Tea Processing Equipment

Find innovative production technology for making tea and connect directly with world-leading specialists

Chinese legend has it that tea was created by accident over 2700 years BC. A servant boiled drinking water for his emperor when leaves from the Camellia sinensis tree fell into it – and the emperor decided to taste the drink. While to make tea nowadays on a medium to large-scale you need tea processing equipment like dryers instead of just a tree and wind blowing it, mythology adds a special flavor to the tea industry story.

Stories about tea

Select your tea process

Tell us about your production challenge

Black tea making: what kind of tea processing equipment do you need?

The tea manufacturing process determines what path the Camellia sinensis leaves will take. This tree’s leaves are the base for every type of tea: fermented (black tea), semi-fermented (oolong tea), and non-fermented (green tea). “Fermented”, however, is just the traditional way manufacturers call the process of oxidation, as teas don’t go through any fermentation.

The first step to produce black tea is withering, when producers subject the green tea leaves to wilting, to enhance the flavor compounds and reduce moisture.

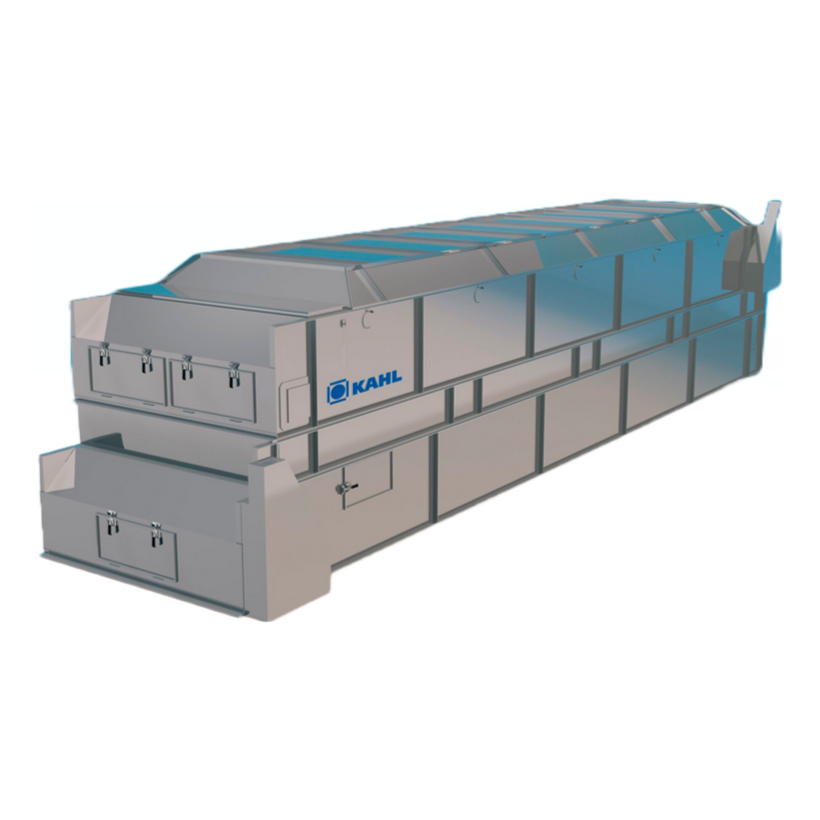

Drying machines are the first step in the tea production line process. You use tea withering troughs that blow hot air from fans in order to dry the leaves. This process takes at least 6 hours, but depending on humidity conditions, it may take days. Once it finishes, the leaves go to a rolling machine.

Rolling machines can belong to two categories – orthodox and CTC. The orthodox method counts with rolling machines that roll the leaves 3 to 4 times, bruising them but not tearing them apart. This usually leads to releasing milder leaves of caffeine. The contrary happens to CTC machines. Called Crush Tear Curl or Cut Tear Curl, CTCs cut the leaves into small pieces repeatedly and allow them to oxidate. This releases the natural juices of tea and increases the caffeine concentration in the product.

Green, white, oolong – manufacturing differences between tea types

While black tea is still the most produced type of tea globally, green tea manufacturing is also rising due to the health benefits perceived by consumers. To make green tea, you subject the tea leaf to heat as high temperatures prevent them from oxidating, guaranteeing that their freshness will be preserved. You can do that by dipping the leaves in hot water or using steam; both methods will inactivate the leaves’ enzymes. Once this happens, a cooler helps to prepare the leaves before they go to a rolling machine. Finally, a dryer takes care of the rolled leaves.

China and Japan are two of the main producers of green tea. Chinese producers often pan-fire the tea leaves in large woks and manually roll them. In Japan, the processes often count with automation; some producers use, for example, highly calibrated machine cutters when harvesting the leaves.

Oolong teas are in the middle of the way between green and black teas. They still need withering troughs before going to rolling machines, but their oxidation time is shorter than black teas and they can also be pan-fired to cut the fermentation process.

When making white tea, the process requires fewer steps and machinery. To produce white tea, which is a very lightly oxidated tea type, you use the buds of very young plants, which are very delicate and cannot be damaged – otherwise, they oxidate. This makes the raw material rare and the process, more expensive. White tea is the less processed type of tea there is, so in this tea production you only need a sorter and a dryer.

How will you serve your tea? Packaging solutions and their characteristics

There are a number of tea packaging solutions depending on which type of product is coming out of your tea factory. If we’re talking about dried leaves, you have the option to combine them with flowers and herbs and pack them in pouches, cans or tea bags.

Pouches use aluminum in their composition, which protects the tea from damage such as oxidation, moisture, and UV light. They can also be made with paper, which is a more eco-friendly material but also lasts for less time. When it comes to teabags, every available shape influences the efficiency of the infusion. Flat, round-shaped, and pyramid tea bags compete in the market to bring both distinctive brand characteristics for consumers and also more flavor to the tea. A few years ago, UK’s Advertising Standards Authority ruled out that, compared to round teabags, pyramid bags had more space for the tea to move, which would allow it to release more taste.

Still in regard to teabags, producers used to make them with paper, but recent manufacturers tried to differentiate their products with more “premium” designs, using other types of materials. The most common of these was polypropylene. A study from McGill University in Montreal, however, showed that this type of tea bag can release billions of microplastics into people’s cups of tea.

Other than that, if your final product is already liquid, you need different tea processing machinery to pack it in cans or bottles, such as filling, capping and labeling equipment.

Processing steps involved in tea making

Which tea technology do you need?

