Ketchup Processing Equipment

Find innovative production technology for making ketchup and connect directly with world-leading specialists

Ketchup processing begins with tons of tomato paste that is mixed and heated together with sugar, vinegar, and spices in a cooking kettle. After cooking, any remaining fibers and particles are filtered out. Once it reaches the right viscosity, your tomato ketchup production process is finished and ready for packaging and transport.

Select your ketchup process

Tell us about your production challenge

Converting fresh tomatoes into a tomato puree

The first thing you need is tomato paste. It’s usually bought as an ingredient due to the seasonal nature of tomatoes. But, if you are processing the paste too, fresh tomatoes first need to be washed in rotating drums, sorted and cut them into smaller pieces. To remove the tomato seeds and the skin from the pulp, the tomatoes must go through a pulping machine and then the resulting pulp has to be filtered through screens. Tomatoes then go to an evaporator which involves a hot break treatment unit that includes heating them at a temperature of 90˚C or higher. The hot break step is a core process for enzymatic inactivation to preserve the pectin.

Ketchup – The Asian’s origin you don’t expect

Kê-tsiap, that’s the original name of our beloved table condiment, comes from southern China, and, here ye, at first it was tomato-free. It was a sauce made with fermented fish. After a long journey through England and America, the recipe of the tomato-based ketchup we know came to us. But how is it made?

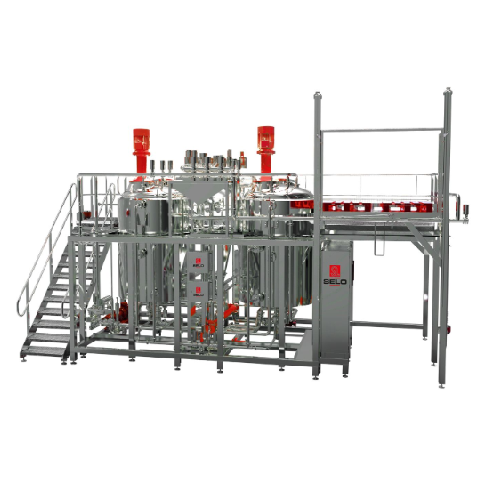

From paste to ketchup – what processing equipment is required?

Tomato paste arrives vacuum-packed in large storage bins, ready for further processing lines. After quality control, and making sure there are no residual tomato seeds, you can move it to a cooking kettle for a second heating treatment where you can add different spices, vinegar and sugar. An industrial cooker mixes all the ingredients and heats them to the desired temperature. The ketchup mixture is filtered to remove fibers and particles and a homogenizer is then used to achieve the right consistency. A de-aerator can help you to get rid of the air stuck into the tomato ketchup which reduces the risk of bacterial growth and discoloration. Before moving to a filling line a final check is done on the viscosity in order to make sauce with the perfect texture.

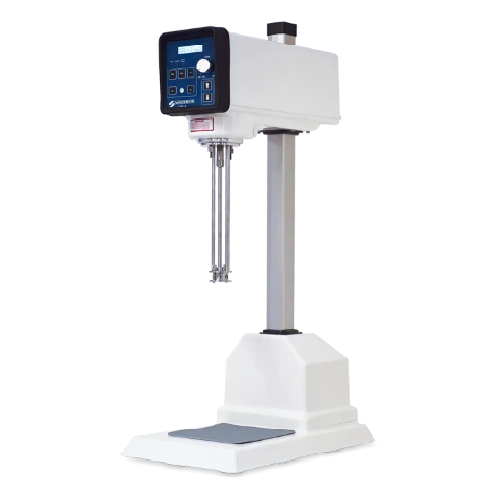

A viscometer to analyse your ketchup's consistency

Have you ever noticed that if you turn a bottle of ketchup upside down nothing happens unless you shake it? Ketchup is made of tomato pieces suspended in a liquid that, by touching each other, create a network that can resist motion as long as you apply the right amount of force to it to make it flow. With a viscometer you can analyze how fast the tomato sauce travels and what is the viscosity. Studies have shown that the correct flow speed is 0.045 km/h or 0.028 miles/hour.

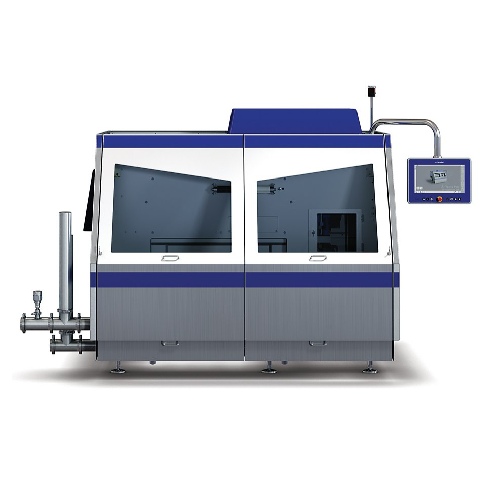

Using a hot fill solution for your ketchup bottles

Before filling, ketchup should be heated to no less than 88°C to avoid contamination. During the hot filling, both the product and the container are sterilized by heat. Hot ketchup is injected into a container that is then kept at high temperatures for a period of time to ensure that there are no bacteria in the food or in the packaging. After hot filling, ketchup should be cooled immediately to preserve the taste and flavor. Although hot filling of ketchup is considered safe for the shelf life, some manufacturers choose to perform a pasteurization process (another heating treatment) at 85-88°C.

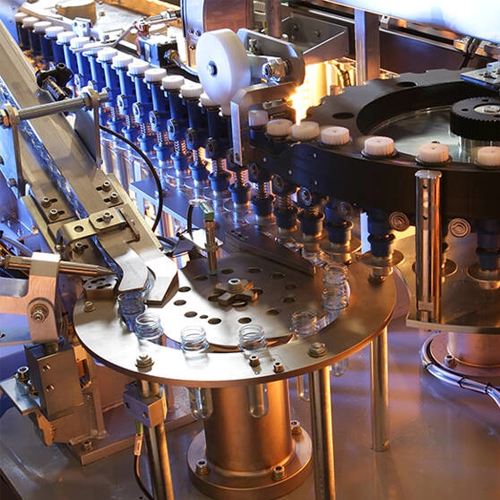

Cap and close your ketchup bottles after filling

You can choose to pack your ketchup in pouches, sachets, tubes, or bottles and it’s important to close your package quickly after filling to avoid contamination or spilling. Capping or other closing systems such as seals are often installed in the same filling system. When filling glass or plastic bottles containers in line, crew caps, lug caps or snap-on are placed after filling up to the desired weight or height.

Processing steps involved in ketchup making

Which ketchup technology do you need?

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

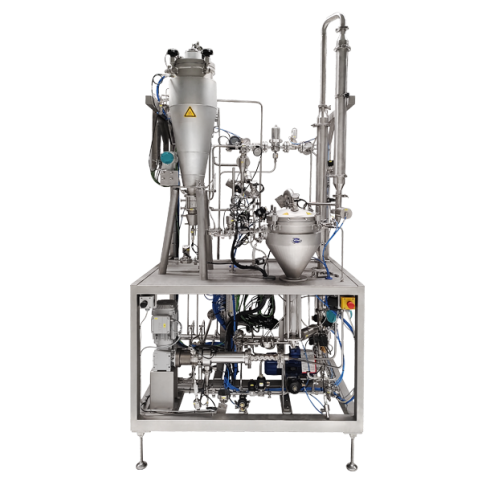

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

Milk powder processing plant

Achieve precise powder formulations with our state-of-the-art milk powder processing plant, ide...

Vacuum de-aeration unit for liquid to pasty products

Optimize your product consistency and stability with continuous de-a...

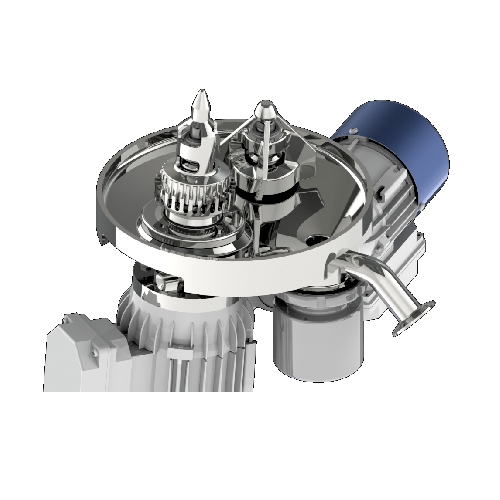

Colloid mill for emulsifying and wet milling applications

Achieve precise mixing and grinding with our colloid mill, des...

