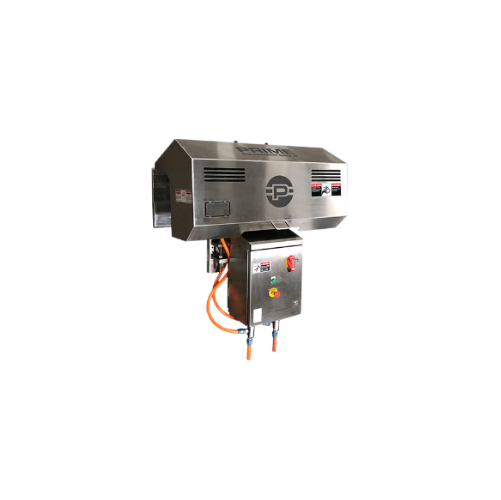

Chicken tender tendon clipper

Achieve precise cuts and streamline your poultry processing with a high-speed solution that efficiently severs tendons while maintaining tender integrity, enhancing both yield and consistency.

Removes Tendons from Chicken Tenders Efficiently

The CTTC-1 Chicken Tender Tendon Clipper from Prime Equipment Group is a specialized machine designed to enhance efficiency in poultry processing. It utilizes a precise cutting mechanism to sever tendons from chicken tenders and wings while integrated into the continuous flow of a production line. Operating at speeds of up to 50 front halves per minute, this clipper significantly reduces manual labor by eliminating the need for hand cutting, resulting in more consistent tender shapes and improved yield. Ideal for poultry processors and industrial kitchens, the CTTC-1 seamlessly mounts onto existing cone lines, minimizing operational disruption. Powered by a 1/2 hp motor and compatible with 480V, 3-phase systems, it ensures robust performance with variable production rates contingent on cone line speed. Designed to integrate with Prime’s Accu-Lock Cone System, this clipper provides both efficiency and reliability, meeting the needs of high-speed, continuous operations while maintaining meat integrity and quality.

Benefits

- Eliminates manual labor, enhancing operational efficiency and reducing labor costs.

- Improves yield consistency through precise tendon removal, increasing overall product quality.

- Integrates seamlessly with existing cone lines, minimizing downtime during installation.

- Increases production speed to match high-demand environments without sacrificing cut precision.

- Adjustable to fit existing systems, enhancing flexibility and adaptability in various processing setups.

- Applications

- Seafood, Meat, Poultry

- End products

- Deboned chicken wings, Chicken fillets, Processed chicken cuts, Tenderized poultry portions, Chicken tenders

- Steps before

- Cut-up, Deboning, Poultry Processing - 1st, 2nd

- Steps after

- Portioning, Slicing, Coating, Cooking, Freezing, Chilling

- Input ingredients

- chicken front halves, wing tendon, shoulder joint

- Output ingredients

- tendon-free chicken tenders, severed wing tendon

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Production Rate

- Variable with speed of cone line

- Motor Power

- 1/2 hp

- Electrical Requirements

- 480V, 3 ph, 60Hz, 10 amps

- Operating Speed

- Up to 50 front halves per minute

- Net Weight

- 600 lbs. (272 kg)

- Automation

- Integrates with Prime Accu-Lock Cone Line

- Working mechanism

- On-line solution, tendon clipping

- Integrated steps

- Severs tendon while connected

- Production capacity

- Up to 50 front halves per minute

- Automation level

- Reduces manual labor

- Adjustability

- Adjustable frame for existing cone lines

- Labor efficiency

- At least one fewer worker per line

- Yield improvement

- Increases tender yield

- Biological compatibility

- Yes

- Cleanability

- High

- Density/particle size

- 0.9–1.1 g/cm³

- Compatibility with Cone Lines

- Prime Accu-Lock Cone Line

- Machine footprint

- Customizable to existing cone lines

- Net Weight

- 600 lbs. (272 kg)

- Frame type

- Adjustable frame

- Discharge method

- Severs main wing tendon

- Control panel type

- Standard or customized control interface

- Integration possibilities

- Compatible with Prime Accu-Lock Cone Line

- Adjustable frame

- Allows operation in existing cone line