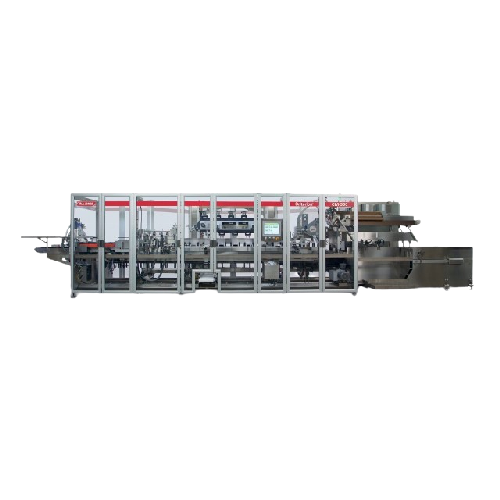

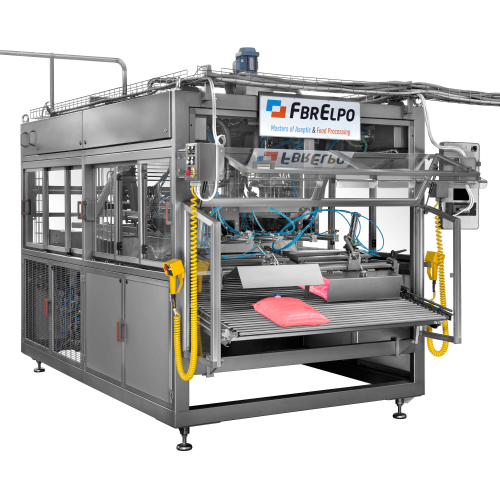

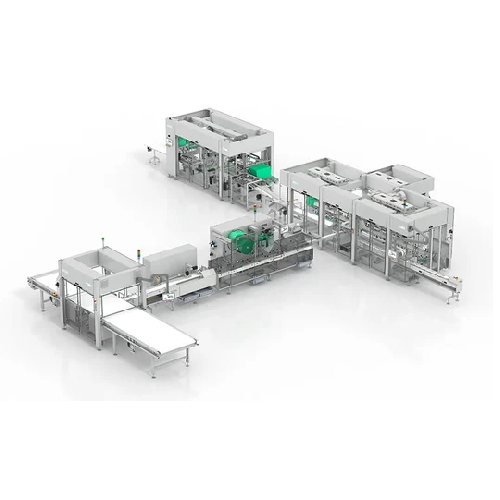

Beverage multi-pack cartoner for cans and bottles

Optimize your beverage production line with high-speed, continuous mult...

Medium-speed end load cartoner for food and beverage packaging

Streamline your packaging line with versatile cartoning c...

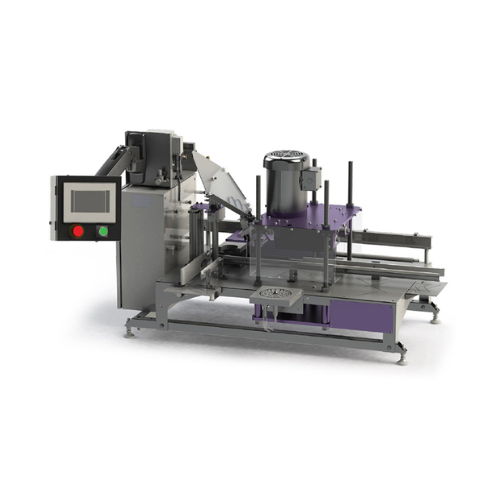

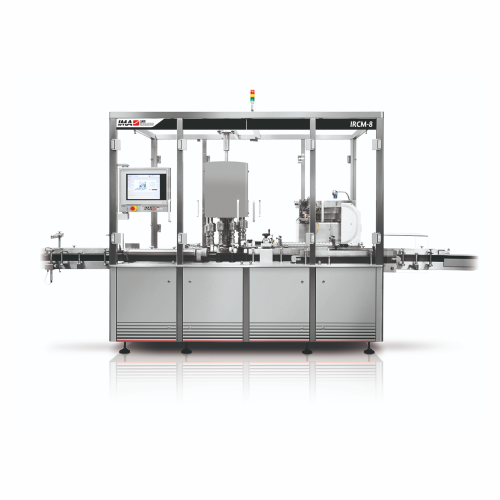

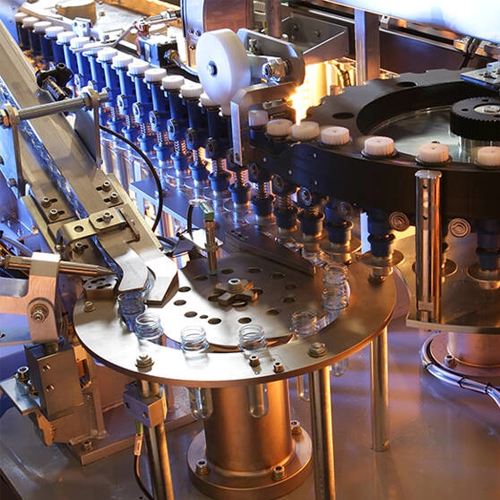

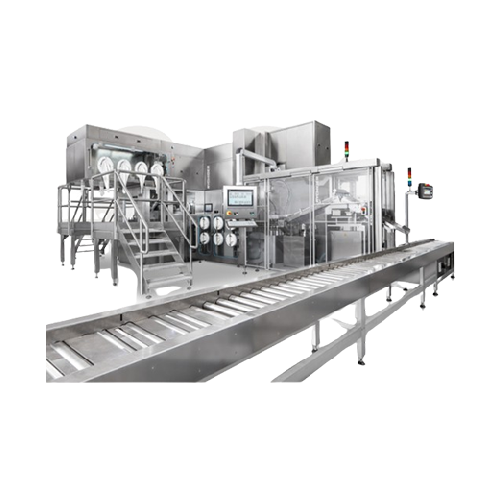

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

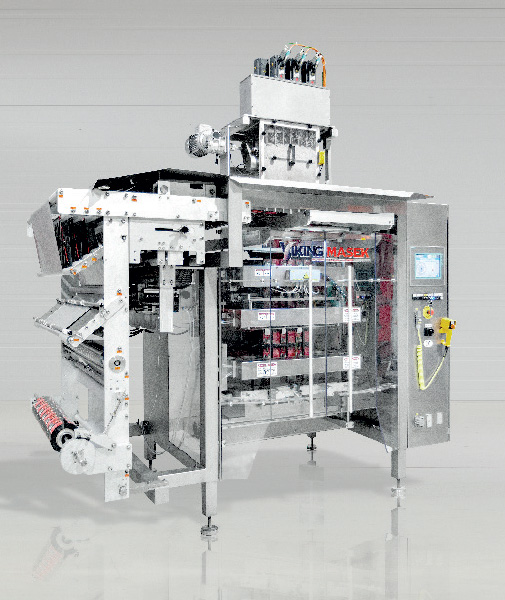

Vertical bagging system for four corner seal bags

Optimize your coffee pod and capsule production with a high-speed, cont...

Vertical packaging system for pet food

Streamline your production line with high-speed packaging capabilities, handling var...

Packaging system for stacked coffee pods

Efficiently package your pods with precise counting and sealing, ensuring optimal ...

System for packaging stacked coffee pods in filter paper

Streamline your pod production with precision bagging and sealin...

Automatic case packaging for pods in single bags

Optimize your production line by streamlining the packaging of coffee and...

Filter paper pod production system

Streamline your production of single-serve beverages with precise weight control and sea...

High-capacity filter paper pod production system

Optimize your pod production line with a high-speed solution that ensures...

Pod production system for filter paper pods

Streamline your pod production with a high-speed solution that ensures precise...