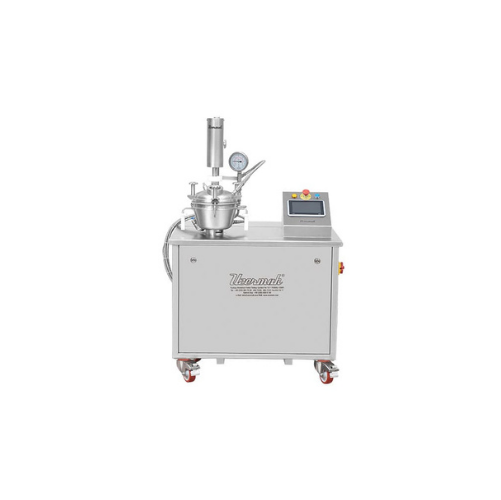

Laboratory homogenizer for viscous products

Achieve ultra-fine textures and improved consistency in pasty and semi-pasty p...

Automation for food processing

Optimize your food production with cutting-edge automation, enhancing efficiency and precisio...

Inline processing system for food and beverage production

Optimize your production line with a versatile inline processi...

Compact production unit for liquid food products with varied viscosities

Streamline your batch production with this ver...

Scraped surface heat exchanger for food processing

Efficiently handle temperature-sensitive food products with a compact ...

Hygienic fluid storage tanks for food industry

Ensure impeccable hygiene in fluid storage with our customizable tanks, des...

Aseptic thermal processor for high viscosity products

Optimize your processing of high viscosity products with precise te...

Atmospheric blending vessel for r&d activities

Optimize your liquid blending processes with this versatile vessel, designe...

Direct steam infusion for high spore kill rate in sensitive food products

Achieve rapid, efficient sterilization and m...

Fs closing devices for industrial packaging solutions

Streamline your packaging process with versatile closing devices, d...

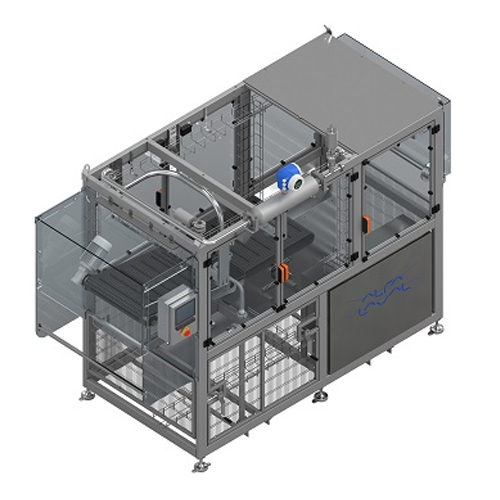

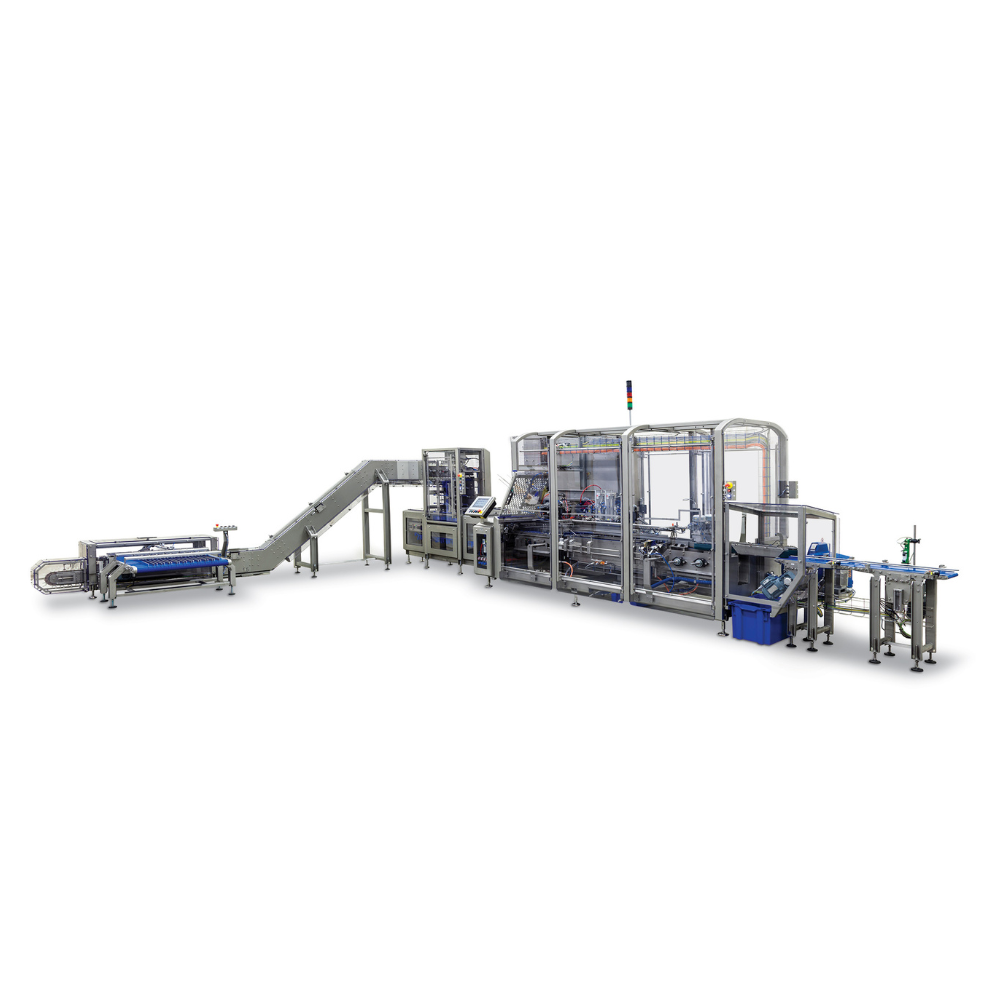

Unpacker for return bottles

Effortlessly manage return bottle operations with high-speed unpacking solutions that ensure pre...

Flexible depalletizers for bottling lines

Streamline your packaging operations with a compact depalletizing solution desig...

Rotary weight filler for edible oil

Optimize your liquid product filling with precise weight control, ensuring high accurac...

Medium-speed shrink wrapper and case packer for food industry

Optimize your packaging line with a combined solution that...

Medium-speed automatic shrink wrapping systems for food and dairy

Optimize your packaging line with this flexible shrin...

Medium-speed wrap around case packer for food and dairy industries

Optimize your end-of-line efficiency with a reliable...

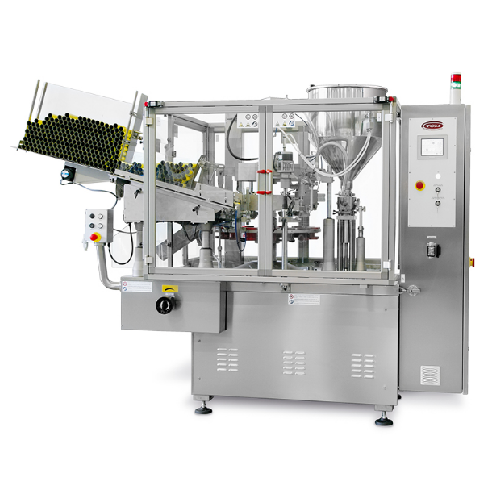

Tube filling solution for plastic and laminate tubes

Ensure precise tube filling and sealing with quick changeovers, enha...

Pick & place robot for packing tubes in boxes

Efficiently streamline your packaging line with this compact case packer, de...

Horizontal continuous motion cartoner

Streamline your packaging process with a high-speed cartoning solution that ensures p...

Dished end for optimized mixing in small-volume vessels

When space constraints challenge vessel design, this solution eli...

