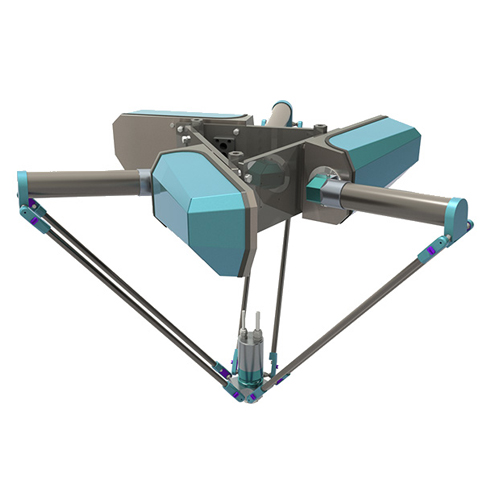

Delta robot for hygienic manufacturing processes

Enhance your processing line with precision and speed, ensuring hygienic handling of unpackaged products and efficient assembly tasks with this advanced delta robot.

Executes High-Speed Picking and Assembly Operations

The ABIflexx Delta Robot series, from ABI Robotic Systems, excels in high-speed picking and assembly tasks, specifically crafted for environments where hygiene is paramount. Featuring three synchronized motor drives, it efficiently manages tasks like handling unpackaged food, assembling components, and cutting various food products. Ideal for industries such as food processing, electronics, and automated production, the ABIflexx series offers seamless integration into existing production lines with its servo and motion control systems. The robots can handle continuous, high-speed operations, boasting exceptional flexibility with optional gripper rotation capabilities. Capable of customizing operations for specific applications, these robots are suitable for handling solid products like fresh produce, snack bars, precision metal components, and more. Available models, including the ABIflexx D3-1100, D3-1300, D4-1100, and D4-1300, offer diverse throughput capacities to match your production needs. Constructed with durable materials to withstand industrial environments, they integrate smoothly with upstream and downstream processes while minimizing energy use through optimized motor controls.

Benefits

- Enhances production efficiency with high-speed, precise operations.

- Minimizes cross-contamination risks in hygienic environments.

- Reduces operational costs with energy-efficient motor drives.

- Integrates seamlessly into existing production lines for improved workflow.

- Offers customization options to meet specific application requirements.

- Applications

- Semiconductor industry, Parts assembly, Component assembly, Food industry, Packaging industry, Access technology, Vehicle technology, Horticulture, Graphic industry, Unpackaged food products, Production automation, Multi-axis handling machines, Medical industry, Food cutting

- End products

- Printed graphics, Automotive parts, Pcb assembly, Fresh cut vegetables, Fresh produce, Snack bars, Wafer cutting, Food packaging, Automated production lines, Precision metal components, Elevator components, Surgical instruments, Flower arrangements, Pre-packaged meals

- Steps before

- Product handling, Component preparation, Material supply

- Steps after

- Product assembly, Quality inspection, Packaging

- Input ingredients

- unpacked products, components

- Output ingredients

- assembled parts, sliced food, packaged goods

- Market info

- Speed

- High speed for quick product handling

- Capacity

- Capable of handling multiple items simultaneously

- Automation

- Automatic assembly and parts handling

- Flexibility

- Gripper rotation for enhanced flexibility

- Hygiene

- Suitable for high hygiene applications

- Cycle time

- Short cycle times for fast operations

- Motor drives

- Three motor drives in the standard model

- Model variations

- ABIflexx D3-1100, D3-1300, D4-1100, D4-1300

- Working mechanism

- Pick and place

- Gripper rotation

- Optional

- Automation level

- Fully automated

- CIP/SIP

- Not specified

- Batch vs. continuous operation

- Continuous

- Handling type

- Unpacked products

- Assembly operations

- Automatic

- Robot Type

- Delta Robot

- Gripper Rotation

- Yes

- Motion Drives

- Three Motor Drives

- Flexibility

- Customizable with Gripper

- Gripper rotation

- Yes

- Integration possibilities

- Easy integration with KEBA controllers

- Control panel type

- Human Machine Interface (HMI)

- Robot models

- ABIflexx D3-1100, ABIflexx D3-1300, ABIflexx D4-1100, ABIflexx D4-1300