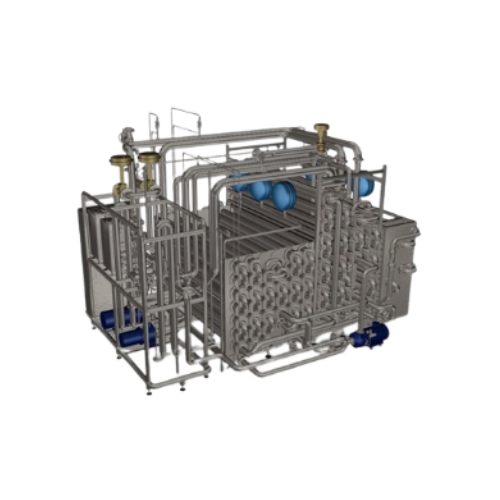

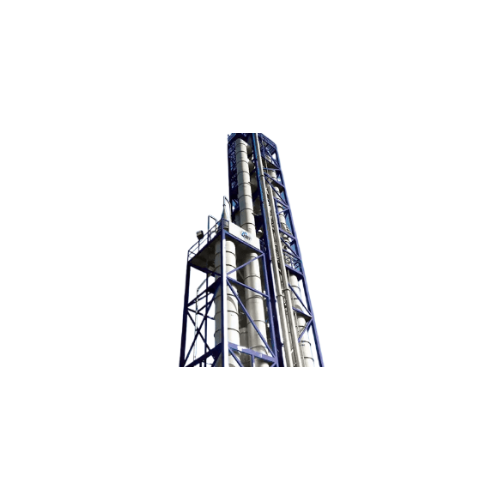

Customized process plants for plant-based beverages

Efficiently scale your production of plant-based beverages with modul...

Horizontal cartoner for diverse industries

Streamline your packaging process with precise cartoning capabilities, effectiv...

Case packer for pharmaceutical and healthcare products

Streamline your packaging line with a versatile case packer design...

Top load cartoning system for pharmaceuticals

Optimize your packaging line with precision top-load cartoning, designed for...

Centrifugal bowl feeder for high-speed bulk item feeding

Optimize your production line with high-speed feeding of diverse...

Uht system for aseptic filling of beverages

Ensure microbiological safety and retain natural flavors in your liquid produc...

Heat exchanger for beverage production

Ensure your beverages maintain their quality and safety with a versatile heat exchan...

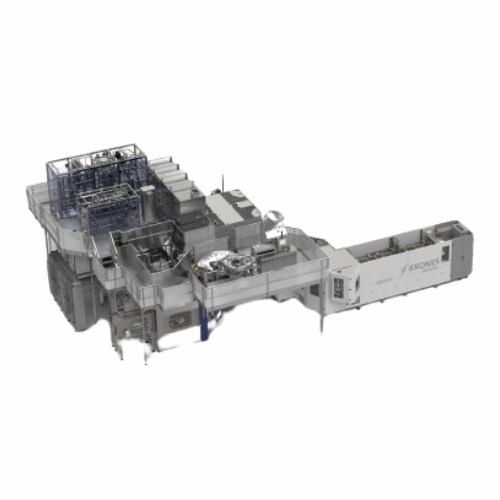

Aseptic filling system for Pet containers

Ensure your beverage products maintain sterility and longevity with a high-speed...

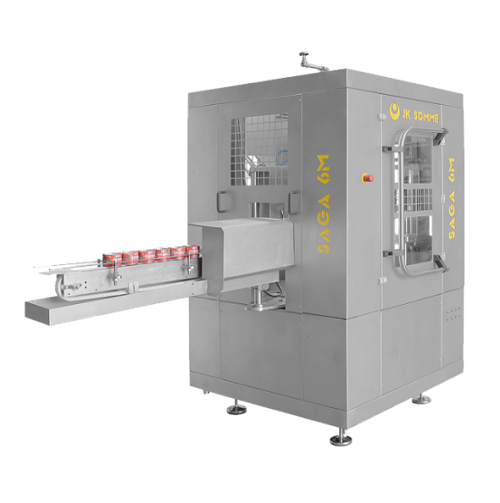

Filler-seamer block for cans

For high-speed beverage production, this solution integrates filling, seaming, and cleaning in ...

Cold aseptic filling system for beverages

Ensure microbiological safety and high product quality with a versatile cold ase...

Intermittent motion cartoner for pharma packaging

Streamline your packaging line with versatile cartoning solutions that ...

Labelling solution for cylindrical containers

Achieve precise and efficient labelling for cylindrical containers with a sy...

Linear labelling system for vials and bottles

Streamline your labelling process with a compact solution designed for preci...

Rotary capper for round and irregular shaped containers

Efficiently cap round and irregular containers with precision and...

Horizontal intermittent motion sachet packaging solution

Optimize your packaging operations with a versatile sachet solut...

Compact cartoner for pharma packaging needs

Achieve seamless integration in your production line with a cartoning solution...

Top loading cartoner for variable box sizes

Achieve precision packaging with a versatile top-loading cartoner that adapts ...

High-speed side loading case packer for small dimensions

Optimize your packaging line with a high-speed solution designed...

Flexible flow wrapping solution for small and medium products

Enhance your production line with a versatile flow wrappin...

Horizontal flow wrapper for medium performance level

Offering high-speed, continuous flow wrapping, this versatile machin...

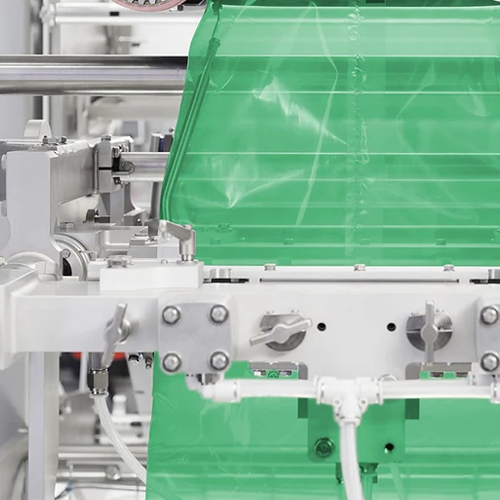

Stand-up pouch making system

Efficiently transform pre-printed reels into customizable stand-up pouches with precise unwindi...

Intermittent motion cartoner for confectionery packaging

For manufacturers needing versatile packaging solutions, this ca...

Capsule filling and sealing system for coffee production

Achieve precise coffee capsule production with a machine that se...

Intermittent cartoner for flexible packaging solutions

Enhance your production line’s efficiency with a versatile c...

Capsule filling and sealing system for coffee

Optimize your capsule production with a system designed to enhance precision...

Capsule filling and sealing system for coffee products

Optimizing the precision of coffee and tea capsule production, thi...

Cartoning system for coffee capsules

Optimize your production line with a space-saving cartoning system designed specifical...

Capsule cartoning system for coffee and tea

Streamline your capsule packaging with a high-speed cartoning solution that ef...

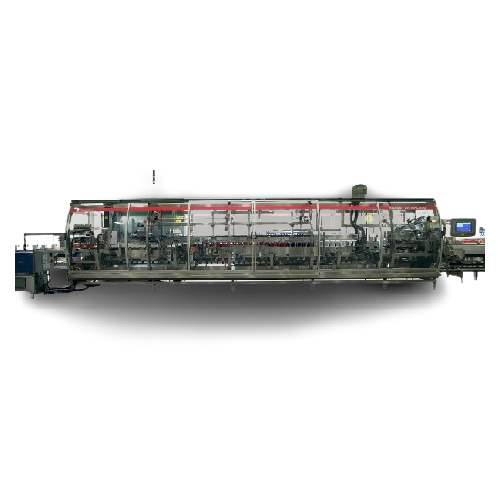

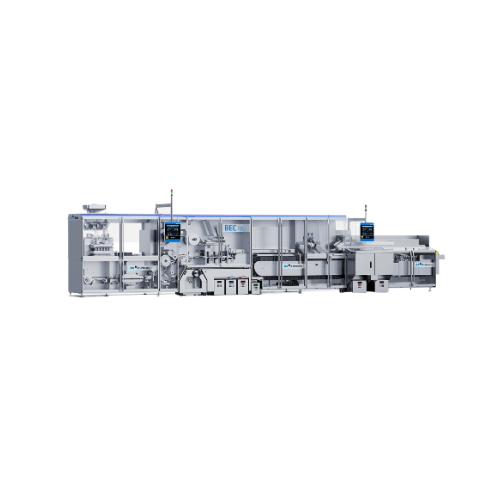

High-speed tea bag packaging solution

Streamline your tea packaging process with a high-speed solution capable of handling ...