Pouch cooling system for food processing

Experience rapid cooling for your pouched food products, minimizing time in the ba...

Precision weighing tank for liquid and dry ingredient blending

Enhance your production line with precision control over ...

Cryogenic freezer for food industry applications

Efficiently tackle high-speed freezing and chilling challenges with a ver...

Heating and cooling system for food and dairy products

Achieve precise temperature control and efficient processing with ...

Industrial powder blender

Optimize your production with precise dry blending, ensuring efficient mixing processes and seamle...

High-shear inline mixer for lump-free products

Achieve consistent texture and prevent clumping in liquid and powder blends...

Pre-mixer for dissolving powders fast

Quickly dissolve powders without lumps or “fisheyes,” ensuring a smooth a...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

Industrial melting tank for diverse manufacturing applications

Optimize your production with this versatile melting tank...

Blender for high viscous products

Tackle high-viscosity challenges with an advanced blending solution designed for efficien...

Customized oil storage tank for industrial use

Enhance production efficiency and ensure seamless integration with customiz...

Cip dosing and water unit for industrial cleaning

Elevate your plant’s hygiene with this system, designed for seaml...

Conical buffer tank for hygienic dairy and food processing

Achieve efficient processing of high-viscosity products with ...

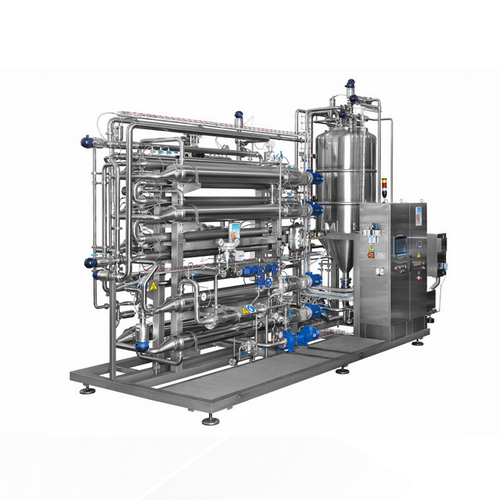

Ultra high temperature treatment system

Achieve extended shelf life and product stability with ultra high temperature treat...

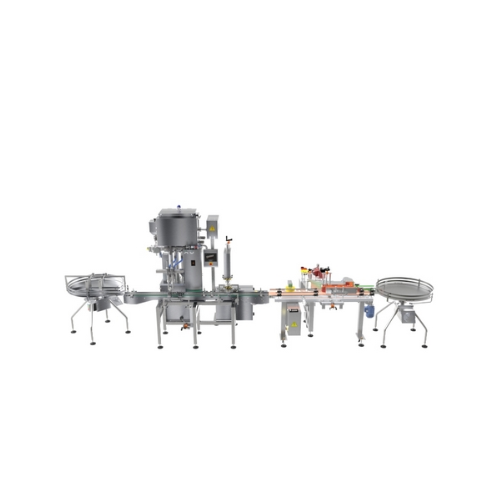

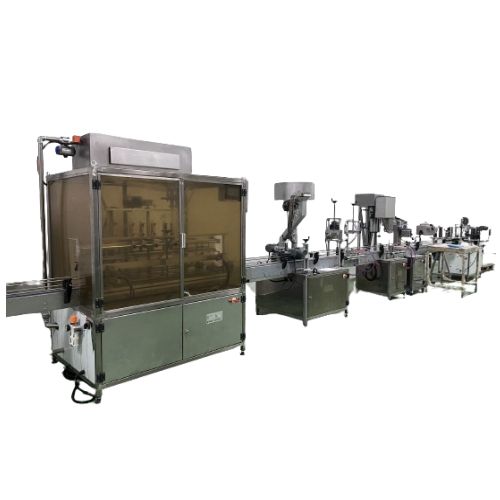

Medium capacity filling line for food and cosmetics

Streamline your production with a versatile filling line that seamles...

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

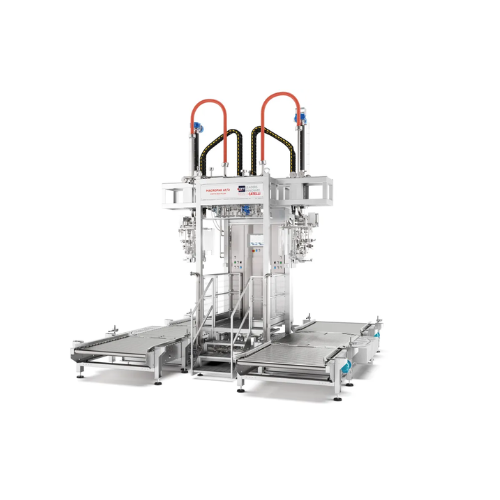

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

Semi-automatic capper for twisting and screwing metal and plastic caps

Effortlessly achieve precise cap tightening with...

Volumetric filler for packaging liquids and semi-solids

Optimize your filling process with precision control and adaptabl...

2-head liquid and viscous product filling system

Streamline your filling operations with precision and versatility designe...

8 head liquid and viscous product filling system

When precision and speed are crucial, this 8 head filling machine ensures...

Volumetric filling and capping solution for liquids and viscous products

Effortlessly integrate high-precision filling ...

Automatic capping system for varied cap types

Enhance your packaging line efficiency with a high-speed capping machine des...

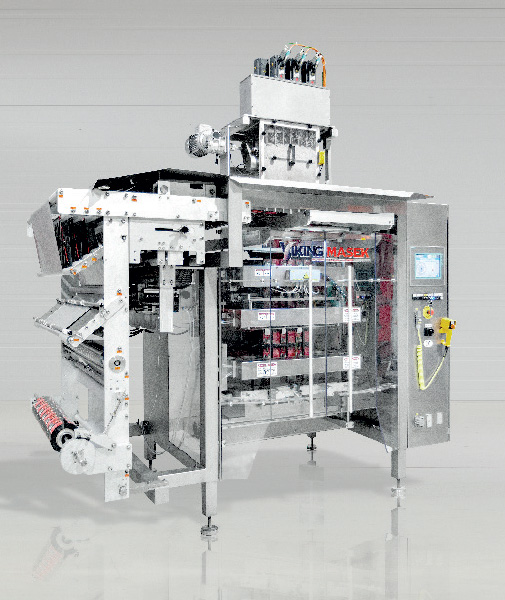

Vertical form, fill and seal packaging system for small bags

Maximize efficiency with small bag portioning for food and ...

Blending system for fine adjustment of original gravity in beer

Ensure precise control over your beer’s original gravity...

Transparent glass barrier coating for Pet bottles

Ensure the longevity of sensitive beverages and liquid foods with glass...

Rejection system for standing bottles and cans

Ensure seamless quality control by precisely rejecting defective bottles an...

Industrial vacuum kettle for sauce production

Achieve optimal flavor retention and nutrient preservation with an industria...

Steam jacketed kettle for cooking sauces and dressings

Enhance your sauce production with a steam jacketed kettle that en...

High-speed drift-dwell motion doypack forming system

Optimize your liquid packaging efficiency with a dual-motion system ...

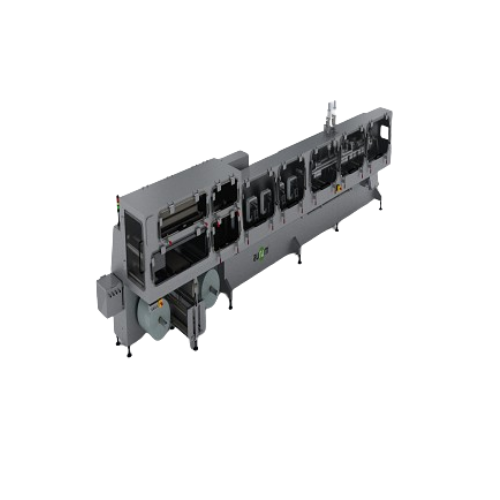

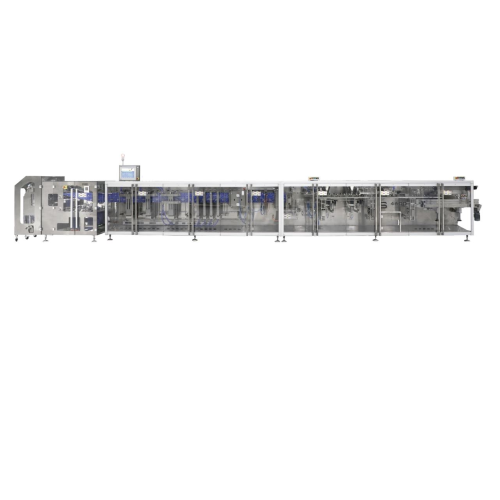

Form fill and seal machine for portion packs

Streamline your portion packaging with a compact system that efficiently form...

