Making Mineral Water

Find innovative production technology for making mineral water and connect directly with world-leading specialists

Mineral water is mother nature’s cocktail of dissolved solids. The concentration of essential chemicals in the water makes it an excellent source of nutrients and electrolytes. Although your bottled product retains most of the properties present at its natural condition, the water still needs some help before it can be safely consumed.

Select your mineral water process

Tell us about your production challenge

The natural chemicals that give mineral water its name

Mineral water is rich in natural elements namely calcium carbonate, magnesium sulfate, potassium, and sodium sulfate.

In the US, only water that contains 250 parts per million dissolved solids in its natural state classifies as mineral water. The EU does not specify any minimum mineral content as long as the water is bottled at source. Member states, however, keep an official register of producers in this sector.

When can you say mineral water is natural

Minerals can theoretically be added to distilled water, but you can only market bottles as ‘natural mineral water’ if the mineralization occurs organically in aquifers. Water picks up its mix of minerals as it seeps through layers of rock on its way from the earth’s surface to underground streams.

While you may decant the sourced water to filter out undesirable chemicals such as iron and arsenic, your production process may not add any minerals further to it.

Still or Sparkling? Managing carbon in mineral water

Natural mineral water contains carbon dioxide. Even if you are bottling non-carbonated water, it still has a degree of CO2 in it – the levels are just not sufficiently significant.

You may, however, decarbonate and re-carbonate the water during processing to control the intensity of effervescence in the bottle. If you want to make a more lively beverage, you can fortify the naturally carbonated water with an extra supply of bubbles.

Declare your fluoride intensity

Fluoride occurs naturally in water, but a high exposure to the mineral can lead to tooth decay and skeletal damage.

If the fluoride concentration in your mineral water is higher than 1 mg/l, you must indicate the fact on the label. Moreover, if the content is over 1.5 mg/l you are bound by the Food and Agriculture Organization to advise customers that the product is not suitable for children under 7 years.

Processing steps involved in mineral water making

Which mineral water technology do you need?

Separators for cooling lubricants and industrial fluids

Efficiently separate complex oil-water mixtures and cooling lubri...

Marine oil and water purification separators

Optimize your marine operations with high-efficiency separators designed to p...

Automatic rotary arm wrapper for palletized loads

Enhance your packaging line with a medium-speed, rotary arm solution de...

Cylindrical buffer tank for processing lightly liquid products

Optimize production continuity with this cylindrical buff...

Compact tunnel pasteuriser for beverages

Ensure beverage safety with precise pasteurisation in a compact design that integr...

High-performance stretch blow moulding and labelling system

Maximize space and efficiency with this compact system that ...

Crate washer with adaptive jetting units

Ensure consistent cleanliness of beverage crates with a washer that adapts to vary...

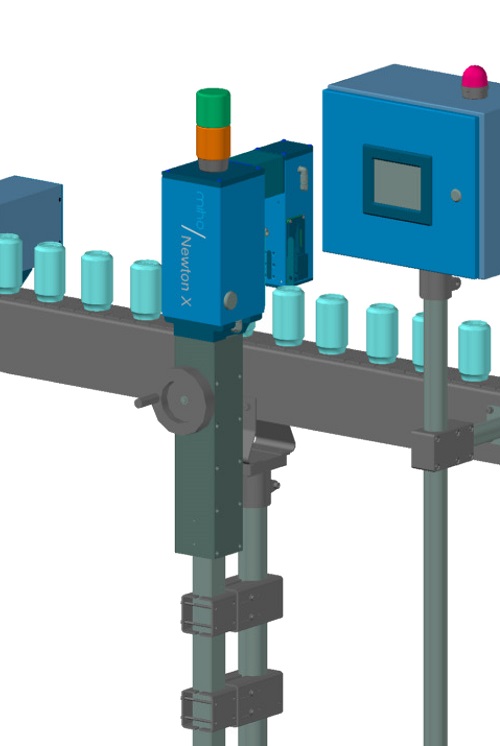

X-ray container inspection system for beverages

Ensure the integrity and quality of your beverage products with cutting-ed...

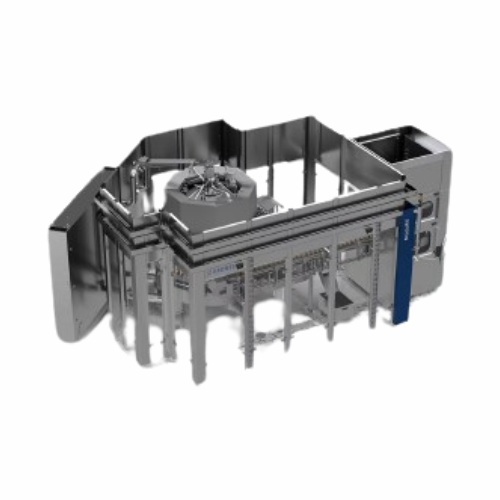

Wet-section block solution for non-carbonated water

Streamline your bottling operations with a compact solution that effi...

