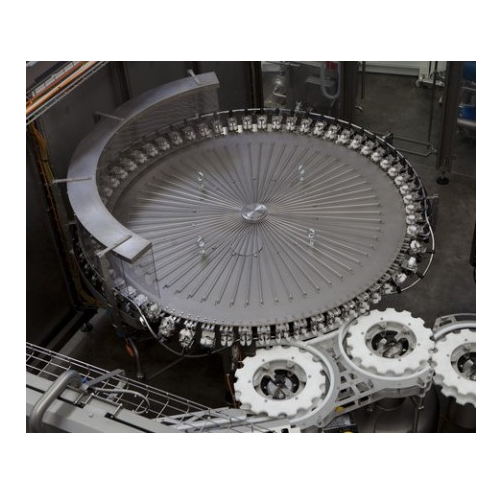

Rotary container rinser

Ensure your bottles are thoroughly clean and sterile before filling, enhancing product safety and shelf-life with precision-engineered rinsing and sterilizing solutions.

Rinses and Sterilizes Bottling Containers

The rotary rinsing and sterilizing machine from AVE-Technologies is a fully automatic solution for beverage and food manufacturers, ensuring meticulous cleaning and sterilization of containers before filling. Engineered for versatility, it accommodates various container materials including glass, plastic, and ceramic, conforming to production requirements with outputs from 3,000 to 90,000 bottles per hour. Utilizing multi-stage rinsing and sterilization, it efficiently processes containers with hot or cold water or SO2, enhancing product safety and integrity. Constructed entirely from stainless steel and high-strength materials, it offers exceptional corrosion resistance, while integrated automatic controls and safety devices ensure seamless operation and operator safety. Designed to meet diverse industry needs, it supports integration with upstream and downstream systems for a continuous production line, featuring customizable options to suit specific requirements. Ideal for applications in wine, beverage, dairy, and foodstuff sectors, it enhances cleanliness and efficiency in bottling and packaging operations.

Benefits

- Enhances product purity and safety by thoroughly cleaning and sterilizing bottles before filling.

- Increases production efficiency with high throughput rates of up to 90,000 bottles per hour.

- Offers versatility with customization for different container materials and sizes.

- Minimizes maintenance with durable stainless steel construction and corrosion-resistant materials.

- Integrates seamlessly into existing production lines, supporting continuous and automated operations.

- Applications

- Beverages, Wine, Bottling and packaging, Water treatment, Foodstuffs, Cider, Beer, Dairy

- End products

- Beer bottles, Wine bottles, Olive oil bottles, Water bottles, Soft drink bottles, Juice bottles, Cider bottles, Milk bottles

- Steps before

- Purification, Container Sorting

- Steps after

- Sterilization, Filling, Packaging

- Input ingredients

- glass containers, plastic containers, ceramic containers, bottles, hot water, cold water, SO2

- Output ingredients

- cleaned containers, sterilized bottles

- Market info

- Della Toffola is renowned for its expertise in designing and manufacturing industrial equipment for the wine-making, beverage, and food processing industries, providing customized, high-quality engineered-to-order solutions with a strong reputation for innovation and reliability.

- Speed

- 3000 to 90, 000 bottles per hour

- Automation

- Fully automatic

- Material Compatibility

- Glass, Plastic, Ceramic

- Process Types

- Rinsing, Sterilizing

- Rinsing Method

- Hot or Cold water

- Sterilization Method

- Water and SO2

- Recycling System

- With pump and filter for wine

- Material

- Stainless steel and high-strength, corrosion-proof materials

- Automation level

- Fully automatic

- Batch vs. continuous operation

- Continuous

- Cleaning method

- CIP / SOP

- CIP/SIP

- CIP

- Corrosive resistance (e.g. acids)

- High-strength, corrosion-proof materials

- Cleanability

- Complete with automatic controls

- Container size

- All sizes

- Container shape

- All shapes

- Container type

- Glass / Plastic / Ceramic

- Machine footprint

- Variable based on hourly output

- Container compatibility

- Glass, plastic, ceramic

- Container size adaptability

- All shapes and sizes

- Construction material

- Stainless steel, high-strength corrosion-proof materials

- Automatic controls

- Yes

- Hourly output capacity

- 3, 000 to 90, 000 bottles per hour

- Control panel type

- Automatic controls

- Container type adaptability

- Glass, plastic, ceramic

- Hourly production range

- 3000 to 90, 000 bottles per hour

- Process type

- Rinsing, sterilizing

- Water temperature

- Hot or cold

- Sterilizing method

- Water and SO2

- Material construction

- Stainless steel, high-strength, corrosion-proof materials

- Operator safety features

- Automatic controls and safety devices