Tea bag packaging system for small production runs

Streamline your tea packaging efficiency with precision knotting techn...

Overhauled tea bag packaging system for black tea

Streamline your tea packaging line with this high-speed solution, desig...

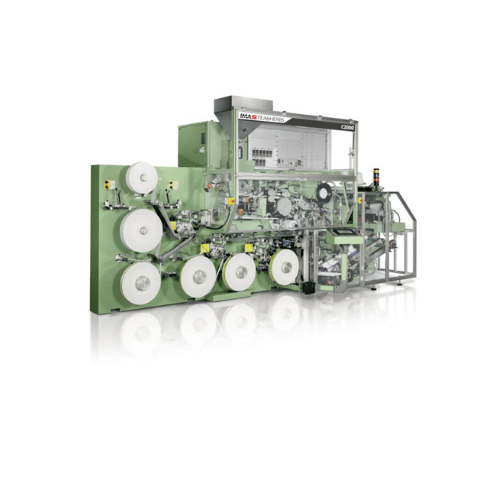

High-speed tea bag packaging system

Enhance your tea production with fast and flexible packaging that infuses superior flav...

Tea bag packaging solution for single-chamber bags

Achieve efficient, high-speed tea packaging with a compact system that...

Tea bag packaging system for long-leaf and premium tea

Optimize your tea bag production with a versatile system designed ...

High-speed tea bag packaging for naked or heatsealed envelopes

Need to enhance production efficiency in tea packaging? D...

High-speed heatsealed tea bag packaging

Achieve unparalleled efficiency in your tea packaging line with a high-speed system...

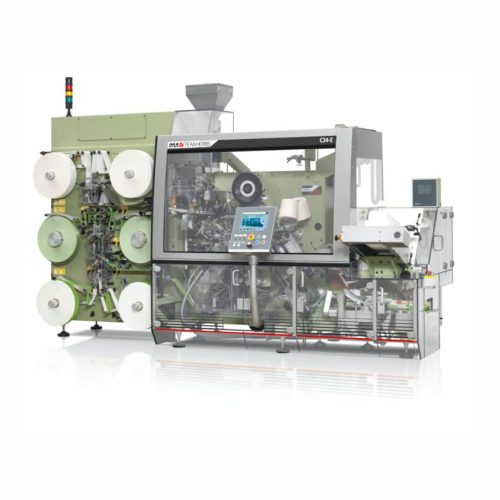

Heatsealable double-chamber tea bag packaging system

Achieve unmatched speed and versatility in tea bag production, deliv...

High-speed tea bag knot packaging line

Achieve precision and efficiency in tea packaging with a system designed for high-sp...

Industrial powder grinder

Achieve precise particle size reduction and classification with advanced equipment designed for co...

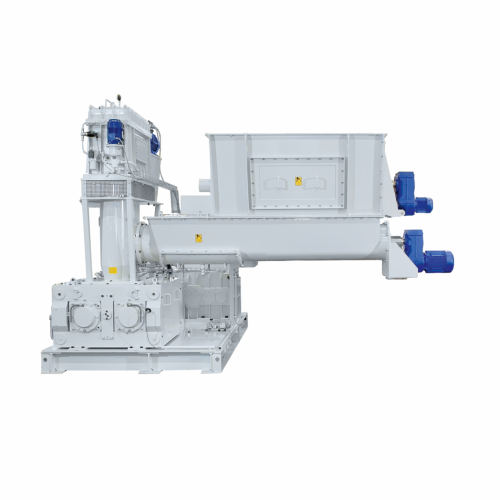

Powder mixing systems

Optimize your production line with precision powder mixing systems that ensure uniformity, enhance prod...

Choppers and disintegrators for industrial size reduction

Enhance your production efficiency by mastering size reduction...

Compactors and granulators for powdery products

Transform loose powders into dense, free-flowing granules that enhance han...

Drying systems for powders and bulk solids

Enhance your production line with precise control of moisture content in powder...

Lab-scale powder processing system

Achieve precise control in ultra-small batch processing with a versatile modular system,...

Powder characteristic evaluation

Ensure precise powder analysis and testing in your laboratory to optimize production qualit...

Cip/sip cleaning for solids processing systems

Ensure seamless transitions and maintain hygienic production environments w...

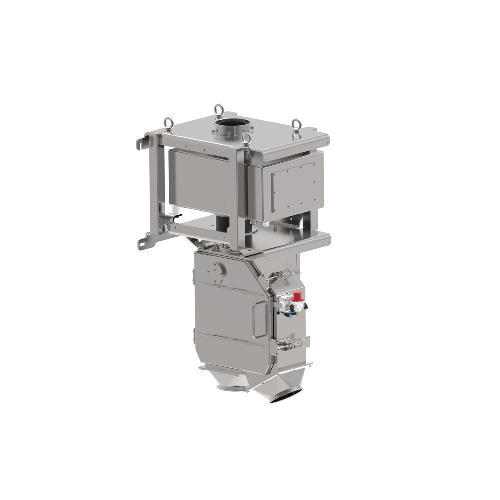

Pneumatic conveying system for bulk material handling

Efficiently transport bulk materials with precision through pneumat...

Industrial pre-crusher for coarse crushing

Optimize your production line by efficiently transforming clumped materials int...

Table roller mills for mineral raw material comminution

Achieve precise mineral raw material comminution and energy-effic...

Conical screw mixer for powder blending

Achieve precise and homogeneous blending with the conical screw mixer, ensuring uni...

Ultra-fine powder flash drying system

Achieve rapid moisture removal and particle refinement with this integrated system, d...

Ultra-fine grinding jet mill for coarse and fibrous materials

Effortlessly achieve ultra-fine particle sizes in coarse a...

Fluidised bed opposed jet mill for fine particle processing

Achieve precise and consistent particle sizes with high-spee...

Jet mill for toner and pigment industries

Optimize particle size and distribution for high-demand applications with this h...

Compactor for powder processing

Designed for transforming powdered materials into uniform granules, this compactor enhances ...

High-pressure roller compactors for chemical, food, and minerals industries

Achieve precise particle compaction and br...

Mechanical conveying systems for bulk solids

Optimize your bulk material processes with advanced mechanical conveying syst...

Multiprocessing system for flexible research and production

Optimize your process development with a versatile system th...

Pelleting and spheronizing equipment for chemical granulates

Optimize your production line with versatile pelleting and ...

Low-dust granulator for plastic parts recycling

Achieve efficient comminution with minimized dust generation, ideal for pr...

Industrial granulator for high-throughput plastic recycling

Facing challenges in efficiently recycling high-volume plast...

High pressure roller mill for medium-fine crushing

Achieve precision in particle size with high-pressure roller mills, id...

