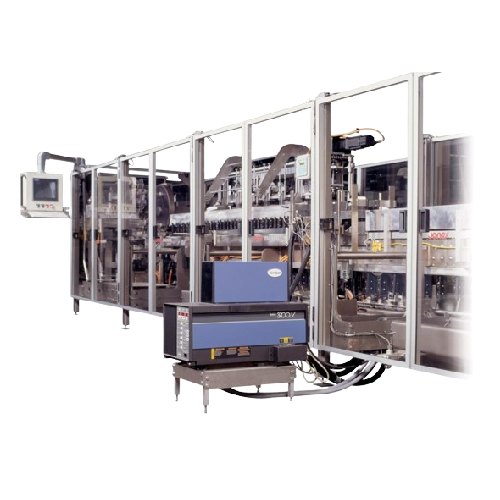

Horizontal end load cartoner for facial tissues

Achieve seamless and efficient cartoning for your tissue products with this high-speed, medium-scale cartoner designed for versatility with flat or cube configurations.

Packs and Cartons Tissue Products Efficiently

The Maxim CMT-300 by R.A Jones is a high-speed horizontal end load cartoner designed specifically for the tissue and hygiene industry. What sets this machine apart is its ability to handle a variety of tissue formats, including flat and cube configurations, while maintaining continuous operation for medium to high-scale production. Equipped with tool-less, quick changeovers, the CMT-300 integrates effortlessly into existing packaging lines, optimizing workflow and minimizing downtime. With a focus on flexibility, it supports pack sizes from 130 mm to 254 mm in height, 140 mm in length, and widths from 50 mm to 152 mm, making it versatile for diverse packaging needs. It uses paperboard cartons sealed with glue for secure packaging, ensuring each product is protected and ready for distribution. Its robust construction supports high throughput while operating efficiently within constrained space, thanks to dimensions of 2500 mm in depth, 2600 mm in height, and 10000 mm in length. The CMT-300 is ideal for tissue manufacturers aiming for increased efficiency without compromising on quality.

Benefits

- Enhances production efficiency with continuous, high-speed operations.

- Reduces operational downtime with quick, tool-less changeovers.

- Offers versatile packaging options to meet diverse customer demands.

- Integrates seamlessly with existing machinery for streamlined processes.

- Ensures product safety and quality with secure glue-sealed cartons.

- Applications

- Hygiene products, Facial tissues, Flat tissues, Other tissue, Cube tissues

- End products

- Toilet tissues, Paper hand towels

- Steps before

- Converting, Folding, Aligning

- Steps after

- Packing, Sealing, Labeling

- Input ingredients

- tissue, flat tissue configuration, cube tissue configuration, paperboard

- Output ingredients

- packaged facial tissue, cartoned tissue, prefolded carton pack, glue-sealed carton

- Market info

- R.A Jones (Coesia Group) is known for its expertise in designing and manufacturing packaging equipment and automation solutions, specializing in cartoning, pouching, and high-speed filling, with a strong reputation for innovation and reliability in the industry.

- Speed

- Up to 300 cpm

- Automation

- Continuous

- Machine Depth

- 2500 mm

- Machine Height

- 2600 mm

- Machine Length

- 10000 mm

- Machine Weight

- 8000 kg

- Insertion Mode

- End Load/Side Load

- Size Changeover

- 30 - 40 min

- Packaging Range - Max Pack Height

- 254 mm

- Packaging Range - Min Pack Height

- 130 mm

- Packaging Range - Max Pack Length

- 140 mm

- Packaging Range - Min Pack Length

- 101 mm

- Packaging Range - Max Pack Width

- 152 mm

- Packaging Range - Min Pack Width

- 50 mm

- Packaging Closing

- Glue

- Packaging Material

- Paperboard

- Operating mode

- Continuous

- Changeover time

- 30 - 40 min

- Insertion mode

- End Load/Side Load

- Automation level

- Automated

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Filling purpose

- Tissues

- Machine depth

- 2500 mm

- Machine height

- 2600 mm

- Machine length

- 10000 mm

- Machine weight

- 8000 kg

- Insertion mode

- End Load/Side Load

- Packaging orientation

- Horizontal

- Insertion mode

- End Load/Side Load

- Packaging configurations

- Flat/Cube

- Packaging closing

- Glue

- Packaging orientation

- Horizontal

- Changeover method

- Tool-less

- Integration possibilities

- Interfaces with upstream converting machinery