Form fill and seal solution for dairy portion packs

Optimize your production with precision portion packing, reducing mat...

Stick pack forming, filling, and sealing solution

Enhance packaging efficiency with a high-speed solution designed for pr...

Flexible filling and sealing system for pre-formed cups

Achieve precise portioning and consistent quality in your product...

Rotary doypack packaging system for various materials

Enhance your packaging line with versatile doypack machines designe...

Rotary doypack for granules, liquids, and powders

Enhance your packaging line with a rotary doypack system designed to ef...

Packaging solution for small bottles and jars

Effortlessly seal and fill non-stackable containers, ensuring precision for ...

Tray sealing machine for buckets

Ensure efficient sealing and preservation with high-speed tray sealing for various food pro...

Thermoforming packaging solution for food and medical applications

Enhance your packaging line with a solution designed...

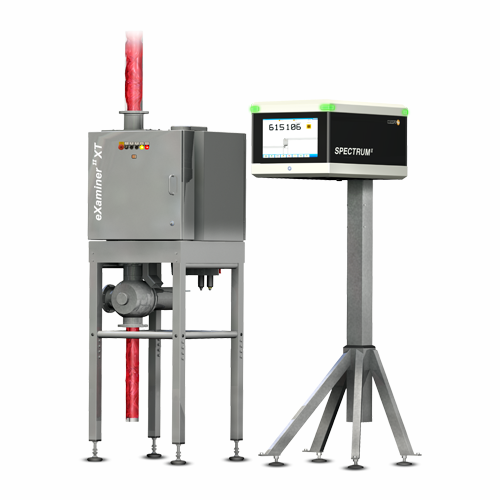

Metal detector for small to medium-sized products

Ensure product integrity and compliance by seamlessly integrating metal...

Multi head weigher for precise portioning

Ensure consistent product portions with our multi head weigher, ideal for high-s...

Vertical form fill seal for small to medium production runs

Ideal for scaling production, this compact packaging solutio...

Top loading case packer for automated box sealing

Streamline your packaging line with a top-loading case packer that effi...

Rotary filler for optimized production processes

Streamline your fill and seal process with precise timing control and enh...

Industrial pick and place system for packaging

Streamline your packaging line with precise robotic pick and place operatio...

Homogenizer for high-pressure homogenization

Optimize your production with high-pressure homogenization, essential for ach...

High-pressure homogenizer for food and pharmaceuticals

Achieve unparalleled consistency and stability in emulsions and di...

Homogenizers for high-pressure applications

Achieve unparalleled product consistency and stability with precision-engineer...

Industrial homogenizer for food and pharmaceutical applications

Ensure product consistency and stability with high-press...

High-pressure homogenizers for dairy and food products

Achieve consistent texture and stability in your liquid products w...

High-pressure homogenizers for dairy and beverage industries

Achieve precise emulsion stability and consistent particle ...

Traysealer for food packaging with rotating table

Enhance your packaging line efficiency with a traysealer that simultane...

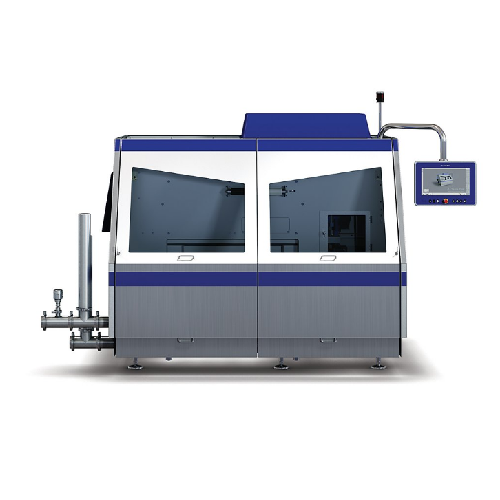

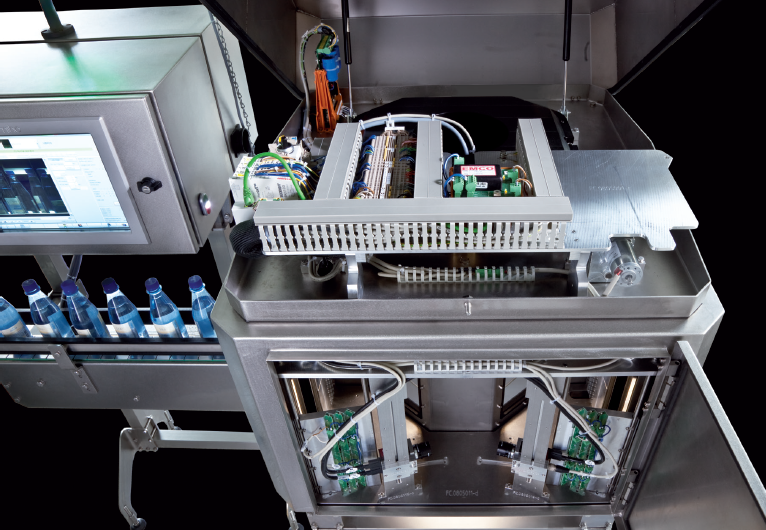

Full container check for fill level and closure inspection

Ensure the integrity of your liquid products with this advanc...

Pipeline inspection for liquid and paste-like products

Ensure your liquid and paste-like products are free from foreign o...

X-ray assisted empty bottle inspection

Enhance your production line with advanced X-ray and optical technology to ensure pr...

Fill level and closure inspection system

Ensure precise fill levels and secure closures in high-speed liquid packaging envi...

Empty bottle inspector for beverage industry

Ensure flawless quality control by thoroughly inspecting empty bottles for de...

Pipeline metal detection for pumpable products

Ensure safety and quality by detecting and rejecting metal contaminants in ...

Scraped surface heat exchanger for high viscous products

Efficiently handle the cooling and heating of high viscous produ...

Stainless steel skids for food process integration

Optimize your production process with compact stainless steel skids th...

Steam-heated hemispherical bottom cookers for sauce production

Streamline your sauce and condiment production with multi...

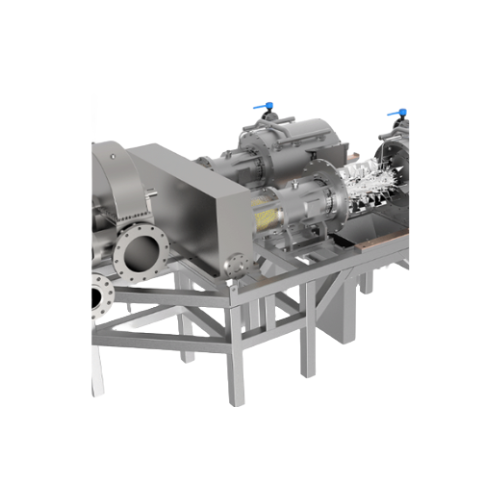

Enzyme inactivators for tomato processing

Efficiently inactivate enzymes to preserve nutritional value and organoleptic qu...

