Versatile size reduction processor for food applications

Enhance your food production line with a processor that excels in achieving precise size reduction, perfect for creating smooth purees, fine emulsions, and uniform particle sizes while maintaining continuous operation for high-speed processing efficiency.

Processes and Reduces Diverse Food Ingredients

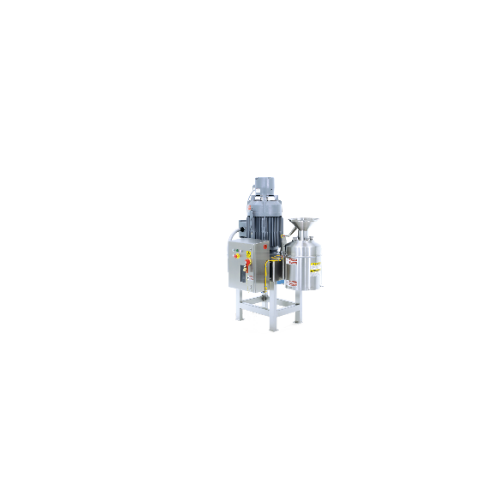

The Comitrol Processor Model 1700 from Urschel Laboratories offers unparalleled versatility in food processing, accommodating a range of reduction heads for varying applications. This processor is particularly suited for creating uniform emulsions, purees, and nut butters, using precisely engineered slicing, cutting, and microcutting techniques. It operates in high-speed, continuous processing environments, ensuring efficient throughput while maintaining product quality. Equipped with a HMI option, it allows for enhanced operational control, identifying sensor misalignments and monitoring machine runtime. Constructed from stainless steel, it provides durability and sanitation, ideal for the stringent demands of food processing. This model is capable of processing diverse food forms—from solid to slurry—to meet the needs of food processors and other industrial food manufacturers.

Benefits

- Enhances production efficiency with continuous, high-speed operation.

- Reduces maintenance time through easy cleanup and design simplicity.

- Optimizes particle size consistency for diverse food applications.

- Improves operational control and diagnostics with HMI integration.

- Ensures long-term durability and hygiene with stainless steel construction.

- Applications

- Nut butters, Dried meats, Condiments, Food processing, Plant-based foods, Emulsions, Beverage ingredients, Purees, Seaweed processing, Snack ingredients

- End products

- Hummus, Beef jerky, Coconut milk beverage, Raspberry puree, Seaweed snacks, Kale smoothie base, Ginger puree, Almond butter, Chicken skin emulsion

- Steps before

- Purification, Grinding, Drying, Emulsification

- Steps after

- Packing, Sterilization, Coating

- Input ingredients

- Chicken Skin, Almond Butter, Beef Jerky, Hemp Cake, Hummus, Kale, Raspberry Puree, Seaweed, Ginger, Coconut Milk

- Output ingredients

- Chicken Skin Emulsion, Almond Butter, Beef Jerky, Hemp Cake, Hummus, Kale, Raspberry Puree, Seaweed, Ginger, Coconut Milk

- Market info

- Urschel is known for its expertise in precision cutting technology and manufacturing industrial food processing equipment, especially cutting machines. It has a strong reputation for quality and innovation in delivering engineered-to-order solutions for the food processing industry.

- Motor Power

- 15, 30, or 40 HP (11.2, 22.4, or 30 kW)

- Maximum Input Size

- 2.5" (63.5 mm) for cutting heads

- 3/8" (9.5 mm) for microcut heads

- 1/4 to 1/2" (6.4 to 12.7 mm) for slicing heads

- Particle Size Range

- .010 to 1.5" (.254 to 38.1 mm) for cutting head

- Microcut Size Range

- .0012 to .0237" (.03 to .6 mm)

- Slicing Thickness

- .020 to .060" (.5 to 1.5 mm)

- Machine Dimensions

- Length

- Width

- 34.62" (879 mm)

- Height

- 70.12" (1781 mm)

- Net Weight

- 1100 lb (499 kg)

- Operation

- Continuous

- Material Construction

- Stainless Steel

- Enclosure Type

- Sealed to deter dust, vapor, and liquid

- Automation Features

- HMI Option Available

- Operating mode

- Continuous

- Motor horsepower options

- 15, 30, or 40 HP

- Input product size for cutting heads

- Up to 2.5" (63.5 mm)

- Input product size for microcut heads

- 3/8" (9.5 mm) to slurry

- Input product size for slicing heads

- 1/4 to 1/2" (6.4 to 12.7 mm)

- Reduction head diameter

- 6" (152.4 mm)

- Enclosure

- Sealed to deter escape of dust, vapor, and liquid

- Cleaning and maintenance

- Designed for easy cleanup and maintenance

- HMI features

- Misaligned sensors, soft start faults, machine runtime, motor loads

- Remote start/stop

- Available with HMI when connected to control center

- Size reduction versatility

- Recommended for free-flowing dry and semi-dry applications

- Cleanability

- Easy cleanup

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Density/particle size

- 0.0012 to 2.5” input size

- Machine footprint

- Length

- Net weight

- 1100 lb (499 kg)

- Motor options

- 15, 30, or 40 HP (11.2, 22.4, or 30 kW)

- Material

- Stainless steel construction

- Reduction heads

- 6" (152.4 mm) diameter

- Sealed enclosure

- Prevents escape of dust, vapor, and liquid

- Input Size Limit

- 2.5" (63.5 mm) for cutting heads, 3/8" (9.5 mm) for microcut, slicing heads

- HMI option availability

- Yes

- Control panel integration

- Remote start/stop

- Reduction head types

- Cutting, Microcut, Slicing