Vial filling line and freeze dryer system

For seamless drug production, integrate reliable vial filling with precision freeze drying, designed to handle high-potency biologics and live vaccines under strict bio-decontamination and environmental controls.

Fills, Freeze Dries, and Isolates Vials

The Vial Filling Line from Telstar integrates a freeze dryer with an aseptic isolator, addressing the stringent sterility needs for biopharmaceutical and vaccine manufacturing. Designed for high potency drug production, this system automates vial filling, freeze drying, and bio-decontamination processes under Grade A unidirectional airflow. It features an automatic loading and unloading system, reducing manual handling and contamination risk. With integrated temperature and humidity control, and RFID glove testing, it ensures precise environmental conditions for handling sensitive products like trastuzumab and live attenuated vaccines. Compliant with GMP standards, the line supports remote monitoring and offers reliable isolation with return BIBO HEPA filters. Installation supports seamless integration into existing production lines, providing operational efficiency and scalability.

Benefits

- Ensures precise sterility with integrated aseptic isolators, minimizing contamination risk.

- Increases operational efficiency with automatic loading and unloading systems, reducing manual intervention.

- Maintains optimal product conditions through dedicated temperature and humidity control.

- Enhances safety for high potency drugs by supporting bio-decontamination and monitoring systems.

- Complies with GMP standards, ensuring quality and regulatory adherence.

- Applications

- High potent drugs, Vaccines, Biopharmaceuticals, Hygroscopic products, Anticancer drugs

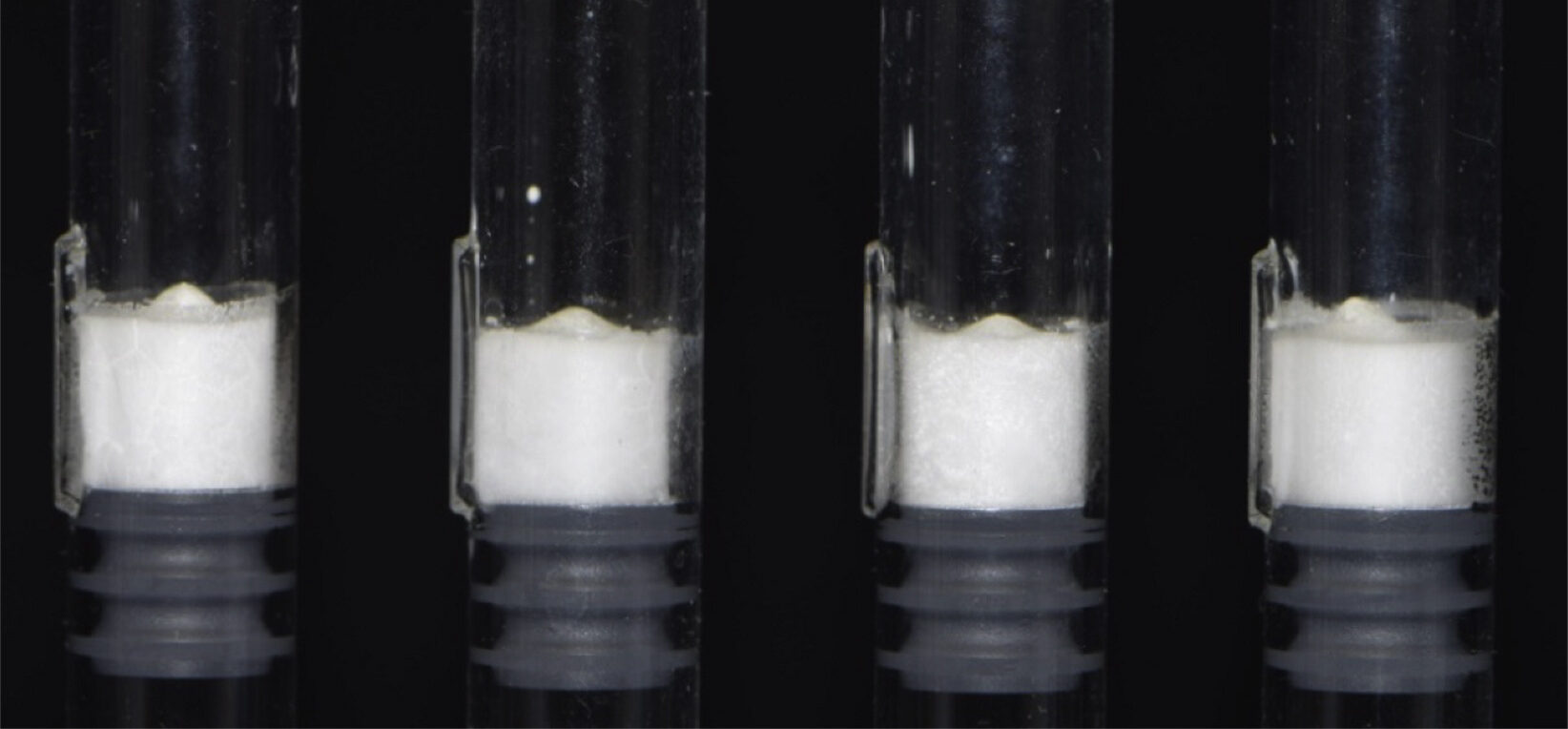

- End products

- Lyophilized enzymes, Docetaxel, Live attenuated influenza vaccine, Pembrolizumab, Trastuzumab

- Steps before

- Purification, Compounding, Solution Preparation

- Steps after

- Sterilization, Packing, Lyophilization

- Input ingredients

- vials, drugs for cancer treatment, hygroscopic products, live attenuated bacteria vaccine

- Output ingredients

- filled vials, lyophilized products, anticancer drugs

- Market info

- Telstar is known for specializing in the design, engineering, and manufacturing of advanced vacuum and aerospace solutions, gaining a strong reputation for their innovative and customized equipment in pharmaceutical, medical, and scientific research sectors.

- Airflow control

- Unidirectional, Grade A

- Temperature control

- Dedicated control system

- Humidity control

- Dedicated control system

- Bio-decontamination system

- Integrated

- Toxic product handling

- Designed for high potency

- Glove testing system

- RFID enabled

- HEPA filters

- Return BIBO

- Automation

- Automatic loading, unloading system

- Batch vs. continuous operation

- Batch

- Automation level

- PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Airflow control

- Grade A unidirectional airflow

- Temperature control

- Dedicated temperature control

- Humidity control

- Dedicated humidity control

- Bio-decontamination system

- Integrated

- Monitoring system

- Integrated viable and non-viable monitoring system

- Glove testing system

- RFID glove testing system

- Drug type

- Anticancer

- Lyophilization

- Sterile production for CDMO

- Lyophilization application

- Vial Application

- Lyophilization application

- Live Attenuated Bacteria Vaccine

- Discharge method

- Automatic loading, unloading system

- Shape and size

- 8 modules

- Integration possibilities

- Automatic loading, unloading

- Isolation technology

- Aseptic Isolator system

- Glove testing system

- RFID

- Temperature control

- Dedicated

- Humidity control

- Dedicated

- Airflow type

- Unidirectional

- Decontamination system

- Integrated bio-decontamination

- Filter type

- BIBO HEPA filters

- Monitoring system

- Integrated viable and non-viable