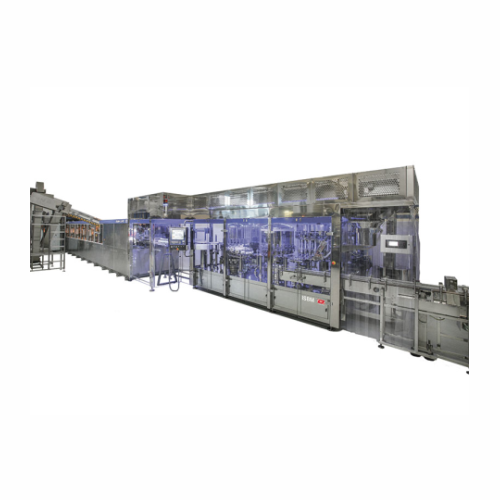

Injection stretch blow moulding line for pharmaceutical solutions

Optimize sterile solution production by forming, filling, and closing PP bottles directly from raw granules, ensuring consistent quality and efficiency while reducing contamination risks.

Forms, Fills, and Seals PP IV Containers

The ISBM Injection Stretch Blow Molding and Filling Line for PP IV Bags and Bottles from GF is a versatile solution for pharmaceutical manufacturing, providing a seamless process from raw material to finished sterile containers. It excels in converting polypropylene granules into precise, sterile IV bags and bottles through a process that involves injection molding preforms, stretch blow molding to precise specifications, and efficient filling and sealing operations. This equipment caters to applications such as sterile water, antibiotic, nutrient, and saline solutions. Featuring options for both intermittent and continuous operations, it can produce up to 250 pieces per minute, with container shapes that are customizable and sterilizable at 121°C.

The ISBM line integrates into production lines smoothly with PLC-controlled automation and compatibility with various RABS systems for enhanced safety. It offers impressive energy efficiency, minimal operational noise, and is designed to meet stringent industry standards for cleanliness and quality, including GMP and FDA compliance. To facilitate easy maintenance and quick changeovers, the system includes configurations for different filling volumes and packaging types, such as PP, alu, and other caps. Additionally, the equipment provides robust customization options, engineering support, and minimal downtime due to its user-friendly maintenance features.

Benefits

- Increases production efficiency with up to 250 pieces per minute.

- Reduces energy consumption through optimized processing of PP materials.

- Enhances safety and compliance with integration of RABS systems and adherence to GMP standards.

- Minimizes operational noise to 75 dB for a more comfortable working environment.

- Lowers maintenance time and costs with user-friendly design and easy integration.

- Applications

- Pharmaceutical liquids, Sterile solutions, Parenterals, Irrigation products, Injectables, Iv solutions

- End products

- Sterile water for injection, Collapsible irrigation solution bottles, Dextrose iv solutions, Antibiotic iv bags, Pp iv bags, Nutrient iv solutions, Sterile saline iv bags, Liquid parenteral vials

- Steps before

- Purification, Injection Molding, Preform Production

- Steps after

- Filling, Closing, Sterilization, Inspection, Packing

- Input ingredients

- PP granules, polymer granules, preform

- Output ingredients

- PP bottles, plastic bottles, bags, filled bottles, formed bottles

- Market info

- GF (Coesia Group) is known for its expertise in automated machinery and industrial solutions, providing customized, engineered-to-order equipment for various industries worldwide, emphasizing innovation, quality, and technological excellence.

- Maximum Filling Volume

- 1000 ml

- Operating Mode

- Intermittent or Continuous

- Processing Speed

- Up to 250 pieces/minute

- Sterilization Temperature

- 121°C

- Air Pressure

- Max 8 bar

- Operating Noise Level

- 75 dB

- Working mechanism

- Injection stretch blow moulding

- Integrated steps

- Forming, filling, closing

- Batch vs. continuous operation

- Intermittent or Continuous

- Automation level

- Intermittent or Continuous

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Not specified

- Container type

- Plastic bottles or bags

- Collapse capability

- 100% collapsible

- Design options

- Customizable design and shape

- Container shape options

- Wide range of container shapes

- Production capabilities

- Up to 250 pieces per minute

- Capacity

- Max filling volume 1000 ml

- Sterilization capability

- Sterilizable at 121°C

- Container shape

- Customizable design

- Integration possibilities

- Integration with various RABS systems

- Control panel type

- Intermittent or continuous motions