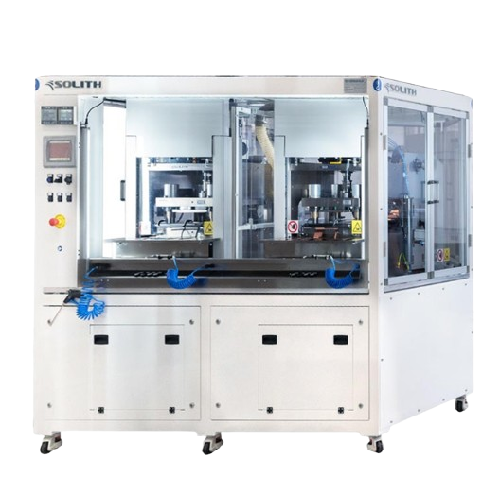

Pouch li-ion cell assembly line

Efficiently assemble high-performance lithium-ion pouch cells crucial for powering electric vehicles and energy storage systems with this specialized assembly line, designed to optimize the production of rechargeable battery packs while ensuring quality and consistency.

Assembles Lithium-Ion Pouch Cells

The Pouch Li-Ion Cell Assembly Line from Sovema Group is meticulously engineered for battery manufacturers aiming to optimize their production processes for lithium-ion pouch cells. This assembly line handles the complex task of assembling reliable and high-capacity cells, essential for electric vehicles, energy storage modules, and consumer electronics. Utilizing precise component placement and state-of-the-art welding techniques, the assembly line ensures consistent cell quality. It features PLC-controlled automation for seamless integration into existing production lines, offering remote monitoring capabilities to optimize workflow. Designed to accommodate various production scales, it supports the manufacturing of cells catering to different energy requirements with high throughput efficiency. Available in robust, corrosion-resistant materials, it meets industry standards for operational longevity and safety. The system’s modular design allows easy customization to match specific production needs, supported by Sovema Group’s expert engineering team for implementation and maintenance.

Benefits

- Enhances production efficiency with seamless automation and remote monitoring.

- Ensures high-quality output suitable for demanding applications like electric vehicles and energy storage.

- Lowers operational costs by optimizing material usage and assembly precision.

- Flexible design accommodates various production volumes and cell specifications.

- Durable construction minimizes maintenance needs and maximizes equipment lifespan.

- Applications

- Batteries, Lithium-ion cells

- End products

- Energy storage system modules, Rechargeable batteries, Lithium-ion pouch cells, Electric vehicle battery packs, Consumer electronics batteries

- Steps before

- Steps after

- Input ingredients

- Output ingredients

- Market info

- Sovema Group is known for its expertise in manufacturing advanced equipment for lead-acid battery production, offering turnkey solutions and innovative technology to enhance battery manufacturing efficiency and quality.

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Integrated steps

- Electrode preparation, cell assembly, electrolyte filling

- Changeover time

- Minimal downtime during transition

- Energy efficiency

- Optimized for reduced energy consumption

- Cleaning method

- Manual

- Working mechanism

- Automated assembly line for Li-Ion pouch cells

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Battery Cell Type

- Pouch Li-Ion