Stretch blow moulder for Pet containers

Optimize energy efficiency and production versatility with this stretch blow moulde...

Water ozonisation system for enhanced disinfection

Ensure impeccable water quality with cutting-edge ozonisation that eff...

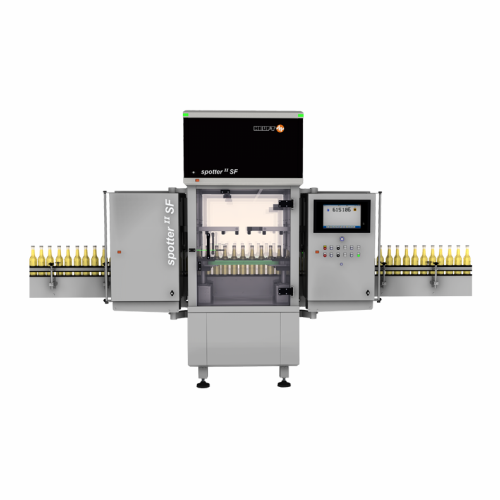

Caustic residue detection for bottle washing

Ensure product purity by detecting and eliminating residual caustic in return...

Decapper for removing screw caps

Efficiently unscrew caps from various bottle types without damaging the threads, even under...

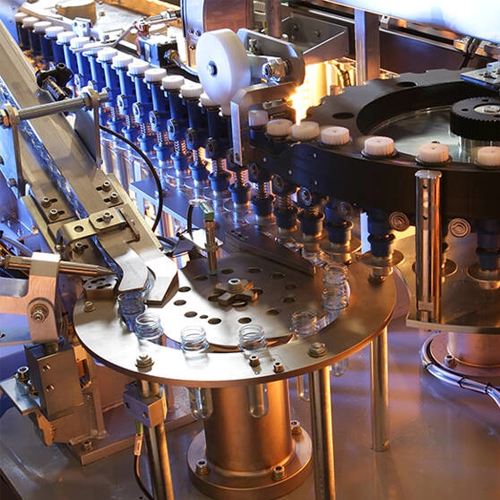

Innovative beer filling and capping technology

Revolutionize your filling process with an integrated system that combines ...

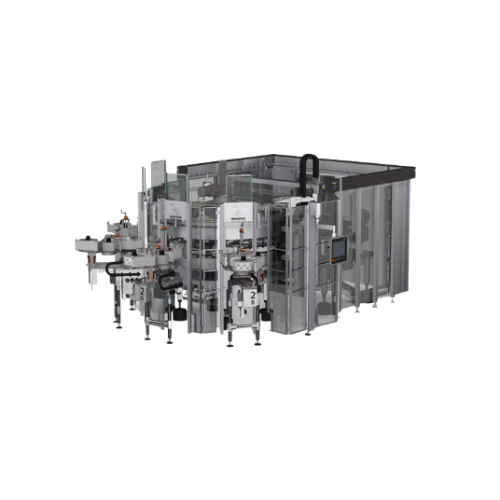

Aseptic bottle sterilisation system for Pet containers

Ensure aseptic integrity and high-speed efficiency in beverage pro...

Automated product change-over system

Maximize your production line efficiency by reducing downtime during product changeove...

Filler-seamer block for cans

For high-speed beverage production, this solution integrates filling, seaming, and cleaning in ...

Ultrapure water demineralizer for critical boilers

Achieve high-purity water production with minimal chemical usage and a...

Self-adhesive labeling for glass and Pet bottles and beverage cans

Maximize your production efficiency with a labeling ...

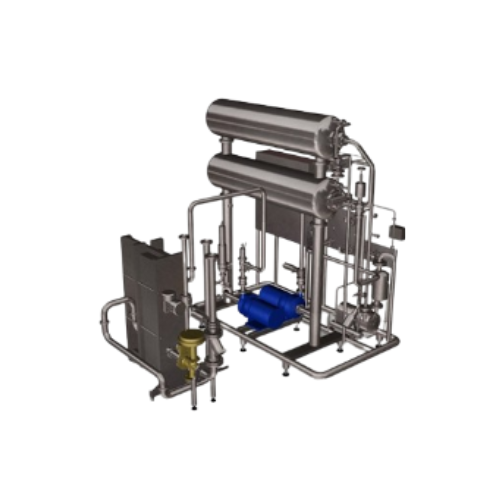

Demineralization and carbonation for bottled table water

Ensure consistent carbonation and precise blending for beverage ...