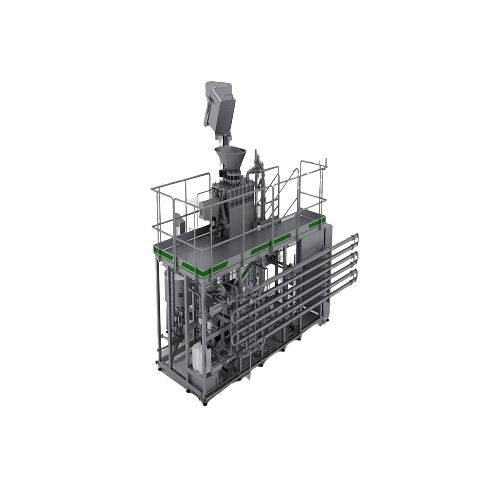

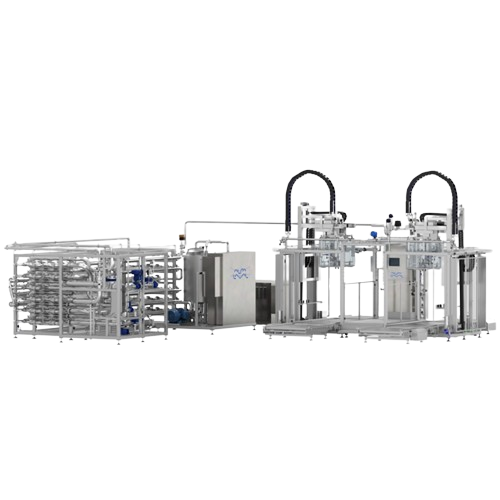

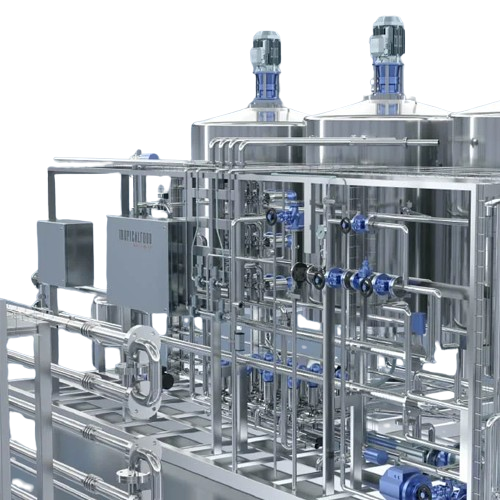

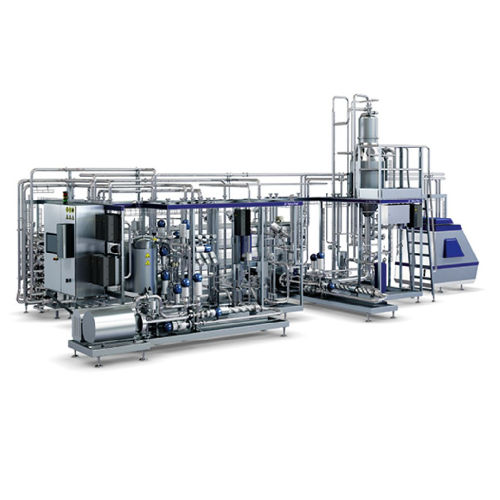

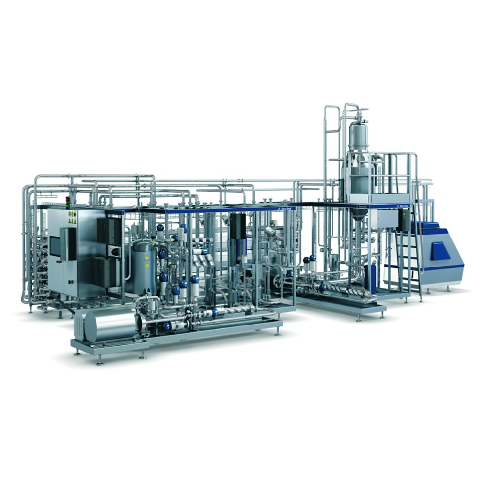

Ketchup and sauce processing line

Achieve precise mixing, cooking, and concentration for your sauces and purees, ensuring o...

Aseptic sterilizers for tomato products

Ensure your tomato-based and fruit products remain safe and shelf-stable with advan...

Scraped surface sterilizers for food industry products

Optimize your food processing line with high-efficiency sterilizat...

Evaporator for pulpy juice concentration

Achieve efficient concentration with reduced energy consumption, thanks to innovat...

Marmalade, sauces, nectars, and baby food processing solution

Maximize flexibility in your production line with a system...

Flash cooler sterilizer for tomato paste

Maximize your production capacity and preserve flavor integrity in high-viscosity ...

Cold glue label applicator for pre-cut labels

Optimize your packaging line with high-speed labeling for a variety of conta...

Liquid food filling solutions

Maximize efficiency in your packaging line with versatile filling machines designed for precis...

Conical powder mixer for uniform powder blending

Achieve consistent powder blending while preserving the integrity of deli...

Ultraclean aseptic storage tanks for hygienic liquid food

Ensure your liquid products remain uncontaminated and maintain...

Automated cleaning in place (cip) systems for beverage processing

Optimize your production with automated CIP systems t...

In-line mayonnaise emulsifying system

Streamline your sauce and dip production with a system designed for efficient emulsif...

Pneumatic dosers for variable density products

Achieve precise dosing for liquid to dense products with versatile pneumati...

Inline high-shear mixer for powders and liquids

Achieve efficient mixing and homogenization in your production line with a...

High-capacity inline mixer for dairy and beverages production

Achieve a rapid and homogeneous mix in high-capacity produ...

Ultra-high shear mixer for emulsification and homogenization

Optimize your production with ultra-high shear mixing, acce...

Vacuum high shear mixer for medium to high viscosity products

Achieve flawless blending and air-free consistency in visc...

High-capacity manual mixer for industrial applications

Optimize your mixing process with a highly efficient, manually ope...

Bigbag filling system for powder and bulk materials

Ensure precise and dust-free bigbag filling with this versatile syste...

Dense-phase powder conveying system

Optimize your powder processing with a system designed to handle abrasive and fragile m...

Transfer hopper with stainless Pd pump for food processing

Eliminate spillage and maintain continuous flow with a positi...

Horizontal screw loader for food processing

Optimize your production flow with a smooth-loading solution designed to effic...

Tunnel for thermal treatment of packaged foods and beverages

Optimize your thermal processing with this customizable tun...

Leaf vegetable sorting and cooling system

Ensure optimal freshness and extended shelf life for leaf vegetables with precis...

Industrial cooking kettles for food processing

Optimize your production with versatile cooking kettles designed to handle ...

Robotic palletizer for material handling

Experience seamless and efficient palletizing with advanced robotic solutions desi...

Precision size grader for tomatoes and round fruits

Ensure precise grading and sorting of tomatoes and round fruits to op...

Robotic case packers for bags and pouches

Efficiently pack a variety of bagged and pouched products with precision handlin...

Robotic handling systems for beverage containers and bins

Streamline your container handling with precision-engineered r...

Industrial can seamers for food and beverage packaging

Streamline your canning process with precision seaming solutions d...

Industrial spiral freezing system

Optimize your food processing line with a reliable spiral system, designed to efficiently...

Sterilizers and pasteurizers for industrial food processing

Optimize thermal processing for viscous foods and beverages ...

Aseptic fillers for liquid and viscous products

Ensure sterile and precise filling of liquid and viscous foods with adapta...

Batch retorts for food sterilization and pasteurization

Achieve optimal sterilization and pasteurization of packaged food...

Tomato processing crushing mill

Optimize your production line with efficient chopping and refining, ensuring uniformity and ...

Robotic depalletizers for bins

Efficiently optimize your warehouse space while ensuring precise and adaptable material handl...

Enzymatic inactivation system for fruits and vegetables

Achieve optimal product quality by maintaining vivid color, robus...

Energy efficient tomato evaporator

Achieve up to 98% steam savings in your evaporation process while ensuring minimal CO2 e...

High-precision rotary weight filler for edible oils and sauces

Achieve exceptional filling precision with solutions desi...

Semi-automatic aseptic filler for single bags

Ensure aseptic integrity and flexibility for your liquid and semi-liquid pro...

Continuous motion liquid filling and capping monobloc

Optimize high-speed liquid filling with seamless transitions from f...

Automatic piston fillers for liquid products

Optimize your liquid filling process with high-precision piston fillers, engi...

Clean-in-place systems for biotechnology and pharma

Ensure seamless transitions between production batches with efficient...

