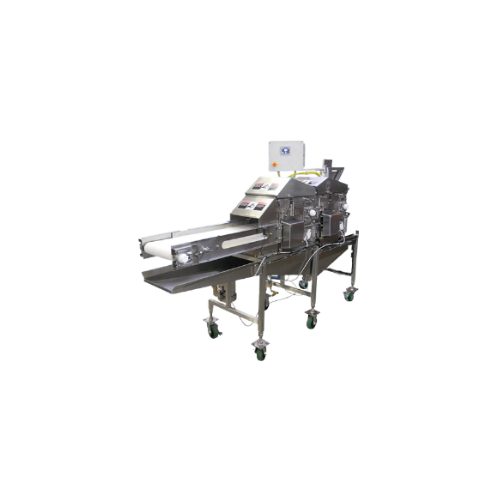

Two-stage turkey thigh skinner

Streamline your turkey thigh processing with a dual-stage skinner that efficiently removes skin and trims excess fat, enhancing product yield and quality.

Removes Skin and Fat from Turkey Thighs

The TSK-12-TS Two-Stage Turkey Thigh Skinner from Prime Equipment Group revolutionizes poultry processing by combining skinning and fat removal in a streamlined, efficient system. This bladeless skinner integrates two stages: the first removes skin, while the second targets residual fat, producing lean turkey thigh cuts. Ideal for meat and poultry processors, this equipment operates with a continuous-feed belt system ensuring consistent throughput, processing up to 60 turkey thighs per minute. Its precise design eliminates the need for down-line manual trimming, reducing labor costs. Operating with dual 2 hp motors at 480V, it optimizes energy use while maintaining productivity. With an emphasis on yield improvement and waste reduction, the TSK-12-TS seamlessly integrates into existing production lines, aiding in efficient turkey processing without compromising quality.

Benefits

- Enhances production efficiency by combining skinning and fat removal processes.

- Reduces labor costs through elimination of manual trimming positions.

- Increases yield with precise fat removal, minimizing meat waste.

- Continuous operation boosts throughput, processing up to 60 pieces per minute.

- Reduces energy costs with optimized motor control and minimal power consumption.

- Applications

- Seafood, Meat, Poultry

- End products

- Turkey thigh cuts, Lean turkey thigh meat, Boneless turkey thighs

- Steps before

- Cut-up, Deboning, Grinding, Injection

- Steps after

- Portioning, Slicing, Packing, Freezing

- Input ingredients

- turkey thighs

- Output ingredients

- leaner turkey thighs, skinless turkey thighs, fat-trimmed turkey thighs

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Electrical Requirements

- 480V, 3 ph, 60 Hz, 20 amps

- Motor Specifications

- 2 x 2 hp motor

- Water Requirements

- 1/4"

- 2 GPM

- 40 PSI

- Production Rate

- Turkey Thighs

- Two-stage processing

- Skinning and trimming integrated

- Automation level

- Continuous-feed system

- Precision trimming

- Bladeless system for precise fat removal

- Labor efficiency

- Reduces labor costs

- Waste reduction

- Optimal trim design to improve yield

- Production rate

- Up to 60 turkey thighs per minute

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Discharge method

- Continuous-feed belt

- Control panel type

- Digital / touchscreen / PLC

- Integration possibilities

- Automation system compatible

- Machine configuration

- Two-stage skinner setup

- Motor specifications

- (2) 2 hp motors

- Design

- Bladeless system