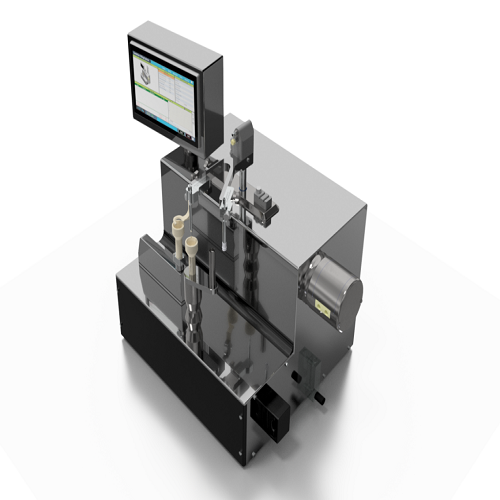

Tabletop vial and syringe filling system

Ensure precise dosing and maintain sterility in small batch production with a compact filling system designed for efficient handling of vials and syringes.

Accurately Fills and Stopper Vials and Syringes

The Tabletop Vial and Syringe Filling System (CFS) from AST is a semi-automatic solution tailored for precise liquid dispensing. Ideal for small batch production, it integrates seamlessly with bench-top operations to fill, stopper, and weigh vials and syringes, catering to biopharmaceutical applications like vaccines and gene therapies. Its compact design fits within isolators or bio-safety cabinets, ensuring sterility and compliance with cGMP standards. The system utilizes a peristaltic or optional rotary piston pump for accurate dispensing, minimizing product shear. With real-time volumetric monitoring and electronic batch reporting, it supports meticulous documentation and regulatory adherence. The intuitive HMI touchscreen enables detailed process control, accommodating diverse material viscosities and container sizes. Customizable features, including inert gas purging and single-use fluid paths, enhance versatility, while the robust construction in pharmaceutical-grade materials guarantees reliability and easy maintenance.

Benefits

- Ensures stringent sterility and compliance with cGMP standards for safe injectable medication production.

- Minimizes operator intervention, enhancing precision with automated filling, stoppering, and weighing.

- Reduces product waste with highly accurate peristaltic or rotary piston pump options.

- Simplifies regulatory reporting with electronic batch documentation supporting 21 CFR Part 11 compliance.

- Compact design allows easy integration into controlled environments like isolators and bio-safety cabinets.

- Applications

- Compounding pharmacies, Clinical trial materials, Biopharmaceuticals, Small batch commercial drug products, Vaccine development, Sterile injectable products, Bio-similars, Gene, Cell therapies

- End products

- Gene editing therapies, Vaccines, Pre-filled syringe medications, Investigational new drugs (ind) for trials, Monoclonal antibodies, Biosimilar insulin, Personalized medicine injections, Antibody-drug conjugates, Stem cell therapies, Insulin injectables, Biologic drug products, Compounded injectable medications

- Steps before

- Container preparation, Pre-sterilization, Cleanroom setup, Fluid path sterilization

- Steps after

- Container closing, Stoppering, Inert gas purging, Manual removal from machine

- Input ingredients

- pre-filled syringes, cartridges, vials, bottles, sterile injectable products, viscous materials

- Output ingredients

- filled vials, filled syringes, filled cartridges, stoppered vials, container with dispensed product

- Market info

- AST is known for its expertise in designing and manufacturing customized engineered-to-order equipment for industrial applications, renowned for precision engineering, innovation, and reliable solutions tailored to meet unique customer specifications and industry standards.

- System Dimensions (LxWxH)

- 840mm x 500mm x 800mm [33" x 20" x 32"]

- Fill Accuracy

- ±0.5%

- Vial Sizes (Dia./Height)

- Ø12mm-47mm / 35mm-100mm

- Syringe Sizes

- 0.5mL to 50mL

- Cartridge Sizes

- 1mL to 20mL

- Vial Finish

- 13mm, 20mm, 32mm

- Materials of Construction

- Pharmaceutical grade stainless steel, plastics, and elastomers

- Pump Options

- Peristaltic, Rotary Piston

- Container type

- Vials, Syringes, Cartridges

- Automation

- Electronically controlled

- Batch documentation

- Electronic Batch Reporting (EBR) system

- Tooling for non-standard/custom container formats

- Available

- Working mechanism

- Semi-automatic bench-top machine

- Batch vs. continuous operation

- Batch

- Automation level

- HMI touchscreen-controlled

- Cleaning method

- Manual

- Compact design for cleanroom integration

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size

- 0.5 mL to 50 mL (syringes)

- 1 mL to 20 mL (cartridges)

- Ø12 mm-47 mm / 35 mm-100 mm (vials)

- Compact footprint

- 840mm x 500mm x 800mm [33" x 20" x 32"]

- Machine footprint

- Compact

- Control panel type

- HMI touchscreen

- Discharge method

- Manual removal

- Container compatibility

- Vials, Syringes, Cartridges

- Material of construction

- Pharmaceutical grade stainless steel, plastics, and elastomers

- Control panel type

- HMI touchscreen

- Integration possibilities

- Peristaltic or rotary piston pump options

- System footprint

- Compact design for isolators, bio-safety cabinets

- Tool-less format change parts

- Available

- Batch reporting

- Optional Electronic Batch Reporting (EBR) system

- Fluid path

- Single-use disposable

- Isolator compatibility

- System upgrade available