Hazelnut Processing Equipment

Find innovative production technology for making hazelnuts and connect directly with world-leading specialists

In Ancient Rome, hazelnut plants were valuable gifts as it was believed to bring happiness. In modern days, hazelnuts still bring happiness, mainly in the form of Nutella. While most nuts are botanically classified as fruits, hazelnuts are, along with chestnuts and acorns, true nuts. Once harvested, the nuts are dried and ready to be processed in various hazelnut processing equipment.

Select your hazelnuts process

Tell us about your production challenge

The hazelnut journey: from a plant to hazelnut processing equipment

It is estimated that almost 700 000 tones of hazelnuts are harvested yearly. A hazel or a filbert tree, which is a slightly larger species but often interchangeably used with hazelnut, becomes productive at the age of 7 and can produce nuts for approximately 80 years. The ideal time to harvest is before or during autumn, as soon as they become loose – hazelnuts fall from the tree once they are mature – to minimize the risk of animal predation. If left on the ground for a long time, rain can cause discoloration of the shell.

That’s why hazelnuts should be collected as soon as possible after falling. Sometimes this means that hazelnuts must be post-ripen. It can be done manually or by using suction machines, for instance, “finger wheel” or straddle-type harvesters, usually used for all commercial harvests, which perform the initial cleaning of the nut and dumps them into a harvest wagon. High-capacity machines (about 1000kg/h) are used for the more detailed cleaning process, followed by sorting nuts by quality, considering the moisture content, kernel size, kernel/nut ratio, and the degree of mouldiness and rottenness.

Hazelnuts may nut be moist: the drying process

In order to meet commercial standards, hazelnuts, which have a high moisture percentage of around 35%, must undergo the following processes: debuding, impurity removal and drying. Drying is a vital process for preservation due to the risk of fungal attacks, as nut trees are the perfect substrates for fostering microorganisms and meeting quality and food safety standards.

Although some confectionery companies require hazelnuts to be dried to 6% of moisture, since the lower water percentage prevents oxidation which changes the taste, 8%-10% is a universally acceptable level of hazelnut moisture content. Hazelnuts can be sun-dried or spread in well-ventilated but safe locations and turned 1-2 times a day. Mechanical dryers such as prune driers or small dehydrators can be used during this process. However, there are also larger drying machines that significantly reduce the drying time of hazelnuts by continuously mixing them while exposing them to a hot blast of air reaching up to 40°C. This dying process can be finished within a day.

So fresh it’s nuts: the proper storage and quality

Although generally non-perishable and can be stored for long periods, hazelnuts must be stored properly to maintain freshness, aroma and taste. It is ideal to store hazelnuts in cold storages with around 0°C and relative humidity of 65-70%. In such conditions, they can stay fresh for up to a year. Hazelnuts can even be frozen for later use as they tolerate temperatures as low as -10°C. Improper storage can result in auto-oxidation and rancidity. It happens when oils and fats are exposed to air, light and bacteria, which changes nuts on a molecular level, leaving them with a “stale” taste and smell.

Furthermore, storing hazelnuts inappropriately can lead to insect pests and molds, which makes the nuts unsafe for consumption. Modified Atmosphere Packaging is an effective method to preserve hazelnuts and significantly prolong their shelf-life. This method entails storing nuts in intact bags and containers with controlled levels of oxygen and other gases. In case of large quantities, a steel or concrete silos is a practical solution: nuts are protected from mechanical damage, and the storage parameters are monitored precisely.

The hazelnut journey continues: processing hazelnuts for various applications

Once harvested, dried and stored properly, hazelnuts are ready to be sold to customers or factories for further treatments in hazelnut processing equipment. Firstly, the hard shell must be removed in a process called shelling or cracking. There are two possible processes: compression cracking in plate crushers or impact cracking by throwing the nuts against hard surfaces. Using a hazelnut shelling line, nuts are separated from the remains of the shells and grouped into classes based on size and quality.

According to the customer’s preference or requirements for the byproduct, hazelnuts can be roasted to various degrees in rotary tunnel ovens in order to improve the flavor and texture. By finely grounding, hazelnuts can further be made into grains, flour or pastes.

NUThing to waste: from hazelnuts shells to sustainable panels

While the nuts can be used in various snacks and delicacies, many shells go to waste. However, a Washington State University scientist developed an innovative idea for producing durable panels for cabinets, tables, and furniture using hazelnut shells. They are naturally sustainable and ideal for such products due to their strength, performance, and beauty with their rich reddish-brown color. The key is preventing degradation by restricting the release of carbon while maximizing the amount of natural fiber but minimizing the amount of resin.

In conclusion, hazelnuts are a popular and versatile ingredient used in a variety of food products. They are harvested by growers and sent to processing lines, where they are sorted and cracked to extract the hazelnut kernels. Nut processing machines like crackers and calibrators are used to separate the kernels into different sizes for different applications. Proper storage is crucial for maintaining the freshness, aroma, and taste of shelled nuts, and they can be frozen for later use. While hazelnuts are the focus of this discussion, almonds and walnuts are other popular nuts that are also commonly processed and used in the food industry.

