High-temperature top-open tube furnace for laboratory applications

Achieve precise thermal processing with this high-temperature tube furnace, ideal for applications requiring consistent heating and sintering capabilities, ensuring exceptional material quality and integrity.

Heats and Sinter Advanced Materials at 1200°C

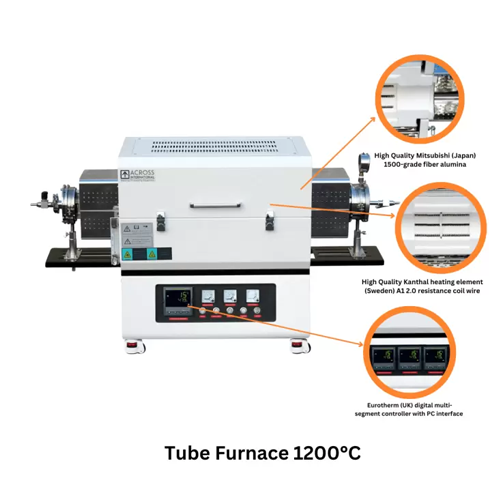

The STF1200.TFM1.2.3, part of Ai’s premium furnace series, is a 1200°C top-open tube furnace designed for demanding thermal applications across fine chemicals, metallurgy, and semiconductor sectors. Its innovative design incorporates Kanthal A1 resistance coil wires and high-grade Mitsubishi alumina fiber insulation, optimizing thermal efficiency and reducing energy consumption. The furnace’s Eurotherm digital controller allows precise temperature control and remote operation. This versatile unit supports complex processes like sintering and thin film coating, with applications in producing high-purity metal oxides, semiconductor wafers, and composite materials. Built to handle both batch and continuous operations, the furnace is ideal for integration into varied thermally intensive research and development environments. The stainless steel construction with vacuum sealing compatibility ensures durability and corrosive resistance. ETL and CE certifications affirm its compliance with international safety standards.

Benefits

- Ensures high-purity and consistency in metal oxide and semiconductor production.

- Reduces operational costs through energy-efficient Kanthal coil technology.

- Offers versatile processing with support for both batch and continuous thermal operations.

- Enhances safety with built-in overheat and power failure protection systems.

- Facilitates integration with research setups through remote monitoring and control capabilities.

- Applications

- Metallurgy, Fine chemicals, Material science, Semiconductor, Coating materials

- End products

- Thin film coatings, Semiconductor wafers, Sintered advanced ceramics, High-purity metal oxides, Nano-material composites

- Steps before

- Sample preparation, Material drying, Binder application, Equipment calibration

- Steps after

- Cooling, Pressure testing, Vacuum sealing, Final inspection

- Input ingredients

- quartz tube, atmosphere gas (inert gas, air), binder material, raw materials for sintering

- Output ingredients

- sintered parts, gaseous byproducts, binder burnout residues

- Market info

- Across International is known for manufacturing high-quality thermal management equipment, such as vacuum ovens, furnaces, and laboratory equipment, with a strong reputation for reliability and innovation in industries like materials research, cannabis processing, and laboratory testing.

- Maximum working temperature

- 1200°C (2 hours maximum continuous run time)

- Maximum constant working temperature

- 1100°C

- Constant working temperature under vacuum

- 1000°C

- Minimum working temperature

- Ambient

- Rated vacuum pressure

- 0.001 Pa / 0.0075 millitorr / 0.00001 mbar

- Rated positive pressure

- 0.02 MPa / 150 torr / 3 psi

- Heating element type

- Kanthal(Sweden) A1 2.0 resistance coil wire

- Thermocouple type

- K

- Refractory lining

- Mitsubishi(Japan) high quality 1500 grade fiber alumina

- Temperature controller

- Eurotherm(UK) digital multi-segment controller

- Maximum heating rate

- < 30°C / min

- Heating zone length

- 16 inches

- Constant temperature zone length

- 10 inches

- Temperature controller precision

- ± 1°C

- Maximum working temperature

- 1200°C

- Maximum constant working temperature

- 1100°C

- Constant working temperature under vacuum

- 1000°C

- Minimum working temperature

- Ambient

- Heating Zone(s)

- Varies by model (e.g., 440mm for 1-Zone)

- Automation level

- Eurotherm digital controller

- Changeover time

- Quick access through top-open design

- Energy efficiency

- Built-in ammeter and dual voltmeters

- Control interface

- PC connection for remote control and monitoring

- Multiple atmosphere processes

- Possible in a single cycle

- Safety features

- Overheat protection and power failure protection

- Abrasion resistance

- High

- Biological compatibility

- Not Applicable

- Cleanability

- Easy

- Corrosive resistance (e.g. acids)

- High

- Density/particle size

- Not Specified

- ETL Certification

- Tested to UL and CSA Standards

- Machine footprint

- 51 ¼" x 23 ¾" x 27 ¾"

- Tubing size

- 60mm to 250mm OD

- Heating zones

- 1-Zone, 2-Zone, 3-Zone

- Heating zone length

- 440mm

- Furnace dimensions (1-Zone)

- 51 ¼" x 23 ¾" x 27 ¾"

- Furnace dimensions (2-Zone)

- 26 x 18 x 26"

- Furnace dimensions (3-Zone)

- 49 x 20 x 29"

- Top-open split chamber

- Yes

- Weight (1-Zone)

- 270 lbs

- Weight (3-Zone)

- 520 lbs

- Control panel type

- Standard Eurotherm 3204 / Optional Eurotherm 3504

- Integration possibilities

- Built-in digital communication port for PC connection

- Heating Zone Options

- 1-Zone, 2-Zone, 3-Zone configurations

- Helium Leak Testing

- Alicat MFC - Helium Leak Tested