Water deaerator for beverage production

Enhance the quality and extend the shelf life of your beverages with our cutting-ed...

Pet bottle stretch blow molding with coating and filling

Extend the shelf life of your beverages and liquid products with...

Dosing and blending system for beverage production

Enhance your beverage production with a flexible system capable of pre...

Multifunctional filter system for beverages and gases

Achieve precise filtration across multiple beverage and gas mediums...

High-performance distribution and combining system

Streamline your packaging operations with a versatile system designed ...

Robotic layer grouping system for container distribution

Streamline your packaging line with precise, high-speed containe...

180° palletizing robot for automated palletizing and depalletizing

Optimize your production line with a versatile solut...

Pet bottle filler for hot and cold still beverages

Achieve high-speed precision in filling and capping for various bevera...

Modular labeling system for beverage containers

Easily adapt to evolving labeling needs with this flexible system, designe...

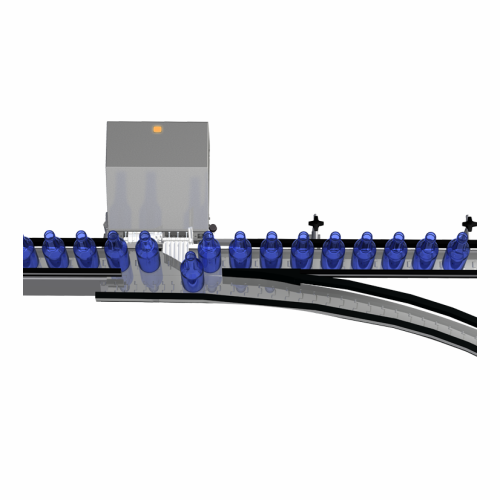

Gentle container conveyor for bottles and cans

Achieve seamless container flow with minimal noise and enhanced precision, ...

Packer and unpacker for returnable and non-returnable containers

Streamline your packaging line with a versatile machine...

Depalletizer with accurate level compensation

Optimize your high-speed assembly line with a depalletizer designed for prec...

Rejection system for standing bottles and cans

Ensure seamless quality control by precisely rejecting defective bottles an...

Container ejection system for Pet bottles and beverage cans

Ensure product quality by seamlessly ejecting defective cont...

Bottle filler for beer and soft drinks in glass bottles

Achieve precision in bottling with reduced CO2 emissions and low ...

Oxygen and carbon dioxide monitoring and elimination system

Achieve precise control over dissolved gases with a system t...

In-line additive dosing systems for beverages

Ensure precision and safety in beverage production by integrating in-line do...

Piping discharge system for product separation in transfer lines

Optimize your beverage production by preventing product...

Micro-filtration system for beverage industry

Achieve microbiological stability at cold temperatures with our micro-filtra...

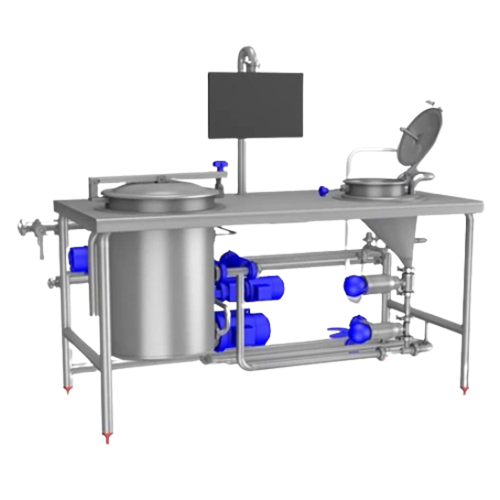

Powder mixing system for beverage industry

Enhance your beverage production with an advanced powder mixing system that ens...

Wine recovery system for bottling processes

Streamline bottling operations by recovering and re-dosing valuable wine, redu...

Co2 dosing system for effervescent beverage bottling

For beverage manufacturers requiring precise carbonation, this solut...