Processing steps involved in hazelnuts making

Which hazelnuts technology do you need?

Almond milk production system

Streamline your plant-based beverage production with a comprehensive system designed to finely...

Nut roasting process with halved energy consumption

Achieve significant energy savings while maintaining high-quality roa...

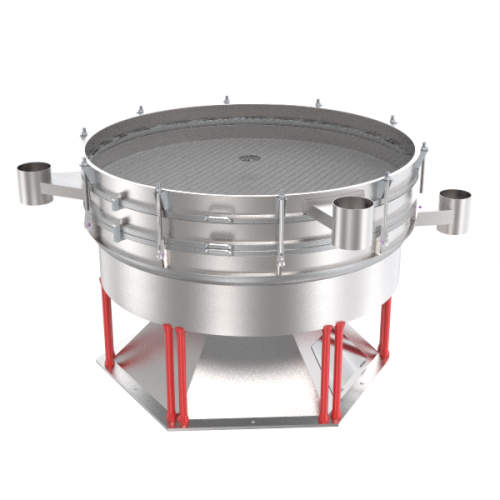

Circular sifter for fatty products and flours

Achieve precise separation and grading of nuts and flours, optimizing your p...

Destoner for nuts and seeds

Efficiently separate heavier particles like stones from a wide range of food products, including...

Nut dicing machine

Efficiently transform whole nuts into uniform cubes with precision cutting technology, ideal for creators ...

Nuts flour production system

Enhance your nut processing efficiency by transforming whole nuts into fine, consistent flour w...

Horizontal roaster system for nuts and seeds

For nut processors aiming to achieve uniform roasting, this system ensures pr...

Aspiration system for nut processing

Streamline your nut processing with precise removal of skins, dust, and lightweight pa...

Paste filling system for high viscosity products

Efficiently fill high viscosity products with precision and speed, reduci...

Hollow wafer spreading machine for consistent coating

Optimize your snack production with precise spreading—achieve unifo...

Continuous cocoa bean roaster

Achieve precise flavor profiles in cocoa and nut processing with a continuous roasting solutio...

Cocoa nib grinding system

Optimize your cocoa and nut processing with precision grinding to achieve a pumpable mass, ensurin...

Modified atmosphere packaging for bulk bins

Achieve ultra-low oxygen levels and preserve product quality during bulk proce...

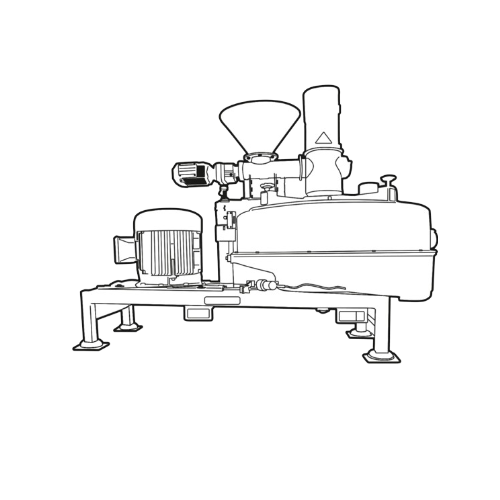

Universal mill for grinding nuts and seeds

Optimize your nut paste production with a high-speed, versatile milling solutio...

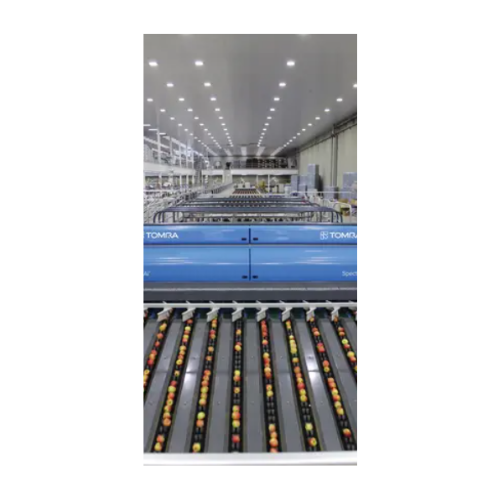

Optical sorter for nuts or dried fruits

Ensure maximum food safety and quality by efficiently sorting and removing shells, ...

Centrifugal separator for reworking chocolate and chopped hazelnuts

Efficiently separate chocolate from chopped hazelnu...

Continuous nut roaster for large-scale nut processing

Streamline your nut processing capabilities with a machine designed...

X-ray scanner for bulk material inspection

Ensure product safety and minimize downtime by intercepting foreign contaminant...

Automatic palletizer for fruit and vegetable crates

Optimize your fruit and vegetable handling with efficient palletizati...

Cucumber sorting and grading solution

Optimize cucumber handling with precise diameter, length, and shape sorting, enhancin...

