Fill level inspection

Connect directly with world-leading production technology suppliers of innovative fill level inspection systems

Fill level inspection ensures that each container is filled with exactly the desired volume of the product during a liquid filling operation. While transparent containers can utilize optical sensors for level detection, difficult to see through containers, such as cans or cartons lined with aluminum, must be scanned using X-rays. When choosing fill level inspection equipment, the size, shape, and opacity of the container must be considered. The production speed, the desired accuracy, and the amount of foaming on the liquid surface are also important parameters to consider. Fill level inspection systems are used to comply with quality control standards.

Which fill level inspection systems technology do you need?

Cup filling system for jars and buckets

Optimize your confectionery and bakery filling processes with this high-speed cup f...

Compact fill level and cap inspection system

Ensure flawless beverage quality by integrating a compact system for precise ...

Inspection systems for fillers and cappers

Ensure precise fill levels and secure cap placements with advanced inspection s...

Bottle inspection system for foreign particles detection

Ensure your beverage products remain uncontaminated with high-pr...

High-precision fill level checker for beverages and containers

Ensure precise fill levels and prevent product wastage by...

Label inspector for beverage and food containers

Ensure precise label application with high-speed inspection, crucial for ...

Vertical packaging for leafy greens

Optimize your packaging line with high-speed vertical systems designed for precise pack...

Hot-fill dosing system for soups and sauces

Ensure precise and efficient dosing of hot and cold liquid foods with integrat...

Compact full product inspection system for pharmaceuticals

Easily detect fill level inaccuracies, closure misalignments,...

Leak detection for pharmaceutical containers

Ensure the integrity of your liquid products in high-speed production by dete...

Full container check for fill level and closure inspection

Ensure the integrity of your liquid products with this advanc...

Final product inspection system for pharmaceutical containers

Ensure the integrity and precision of packaged pharmaceuti...

Full container inspection for pharma and food industries

Ensure precise fill levels and secure closures in your productio...

Fill level and closure inspection system

Ensure precise fill levels and secure closures in high-speed liquid packaging envi...

Final container inspection for beverages

Ensure flawless product presentation and secure branding by detecting misaligned l...

Full container check system for beverage industry

Streamline your quality assurance process with advanced detection techn...

Manual filling system for bag-in-box packaging

Streamline your liquid filling process with a manual system designed for pr...

Cap and fill level inspection system for bottles

Ensure precise cap placement and accurate fill levels in your bottling li...

Fill level inspection system for beverage bottling

Ensure compliance and optimize quality control with a system that accu...

Leak detection system for cans

Ensure the integrity and shelf-life of canned goods with precise leak detection, pressure mea...

Cap inspection and fill level inspection system for beverage containers

Ensure precise cap application and fill level m...

Desiccant inserter for pharmaceutical containers

Prevent product degradation by efficiently inserting desiccants into cont...

Tabletop food depositor for portion control

Streamline your food production with precise portion control, reducing waste a...

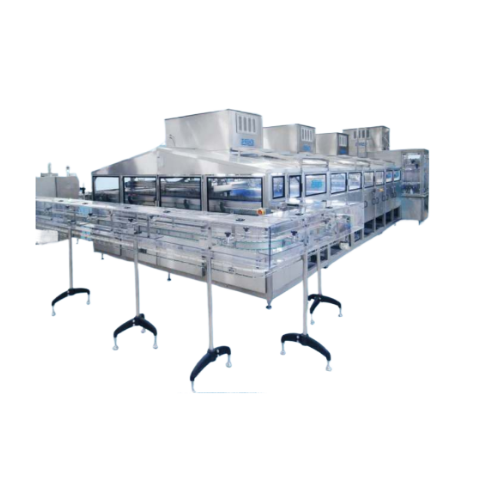

Automatic inspection and leak test for pharma containers

Ensure container integrity for injectables with high-speed inspe...

Semi-automatic filling and closing system for pre-formed containers

Streamline your packaging process with reliable sem...

Caramel treats production line

Enhance your snack production with a comprehensive solution for crafting caramel treats, effi...

Semi-automatic weight filling system for liquid products

Achieve precise and versatile liquid filling performance with th...