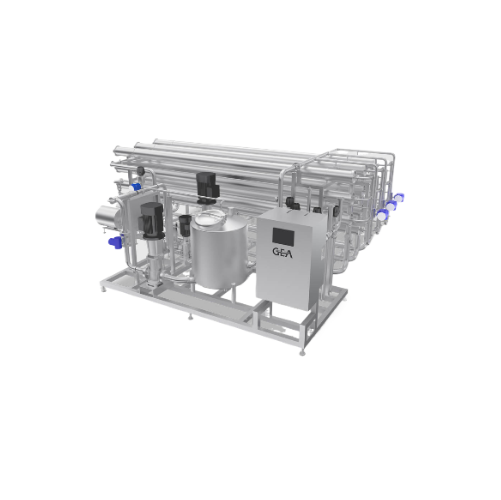

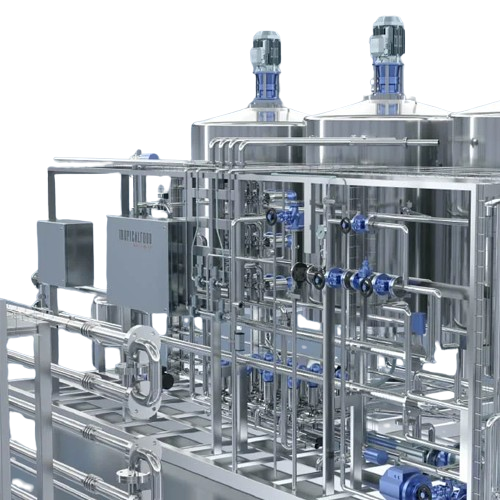

Automated system for cleaning in place (cip)

Ensure thorough, efficient cleaning of your production equipment with a syste...

Leak detection system for plastic containers

Ensure product integrity and prevent costly recalls with this advanced system...

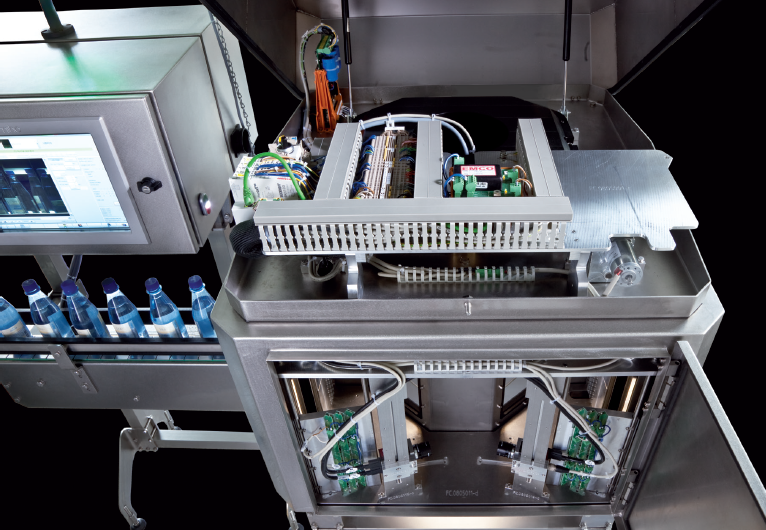

Full container inspection for glass and Pet bottles

Ensure the highest product quality by detecting foreign objects and m...

Fill level and closure inspection system

Ensure precise fill levels and secure closures in high-speed liquid packaging envi...

Final container inspection for beverages

Ensure flawless product presentation and secure branding by detecting misaligned l...

Full case check for beverage production lines

Ensure complete packaging integrity by detecting and removing cases with mis...

Curve rejector for beverage containers

Ensure seamless and upright rejection of faulty containers in tight spaces, maintain...

Empty bottle inspection for beverages

Ensure high quality control and prevent contamination in beverage production lines wi...

Empty bottle inspector for beverage industry

Ensure flawless quality control by thoroughly inspecting empty bottles for de...

Complete bottling lines for beverage industries

Optimize your bottling process with high-speed, precision-engineered lines...

Ultra hygienic filler for non-aseptic products

Optimize your production with high-speed filling and sealing of liquid prod...

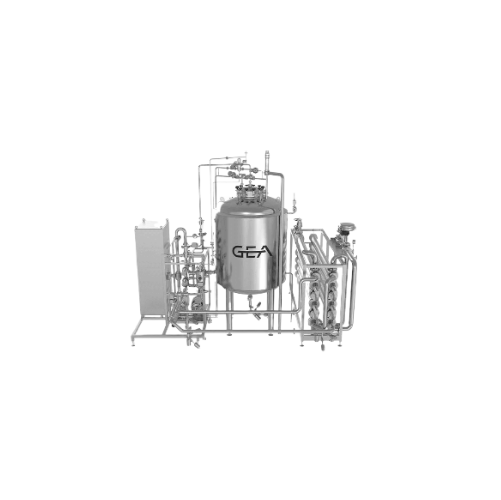

Reverse osmosis with remineralization for drinking water production

Enhance your beverage production with precise water...

Nanofiltration systems for water pretreatment

Achieve precise water quality with advanced nanofiltration systems designed ...

Organic ultrafiltration for water bottling lines

Optimize your beverage production with efficient pre-treatment, ensuring ...

