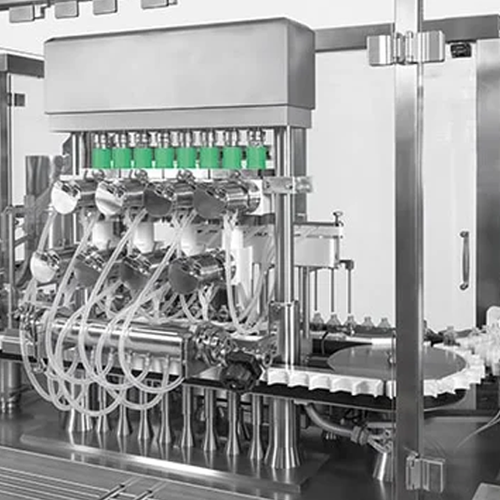

Bulk vial liquid filling system

Ensure reliable and efficient processing of critical biopharmaceutical and pharmaceutical liquids, like vaccines and monoclonal antibodies, with our advanced vial filling system designed for high-speed, precise operations in sterile environments, adaptable to both small-batch and large-scale production needs.

Fills and Seals Vials for Liquid Pharmaceuticals

The FLC 3000 from Syntegon is designed to efficiently fill and seal vials in liquid pharmaceutical production lines, particularly for high-demand products like Covid-19 vaccines and monoclonal antibodies. Its compact GMP-compliant design supports a wide filling range of 0.2 to 500 milliliters and achieves throughput of up to 600 vials per minute, reducing changeover times with only three format part sets required. The machine’s peristaltic pump technology ensures precise dosing while maintaining sterility, and it integrates seamlessly into production environments with options for full in-process control. A clean and hygienic design facilitates easy maintenance and operator safety, meeting stringent GMP and FDA requirements. The FLC 3000 can be customized with additional filling technologies and systems as needed, providing robust support for both batch and continuous operations.

Benefits

- Maximizes output with speeds up to 600 vials per minute.

- Ensures precise dosing and sterility to maintain product integrity.

- Streamlines production with minimal changeover times due to three format part sets.

- Meets GMP and FDA standards, ensuring regulatory compliance.

- Integrates easily into existing systems, supporting both batch and continuous operations.

- Applications

- Pharmaceutical liquids, Liquid formulations, Vaccines, Oncology preparations, Pharmaceutical containers, Biopharmaceuticals, Pharmaceuticals

- End products

- Trastuzumab injection, Insulin vials, Monoclonal antibodies, Covid-19 vaccines, Chemotherapeutic agents, Antiretroviral syrups, Liquid biologics, Ready-to-use vials, Sterile saline solutions

- Steps before

- Washing, Depyrogenation, Inspection

- Steps after

- Closing, Crimping, Inspection, Capping, Tray Loading, Sterilization

- Input ingredients

- bulk vials, RTU vials, pharmaceutical liquids, biopharmaceuticals, Covid-19 vaccines, oncology preparations

- Output ingredients

- filled vials, sealed vials, safe pharmaceutical products, inspected pharmaceutical products

- Market info

- Syntegon is known for its expertise in processing and packaging technology, offering innovative solutions for the food and pharmaceutical industries. It has a strong reputation for advanced equipment, sustainability, and customer-oriented service.

- Speed

- Up to 750 vials/min

- Capacity

- 600 vials per minute, 36, 000 vials/hour

- Filling Volume

- 0.2 to 500 ml

- Automation

- Inline inspection systems

- Machine Design

- Compact GMP-compliant

- In-process Control (IPC)

- 100%

- Scalability

- Small to large production batches

- Changeover Time

- Minimal

- Operation Output

- Up to 200 containers/min

- Footprint

- Small

- Flexibility

- Multiple filling technologies

- Inspection Type

- Visual, Inline

- Filling Method

- Combi filling platform

- Filling speed

- 600 vials/min

- Filling volume

- 0.2–500 ml

- Output capacity

- up to 36, 000 vials/hr

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Batch operation

- Changeover time

- Minimal

- CIP/SIP

- CIP available

- Cleaning method

- CIP

- Inline inspection solutions

- Stopper position, crimp quality

- Cross-process solutions

- KIV tracking and identification

- Portability

- Mobile (for FLT 1000)

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Yes

- Discharge method

- Volumetric / gravity

- Control panel type

- Touchscreen

- Machine footprint

- Small / mobile platform

- Filling volume range

- 0.2 to 500 ml

- Filling speed

- 600 vials per minute

- Compact GMP-compliant design

- Yes

- Single or multiple filling technologies

- Perialistic pump / Combi filling

- Control panel type

- PLC / HMI

- Integration possibilities

- SCADA / ERP Integration

- Machine design

- Compact GMP-compliant

- Automation level

- Manual / PLC / SCADA

- Discharge method

- Inline / Manual

- Transport system

- Precise sensitive handling

- Retrofitting capabilities

- Multiple fill technologies