Aseptic filling line for biopharmaceutical products

Achieve precision and sterility in high-speed liquid filling operations with automated vial handling, ensuring compliance and reliability for advanced therapeutic production.

Fills, Weighs, Seals, and Caps Biopharmaceutical Vials

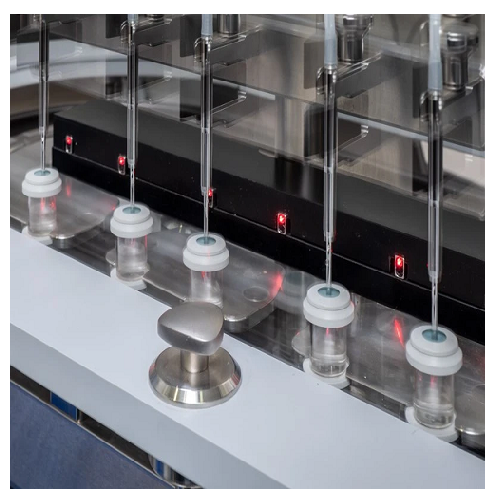

The Crystal™ PX Filling Line from SKAN Group is engineered to deliver precise, high-speed fill and finish operations for biopharmaceutical applications. This platform supports your production of innovative therapies—including CAR-T cell therapies, mRNA vaccines, and viral vectors—by providing 100% in-process control (IPC) and compliance with Good Manufacturing Practice (GMP) standards.

Designed for versatility, the Crystal™ PX accommodates a wide range of vial sizes, from 0.1 ml to 50 ml, and achieves a throughput of up to 10,800 vials per hour. The integrated AT-Closed Vial® technology ensures a robust aseptic filling environment with ISO 5 class conditions, safeguarding product sterility and integrity.

Key components such as automated vial loading and weight-checking stations, laser re-sealing units, and capping modules streamline the filling process and enhance production efficiency. The system’s tool-less format change and single-use product path facilitate swift transitions between production batches, minimizing downtime.

The equipment’s adherence to CFR 21 part 11 ensures compliance with electronic records and signatures, while installation options for isolators or RABS (Restricted-Access Barrier Systems) make it adaptable to different manufacturing environments. This highly automated line is ideally suited for pharmaceutical manufacturers, biopharmaceutical companies, and developers of cell and gene therapies seeking reliable, sterile, and efficient filling solutions.

Benefits

- Ensures sterility and product integrity with ISO 5 class aseptic filling.

- Increases efficiency with up to 10,800 vials per hour throughput.

- Reduces changeover time with tool-less format change for flexible production.

- Enhances compliance with CFR 21 part 11 electronic records and signature guidelines.

- Optimizes resource use with single-use product paths minimizing cross-contamination risk.

- Applications

- Gene therapy products, Viral vectors, Cell therapy, Biopharmaceuticals, Exosomes, Plasmid dna

- End products

- Adeno-associated viral (aav) vectors, Gene-modified stem cell therapies, Exosome-based drug delivery systems, Car-t cell therapy, Crispr-based gene editing therapies, Mrna vaccines, Lentiviral vectors, Plasmid dna vaccines

- Steps before

- Purification, Preparation of ready-to-fill AT-Closed Vial®, Vial loading

- Steps after

- Capping, Acceptance controls, Packing

- Input ingredients

- ready-to-fill AT-Closed Vial®, vials, biopharmaceutical products, cell therapy starting materials, gene therapy starting materials, exosomes, viral vectors, plasmid DNA

- Output ingredients

- filled vials, capped and re-sealed vials

- Market info

- Aseptic Technologies is known for its innovative solutions in the field of aseptic filling and finishing systems. They specialize in advanced equipment designed for sterile manufacturing processes, particularly in the pharmaceutical and biotech industries.

- Capacity

- Up to 180 vials/min

- Filling volume

- 0.1 ml to 50 ml

- Filling speed

- Up to 10, 800 vials/hour

- Accuracy

- 100% IPC of weight

- Automation

- Automated vial loading

- Cleanroom Classification

- ISO 5 conditions

- Working Mechanism

- AT-Closed Vial® technology

- Integrated Steps

- Automatic vial loading, weighting, acceptance, filling, laser re-sealing, and capping

- Batch vs. Continuous Operation

- Continuous

- Changeover Time

- Tool-less format change

- CIP/SIP

- H₂O₂ decontamination

- Automation Level

- High-speed fill, finish operations

- Cleaning Method

- H₂O₂ decontamination

- Energy Efficiency

- Not specified

- Air Incorporation Control

- ISO 5 conditions

- Biological compatibility

- Compatible with cell and gene therapy products

- Cleanability

- ISO 5 cleanroom compatible

- Corrosive resistance (e.g. acids)

- High resistance to H₂O₂

- Density/particle size

- Supports a range of vial sizes

- GMP Compliance

- Full GMP Compliance

- Sterility Assurance

- ISO 5 Conditions

- CFR Compliance

- 21 Part 11 Compliant

- Discharge method

- Automated vial loading

- Filling volume

- 0.1 ml to 50 ml

- Barrier System

- Closed RABS / Isolator