Reverse osmosis systems for industrial water treatment

Achieve optimal water purification in beverage production lines wi...

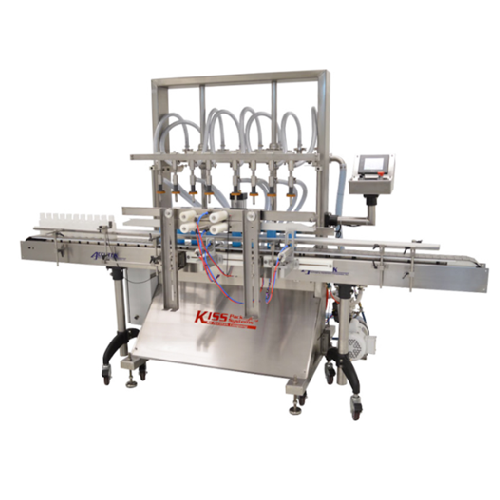

Electronic filling system for non-carbonated beverages

Optimize your bottling process with precision filling technology t...

Isobaric filling solution for carbonated drinks

Achieve precision filling for carbonated and still beverages with advanced...

Roll linear labelling machines for bottling and packaging

Achieve precise and efficient labeling with roll linear labell...

Inline carbonation solution for beverages

Achieve precise carbonation control and consistency in your beverage production ...

Press-on capping system for bottles

Ensure precise and secure closure of various bottle types with our versatile press-on c...

Automated Cip systems for beverage and food industry

Ensure high hygiene standards in your production line with advanced ...

Zero effluent discharge system for solvent extraction plants

Eliminate wastewater in your solvent extraction process whi...

Saturation unit for carbonating beverages

Elevate your beverage production with continuous carbonation, ensuring precise g...

Cleaning solution tanks for beverage production

Achieve superior internal cleaning of beverage containers with our advance...

Self-adhesive labelling system for bottles

Enhance your bottling line with a versatile labelling system that supports medi...

High-speed wet glue labelling system

Ensure precise labelling on diverse bottle types with our versatile rotary labelling s...

Compact combined labelling solution for bottling lines

Optimize your bottling line with a versatile, compact labelling so...

Combined wet glue and self-adhesive labeling system

Achieve seamless labeling with combined wet glue and self-adhesive te...

Storage tank for dairy products and juices

Designed for optimal preservation and hygiene, these storage tanks prevent sedi...

Premix system for soft drinks production

Efficiently produce both carbonated and non-carbonated beverages by integrating th...

Mixer-pasteurizer-carbonator for soft drinks and juices

Optimize your beverage production with a versatile system that se...

Bioreactors for cell culture processes

Efficiently cultivate sensitive cell lines with customizable bioreactors designed to...

No-oxygen filler for wine bottling

Enhance liquid bottling with seamless integration that minimizes oxygen exposure, ensuri...

High-capacity no-oxygen wine filler

Ensure optimal flavor retention and prevent oxidation in your bottling process with adv...

Automated quality control for beverage packaging

Streamline beverage quality control with 24/7 automated analysis, ensurin...

Co2/o2 beverage filling device

Ensure precise beverage analysis by maintaining carbonation integrity with a system that tran...

Packaged beverage analyzer for alcohol and Co2

Ensure precise beverage analysis with a streamlined solution that integrate...

In-line leakage detection for sealed water bottles

Ensure the integrity of your bottled beverage products with reliable i...

Preform inspection system for blown containers

Ensure defect-free blown containers and minimize line jams with a robust pr...

Code inspection system for beverage industry

Ensure accurate labeling and avoid costly recalls with a high-speed code insp...

Water treatment multi medium filter tank

Ensure your bottled water’s purity with a multi medium filtration system tha...

Spiral conveyor for individual bottles and cans

Streamline your production line’s space and layout with a compact co...

Linear big bottle water filling solution

Streamline your large-format water bottling process with integrated washing, filli...

Ozone generator for water sterilization

Ensure the purity and safety of your water products with an ozone generator that ef...

Semi-automatic Pet bottle blow molding solution

Optimize your production with precise and efficient blow molding for creat...

Semi automatic Pet bottle blow molding for 5l bottles

Maximize production efficiency by precisely forming PET containers ...

Semi automatic Pet bottle blow molding solution

Streamline your production with a semi-automatic solution designed for eff...

Semi automatic Pet bottle blow molding system

Enhance your production efficiency with a versatile blow molding system that...

Water cooled screw chiller for industrial cooling

Optimize your beverage production line with precise temperature control...

Automatic Pet bottle blowing solution

Achieve precise PET bottle molding with high-speed, automated operations that seamles...