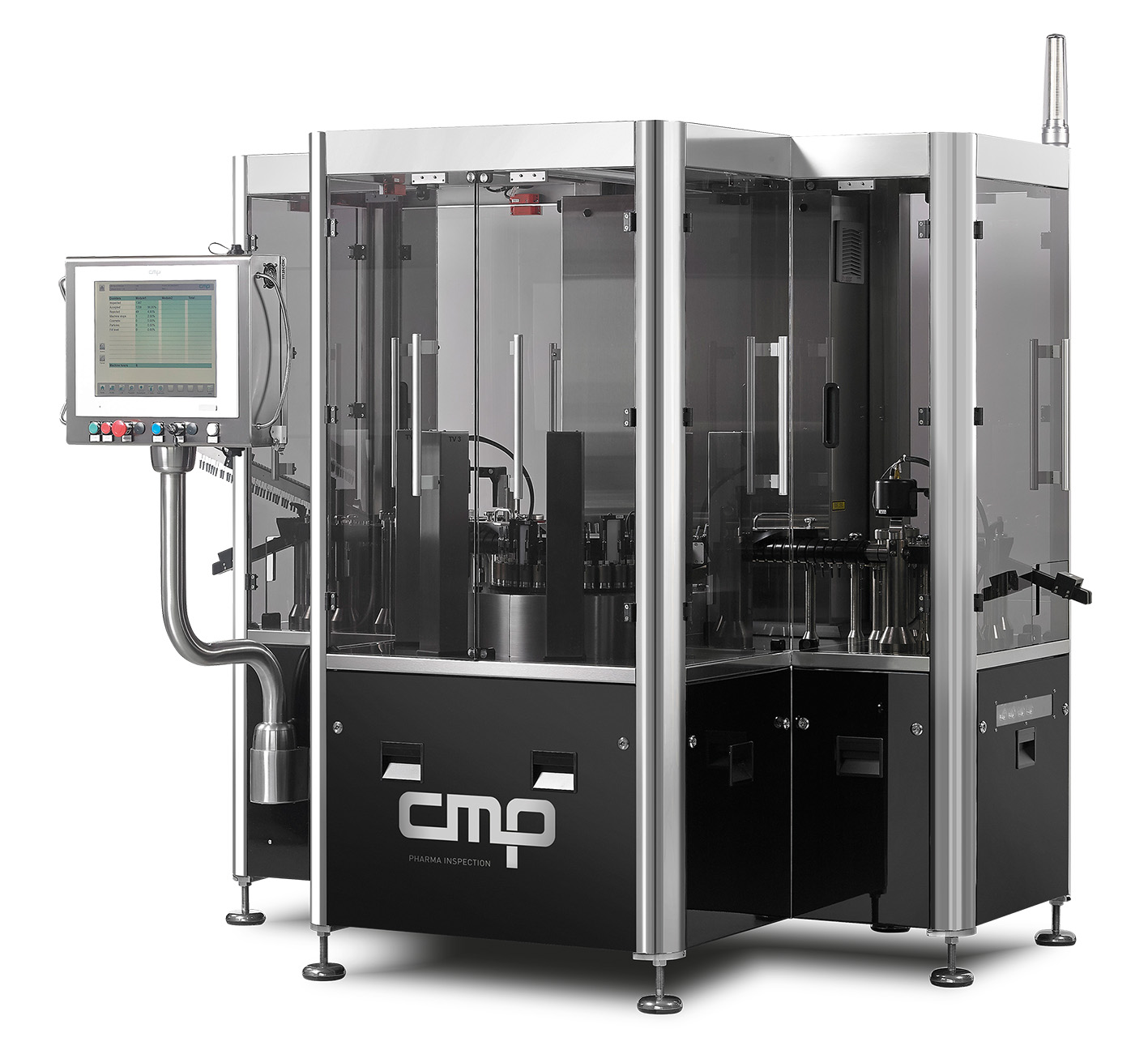

Flexible automatic inspection machine for ampoules, vials, cartridges

If you are looking to improve the efficiency of y...

Flexible automatic inspection machine for syringes

Manufacture of pre-filled syringes requires the highest quality inspec...

Small automatic inspector for ampoules, vials, or cartridges

Inspect small batch production of ampoules, vials, or cartr...

Semi-automatic inspection machine for ampoules, vials or cartridges

If you need to increase the efficiency of your manu...

Visual and HVLD inspection for ampoules, vials and cartridges

Do you need to improve the efficiency and capability of yo...

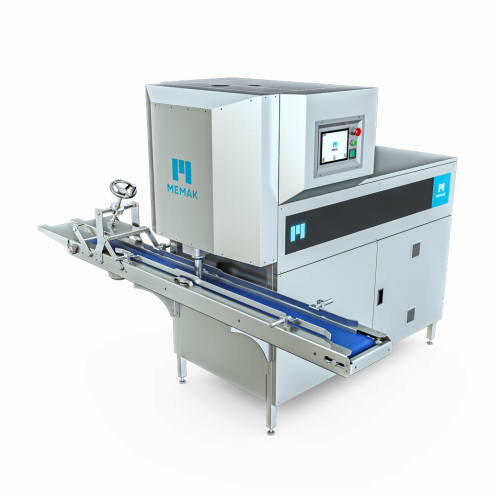

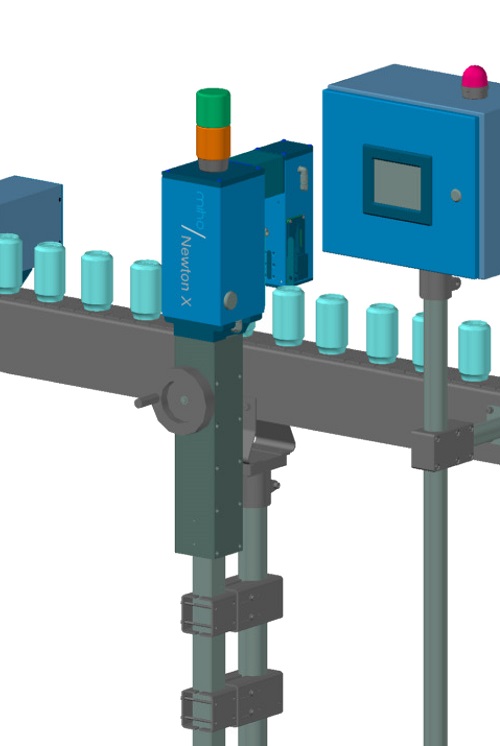

High-precision X-ray fill level controller

High-speed, high precision X-ray system to inspect containers that are difficul...

X-ray fill level controller

For containers that are difficult to see through, such as cans or cartons lined with aluminium, ...

Optical fill level controller

Accurate fill level inspection for transparent, opaque and foaming liquids, that makes sure th...

High-frequency fill level controller

In terms of high-frequency technology, the fill level detection is considered a standa...