High-pressure roller mill for medium-fine crushing

Achieve precise granule distribution in medium-fine crushing applicati...

Fluidised bed opposed jet mill for ultrafine powder production

Achieve contamination-free ultrafine powder milling with ...

Sugar grinding and recrystallization system

Optimize your sugar production with a system that integrates grinding and recr...

Versatile fine impact mill for soft materials

Achieve precision grinding with flexibility for a wide range of materials, e...

Flake crushers for gentle crushing of brittle materials

For processes needing precise granule control, our equipment ensu...

Flake crusher for hygroscopic substances and lumped salts

Efficiently turn fragile, aggregated materials into manageable...

Fine cutting mill for soft to medium-hard plastics

Achieve precise size reduction and smooth particle shapes in plastic p...

Compact granulator for plastic comminution

Optimize your plastic recycling operations with a compact granulator designed t...

Heavy-duty shredder for difficult materials

Struggling with stubborn materials that resist conventional shredding? This ro...

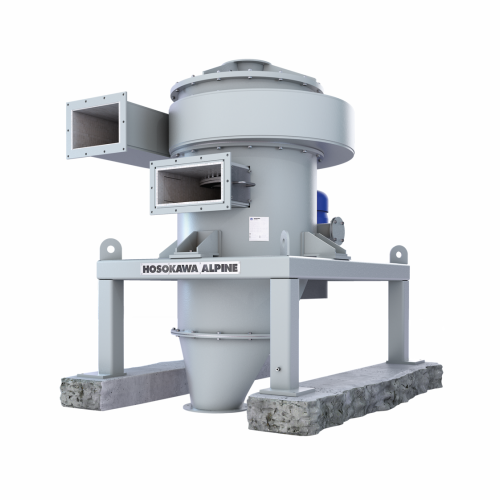

Air classifier for fine powder processing

Enhance your production line with precise particle size control and energy-effic...

Gravity classifier for precise particle separation

Achieve sharp separations in particle processing with minimal maintena...

Ultrafine classifier for toner and pigments

Achieve unparalleled precision in classifying fine powders essential for high-...

Ultrafine air classifier for powder separation

Achieve precise particle separation with technology designed to enhance you...

Ultrafine classifier for soft to medium-hard mineral processing

Achieve exceptional particle precision with an ultrafine...

Discharge systems for difficult bulk materials

Achieve seamless bulk material discharge with our advanced systems that eff...

Automatic bulk material filling system

Ensure precise, contamination-free filling of various bulk materials with an advance...

Fine impact mills for particle size reduction

Achieve precise particle size reduction with fine impact mills, essential fo...

Powder flowability and compressibility analysis

Ensure accurate powder flowability and compressibility data with this adva...

Ball mill for dry comminution of hard materials

Achieve ultrafine particle sizes and precise material breakdown with this ...

Air classifier for fine to medium-fine separation

Reduce energy consumption and wear while achieving high precision in th...

Air jet sieve for particle size analysis

Achieve precise particle size distribution effortlessly for your powders, ensuring...

Laboratory system for powder and particle processing

When precision in powder processing is crucial, this versatile labor...

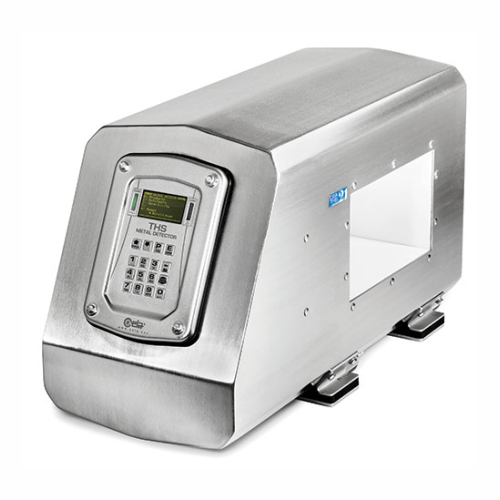

Industrial metal detector for gravity feed applications

Ensure the purity of your products by detecting and removing both...

Ferrous-in-foil metal detection system

Enhance quality control for foil-packaged goods with precise ferrous metal detection...

X-ray inspection system for contaminant detection

Detect and eliminate foreign contaminants in a wide range of food produ...

X-ray inspection system for low-density foreign objects

Enhance your inspection capabilities with advanced X-ray technolo...

Metal detection and weight verification system

Optimize space and boost inspection accuracy by combining metal detection a...

Conveyor belt metal detection system for food processing

Enhance product safety and ensure compliance with the most strin...

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Multi-spectrum metal detector for food industry

Achieve unmatched detection accuracy in your food processing line with thi...

Bucket conveyor for wet and dry free-flowing products

Seamlessly elevate, lower, or convey free-flowing products without ...

X-ray inspection system for detecting foreign objects in food products

Ensure product safety and quality by detecting e...

On-machine seasoning system for potato chips

Achieve uniform seasoning coverage for various snack foods with minimal wasta...

Continuous french fry fryer

Achieve optimal frying conditions with precise temperature control and rapid load adjustments, e...

Industrial heat recovery system

Transform exhaust heat from fryers into usable energy, reducing operational costs and boosti...

Incline transfer conveyors for dry, fresh, and frozen food products

Efficiently transfer a variety of solid and granule...

Linear weigher for dry or frozen free-flowing products

Optimize precision in high-speed weighing tasks with a compact sol...

Industrial belt press for fruit and vegetable processing

Optimize your juice yield and reduce drying costs in starch and ...

Aseptic filling system for bag-in-box packaging

Efficiently fill a range of liquid products into pre-sterilized bags while...

Aseptic filler for liquid and particulate products

Achieve precise, sterile filling of both liquid and chunky products wi...

Aseptic filler for bag in box packaging

Optimize your bag-in-box packaging process with high-speed aseptic filling, ensurin...

Industrial mixer for batch granules or grains

Achieve precise mixing with seamless integration of heating, sterilization, ...

5-in-1 industrial mixer for food and chemical industries

Streamline your production with a multifunctional system that ef...

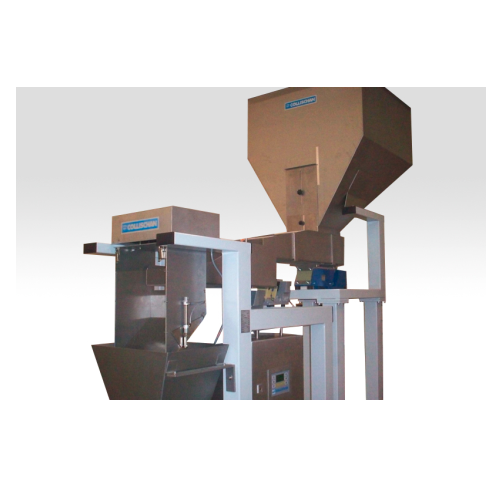

Weigh filler for bulk quantities 2-20kg

Optimizing your filling process with precision, this equipment handles bulk quantit...

Weight filler for small batches in explosive areas

Efficiently handle and weigh small batch products with precision, even...

Basic checkweigher for weight control in low to medium performance

Ensure accurate weight control with a versatile chec...

Static checkweigher for accurate measurement

For those needing unparalleled precision, this static checkweigher ensures ex...

High-performance checkweigher for pharmaceutical tablet cartons

Achieve precision weighing at speeds up to 500 units per...

Counting system for tablets and capsules

Effortlessly count a variety of tablets, capsules, and dragées with precision, ens...

