC-controlled for automation

- Integration with existing systems

- Compatible with various spray dryer models

- Cooling options

- Additional cooling capacity

- Electrical requirements

- Varies depending on existing setup

- Operational flexibility

- Can operate separately from spray dryer

- Maintenance compatibility

- Non-disruptive to production schedule

- Heat pump technology

- High temperature and low temperature capabilities

- Component configuration

- Customizable to plant requirements