Potato Chips Manufacturing Equipment

Find innovative production technology for making potato chips and connect directly with world-leading specialists

Manufacturing potato chips is a farm-to-fork process from raw material to the final product. From washing and peeling to processing and frying and more in between. Freshly harvested potatoes are first washed, peeled, and sliced into thin potato slices. After washing them again to remove the starch, potatoes are then blanched, fried, seasoned, packed, and served, ready for your consumer’s enjoyment.

Select your potato chips process

Tell us about your production challenge

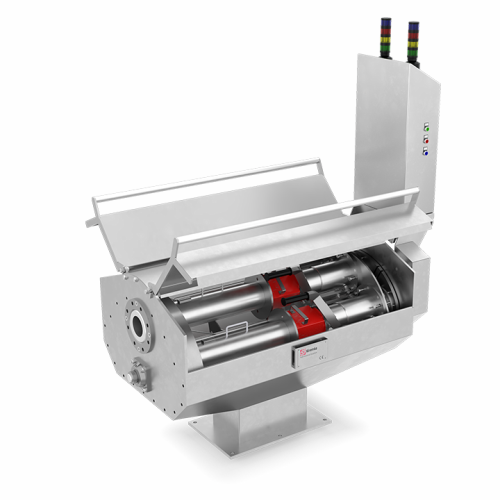

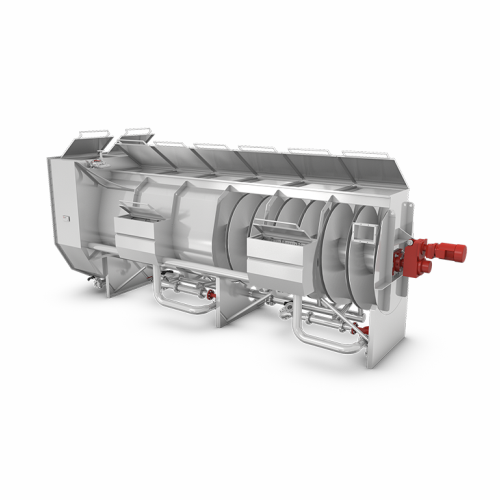

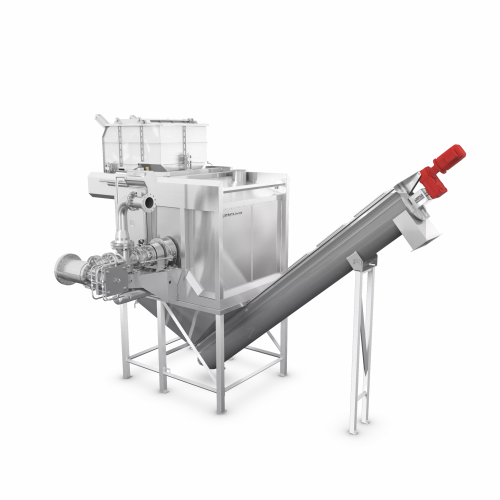

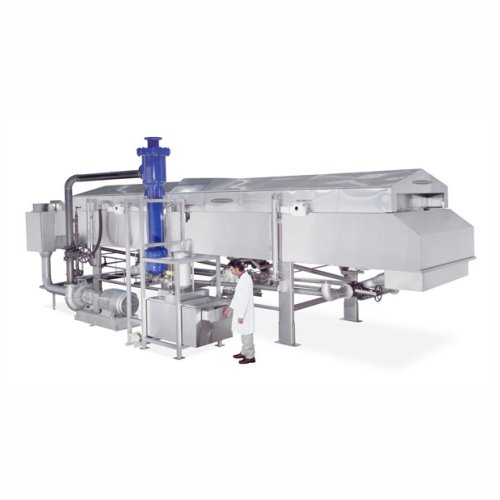

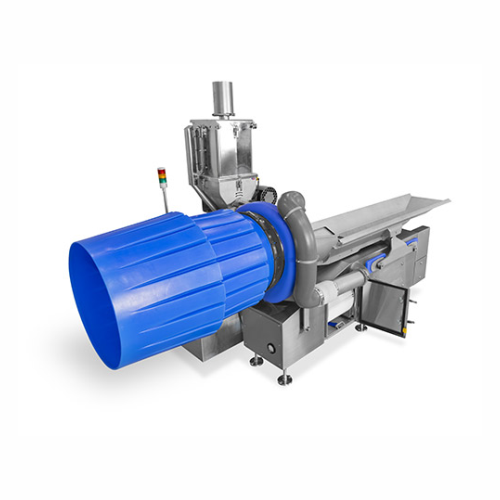

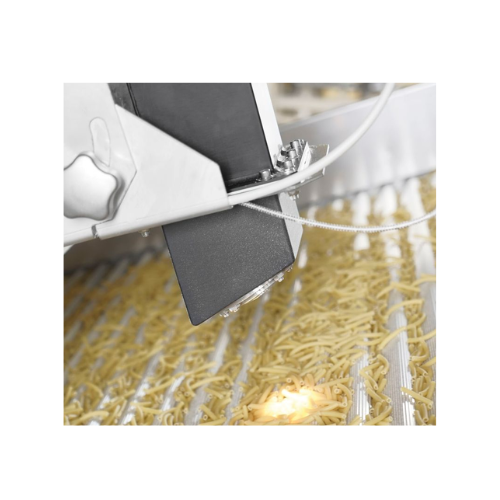

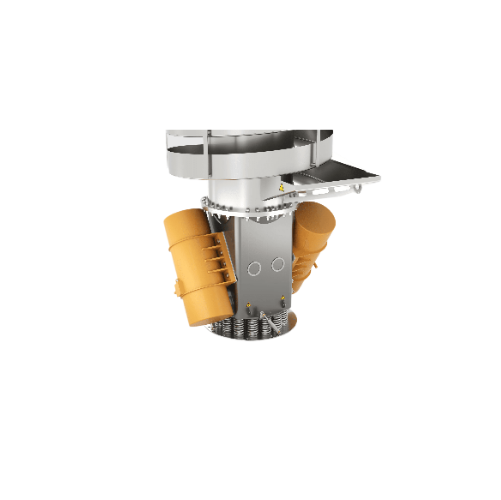