Automatic reverse osmosis water treatment plant

Ensure high-purity water by seamlessly integrating this reverse osmosis tr...

Automatic single side adhesive labeling solution

Streamline your packaging line with precision; this solution offers effic...

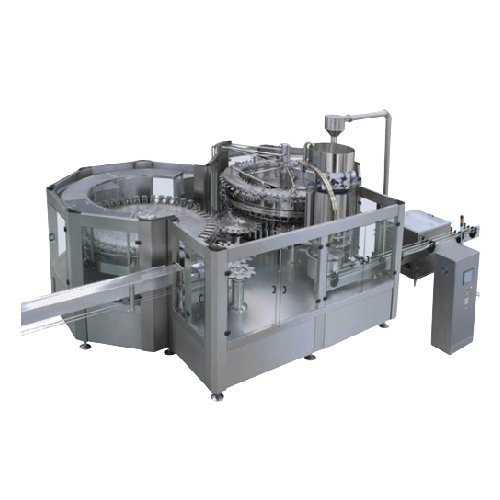

Glass bottle carbonated soft drink washer, filler, and capper

Streamline your bottling process with this machine that se...

Industrial air cooled chiller for carbonated beverages

Optimize your beverage production with precise temperature control...

Automatic beverage bottle shrink packaging solution

Optimize your beverage packaging process with advanced shrink wrappin...

Automatic bottle cold glue labeling solution

Achieve precise labeling for diverse container types, enhancing your producti...

Automatic bottle self adhesive labeling solution

Enhance your production line with precision labeling for diverse containe...

Automatic carbonated beverage mixing system

Optimize your beverage production by ensuring precise carbonation and mixing w...

Automatic servo Pet bottle blower

Elevate your production capabilities with a PET bottle blowing machine designed for high-...

Ultra filtration water treatment system for drinking water

Achieve exceptional water purity with advanced hollow fiber u...

High-capacity carbonated drink filling system

Optimizing your carbonated beverage production, this high-speed filling syst...

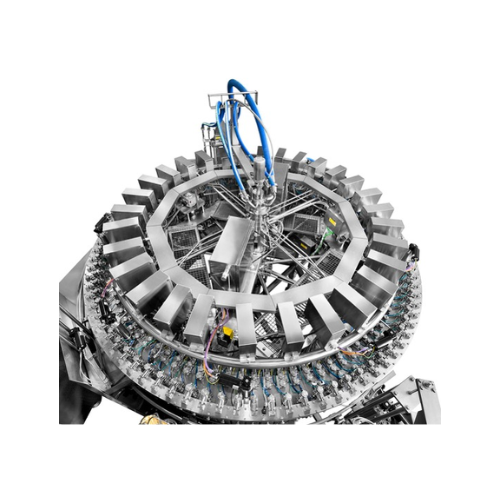

Automatic mineral water filling system

Optimize your bottling line with a machine designed for high-speed washing, filling,...

Large bottle water filling system

Streamline your bottled water production with an integrated solution that efficiently was...

Automatic mineral water filling system

Enhance your bottling line with an advanced solution that seamlessly integrates wash...

Carbonated drink filling solution for Pet bottles

Optimize your carbonated beverage production with an all-in-one filling...

5 gallon water filling system

Streamline your bottling process with this integrated system, expertly combining rinsing, fill...

Dryer for pigments and hydroxides

Achieve precision drying of complex suspensions and pastes into uniform powders, optimizi...

Mobile mixing system for beverages in breweries

Optimize blending and carbonation processes with a mobile solution that st...

Automatic bottle washer for packaging lines

Ensure your bottles are impeccably clean and ready for filling, as this soluti...

Rotary capper for high-speed bottling

Streamline your bottling process with a rotary capper designed to ensure accurate and...

Automatic pressure overflow filler for low to medium viscosity liquids

Ensure consistent fill levels for low to medium ...

Water remineralization system for mineral and flavored water production

Achieve precision in mineral content with a sys...

Beverage deaeration, carbonation and mixing system

Streamline your beverage production process with an efficient solution...

Hygienic centrifugal pump for beverage applications

Ensure gentle handling and efficient transfer of sensitive liquids wi...

Condensate polisher for industrial water reuse

Transform waste streams into high-quality water, ready for reuse in diverse...

Carbonation system for non-alcoholic beverages

Achieve precise carbonation for diverse beverages with this system, ensurin...

Air conveyor for empty Pet bottles

Optimize your bottling line with an advanced air conveyor that reduces energy consumptio...

Container drying system for packaging lines

Ensure precise label applications by efficiently removing moisture from the su...

