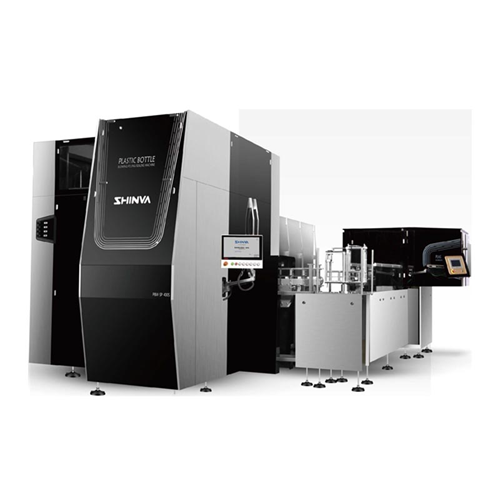

Reciprocating plastic bottle blow-fill-seal system

Achieve seamless integration of bottle forming, filling, and sealing with this advanced blow-fill-seal system, ensuring aseptic conditions and high throughput for liquid pharmaceutical products.

Integrates Blow Molding, Filling, and Sealing

The Reciprocating Plastic Bottle Blow-Fill-Seal Machine from Shinva is a high-efficiency solution for aseptic liquid packaging in the pharmaceutical and biotech industries. It integrates blow molding, filling, sealing, cleaning, sterilization, and drying into a seamless operation, ensuring contamination-free products such as IV saline solutions and pediatric oral formulations. Featuring high-speed continuous processing, it enhances production efficiency and supports various bottle shapes with customizable molds. The machine utilizes advanced aseptic technologies compliant with GMP standards, and its automation is operated via a large-size color IPC display for reduced error rates. Maintenance is streamlined with an intelligent maintenance system, and options for material selection ensure chemical compatibility and durability.

Benefits

- Ensures product sterility with integrated aseptic blow-fill-seal process.

- Reduces contamination risk by automating cleaning and sterilization.

- Customizable bottle design accelerates time-to-market for new products.

- Streamlines production with high-speed continuous operation.

- Intelligent maintenance system minimizes operational disruptions.

- Applications

- Pharmaceutical solutions, Liquid formulations, Non-terminal sterilization products, Terminal sterilization products, Aseptic liquid products

- End products

- Topical antiseptic solutions, Vitamin supplements, Cough syrups, Pediatric oral solutions, Nasal sprays, Respiratory therapy inhalants, Electrolyte solutions, Antibiotic suspensions, Ophthalmic solution, Iv saline solution

- Steps before

- Plastic Bottle Forming, Liquid Preparation

- Steps after

- Sterilization, Packing, Quality Inspection

- Input ingredients

- plastic material, liquid medicine

- Output ingredients

- plastic bottle, sealed bottle, sterilized bottle

- Market info

- Shinva is known for manufacturing medical equipment, including sterilization and disinfection devices, radiotherapy products, and diagnostic imaging systems, demonstrating expertise in healthcare solutions and a strong reputation for quality in the medical industry.

- Automation

- High automation

- Control Panel Type

- Large-size color IPC displays

- Performance

- Stable performance

- Safety

- High safety

- Cleaning Method

- Automatic cleaning

- Sterilization

- Automatic sterilization

- Drying

- Automatic drying

- Customization

- Customized service of bottle shape and mould

- Aseptic Guarantee

- Aseptic production technologies

- Operation Maintenance

- Intelligent maintenance system

- Working Mechanism

- Blow-Fill-Seal (BFS)

- Integrated Steps

- Forming, Filling, Sealing

- Automation Level

- High Automation

- Visual Warning System

- Visual Warning System

- Intelligent Maintenance System

- Stable and Efficient Operation

- Modular Design

- Standardized Modular Design

- Customizable Features

- Bottle Shape and Mould

- Turnkey Solution

- Plastic Bottle Production Process

- Sterilization and Drying

- Automatical Cleaning

- Control panel type

- Large-size color IPC display

- Control panel type

- Large-size color IPC

- Integration possibilities

- Intelligent maintenance system

- Bottle shape and mould

- Customized

- Modular design

- Standardized