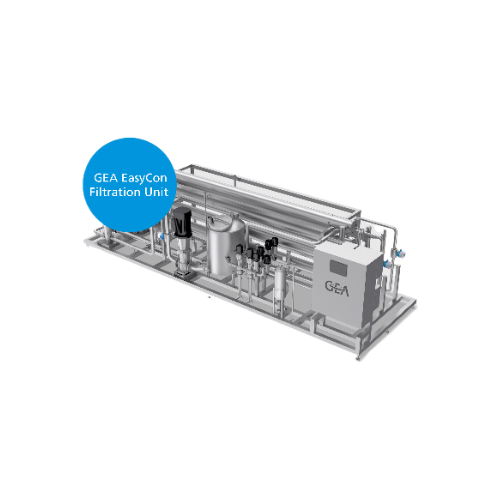

Membrane filtration unit for dairy applications

Achieve precise concentration of dairy products with advanced membrane filtration technology, ensuring optimal solids content for enhanced product quality while maintaining low energy usage and minimizing thermal stress.

Concentrates and Demineralizes Liquid Products

The GEA EasyCon membrane filtration unit offers a versatile solution for dairy, food, and beverage processors seeking efficient concentration and demineralization of liquid products. Utilizing advanced cross-flow filtration technology with nanofiltration and reverse osmosis membranes, this compact, plug-and-play unit concentrates liquids, reaching up to 25% total solids without thermal stress. Designed for capacities ranging from 2,000 to 32,000 liters per hour, EasyCon operates at low temperatures (10–15 °C), safeguarding product integrity. The unit features automatic control with a user-friendly touchscreen interface for seamless integration into existing production lines. Its frame-mounted, modular design reduces installation costs and maximizes return on investment. Available in materials suited for diverse applications, it includes a clean-in-place (CIP) system to ensure efficient cleaning and maintenance. Ideal for producing milk concentrates, whey protein, casein, and more, the EasyCon system supports a wide array of end products, ensuring high-quality outcomes with reduced energy and operational costs.

Benefits

- Enhances product quality by concentrating liquids without thermal stress.

- Reduces operational costs with efficient plug-and-play installation.

- Increases production flexibility by processing multiple product types.

- Lowers energy costs through operation at reduced temperatures.

- Simplifies maintenance with integrated clean-in-place (CIP) capabilities.

- Applications

- Food, Beverage, Dairy farming, Alternative protein, Dairy

- End products

- Casein, Cream concentrate, Lactose-reduced milk, Alternative dairy protein isolates, Protein-enriched beverages, Milk concentrates, Whey protein concentrate, Fermented dairy products, Beverage concentrates

- Steps before

- Pre-filtration, Mixing

- Steps after

- Thermal processing, Final packaging

- Input ingredients

- feedstocks, solids, liquid dairy products

- Output ingredients

- concentrated dairy solutions, concentrated solids with up to 25% TS, water

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Capacity

- 2, 000-32, 000 l/h

- Concentration Factor

- Volumetric Concentration Factor (VCF) of 4.0

- Concentration Capability

- Up to 25% total solids (TS)

- Operating Temperature

- 10–15 °C

- Feed Rate

- Small-to-medium feed rates

- Filtration Type

- Nanofiltration (NF) or Reverse Osmosis (RO)

- Automation

- Automatic control with touchscreen

- Working Mechanism

- Nanofiltration or Reverse Osmosis

- Integrated Steps

- Filtration, Concentration

- CIP Principles

- Clean-in-Place (CIP) with dosing unit

- Batch vs. Inline Flow

- Inline Continuous

- Automation Level

- Automatic control and visualization with touchscreen

- Temperature Range

- Approximately 10–15 °C

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Control panel type

- Touchscreen

- Control panel type

- Touchscreen

- Integration possibilities

- Automatic control and visualization

- Installation type

- Frame-mounted, plug, play

- Compact footprint

- Yes

- Modular design

- Standardized modular design