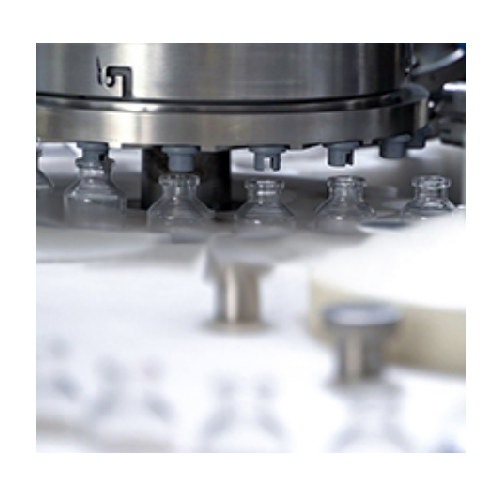

Continuous motion rotary vial filling and stoppering solution

Optimize your vial production with a high-speed, continuous motion solution designed for precise filling and secure stoppering, ensuring seamless integration into aseptic environments while minimizing downtime and maintenance.

Fills, Stopps, and Caps Aseptic Liquid Vials

The RFS-100/200 HYGEIA by Siempharma is a continuous motion rotary vial filling-stoppering machine, designed for high-speed aseptic processing of liquid formulations. It excels in pharmaceuticals by efficiently handling small to large volume vials, including complex applications like vaccine and biopharmaceutical vial production. Its multi-turret filling system allows precise filling and stoppering, accommodating up to 200 pieces per minute. With optional integration of an alu-capping station, it seamlessly fits into existing production lines. The machine is encased in a robust AISI 304 stainless steel structure, ensuring durability and corrosion resistance. Compliance with GMP standards, CFR21 part 11, and EU ANNEX 11 highlights its commitment to stringent regulatory environments. User-friendly HMI and easy-change size parts enhance operational flexibility, while the automatic vial rejection system maintains quality without halting production. Engineering support and customizable configurations are available to meet specific manufacturing needs.

Benefits

- Enhances productivity with continuous motion operation handling up to 200 vials per minute.

- Maintains product quality by seamlessly integrating aseptic filling, ensuring sterility.

- Reduces maintenance costs with durable design and minimal wear on mechanical parts.

- Increases operational flexibility with easy size changes and user-friendly interface.

- Ensures regulatory compliance with GMP standards and CFR21 part 11 readiness.

- Applications

- Biopharmaceuticals, Liquid formulations, Pharmaceuticals

- End products

- Insulin vials, Antibiotic vials, Hormone replacement therapy vials, Radiopharmaceutical vials, Eye drop vials, Biological therapeutic proteins, Monoclonal antibody solutions, Rehydration solutions, Vaccine vials, Chemotherapy drug vials

- Steps before

- Vial production, Aseptic preparation, Liquid formulation

- Steps after

- Rubber stoppering, Aluminum capping, Quality control, Rejection of faulty vials, Packing

- Input ingredients

- vials, liquid products, lyo products, rubber stoppers, alu-seals

- Output ingredients

- capped vials, sealed vials, stoppered vials

- Market info

- Speed

- Up to 200 pieces per minute

- Vial Size

- Up to 500 ml

- Automation

- Continuous Motion

- Filling Method

- Rotary filling

- Stoppering

- Full or Partial Rubber Stoppering

- Capsize

- Alu-seals

- Capping Turrets

- 2 Turrets with 8 Heads Each

- Machine Compliance

- CE Rules

- User Interface

- Touch Screen HMI

- Standards Compliance

- GMPs, INDUSTRY 4.0

- Support for Filling

- Liquid and Lyo Products

- Size Change Parts

- Easy Change

- Infeed System

- Infeed conveyor belt with inverter for speed adjustment

- Working Mechanism

- Continuous Motion, Rotary

- Integrated Steps

- Vial Filling, Stoppering, Alu-Capping

- CIP/SIP

- CIP 121°C / SIP 135°C

- Automation Level

- PLC / Touch Screen HMI

- Batch vs. Continuous Operation

- Inline Continuous

- Cleaning Method

- Facilitated Cleaning

- Changeover Time

- Easy Change Size Parts

- Abrasion resistance

- Low level wear

- Cleanability

- Easy to clean

- Corrosive resistance (e.g. acids)

- AISI 304 stainless steel

- Biological compatibility

- Aseptic production compatible

- Machine footprint

- Compact

- Structure material

- AISI 304 stainless steel

- Safety guards

- Stainless steel frame with safety interlock switches

- Clear separation for sections

- Vial transport and drive mechanisms

- Control panel type

- Touch Screen HMI

- Discharge method

- Outfeed conveyor belt

- Control panel type

- Touch Screen HMI

- Integration possibilities

- Alu-capping station integration (monobloc solution)