Digital torque viscometer for starch analysis

Experience rapid and precise starch gelatinization analysis with a compact, ...

Heater for enzymatic inactivation of fruit and vegetable pulp

Optimize your puree and concentrate production with effici...

Top load and side load case packer with vision guided robotics

Optimize packing efficiency and flexibility with a versat...

Scraped surface sterilizer for high viscosity liquid products

Optimize your production of high viscosity liquids with a ...

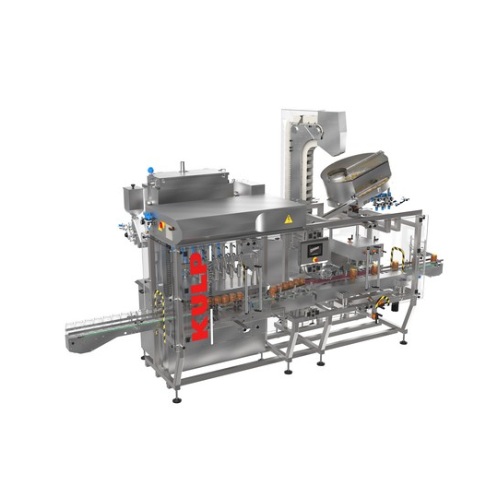

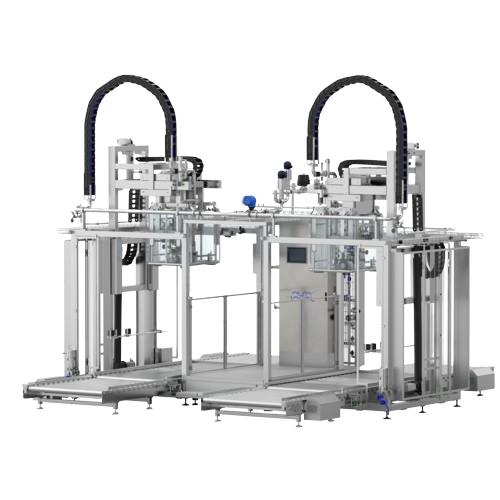

Ketchup production line

Optimize your sauce production with advanced equipment designed to ensure consistent blending, precis...

Tomato processing plant for sauce and paste

Efficiently transform raw tomatoes into a variety of high-demand products, fro...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Turbo extractors for tomato and fruit hot extraction

Optimize your fruit and vegetable processing with high-capacity turb...

Homogenizer for high viscosity emulsion and dispersion

Achieve unparalleled dispersion and emulsification with a system d...

Industrial vacuum mixer and reactor for liquids

For manufacturers needing precise blending and stability, this advanced va...

Vacuum mixer reactor for liquids and semi-solids

Achieve precise mixing and emulsification of complex liquid formulations ...

Cleaning system Cip for internal equipment maintenance

Ensure optimal hygiene and production efficiency with this portabl...

In-line external homogenizer for industrial fluid processing

Maximize fluid consistency and ensure efficient material di...

Aseptic cooking line for industrial food processing

Achieve seamless aseptic cooking and filling for diverse food product...

Aseptic linear doypack filler

Ensure extended shelf life and preserve quality in liquid food products with this high-speed a...

Linear filler for preformed containers

Streamline your packaging process with a compact solution that ensures precise filli...

Checkweighers with chain conveyors for diverse package types

Optimize your production line with precision weighing, acco...

Empty bottle inspection system for beverage industry

Enhance your production line’s efficiency by detecting defects...

Automatic Pet bottle blowing solution

Achieve precise PET bottle molding with high-speed, automated operations that seamles...

Automatic detergent shampoo filling solution

Streamline your filling process with precise volume control, achieving consis...

Automatic edible oil filling & capping solution

Streamline your liquid packaging operations with precise, high-speed filli...

Automatic servo Pet bottle blower

Elevate your production capabilities with a PET bottle blowing machine designed for high-...

Automatic food cooking oil bottling solution

Ensure precise volumetric filling for a range of liquid products, enhancing y...

Gravimetric filling solution for inconsistent density products

Achieve precise weight accuracy in your filling processes...

Flexible bag-in-box filler for liquid and viscous products

Optimized for flexibility and efficiency, this bag-in-box fil...

Bag-in-box filling solution for non-aseptic products

Maximize your production line’s efficiency with a high-speed f...

Plate heat exchanger sterilizer for food products

Ensure consistent product quality and microbiological stability in your...

Thousand-litre aseptic filler

Ensure the aseptic filling of bulk liquid and viscous food products, reducing contamination ri...

Aseptic processing equipment for food products

Optimize aseptic processing to ensure microbiological stability and product...

Double-wall scraped surface heat exchanger

Achieve high-capacity processing with gentle handling for shear-sensitive produ...

Scraped surface heat exchanger for viscous products

Efficiently handle challenging viscosities and heat-sensitive product...

Scraped surface evaporator for high-viscosity materials

Efficiently concentrate high-viscosity and hard-to-handle materia...

Gasketed plate heat exchangers for hygienic applications

Ensure optimal hygiene and thermal efficiency in your processing...

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

Vacuum cooker-cooler for jams and sauces

Optimize your food production with a vacuum cooker-cooler that enhances flavor whi...

Inline wet mill for mayonnaise emulsions

Eliminate the challenges of achieving stable, uniform emulsions in your sauces and...

Pilot scale mixers for product development and small production runs

Optimize your mixing processes with precision cont...

Low-shear portable mixer

For processes demanding strict hygiene, this mixer eliminates rust and chipped coatings by offering ...

High shear emulsifier for hygienic applications

Achieve precise emulsification and consistent mixture quality with enhance...

Automatic volumetric filler for liquid products

Optimize your production with this high-precision volumetric filler, desig...

Full body sleeving systems for packaging applications

Achieve seamless, high-speed labeling precision for diverse contain...

Tamper evident heat tunnel for safety banding

Achieve precise and consistent tamper-evident sealing on containers with a h...

Rotary bottle rinser for high-speed production lines

Ensure thorough cleaning and preparation of containers with a high-s...

Auto-indexing filler for aqueous solutions and light oils

Streamline your bottling process with this six-head filler, pe...

Automatic timed flow volumetric filling machine

Streamline your liquid packaging process with precise volumetric filling o...

Automatic labeler for low profile containers

Optimize container labeling with precision and efficiency, addressing the cha...

Tabletop labeler with integrated thermal printer for round containers

Efficiently label and print variable data on roun...

High-speed bottle orientator

Efficiently streamline your bottling process by ensuring containers are swiftly and accurately ...

Rotary capper for high-speed bottling

Streamline your bottling process with a rotary capper designed to ensure accurate and...

Accurate net weight filling for liquid and semi-liquid products

Ensure precise filling of diverse viscosities, from thin...

Customizable sanitary conveyor systems

Efficiently transport and handle diverse products with a sanitary conveyor system de...

Cooling tunnel for Pet container hot fill cooling

Ensure product integrity with a cooling tunnel that swiftly reduces PET...

Semi-automatic overflow liquid filler

Optimize your production line with a reliable filling solution for low to medium visc...

Form, fill, and seal system for single-use pouches

Achieve precise portion control and secure sealing with an integrated ...

Automatic pressure sensitive labeling system

Enhance your production line’s efficiency with a versatile labeling sys...

Automatic capper for dual head o-ring chuck

Ensure precise cap application with dual-head precision, handling various bott...

Accumulation turntable for bottling lines

Optimize your production line’s efficiency with a 42-inch diameter accumul...

Beverage thermal treatment systems

Optimize beverage production by ensuring precise thermal treatment, enhancing flavor sta...

Industrial swirl bath washer for sliced vegetables

Achieve optimal cleanliness with a delicate touch—this advanced swirl ...

Semi-automatic tray sealing for ready meals

Achieve versatile packaging with a semi-automatic tray sealing solution design...

Automatic tray sealer

Maximize throughput and shelf life with our high-speed inline tray sealing solution, ideal for diverse ...

R&d vessels for research and development centers

Optimize your R&D operations with versatile vessels designed to hand...

Clean-in-place system for diverse processing needs

Ensure the precision and consistency of your cleaning cycles with a ro...