Precision weigh filler for food and pharma industries

Optimize precision in multi-component dosing with seamless integrat...

Complete packaging lines for various containers

Streamline your packaging process with versatile equipment capable of hand...

Microdosing system for granules and powder

Achieve precise dosing with minimal variance across all fills, ensuring consist...

Flash pasteurizer for beverage production

Ensure beverages maintain quality and safety with precise temperature control an...

Premix system for carbonated beverages

Ensure precise carbonation and blending for your beverage lineup with this advanced ...

Mixer-pasteurizer-carbonator for soft drinks and juices

Optimize your beverage production with a versatile system that se...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

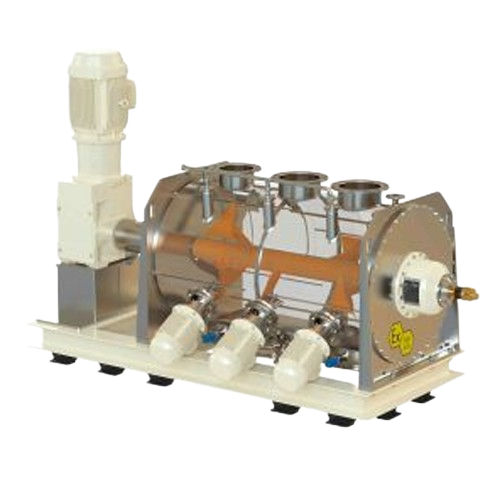

Horizontal ploughshare mixer for solids and powders

Achieve uniform blends of diverse solids and powders with precision a...

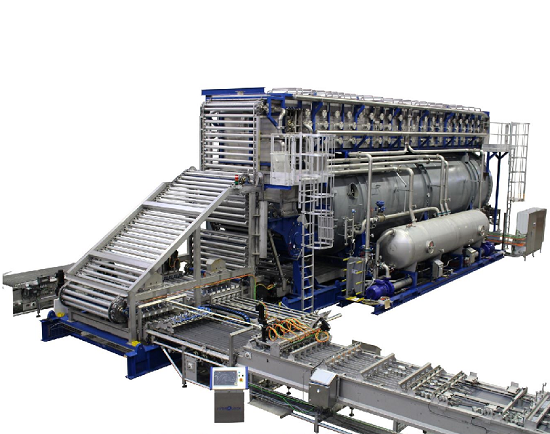

Aseptic cooking and filling line with two reactors

Streamline your production with a versatile line that combines high-ef...

Plate type pasteurizer for juice and tea drinks

Ensure optimal heating, sterilization, and cooling for juice and tea produ...

8000bph fruit juice filling system

Optimize your beverage production line with a high-speed fruit juice filling system, des...

Centrifuge separator for food and beverage clarification

Ensure high efficiency and minimal product loss in your producti...

Single chamber tea bag packer with sealed filter paper

Efficiently pack diverse tea varieties into neatly sealed single c...

Beverage thermal treatment systems

Optimize beverage production by ensuring precise thermal treatment, enhancing flavor sta...

Customizable storage tanks for industrial use

Optimize your production with versatile storage tanks designed for precise c...

Clean-in-place tanks for industrial sanitation

Optimize your sanitation processes with clean-in-place tanks, designed to r...

Industrial pressure vessels

Ensure product integrity and regulatory compliance with engineered-to-order pressure vessels, de...

Clean-in-place system for diverse processing needs

Ensure the precision and consistency of your cleaning cycles with a ro...

Powder can seamer for nutraceutical and beverage powders

Achieve precision and hygiene with this can seamer designed for ...

Automated valve manifolds for clean-in-place solutions

Optimize your production efficiency with automated valve manifolds...

Barcode reading and verification system

Ensure every container has the correct product with a cutting-edge scanning system ...

Powder induction system for efficient liquid powder mixing

Achieve precise and dust-free powder incorporation into liqui...

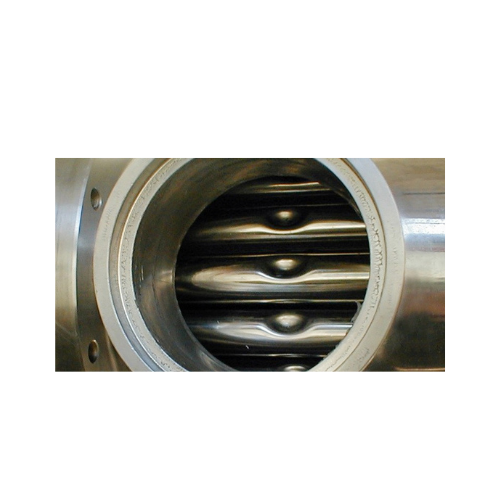

Tube-in-shell heat exchanger for low viscosity products

Enhance your beverage and food processing efficiency with a cutti...

Heat exchanger for dairy and beverage applications

Optimize your liquid product thermal processing by directly regenerati...

On-food traceability technology for produce

Enhance your product authenticity with a revolutionary traceability technology...

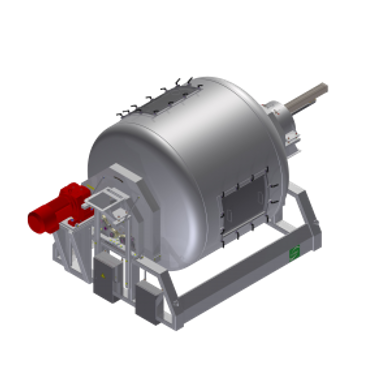

Expandable high pressure processing system

Optimize your production line with an expandable high-pressure processing syste...

High pressure processing water filtration system

Ensure super clear water after high pressure processing to protect your s...

High pressure food processing solution for medium-scale producers

Achieve reduced operational costs with high-pressure ...

High pressure processing for diverse food products

Maximize production versatility and ensure product safety with a high-...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

Rotary can filler and closer for metal cans

Achieve seamless integration in your production line with a solution that sinc...

Volumetric filler for various food products

Achieve high precision and flexibility in your filling processes with a volume...

Industrial weight filler for bottles and jars

Achieve precise product filling with our weight filler system, expertly desi...

Hybrid evaporator for highly viscous tomato concentrate

Achieve superior concentration and energy efficiency with a versa...

Can seamer for high-speed liquid applications

Ensure consistent seal integrity and maximize throughput with this advanced ...

Extrusion blow molder for custom bottles

Enhance your production line by creating versatile and customized bottles with sea...

Industrial sifters for beverage processing

Optimize your beverage production with precisely engineered sifters that ensure...

Reverse osmosis dealcoholization technology

Elevate your beverage production capabilities with advanced dealcoholization t...

Centrifuge for beverage clarification

Elevate your beverage production with enhanced clarification, ensuring your drinks me...

Reverse osmosis dealcoholization technology for beer

Achieve consistent flavor profiles in your non-alcoholic beer produc...

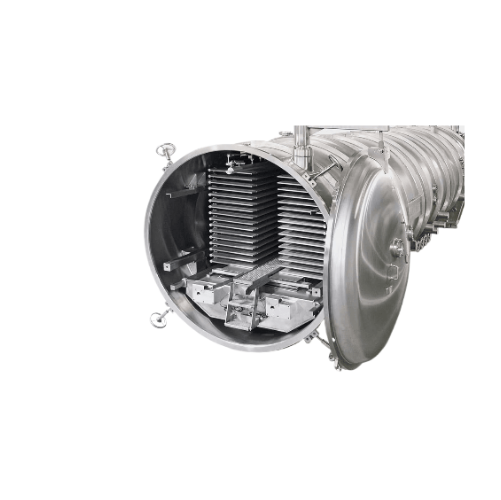

Industrial freeze drying system for high-volume food products

Achieve precise moisture removal and preserve product qual...

