Shrink wrapping solution for high capacity beverage and dairy bundles

This modular shrink wrapping and tray forming solution offers seamless integration into high-speed production lines, enhancing packaging efficiency for diverse product sets, including multi-pack beverages and snack bundles.

Streamlines Shrink Wrapping and Tray Forming

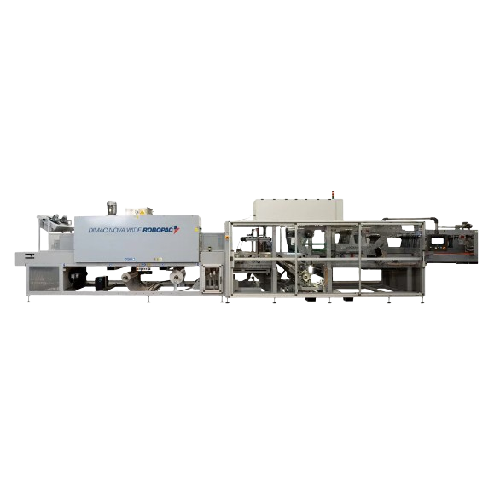

The DIMAC NOVA WIDE from Robopac is a cutting-edge shrink wrapper and tray forming machine tailored for high-speed, automated packaging needs across multiple industries including beverages, food, home, personal care, and lubricants. This equipment excels with its modular design, enabling future expansions and custom configurations. It features a user-friendly touch screen for seamless operation, and offers continuous processing with an output capacity of up to 65 packs per minute in dual lanes. Automated reel and format change capabilities minimize downtime, and its film feeding and cutting group is fully accessible for maintenance, significantly reducing production interruptions. Additionally, the high-performance shrink tunnel optimizes air flow for various packaging configurations. Constructed for durability, it integrates easily with existing production lines, providing a robust solution for efficient packaging of products ranging from beverage multipacks to lubricant cans.

Benefits

- Increases operational efficiency with dual-lane capabilities supporting up to 130 packs per minute.

- Minimizes production stops with automated reel and format change features.

- Enhances maintenance efficiency through fully accessible film feeding and cutting components.

- Future-proofs production lines with scalable modular design.

- Optimizes air flow in shrink tunnels, improving packaging quality and consistency.

- Applications

- Food, Personal care, Paper and tissue, Beverage, Lubricants, Corrugated, Home

- End products

- Shampoo sets, Bottled water multipacks, Beverage cans, Engine oil bottles, Toilet paper rolls, Lubricant cans, Corrugated box bundles, Soap bundle packs, Soda packs, Paper towel bundles, Snack multipacks

- Steps before

- Filling, Sealing

- Steps after

- Palletizing, Depalletizing, Stretch Wrapping, Banding

- Input ingredients

- film, reel, liquid products, beverage packaging, dairy packaging

- Output ingredients

- shrink-wrapped bundles, tray-formed packaging, packaging in single lane, packaging in double lane, packaging in triple lane

- Market info

- OCME, part of Aetna Group Italy, is renowned for manufacturing innovative, high-quality packaging and material handling solutions, including filling, palletizing, and conveying systems, with a strong reputation for reliability and technological advancement in industrial sectors.

- Output Capacity

- Up to 65+65 PPM

- Machine Length

- 6765 mm (F) / 6765 mm (P) / 8444 mm (T)

- Machine Width

- 1563 mm

- Worktop Height

- 1050 - 1150 mm

- Total Power

- 42 kW

- Air Pressure

- 6 BAR

- Air Consumption

- 20 - 100 Nl/min

- Film Types

- Single, Double, or Triple Lane

- Packaging type versatility

- Film only in single, double or triple lane

- Automation level

- Automatic reel change / Fully automated film sealing and cutting

- Ease of maintenance

- Completely accessible film feeding and cutting group

- Modular design

- Extremely modular

- Options can be added later

- User interaction

- Wide and user-friendly touch screen display

- Changeover flexibility

- Automatic format change via operator panel

- Energy efficiency options

- High Performance and H.P. plus shrink tunnel

- Changeover time

- Fast due to automatic format change

- Cleaning method

- Facilitated by full visibility and accessibility, LED lighting

- Output capacity

- Up to 65+65 PPM

- Film compatibility

- Shrink, Tray

- Cleanability

- Easy access for maintenance

- Density/particle size

- for liquid products

- Output Capacity

- Up to 65+65 PPM

- Types of Packaging

- Film only in single, double or triple lane

- Machine Frame

- Wide

- Film Feeding and Cutting Group

- Completely accessible

- Shrink Tunnel

- High performance, external regulation for air flow

- Automatic Reel Change

- Yes

- Automatic Format Change

- Yes

- Film Feeding

- External film group for reel loading

- Touch Screen

- Wide and user-friendly

- Cleaning Accessibility

- Full length sliding doors

- Lighting

- LED lighting for easy maintenance

- Machine length

- F 6765 - P 6765 - T 8444 mm

- Machine width

- 1563 mm (+ electric panel)

- Worktop height

- 1050 - 1150 mm

- Film unit

- Easy accessibility with swinging conveyor

- Machine frame

- Wide with full length sliding doors

- Control panel type

- User-friendly touch screen display

- Accessibility

- 2/3 machine length open for full visibility

- Control panel type

- Touch screen display

- Modular design

- Extremely modular way for scalability

- Film unit accessibility

- Swinging conveyor and extractable unit

- Automatic reel change

- Yes

- Automatic format change

- Electronic through brushless motors

- External film group

- For better access and reel sealing

- Accessibility

- Full length sliding doors

- Lighting

- LED lighting for working area