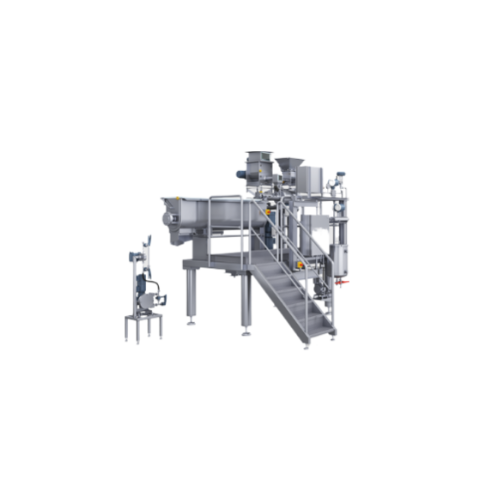

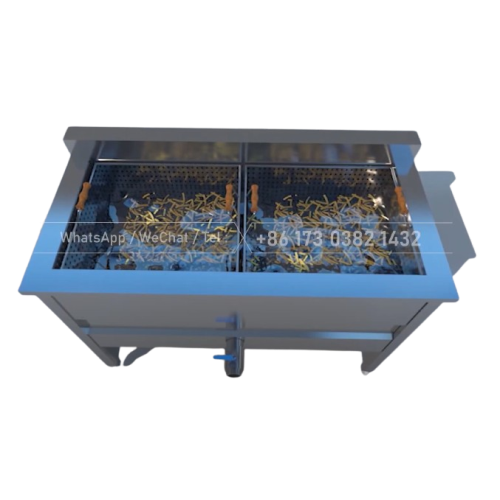

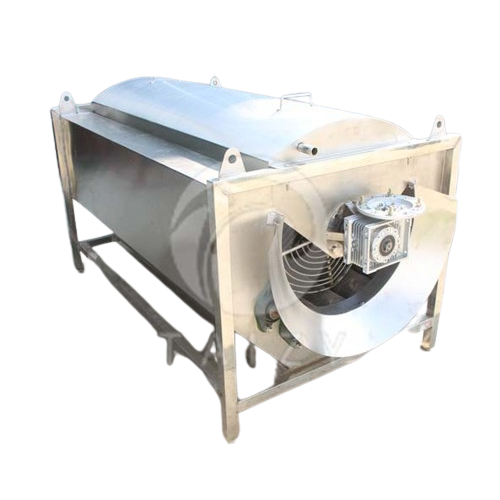

Tumbling seasonings for even coatings

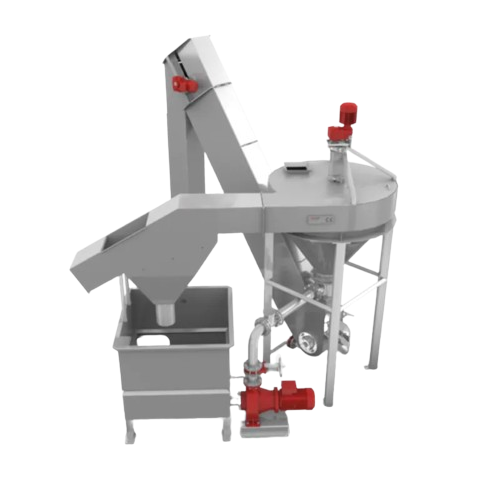

Seasoning potato chips involves the use of two main ingredients: the oil and the seasoning powder. The process involves coating your potato chips in oil and adding the seasoning powder to achieve the right flavor for your product.

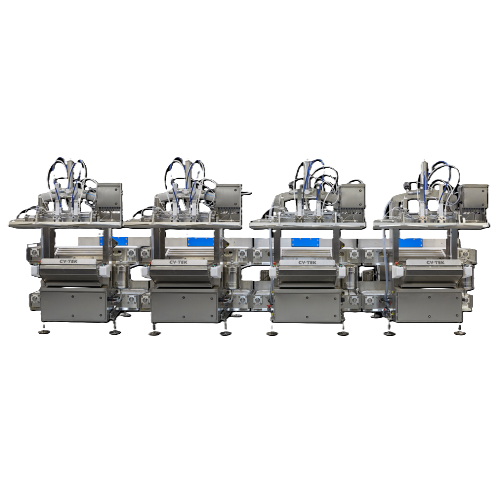

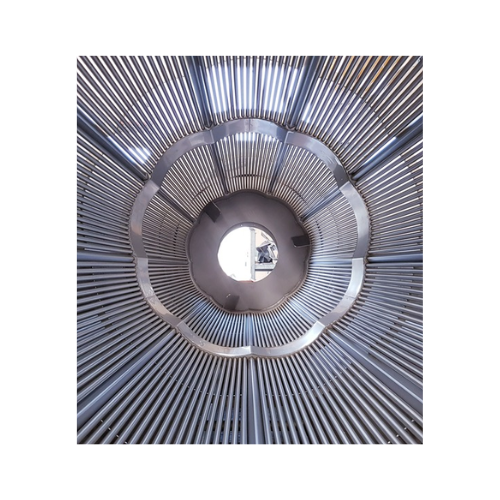

Potato chips production line dosing systems are specifically designed for the automatic seasoning your product. Oil is first sprayed to your chips, thinly coating them, and tumbled in a rotating drum. Afterwards, to another rotating drum where you can add the seasoning powder. The coating is spread evenly by tumbling the chips in the drum. This is one of many steps in a potato chips production line.

The road to making healthier potato chips

Potato chips are notoriously known to be unhealthy because of the oils used during their making process. This is due to the fact that they are made in a specialised frying machine. As an alternative, you can use healthier oils to fry and coat your chips. These include sunflower, olive, avocado, coconut, and even peanut. Their frying properties, high nutritional content, and flavor profile contribute to healthier chips. Similar efforts are employed with all types of fried production chips. For example, vegetable, plantain and banana chips.

Natural preservatives can also make your potato chips healthier. Rosemary extract has been established as an alternative to otherwise carcinogenic preservatives.

You can also do other cooking methods such as kettle cooking. With it, you batch cook the potato chips in a commercial deep fryer or an industrial frying machine, with a smaller quantity of oil.