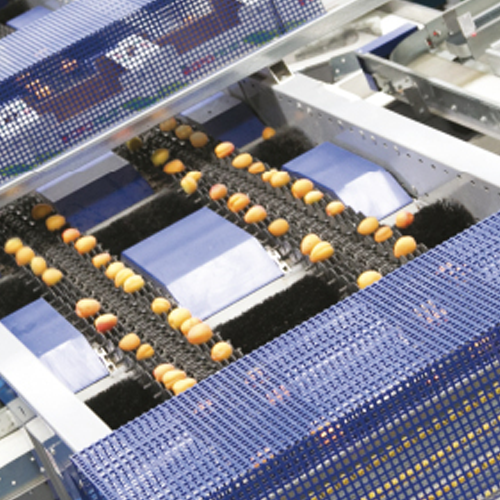

Hazelnut sorting and quality selection system

Optimize your hazelnut processing with a system designed to detect defects a...

Pepper sorting and grading technology

Ensure consistent quality and precision in size and color sorting for a wide array of...

Grading and sorting solutions for apricots

Optimize your fruit production with precise grading and sorting technologies de...

High-precision sorter for nuts, coffee, seeds, and grains

Achieve unrivaled accuracy in sorting nuts, seeds, and grains ...

Intelligent optical fruit sorting and grading system

Enhance product quality and reduce waste with cutting-edge optical s...

Peanut roaster for various nuts

Elevate your nut processing with efficient roasting solutions that enhance flavor, texture, ...

Garlic peeling equipment for industrial applications

Achieve optimal peeling efficiency with this garlic and nut peeling ...

Lay-on systems for precise sprinkling and nut depositing

Optimize your confectionery production with precision sprinkling...

Nuts paste refining mill

Transform nuts and dried fruits into fine pastes with precise particle control, ideal for creating p...

Dried nuts roasting system

Efficiently transform raw dried nuts into high-quality pastes and creams, optimizing flavor and t...

Chocolate and sugar coating system

Achieve consistent, high-quality coating for nuts, dried fruits, and confectionery with ...

Industrial nut crusher for dried fruit processing

Optimize your nut and dried fruit processing by reducing them to precis...

Chocolate products aligner for chocoform extruder

Enhance your chocolate production line efficiency with a precision alig...

Chocolate and nut cluster production line

Optimize your confectionery production with precise control over chocolate and n...

Cluster production system for chocolate with nut inclusions

Efficiently create customized chocolate clusters with precis...

Coffee, dried nuts, and cocoa beans roaster

Achieve precise and customizable roasting for a variety of beans and nuts with...

Industrial roaster for coffee, nuts, and cocoa beans

Optimize your roasting processes with a versatile solution designed ...

Vacuum and Gas Injection System for FIBCs

Products packed in large bulk bags, such as FIBCs, require vacuum pressure and a...

Automatic FIBC Sealing machine

When sealing large bags containing bulk products, a sealer must be reliable to keep the MAP s...

Sensor for Modified Atmosphere FIBCs

Every year, more than 200 million FIBCs are filled with food for storage and transport...

Modified Atmosphere Big Bags

Manufacturers requiring big bag packaging have specific sizes, shapes, and material requirement...

Continuous bagger with twin sealing jaws

If you want to pack into gusseted and pillow style bags and packing speed is impor...

Industrial Nut Roaster

Moisture considerably depletes the shelf life of nut products. At the same time, however, manufacturer...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

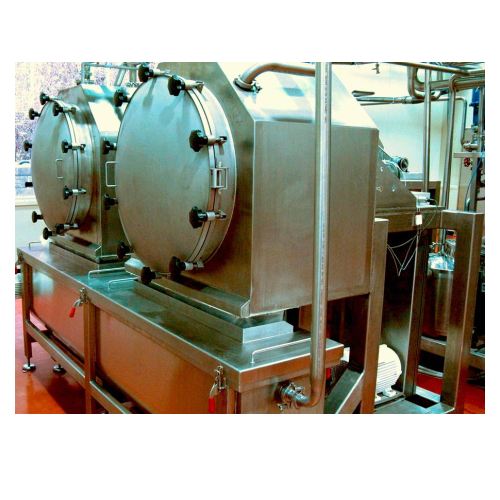

Washing cabinet for food bulk containers

With an ever-increasing demand for output and stricter hygiene regulations for foo...

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Infrared rotating drum dryer

Traditional drying methods are often slow and can actively damage ingredients, reducing the fin...

Entry-level infrared nut drying machine

For small scale production of cocoa beans and nuts, the use of traditional toasters...

Small scale nut chopping machine

Many confectionery and bakery products use nuts as a key ingredient or decoration. The abil...

Small scale nut grinder

Many confectionery and bakery processes rely on the uniform grinding of raw ingredients such as nuts,...

Continuous fluid bed dryer

In a Fluid Bed, a product or solid is made fluid by an upward moving flow of gas. The mechanical ...

Industrial nut grater

Pressure from the grinding process can cause damage to food products as well as induce unwanted heating...

Nut dicer

Dicing nuts can generate a large volume of wasteful and messy powdered nut residue.

Automatic ring-straddle stretch wrapper

Imagine a stretch wrapper that can wrap up to 180 loads per hour without putting to...