Centrifuge for beverage clarification

Elevate your beverage production with enhanced clarification, ensuring your drinks me...

Reverse osmosis dealcoholization technology for beer

Achieve consistent flavor profiles in your non-alcoholic beer produc...

Combined heating and cooling solution

Optimize your production with a dual-purpose system designed to efficiently manage bo...

Clarifying decanter for starch recovery

Ensure optimal dewatering and separation of starch, pulp, and fibers with this high...

3-phase separating decanter for industrial fluids

Optimize your waste oil and oily wastewater management with a high-spee...

Self-adhesive label applicator for cylindrical and shaped containers

Achieve precise and high-speed labelling of variou...

Cold-glue labeller for cylindrical or shaped containers

Achieve seamless high-speed labeling of glass, plastic, and metal...

Modular and combined labeling machines for bottling

Achieve high-speed labeling with unmatched flexibility, combining mul...

Pre-cut hot-melt label applicator for bottles

Optimize efficiency and precision in your labeling process with this advance...

Rotary gravity fillers for diverse liquid products

Achieve precise filling and optimal packaging efficiency for a wide ra...

Carbonated beverage can filler for beer and kombucha

Looking to enhance your beverage production efficiency? This can fil...

Checkweigher and metal detector for heavy loads

Streamline your inspection process by combining precision weighing with co...

Heavy-duty submersible chopper pump for biogas plants

Effectively manage fibrous waste and prevent clogging in demanding ...

Shaftless spiral conveyor for difficult waste handling

Efficiently tackle complex waste handling challenges with a design...

Shaftless spiral conveyor for waste water treatment

Efficiently handle challenging materials like de-watered sludge and s...

Internally fed rotating drum screen for wastewater treatment

Streamline your wastewater management with this advanced fi...

Electronic pressure meters for silo safety monitoring

Ensure precise pressure management in your systems with this advanc...

Coconut processing line for green coconut water and cream

Enhance your coconut processing with a fully automatic line th...

Falling film concentrators for low viscosity fruit juices

Achieve high concentration levels in fruit and dairy products ...

Water revitalizer for enhanced hydration and vitality

Transform ordinary water into a structured liquid with enhanced oxy...

Large-volume sterile liquid storage solution

Efficiently store and transfer large volumes of sterile process liquids with ...

Continuous carbonator for beverage production

Optimize your beverage production with seamless continuous carbonation, ensu...

In-line blender for carbonated soft drinks

Enhance your beverage production capabilities with a solution that precisely bl...

Watermelon peeling solution for industrial use

Streamline your fruit processing with a machine designed to efficiently pee...

Direct drive centrifuges for dairy and beverage processing

Optimize energy efficiency in high-speed liquid separation wi...

Hyper-clean electronic volumetric filler for Pet bottles

Enhance your liquid filling operations with precision and hygien...

Integrated stretch-blow moulding, filling, and capping system for still liquids

Streamline your bottling process with ...

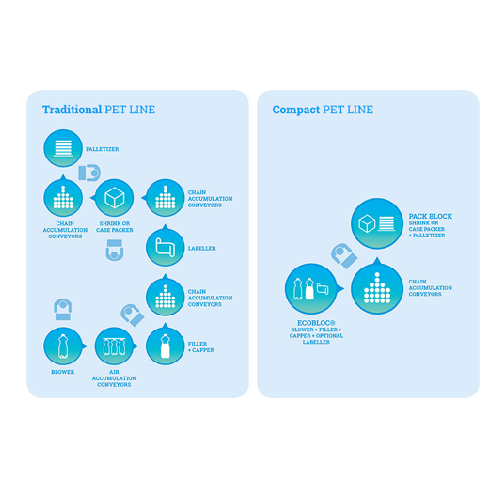

Compact bottling line for water

Revolutionize your bottling process with a compact solution that integrates multiple operati...

Steady and moving pallet palletizers

Optimize your packaging line with advanced palletizing solutions designed to handle di...

Integrated linear blowing and filling system for Pet containers

Streamline your PET container production with integrated...

Integrated rotary blowing and filling system for Pet bottles

Optimize your beverage production with an integrated rotary...

Integrated preform production and bottling system for Pet bottles

Achieve seamless production of PET bottles, from pref...

Isobaric filler for glass and Pet bottles

Achieve precise liquid filling with enhanced operational flexibility and hygiene...

Gravity filling system for Pet bottles

Optimize your beverage production with an advanced gravity filling system, designed ...

Degassing and carbonation system for mineral water

Optimize your carbonation process with a compact system that ensures p...

Compact carbonation unit for carbonated beverages

Enhance beverage quality with precise carbonation, ensuring consistent ...