Basket tracking system for automated batch retort systems

Efficiently manage and monitor your batch processing with a sy...

Aseptic processing system for food products

Streamline your food processing line with an efficient aseptic processing syst...

Uht sterilizer for dairy and high-viscosity products

Optimize your production of dairy alternatives and fruit-based drink...

Cold break system for tomato processing

Enhance product quality and consistency in liquid processing by utilizing precise t...

Juice extractors for variety of fruits and vegetables

Streamline your juice and puree production with advanced extraction...

Volumetric piston filler for liquid and viscous products

Achieve precise volume control and enhance product integrity wit...

Aseptic filler for juices and beverages

Ensure sterile packaging with precision. This aseptic filler offers high-speed, con...

Aseptic filler for packaged dairy and beverages

Ensure product sterility and extend shelf life efficiently with high-speed...

High shear mixer for dairy and personal care products

Achieve consistent emulsification and stable homogeneity with high ...

High shear test mixers for developing new products

Streamline product development with high shear test mixers, allowing y...

Bowl cutter and emulsifier for food processing

For food processors looking to achieve precise cutting, mixing, and emulsif...

Loose package conveyor systems for packaging lines

Optimize your packaging line operations with advanced conveyor systems...

Pre-cut hot-melt label applicator for bottles

Optimize efficiency and precision in your labeling process with this advance...

Large production autoclaves for laboratory and pharmaceutical use

Enhance your production line with our large autoclave...

Ultraclean filling monoblocks for food industry

Enhance product safety and quality with monoblocks designed for ultraclean...

Complete filling and closing line for food containers

Optimize your production line with a versatile solution that ensure...

Rotary gravity fillers for diverse liquid products

Achieve precise filling and optimal packaging efficiency for a wide ra...

Rotary piston fillers with plunger for viscous products

Optimize your filling process with high-speed, rotary piston fill...

Mixing vessel for liquid, sauce, and cream products

Maximize efficiency in your production line with a versatile solution...

Twin shaft mixers for fragile and high throughput applications

Maximize mixing efficiency and protect delicate materials...

Industrial sigma mixer extruder for homogeneous mixing and extrusion

Achieve precise mixing and seamless extrusion of d...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Side-mount agitator for large tank mixing

Achieve efficient mixing in large tanks with reduced energy consumption by lever...

Continuous motion liquid packaging system

Achieve precise and clean liquid packaging with advanced servo-driven squeegee s...

Complete mixing systems for industrial applications

Optimize your production efficiency and product consistency with adva...

Complete mixing solution for food, cosmetics, and chemical industries

Optimize your production line with a system that ...

Mechanical homogenizer for fine cutting and emulsifying

Achieve precise particle size control and consistent texture in y...

Industrial milling systems for food processing

Streamline your food production line with robust milling and cutting soluti...

Multifunctional industrial food mixer

Efficiently handle complex food processing tasks from mixing to homogenizing with a m...

Multifunctional cheese and sauce processor

Optimize your production of sauces, dressings, and confectionery fillings with ...

Multifunctional industrial mixer for processed cheese and sauces

Optimize your batch production with a versatile solutio...

Viscous and liquid product processor

Optimize your production of viscous slurries and liquid formulations with a versatile ...

Automated sandwich production line

Optimize your sandwich production with high-speed automation that effortlessly handles d...

Tubular pasteurizers for fruit pulp and tomato concentrate

Enhance your fruit and tomato product preservation with effic...

High pressure aseptic sterilizer for tomato paste

Ensure your tomato paste achieves optimal safety and quality with a hig...

Aseptic sterilizers for fruit concentrates and pulp

Optimize your fruit processing by maintaining product quality and she...

Aseptic filler for fruit juices and purees

Ensure product integrity and shelf stability with a versatile filler designed t...

Batch evaporators for fruit juice and tomato concentration

Achieve high-quality fruit and tomato concentrates while pres...

Coconut processing line for green coconut water and cream

Enhance your coconut processing with a fully automatic line th...

Aseptic filler for fruit juice and puree

Ensure optimal product safety and quality with this aseptic filler, designed to ha...

Rotary cup filling and closing system

Maximize production efficiency with a system that offers precision filling and secure...

Forming, filling, and sealing system for liquid food products

Achieve precise portion control and versatile packaging wi...

Electric tomato squeezer for large-scale production

Optimize your tomato processing with this high-capacity electric sque...

Tomato squeezer for efficient food processing

Efficiently transform raw tomatoes and other fruits into smooth sauces and p...

Electric tomato squeezer for family and small community use

Ideal for crafting homemade sauces and preserves, this elect...

X-ray inspection for tall packages in cans and bottles

Ensure your production line detects foreign objects in tall packag...

X-ray detection for food inspection

Ensure product integrity in high-speed packaging lines by detecting metallic and non-me...

Horizontal form-fill-seal systems for pouch packaging

For production lines that demand efficient pouch creation, these hi...

Automatic tube filling for multi-color products

Achieve precision in multi-color product packaging with seamless co-extrus...

Automatic tube filling solution for medium to high volume production

Boost your production line efficiency with a robus...

Continuous sugar dissolver for beverage and food production

Efficiently dissolve crystalline sugar in water up to 65°Bri...

Food pasteurizer for prepared foods

Optimize your prepared food production with precise temperature control and automated o...

Drum unloader for liquid ingredients

Streamline the unloading of viscous liquid ingredients with advanced water injection t...

Coiled heat exchanger for high viscosity products

Efficiently handle high-pressure, viscous product heating and cooling w...

Tubular heat exchanger for food processing

Optimize energy consumption and ensure unparalleled food safety during heat tre...

Homogenizer for high-capacity food processing

Achieve superior emulsification and suspension handling with this high-press...

Powder feeder for consistent and accurate dosing

Ensure precise powder dosing with high hygiene standards to maintain prod...

Continuous ultra-high temperature treatment for prepared food products

Optimize your prepared food production with cont...

Continuous sugar dissolver for beverage production

Optimize your production line with a system that efficiently dissolves...

Ultra-high temperature processor for premium liquid foods

Achieve superior product quality and flexibility with advanced...

Efficient pasteurizer for prepared foods

Achieve precise heat treatment and reduce product waste with a modular pasteurizat...

High shear mixer for dairy and beverage industry

Achieve consistent product quality with a high shear mixer, enabling seam...

High shear mixer for smooth or particulate food products

Achieve consistent quality in diverse food products with precise...

Batch mixer for soft drinks ingredients

Effectively manage diverse ingredient formats with a high-performance mixing system...

High-pressure homogenizer for dairy and beverage products

Achieve optimal product consistency and extend shelf life with...

Autonomous ingredient dissolver for high volume dry ingredient mixing

Streamline your production by seamlessly mixing d...

Batch dissolver for sugar or dextrose

Efficiently dissolve crystalline substances like sugar and dextrose with precision, e...

Industrial plate heat exchanger for food processing

Ensure consistent product quality with precise temperature control an...

Aseptic tank for blending and buffering

Optimize your production line with a secure aseptic tank that ensures precise in-li...

Liquid sugar storage tank

Ensure seamless liquid sugar management in your production line with advanced storage solutions de...

Compact filling system for retortable carton packages

Simplify your production of ready meals and soups with a space-savi...

Filling system for gable top packages

Achieve precise, cost-effective filling with reduced energy consumption for chilled l...

Compact aseptic filling solution for versatile production

Maximize production line efficiency with a compact filling sys...

Versatile filling system for aseptic packaging

Achieve seamless integration in high-speed aseptic packaging with this flex...

Aseptic filling solution for liquid food packaging

Optimize liquid food production with advanced aseptic filling, ensurin...

Automatic liquid filling solutions for various containers

Ensure precise liquid packaging for diverse container types, e...

Manual monoblock for filling and capping spouted pouches

For those handling liquid or semi-dense products, this manual mo...

Manual filling and capping for spouted pouches

Optimize your production line with a versatile solution for filling and cap...

Manual filler and capper for spouted pouches

Easily manage filling and capping for flexible pouches with precise volumetri...

Accurate volumetric filler for liquid and semi-dense products

Achieve precise dosing and filling of various liquid and s...

