Compact drying solution for regular skim and Wpc powders

Streamline your drying process with a compact solution that efficiently transforms raw inputs into high-quality protein and milk powders, perfectly integrating with your existing line for cost-effective, one-stage drying and product handling.

Dries and Cools Dairy and Food Powders

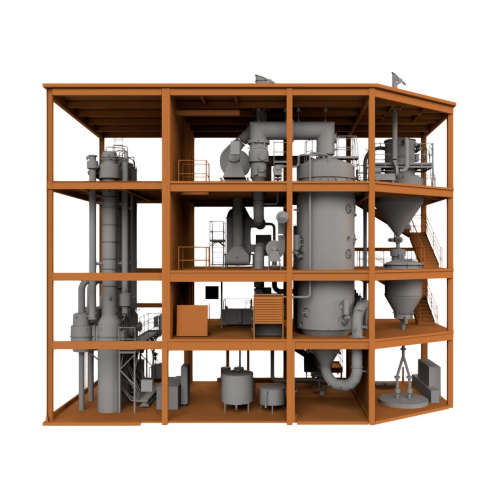

The U-Tube Dryer from Kovalus Separation Solutions is designed for efficient drying and cooling of dairy and food powders, including whey protein and milk protein concentrates. This compact dryer utilizes a one-stage drying process, making it ideal for streamlined operations and reduced investment costs. It efficiently processes skim milk powders, whey protein isolates, and non-fat dry milk, supporting flexible production requirements across various industries, such as dairy, food, beverage, and life sciences.

Capable of integrating seamlessly into existing production lines, the U-Tube Dryer is equipped with a powder cooling and transport system, ensuring minimal product degradation. It supports downstream integration with emission control systems like baghouses. Built for minimal energy consumption, this dryer helps optimize operational costs. The design is focused on ease of maintenance, and its robust construction ensures reliability in demanding industrial environments.

Benefits

- Lowers operational costs with efficient one-stage drying.

- Enhances product quality by ensuring precise powder cooling and transport.

- Minimizes installation space requirements due to its compact design.

- Supports environmental compliance with easy integration into baghouse emission systems.

- Reduces energy usage, contributing to cost-effective production.

- Applications

- Skim milk powder, Beverage powders, Whey protein concentrates, Food powders, Dairy powders, Milk protein concentrates

- End products

- Skimmed milk powder, Non-fat dry milk (nfdm), Milk protein concentrate (mpc), Whey protein isolate powder, Whey protein concentrate 80 (wpc80)

- Steps before

- Emulsification, Separation, Concentration

- Steps after

- Packing, Powder Cooling, Emission Control

- Input ingredients

- skim milk, whey protein concentrate, milk protein concentrate

- Output ingredients

- NFDM powder, skim powder, WPC80 powder, MPC powder

- Market info

- Kovalus Separation is known for manufacturing industrial engineered-to-order (ETO) separation equipment, specializing in tailored solutions for complex filtration and separation needs, with a strong reputation for innovation, quality, and reliability in various industries.

- Drying type

- One stage drying

- Powder type

- Regular (non-agglomerated) powders

- Products handled

- NFDM, skim, WPC80, WPI, MPC's

- Size

- Compact design

- Cooling system

- Powder cooling/transport system

- Investment cost

- Low

- Outlet type

- Bottom powder and exhaust air outlet

- Emission control

- Baghouse emission system

- Working Mechanism

- One stage drying

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC / SCADA

- Energy efficiency

- Low investment costs

- Drying Effluent Management

- Exhaust air outlet to baghouse emission system

- Powder Handling

- Powder cooling/transport system

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Agglomeration risk

- Low

- Product Type

- Regular Skim, WPC, MCP Powders

- Cooling/Transport System

- Equipped

- Discharge method

- Bottom powder and exhaust air outlet to baghouse emission system

- Compact design

- Yes

- Powder cooling/transport system

- Included

- Exhaust air outlet to baghouse emission system

- Included