Batch freeze drying system for food and beverage preservation

Achieve precise and efficient preservation of your food an...

Carbonated beverage can filler - 4 spout open fill

Optimize canning carbonated beverages while minimizing CO2 loss with t...

Hot fill bottling unit for juices and isotonic beverages

Ideal for producers handling delicate or specialty liquids, this...

Level bottle filler for wine and spirits

Achieve consistent fill levels with precision sensor technology, ideal for ensurin...

Volumetric bottle filler for distilled spirits

Ensure precise volume control and compliance with regulatory standards in y...

Counter pressure filler for carbonated beverages

Ensure optimal carbonation and minimal oxygen exposure during bottling, e...

Counter pressure can filler for carbonated beverages

Achieve precise carbonation levels and minimal oxygen exposure in ca...

Counter pressure bottle filler for carbonated beverages

Maintain carbonation levels while filling bottles efficiently, en...

Counter pressure bottle filling system for carbonated beverages

Enhance your bottling efficiency with a versatile counte...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Stand-up pouch filling and sealing system

For packaging lines that demand quick, efficient, and flexible pouching, this hi...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Stand-up pouch packaging for various products

For manufacturers seeking versatile packaging solutions, this machine delive...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Horizontal flat pouching system for up to 180ml capacity

Optimize your packaging process with a high-speed solution desig...

Horizontal stand-up pouching system for liquids and solids

For producers aiming to optimize efficiency and precision, th...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

Automatic rotary premade pouch filler and sealer

Optimize your production line with high-speed pouch filling and sealing, ...

Sachet packaging lines for pharmaceuticals

Optimize your pharmaceutical production with high-speed sachet packaging lines ...

Automatic pour over coffee maker

Enhance your coffee and tea offerings with seamless brewing precision, optimizing pour-over...

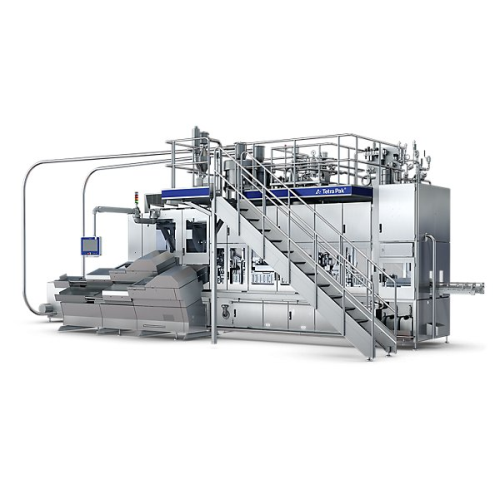

Indirect Uht treatment for dairy products

Ensure your beverages achieve extended shelf life with consistent quality using ...

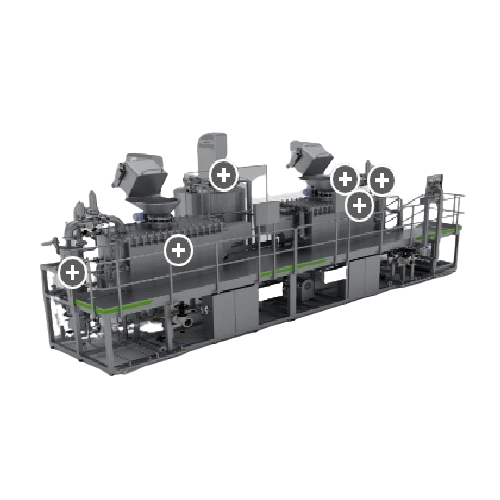

Single-pass tea extraction system

Achieve consistent, high-quality ready-to-drink tea extraction with a streamlined, semi-c...

Uht processing unit for dairy products

Optimize your liquid food production with continuous, high-capacity UHT treatment th...

Indirect Uht processing for dairy products

Enhance your dairy and beverage operations with state-of-the-art ultra-high tem...

Single-pass extraction system for tea

For tea producers seeking consistent, high-quality extraction, this semi-continuous s...

Filling system for gable top cartons chilled products

Achieve precise filling and reliable sealing for chilled beverages ...

Horizontal flow wrapper for food packaging

Simplify your packaging process with our high-speed horizontal flow wrapper tha...

Vffs packaging solution for diverse bag styles and high hygiene standards

Enhance your packaging operations with high-...

Industrial bag sealing solution for medical and food applications

Enhance your packaging line with reliable and versati...

Direct drive centrifuges for dairy and beverage processing

Optimize energy efficiency in high-speed liquid separation wi...

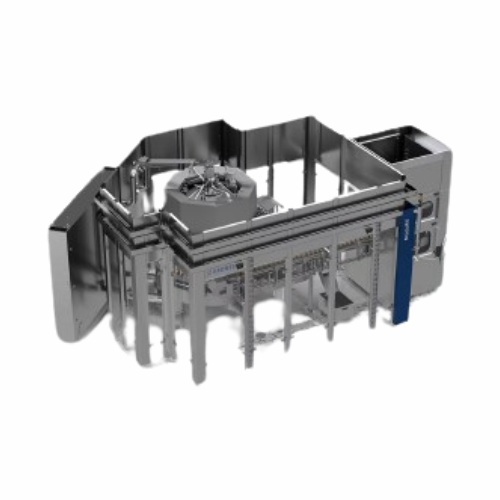

Combi ultra high temperature (uht) processing plant for dairy and beverages

Achieve precise heat treatment for diverse...

Steady and moving pallet palletizers

Optimize your packaging line with advanced palletizing solutions designed to handle di...

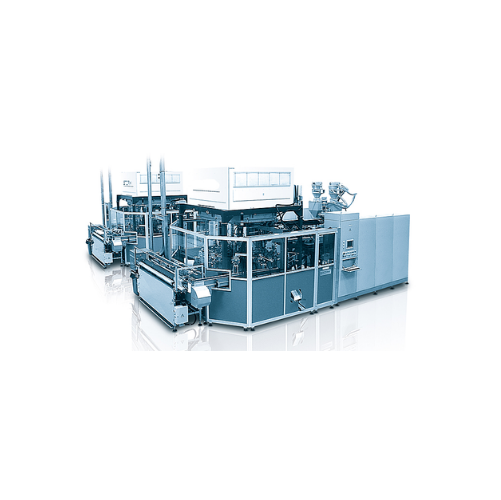

Integrated linear blowing and filling system for Pet containers

Streamline your PET container production with integrated...

Integrated rotary blowing and filling system for Pet bottles

Optimize your beverage production with an integrated rotary...

Isobaric filler for glass and Pet bottles

Achieve precise liquid filling with enhanced operational flexibility and hygiene...

Cip sanitizing unit for food and beverage production

Ensure meticulous hygiene with a compact unit designed for seamless ...

Degassing and mixing unit for beverage production

Ensure precise beverage formulation and maintain high quality standards...

Single-stage plastic container production system

Eliminate multiple steps and minimize production costs with an integrated...

Linear blowing systems for Pet bottle production

Ideal for producers seeking versatile container solutions, this system en...

