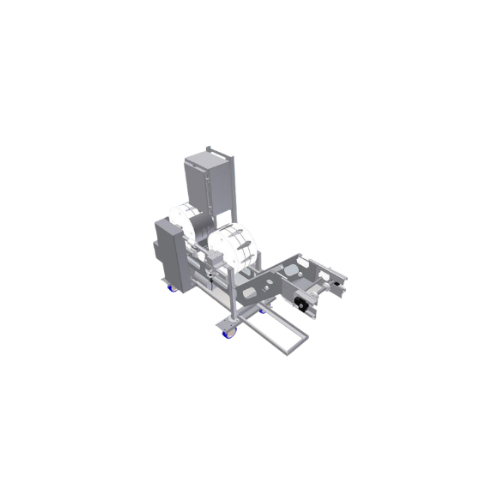

Chicken tender portion sizer

Streamline your poultry processing with a solution designed to cut and portion chicken precisely, ensuring consistency and reducing manual labor.

Precisely Portions and Cuts Poultry and Meat

The Prime PS-7 from Prime Equipment Group is a versatile poultry tender portioning machine engineered for precise cutting and size consistency. Utilizing interchangeable product cavity wheels, it tailors portions to meet specific output requirements across poultry, meat, and seafood processing. The PS-7 efficiently reduces manual intervention, ensuring uniformity in products like chicken tenders, nuggets, and diced pieces. Operable in continuous or semi-automated environments, it integrates seamlessly with existing lines, supported by optional custom conveyor systems for optimal workflow. Equipped with a 1 hp motor, the system requires minimal electricity and water, promoting sustainable operation. Tailored configurations and engineering support are available to fit unique production needs, enhancing both efficiency and product reliability.

Benefits

- Minimizes manual labor and product re-handling, improving operational efficiency.

- Ensures consistent and precise portion sizes, enhancing product quality.

- Allows for easy customization to meet specific production requirements.

- Operates sustainably with low energy and water usage.

- Integrates smoothly into existing production lines.

- Applications

- Seafood, Meat, Poultry

- End products

- Chicken nuggets, Portion-controlled chicken servings, Poultry medallions, Tailored poultry cuts, Sliced turkey breast, Boneless chicken strips, Diced chicken, Marinated chicken pieces, Chicken tenders, Breaded chicken fillets

- Steps before

- Poultry Sizing, Conveying, Sorting, Loading

- Steps after

- Packaging, Freezing, Chilling, Coating, Cooking

- Input ingredients

- raw chicken tenders, whole chicken pieces

- Output ingredients

- cut chicken tenders, portioned chicken products, consistent end product size

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Electrical Requirements

- 1 hp motor

- 480V,3 ph,60 Hz,10 amps

- Water Requirements

- 1/4″ connection

- 1.0 GPM (3.78 LPM)

- 40 PSI

- Net Weight

- 300 lbs. (136 kg)

- Portion Size

- Customizable

- Automation

- Portion control

- Automation level

- Manual / PLC

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual / CIP

- Energy efficiency

- 0.5–2 kWh/kg

- Changeover time

- Quick and flexible

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Slim and narrow design

- Net Weight

- 300 lbs. (136 kg)

- Product cavity wheels

- Interchangeable

- Control panel type

- Not specified

- Compact footprint

- Yes

- Discharge method

- Not specified

- Control panel type

- Customizable

- Product cavity wheels

- Interchangeable

- Portion size customization

- Customizable