Nasal spray and eye drop filling solutions

Enhance the precision and flexibility of your liquid filling operations with our high-speed system, expertly designed to handle diverse pharmaceutical liquids like eye drops and nasal sprays efficiently, meeting rigorous quality and aseptic standards.

Fills and Caps Eye Drops and Nasal Sprays

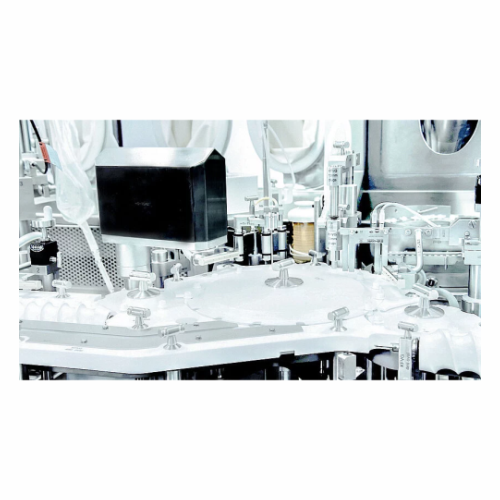

Groninger’s Nasal Spray and Eye Drop Rotary Filling and Capping Machine is tailored for high-efficiency processing of pharmaceutical liquids. Featuring a rotary piston pump and mass flow filling systems, it accommodates liquid viscosities from thin to viscous. Ideal for moisturizing and anesthetic eye drops, saline and decongestant nasal sprays, it supports CMOs and CDMOs with versatile production needs. Capable of handling glass and polymer containers, the machine achieves a throughput of 50 to 400 units per minute, with integrated quickconnect technology enabling fast, tool-free format changes. Each unit incorporates 100% In-Process-Control (IPC) for precise content verification, complying with GMP and EU requirements. Aseptic processing is ensured through advanced sorting and feeding systems, with clean-in-place/sterilize-in-place (CIP/SIP) modules for easy maintenance. Customizable and ergonomically designed, the system efficiently integrates into existing pharmaceutical production lines, supporting bulk processing and tray loading with automation.

Benefits

- Enhances production efficiency with quickchange capabilities and high throughput.

- Ensures product quality with 100% In-Process-Control (IPC) for precise filling accuracy.

- Minimizes contamination risks with aseptic, easy-to-maintain CIP/SIP modules.

- Increases operational flexibility with tool-free format changes for various container types.

- Complies with GMP and EU standards for rigorous pharmaceutical applications.

- Applications

- Nasal sprays, Otc products, Pharmaceutical liquids, Eye drops

- End products

- Preservative-free eye drops, Gamma sterilized eye drops, Decongestant nasal spray, Saline nasal spray, Anesthetic eye drops, Moisturizing eye drops, Medicated nasal spray, Glass-contained pharmaceutical liquids, Over-the-counter nasal solution, Polymer-based eye drop solutions

- Steps before

- Sterilization, Gamma sterilization, ETO sterilization, Sorting, Feeding

- Steps after

- Tray loading, Packaging, Storage

- Input ingredients

- eye drops, nasal sprays, glass containers, polymer containers, water-like liquids, WFI-based liquids, gamma-sterilized primary packaging, ETO-sterilized primary packaging

- Output ingredients

- filled eye drop bottles, filled nasal spray bottles, capped eye drop bottles, capped nasal spray bottles, trayed products

- Market info

- Groninger is known for its expertise in manufacturing high-quality filling and packaging machinery for the pharmaceutical, cosmetics, and consumer healthcare industries, with a strong reputation for innovation, precision engineering, and customer-focused solutions.

- Speed

- 50 to 400 units per minute

- Capacity

- 3, 000 - 24, 000 units per hour

- Container Type

- Glass / Polymer

- Filling Method

- Rotary piston pump / Mass flow filling systems

- In-Process-Control (IPC)

- 100% IPC

- Changeover system

- Quickconnect technology

- Filling Accuracy

- Checked by weighing before and after filling

- Gassing function

- Residual oxygen content less than 5%

- Automation

- Automatic lines

- Sorting Unit

- For round and oval objects

- Capping Mechanism

- Quickconnect technology for aseptic closing

- Cleaning Module

- CIP/SIP module

- Closing Accuracy

- Monitored tightening technology

- Tray Loading System

- Fully automatic pick, place system

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Quick with quickconnect technology

- CIP/SIP

- CIP 121°C / SIP 135°C

- Energy efficiency

- High due to efficient process

- Cleaning method

- CIP / SIP / Manual

- Processing speed

- 50 to 400 units per minute

- Container flexibility

- Glass and polymer containers

- Adaptability

- Quick and flexible adaptation

- Gassing function

- Headspace with residual oxygen content, lt

- 5%

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Quickconnect changeover capability

- Tool-free format change

- Container material compatibility

- Glass / Polymer

- Production speed

- 50 to 400 units per minute

- Production volume

- 3, 000 - 24, 000 units per hour

- Control panel type

- HMI

- Control panel type

- HMI with quickconnect technology

- Integration possibilities

- Compatible with oRABS and isolators

- Format changeover

- Tool-free via quickconnect

- Filling process adaptation

- Customizable for product requirements

- Product compatibility

- Glass and polymer containers