Cartoning solutions for beverage and food industries

Optimize your packaging line with a versatile range of cartoning sys...

Single-stage plastic container production system

Eliminate multiple steps and minimize production costs with an integrated...

Large size container linear blow molder

Optimize your large-scale production of containers with a solution designed to stre...

Linear blowing systems for Pet bottle production

Ideal for producers seeking versatile container solutions, this system en...

Rotary blower for Pet bottle production

Optimize PET bottle production with cutting-edge efficiency, reducing energy consum...

Volumetric gravity filler for large Pet bottles

Optimize your production line with a high-speed volumetric gravity filler,...

Volumetric filler for Pet bottle beverages

Experience seamless integration into your bottling line with this advanced volu...

Isobaric filling system for carbonated beverages in Pet bottles

Achieve precise carbonation levels and seamless integrat...

Automatic bottle filling system for animal drinking water

Streamline your laboratory bottling process with a high-effici...

High-speed FFS machine for water cups

Packing water in cup containers, asks for good hygiene in order to avoid contaminatio...

Linear automatic bottling machine for liquids

Autonomous filling systems are a very widely utilized solution for the consi...

Shrink wrapping machine for PET bottles

During a shrink-wrapping process, a change of reel can slow down the production cyc...

Mixing tanks for beverages

Juice production lines require multiple ingredients to be typically mixed with water. The incorpo...

Water treatment for beverage preparation

Water is one of the main ingredients in producing juices and other beverages. If i...

Carbonation machine for beverages

For producers of alcoholic beverages it can be interesting to include hard seltzer in the...

Shrink sleeve labeling machine

Shrink sleeves are new type of full-colour labels that give the opportunity to create a 360-d...

Steam tunnel for shrink sleeve labels

When it comes to the option of applying sleeves or film on a container without wrinkl...

Hot air tunnel for shrink sleeve labels

Sleeves are very popular in food, beverage, Chemical and pharmaceutical industry be...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Automatic bottling machine for beverage

One of the biggest challenges when bottling beverage drinks is that many of the bot...

Industrial bottle sterilizer

Sterilization is an important process in the beverage industry to kill microorganisms. It is im...

Air knife system for bottling lines

Wet containers are unacceptable and can be problematic in the food and beverage industr...

CIP system for beverage

Clean-in-place operations are a mandatory part of food and beverage processing which cannot fail. How...

Water distillation system

Water used in pharmaceutical processes must meet high standards of regulatory bodies. These includ...

Versatile bottle sorting system

Quality bottle sorting machine and inspection system which can be put to use not only after ...

High-speed unscrambler for large bottles

Large volume plastic bottling plants need high-speed unscramblers suitable for lar...

High-speed unscrambler for small bottles

Large-scale production of smaller volume bottled product needs a gentle, accurate ...

Low-speed unscrambler

Smaller plastic bottling lines need a lower cost, lower volume unscrambling machine that maintains gent...

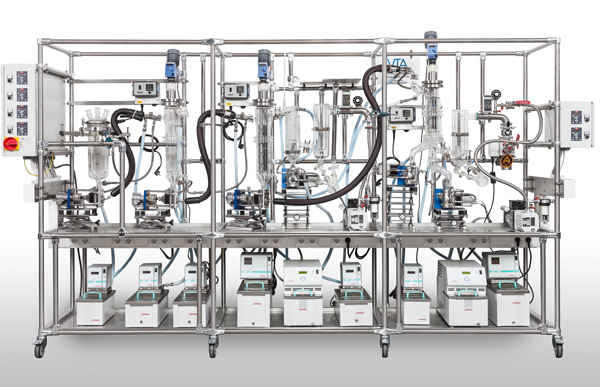

Laboratory multi-stage distiller

A laboratory multi-stage distillers that combines the wiped film and short path distillatio...

Laboratory wiped film distiller

Reach reliable conclusions testing the distillation of high-boiling or highly viscous materi...

Full crate inspection system

State of the art crate inspection system that uses a laser camera system to see if the bottles ...

High-precision X-ray fill level controller

High-speed, high precision X-ray system to inspect containers that are difficul...

X-ray fill level controller

For containers that are difficult to see through, such as cans or cartons lined with aluminium, ...

Advanced residual liquid inspection system

Advanced and easy to use inspection system that eliminates the risk of residual...

Residual liquid inspection system

Inspection system that eliminates the risk of residual liquid, water or left over drink i...

Empty bottle shape, colour and size sorting system

Accurate bottle sorting system that differentiates between the bottles...

Empty crate inspection system

Extensive and much-differentiated inspection of both the crate and the bottle that allows you ...