Automated Cci tester for pharmaceutical containers

Ensure the integrity of every pharmaceutical package swiftly with high-speed, non-destructive testing for liquid, solid, and lyophilized products, maximizing production without sacrificing accuracy.

Performs Leak and Integrity Testing for Pharma Containers

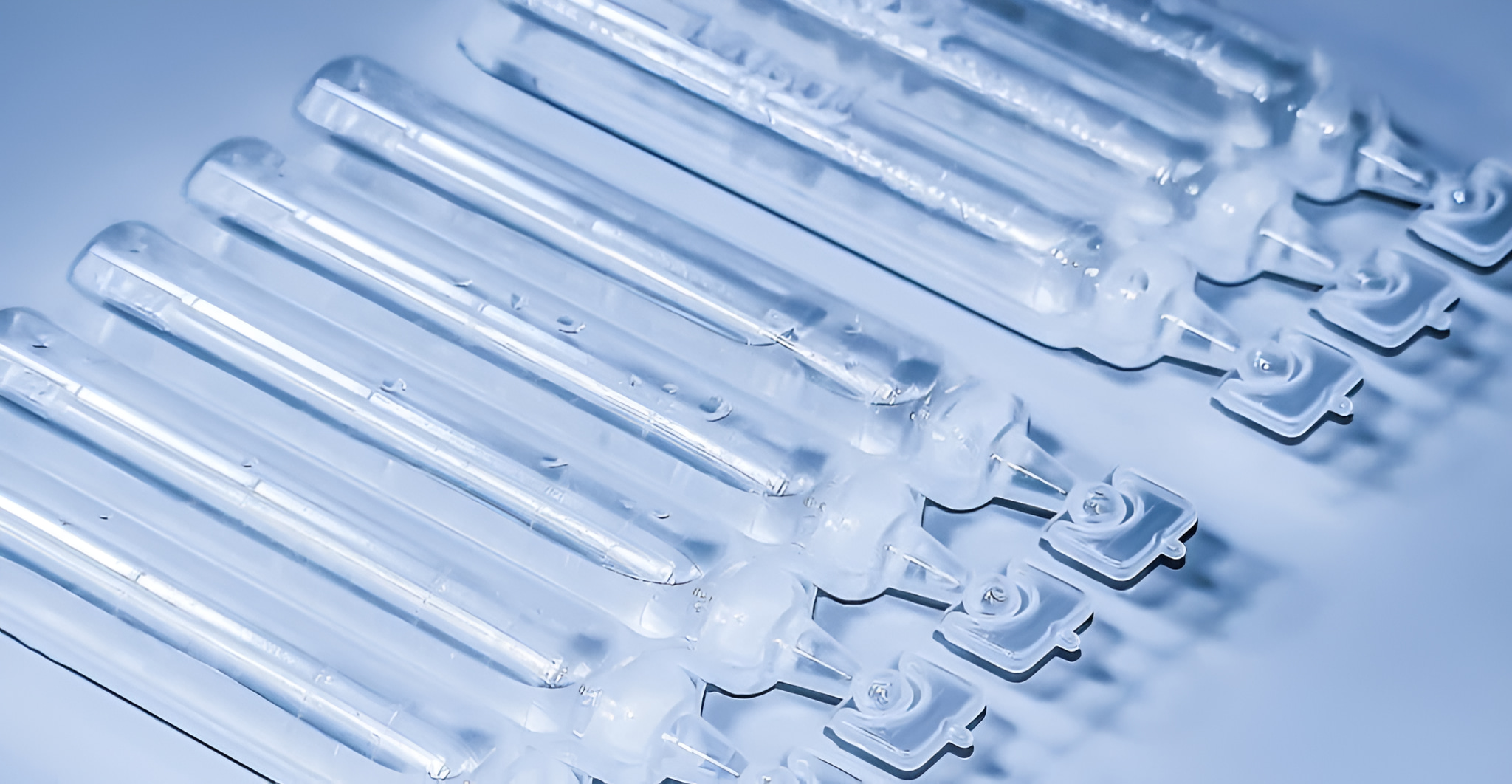

The Automated Container Closure Integrity Tester (R DPX) from WILCO AG is designed for robust leak testing of pharmaceutical containers in high-speed production lines. Specializing in both liquid and lyophilized products, this equipment utilizes vacuum and pressure decay testing to ensure container integrity. It is ideal for applications involving blow-fill-seal containers, small and large volume parenterals, and pre-filled auto-injectors. With the capability to process up to 600 samples per minute, the R DPX seamlessly integrates into multi-product lines, offering tool-less format changeovers and reliable handling for minimum downtimes. The system adheres to GMP guidelines, ensuring compliance with strict pharmaceutical standards while maintaining high throughput and operational efficiency.

Benefits

- Achieves 100% container integrity testing to meet stringent regulatory standards.

- Maximizes throughput with the capacity to test up to 600 containers per minute.

- Minimizes downtime with tool-less format changes and reliable product handling.

- Reduces production costs by preventing contamination and product loss.

- Ensures compliance with GMP and other international pharmaceutical guidelines.

- Applications

- Liquid formulations, Blow-fill-seal containers, Lyophilized products, Pharmaceutical containers, Biopharmaceuticals, Glass containers, Solid products, Plastic containers, Auto-injectors, Small volume parenterals, Large volume parenterals

- End products

- Pre-filled auto-injector pens, Glass ampoules, Intravenous solution bags, Plastic infusion bottles, Single-use sterile syringes, Oral liquid medications, Protein therapeutics, Vaccine vials, Solid oral dosage forms, Freeze-dried antibiotics

- Steps before

- Filling, Sealing

- Steps after

- Packing, Labeling

- Input ingredients

