Closed vial dispensing system for radiopharmaceutical production

Ensure precise radiotracer dosages and maintain sterility standards with a system designed to fill closed vials through a transseptal approach, optimizing the integrity and safety of your nuclear medicine operations.

Dispenses and Fills Radiopharmaceutical Vials Transseptally

The ARGO-T from Comecer represents a breakthrough in radiopharmaceutical vial dispensing, offering a closed vial transseptal filling system that adheres to cGMP guidelines. Uniquely designed for use in nuclear medicine and radiopharmacy, ARGO-T facilitates precise dosing of radiotracers such as fluorodeoxyglucose (FDG) and lutetium-177 therapy agents. The system employs a controlled volume dispensing mechanism, integrating an innovative needle with a sterile filter to ensure accuracy within 5% for volumes between 1 to 10 ml. Suitable for integration into Class A shielded isolators, it simplifies operations in radiopharmaceutical production environments. Compact and lightweight, it includes a label printer and barcode reader for seamless inventory tracking and product identification, enhancing operational flow. Additionally, ARGO-T supports effective sterile conditions with its sterilizing filter and bubble point test line, making it indispensable for maintaining product integrity in high-stakes environments.

Benefits

- Enhances precision in radiopharmaceutical dosing, minimizing wastage and ensuring patient safety.

- Streamlines workflow with automatic vial perforation, reducing manual intervention and error.

- Compact design facilitates easy integration in existing Class A shielded environments.

- Ensures regulatory compliance with cGMP standards for radiopharmaceutical production.

- Supports accurate inventory management with integrated label printing and barcode reading.

- Applications

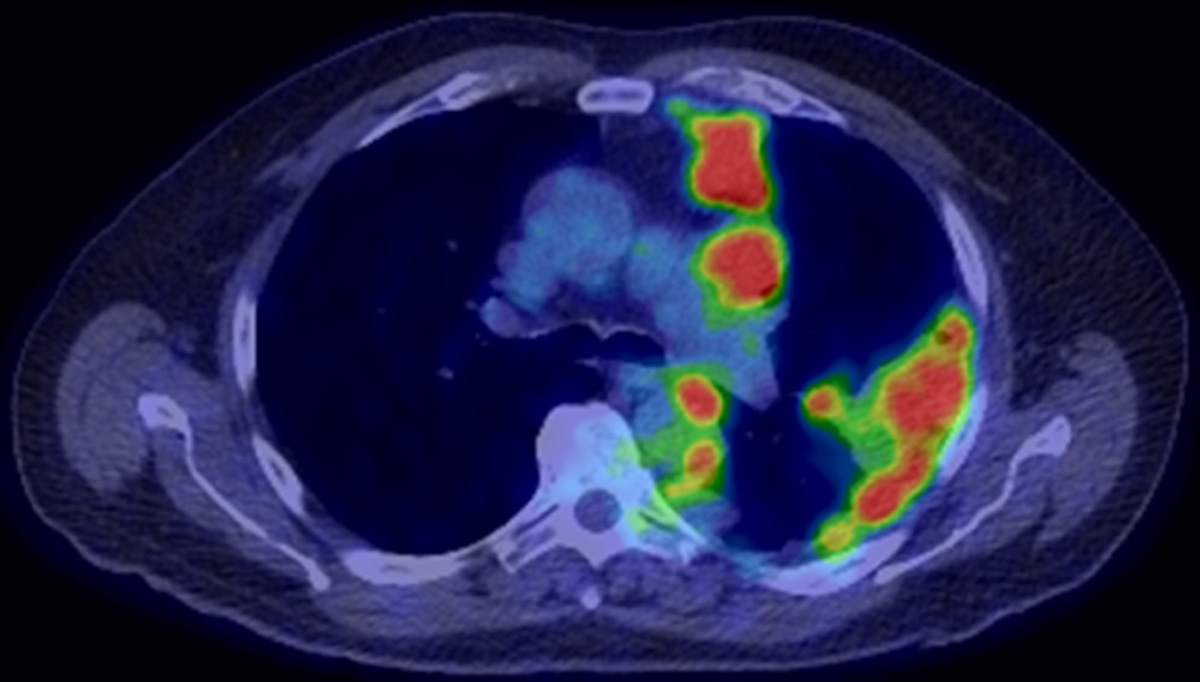

- Pet diagnosis, Radiopharmaceuticals, Metabolic radiotherapy, Spect diagnosis, Radiotracers, Nuclear medicine