Bench-top piston filler for liquid and semi-dense products

Optimize your filling precision with a versatile piston fille...

Tomato paste processing line

Streamline your tomato processing with our comprehensive production line, ensuring high-quality...

Mango juice production line

Streamline your mango juice production with a complete solution that efficiently transforms fres...

Colloid mills for shearing and mixing in food processing

Optimize your liquid formulations with precise colloid mills, en...

Scraped surface heat exchangers for high viscosity products

Ideal for continuous processing, these heat exchangers effic...

Deaerator for liquid food products

Enhance product quality by efficiently removing air and preserving vital aromas in liqui...

Pilot plants for small-scale viscous product processing

Optimize your product development with pilot plants designed for ...

Integrated stretch-blow moulding, filling, and capping system for still liquids

Streamline your bottling process with ...

Laboratory in-line mixer for precise mixing and reproducibility

Achieve precise laboratory-scale mixing with rapid proce...

Linear blowing systems for Pet bottle production

Ideal for producers seeking versatile container solutions, this system en...

High shear mixer for efficient particle size reduction

Achieve rapid and precise blending and particle reduction in your ...

High shear lab mixer for laboratory work and r&d

Achieve unparalleled precision and consistency in laboratory and pilot-sc...

Dosing system for packaging lines

For producers looking to optimize their packaging lines, this dosing system offers precis...

Aseptic filling technology for dairy products

Ensure product integrity and extend shelf life with a high-speed aseptic fil...

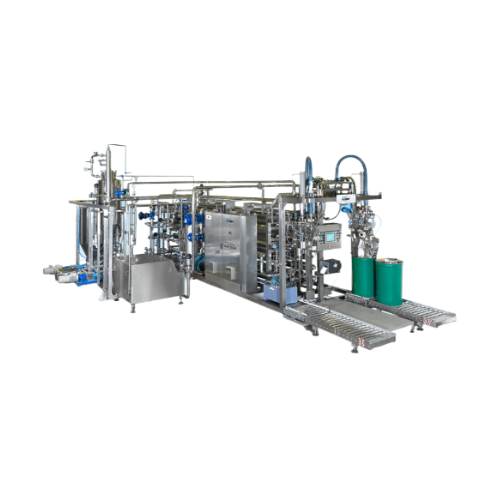

Mayonnaise production line

Streamline your high-capacity mayonnaise production with precise mixing, emulsifying, and pasteur...

Automated sauce production lines

Streamline your sauce production with flexible lines designed for rapid recipe changeovers,...

Automated mayonnaise and dressing production line

Ensure the consistent quality of your mayonnaise, dressings, and sauces...

Blow-fill-cap solution for low/medium batch production

Streamline your production line with a compact blow-fill-cap syste...

High hygienic filler for chilled beverages

Enhance cold beverage production with a modular, hygienic filler offering chemi...

Yoghurt and dairy desserts filling solution

Maximize efficiency in filling and sealing multi-product dairy desserts and be...

Baby food production line

Ensure optimal safety and precision with this production line, designed for processing delicate ba...

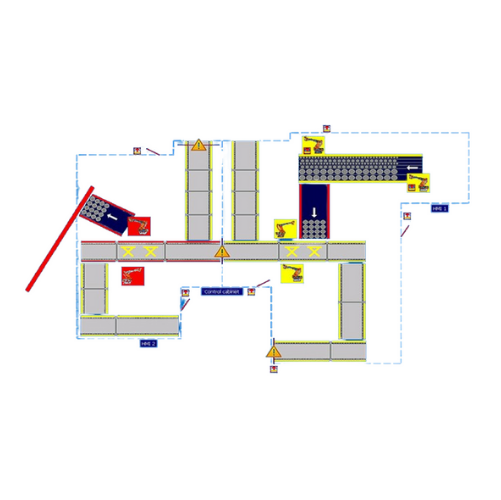

Ketchup manufacturing line

Streamline your sauce production with precision-engineered efficiency, allowing for seamless reci...

High-speed moisture analyzer for liquid and pasty samples

Ensure precise moisture analysis with rapid microwave drying, ...

Vacuum process system for food product mixing and emulsifying

Optimize your production of sauces, dressings, and condime...

Skid mounted process plant

Simplify your production setup with skid-mounted process plants, designed for quick installation ...

High pressure plunger pump for continuous food processing

Achieve consistent texture and quality in spreads and sauces w...

Industrial Sauce Homogenization and Emulsifying System

Texture and consistency are critical to foods with delicate compos...

Homogenization and emulsifying system for fine foods

Texture and consistency are critical to foods with delicate composit...

Marmalade and Jam Processing Machine

When producing jams and marmalades, preserving the natural flavours, aromas and colors...

Autoclave sterilizer for food cans and jars

An autoclave is a must-have machine for canned food production lines. It perfo...

Shrink wrapping machine for PET bottles

During a shrink-wrapping process, a change of reel can slow down the production cyc...

Jam pasteurizer with temperature control

Microorganisms and pathogenic forms in fresh fruit jams can shorten storage time. ...

High speed carton closing machine

Choosing a carton closing machine becomes a significant consideration when the closing of...

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

Display tray cartoner machine

Packaging products usually require a great deal of flexibility to comply with demand from mark...

Automatic filling machine for sauce

Traditional sauce filling units can struggle to maintain a high quality of output in ca...

Tunnel pasteurizer for beverage

In the beverage industry, beverages need to be pasteurized in order to destroy pathogens, an...

High pressure industrial homogenizer

For any industrial pharmaceutical process that relies on high pressure homogenization ...

Pilot high pressure homogenizer

For maximum value, a high-pressure homogenizer that’s suitable for both laboratory and pilot...

Pipeline metal detector for sauces

Ensuring liquid and viscous products such as sauces, soups, juices and meat are contamin...

Vacuum based homogenizer

When producing liquid and viscous products such as mayonnaise, sauces, dressings and ketchup it’s vi...

Universal Mixer and Cooker for Sauces

Sauce cookers and mixing machines have traditionally been designed to suit one proces...

Modular HFFS Machine

A large range of sizes and types is available, with traditional horizontal form fill and seal machines b...

HFFS machine with servo-control system

Traditional HFFS machines use mechanical cams to drive the production path through t...

High Speed Premade Pouch Packaging Machine

Pre-made pouches can be problematic for traditional cam-driven mechanical HFS m...

Retort Pouch Packaging Machine

A wide variety of products that were previously canned are now able to be more economically p...

Versatile bottle sorting system

Quality bottle sorting machine and inspection system which can be put to use not only after ...

Bag-in-Bag machine

If you are looking for a compact packing machine that packs multiple smaller packs in one master bag; this...

Stickpack Machine

If you are looking to pack your product into stick packs from 17 x 40 mm to 100 x 200 mm in size, you may b...

Sachet Machine

If you want to pack into eye-catching 4-side sealed sachets between 40×50 mm and 250×200 mm in size, ...

Shrink sleeve applicator - 600 per minute

Several industries require the flexible addition of shrink sleeves to containers...

In-line tamper evident applicator head

Integrating tamper protection equipment into an existing production line means addit...

Shrink sleeve applicator - 800 per minute

High speed, in-line shrink sleeving systems require dual head capability with hi...

Advanced auto-steam shrink system

Design and development of shrink sleeves could be made much easier if small batches of sa...

Premium steam tunnel for sleeve application

Maximum flexibility in terms of pressure, temperature and ramp setting and adj...

Shrink tunnel for applying sleeves to different containers

Maximum flexibility is required when setting pressure and dir...

Tamper-evident sleeve applicator for caps

Reliability, continuity and changeover time are key success factors for tamper-e...

Energy efficient tunnel for sleeve application

Hot air application of shrink sleeves is much more efficient than tradition...

High-frequency fill level controller

In terms of high-frequency technology, the fill level detection is considered a standa...

Empty bottle shape, colour and size sorting system

Accurate bottle sorting system that differentiates between the bottles...

Smart Industrial Sauce Cartoning System

Large volume producers of sauces and ready meals continuously pack different produc...

Batch processing system for emulsions and suspensions

Emulsions enhance foods with a creamy mouthfeel and richer flavors....