- small volume parenterals, large volume parenterals, BFS cards, BFS bottles, IV bags, vials, ampoules, cartridges, liquid products, lyophilized products, solid products, non-conductive products, oily liquids

- Output ingredients

- tested pharmaceutical containers, container integrity test results, leak detection reports, quality verification data

- Market info

- Speed

- Up to 600/min

- Format range

- 1ml up to 250ml

- Container Type

- Vials and Ampoules

- Container Material

- Glass and Plastic

- Product Type

- Liquid, Lyophilized, and Solid

- Non-destructive Test Method

- Yes

- Automation

- Fully Automated

- Leak Detection Method

- Vacuum and Pressure Decay

- Sensitivity

- High sensitivity with LFC method, reg

- Compliance

- 21 CFR part 11

- Test Method Standard

- USP 1207, ASTM – F 2338

- GMP Design

- Designed for GMP environments

- Toolless Format Changeover

- Yes

- Automation level

- High-speed, up to 600 samples/min

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Toolless, quick format changes

- Cleaning method

- Non-destructive, inline testing

- Reliability

- Design supports high throughput with minimum downtime

- Handling

- Gentle product handling to minimize defects

- Testing capabilities

- Liquid, lyophilized, solid products

- Product size variability

- Handles 1ml to 250ml containers

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container type

- Glass / Plastic / BFS

- Container shape

- Vial / Ampoule / Cartridge / IV Bag

- GMP Compliance

- Yes

- 21 CFR part 11 compliance

- Yes

- USP <1207> compliance

- Yes

- ASTM F2338 compliance

- Yes

- EU GMP Annex 1 compliance

- Yes

- Footprint

- Compact

- Container type compatibility

- Vials, ampoules, cartridges

- Container material compatibility

- Glass, plastic

- Container size

- 1ml up to 250ml

- Control panel type

- Integrated

- System integration capability

- 21 CFR part 11 compliance

- Product handling system

- Reliable and tool-less format changeover

- Test method configuration

- Variety of product/package configurations

- High-speed operation

- Up to 600/min

- Control panel type

- PLC / HMI

- Integration possibilities

- OPC Server / Network Integration

- Toolless format changeover

- Yes

- Configuration flexibility

- Multiple formats and sizes