- End products

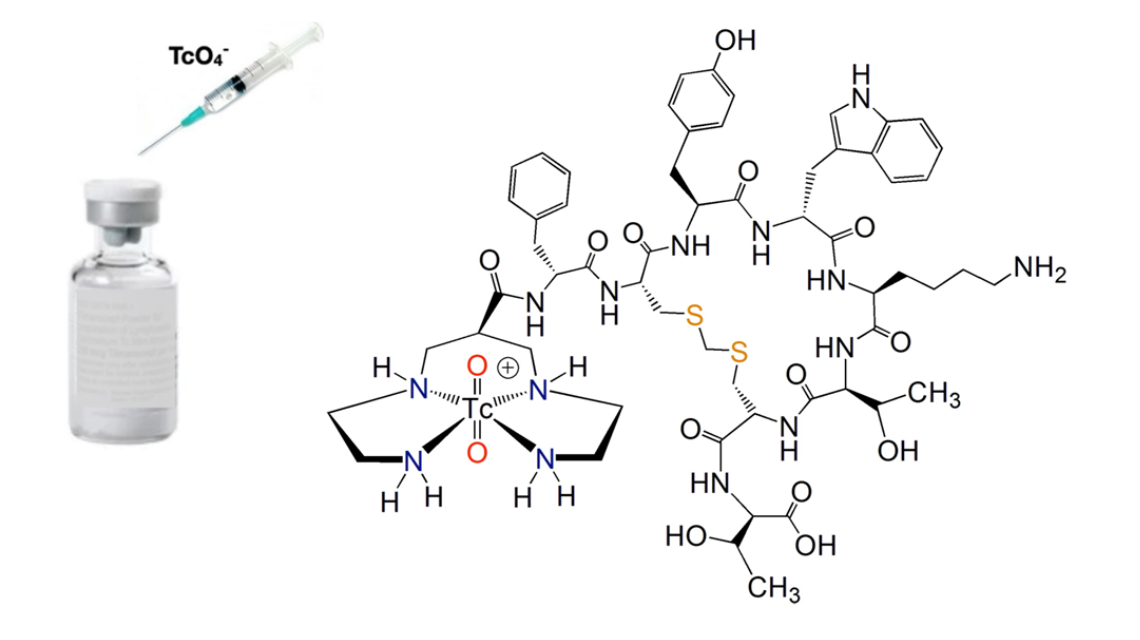

- Yttrium-90 radioisotopes, Lutetium-177 therapy agents, Technetium-99m radiopharmaceuticals, Fluorine-18 labeled tracers, Copper-64 pet agents, Gallium-68 labeled compounds, Fluorodeoxyglucose (fdg), Iodine-131 treatment doses, Samarium-153 therapeutic agents

- Steps before

- Radiopharmaceutical formulation preparation, Radiotracer synthesis

- Steps after

- Sterilization, Label printing, Radioactive dose calibration, Barcode scanning, Packaging in shielded container

- Input ingredients

- radiotracers, closed vials, sterile filter

- Output ingredients

- filled closed vials, dispensed radiopharmaceuticals

- Market info

- Comecer is known for manufacturing advanced containment and isolation systems, particularly in the pharmaceutical and nuclear medicine sectors, with expertise in custom-engineered equipment, ensuring high safety and compliance standards.

- Automation

- Automatic dispensing

- Filling method

- Transeptal vial filling needle

- Filling volume

- Within 5% accuracy for 1 to 10 ml

- Compliance

- cGMP compliant

- Needle

- Specific designed piercing and filling needle

- Filtration

- 0.22 μm sterile filter

- Integration

- Compact for Class A shielded isolators

- Dimension,Weight

- Compact dimensions for easy moving

- Pumping system

- Integrated pumping syringe in disposable kit

- Labeling

- Label printer for vial and shielded container

- Data Handling

- Barcode reader and concentration calculation

- Automation level

- Automatic

- Batch vs. continuous operation

- Batch

- Biological compatibility

- Yes

- Cleanability

- Sterile

- Corrosive resistance (e.g. acids)

- Yes

- Vial type

- Closed Vial

- Radiopharmaceutical purpose

- PET and SPECT diagnosis

- GMP Compliance

- cGMP

- ISO Certification

- ISO 13485

- Dispensing system integration

- Class A shielded isolators

- Integration with IIoT platforms

- Illuminate™ MI

- Flexible holder support

- Compatible with different vial formats

- Discharge method

- Automatic perforation of vial with needle