Rotary blower for Pet bottle production

Optimize PET bottle production with cutting-edge efficiency, reducing energy consum...

Metal detection system for powders & granules

Ensure product integrity and protect your machinery from metallic contaminan...

Top-loading delta robot automation solution

For high-speed operations requiring precise product handling, this top-loading...

Top loader robots for precision packaging

Optimize packaging operations with versatile robotic top loaders that achieve hi...

Lab punching and sealing system for cleanroom conditions

Test and refine your packaging processes with precision, ensurin...

Cartoner for pharmaceutical products

Effortlessly streamline your packaging line with compact cartoning capabilities, ensur...

Sterile filling platform for pharmaceuticals

Achieve precise, high-speed aseptic filling and packaging with advanced compl...

Coffee capsule filling and sealing solution

Optimize your production with a high-speed solution designed to fill and seal ...

Coffee capsule filling and sealing system

Boost capsule production efficiency and reduce downtime with a high-speed system...

Coffee capsule filling and sealing line

Elevate your capsule production with a high-speed filling and sealing solution that...

Production system for molecular diagnostics

Eliminate bottlenecks in molecular diagnostics production with a versatile sys...

Compact case packer for secondary packaging

Optimize your secondary packaging process with a case packer that operates cle...

Horizontal cartoning system for coffee pods

Enhance your packaging line efficiency with a system designed for gentle handl...

Sequentially automated case packer for small products

Efficiently pack diverse small products into large cases with preci...

Compact palletizer for food and beverage products

Optimize your end-of-line operations with a space-saving palletizer tha...

Standardized modular tray former for secondary packaging

Optimize your packaging line efficiency with this modular tray f...

Lab device for testing coffee capsules

Achieve precise testing and reproducibility of coffee capsule parameters crucial for...

Filling and sealing solution for beverage capsules

Optimize your production with a modular capsule filling and sealing so...

Coffee capsule filling and sealing machine

For producers seeking a compact yet powerful machine, this system efficiently f...

Filling solution for powders and liquids in diagnostics

Simplify precision filling of diverse products, from freeze-dried...

Semi-continuous freeze dryer with easy-loading

Freeze-drying is both a time- and energy-consuming process. In addition to ...

Agitator bead mill for functional foods and flavors

Fine-grinding solid flavors to improve taste properties and integrati...

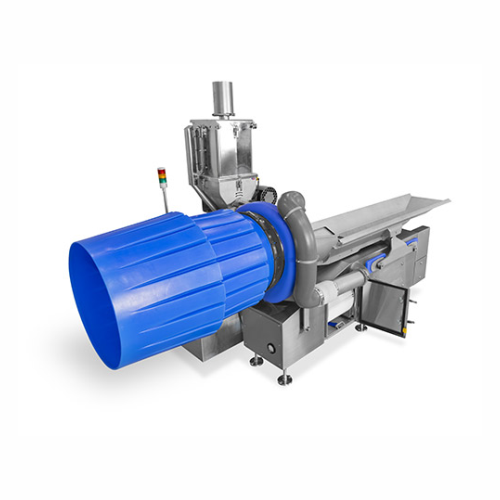

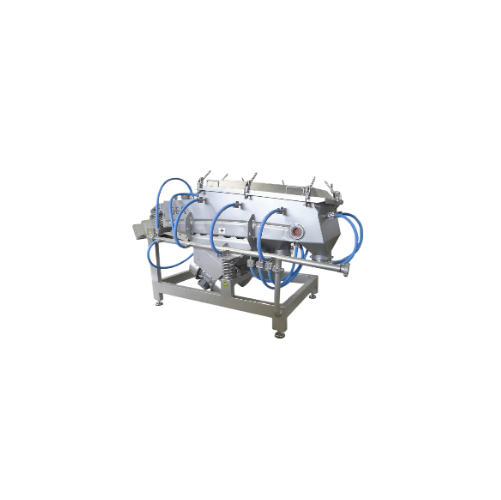

Gentle mixer for tea blending

The blending process is critical to the flavor quality of tea. But the physical impact of the ...

Semi-manual can sealer

When starting out in the canned product business, you do not necessary want to invest in industrial sc...

Leak tester for vacuum packaging

Roasted coffee beans, as well as grounded coffee, rapidly diminish in flavor. The oxyge...

High speed can seamer

Tin plate thickness for cans has gradually reduced over the years, which makes it a hassle to use new c...

Horizontal cartoner for food products

Depending on the primary product packages, food products like confectionery (biscuits...

Continuous sterilizer for tin cans and jars

A concern in the coffee industry is maintaining the freshness, taste, and qual...

Industrial drying cabinet

The production of high-quality biltong and similar dried meat products can pose problems with main...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

CIP system for beverage

Clean-in-place operations are a mandatory part of food and beverage processing which cannot fail. How...

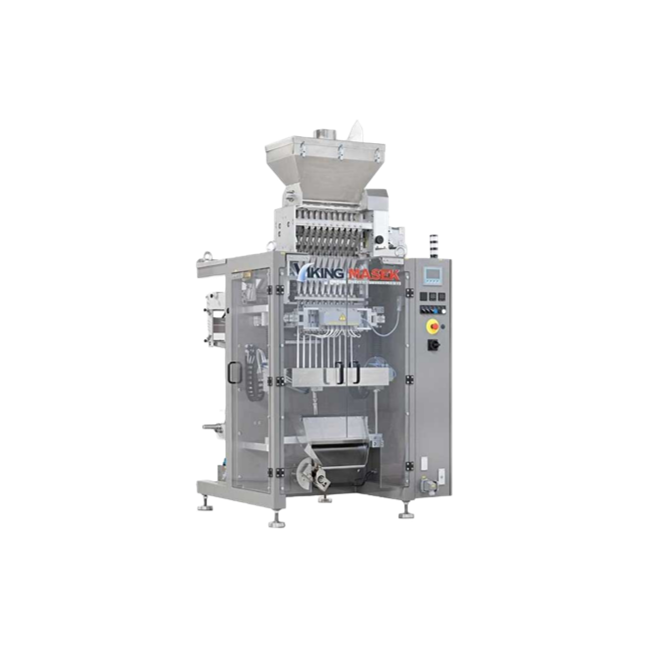

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Industrial dehydration machine

Dried fruits are popular both as food in themselves and as ingredients. Traditional drying te...

Entry level HFFS Machine for flat sachets

Traditional horizontal form fill and seal sachet machines for lower volume lines...

High-Speed Pouch Packaging Machine

For large scale production of powders and liquids in a wide range of industry sectors, a...

Checkweigher for sachets and sticks

The checkweighers for multiple lanes have a 1.5 times faster response speed and 2 times...

Sachet Machine

If you want to pack into eye-catching 4-side sealed sachets between 40×50 mm and 250×200 mm in size, ...

Pilot evaporation plant for the recovery of extracts

For development of concentrates of extracts based on water or ethano...

Continuous belt freeze dryer

Freeze drying is the most gentle and aroma protective method of drying, widely used in the coff...

High-speed unscrambler for small bottles

Large-scale production of smaller volume bottled product needs a gentle, accurate ...

Full crate inspection system

State of the art crate inspection system that uses a laser camera system to see if the bottles ...

High-frequency fill level controller

In terms of high-frequency technology, the fill level detection is considered a standa...

Empty bottle height sorting system

An empty bottle sorting system that uses the light barrier technology. It detects bottle...