Finally, if you prefer to carry your potato chips manufacturing with frying, there are technologies that decrease the frying oil turnover. This is important to maintain the oil quality in the production. It also helps making the oil change more efficient and avoids a high Free Fatty Acids (FFA) percentage, contributing to a longer product shelf life.

Other technologies for sweet potato chips

Sweet potato chips are a healthy alternative to regular potato chips. With their high Vitamin A and fiber content, these chips may be the preference for consumers wanting to satisfy that craving.

The potato chips manufacturing process is similar for both potato variants. Using oven technologies, such as baking and drying, can significantly boost the nutritional value of your sweet potato chips. These processes retain the sweet potatoes’ natural nutrients for consumption. In addition, the non-use of oil prevents the formation of carcinogenic compounds while decreasing their fat content.

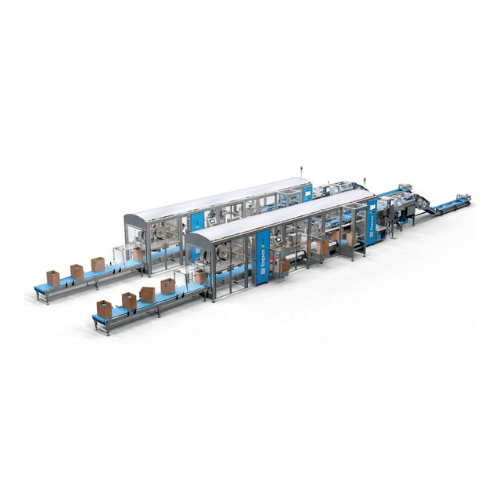

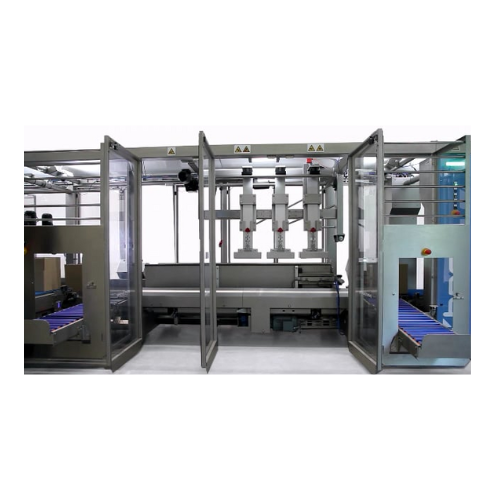

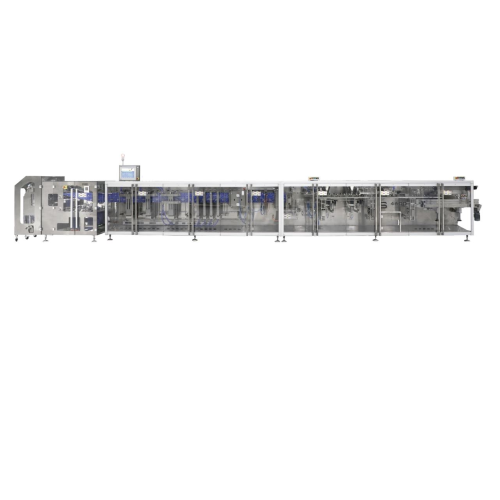

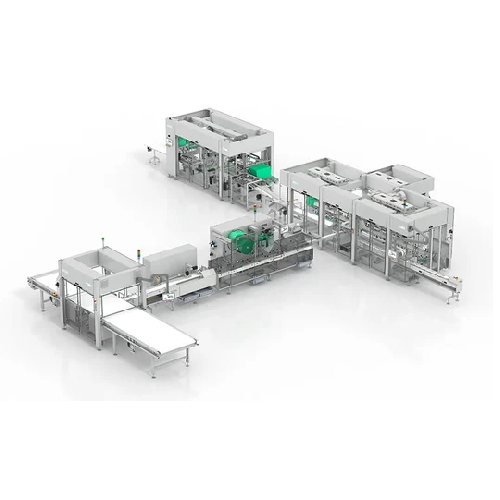

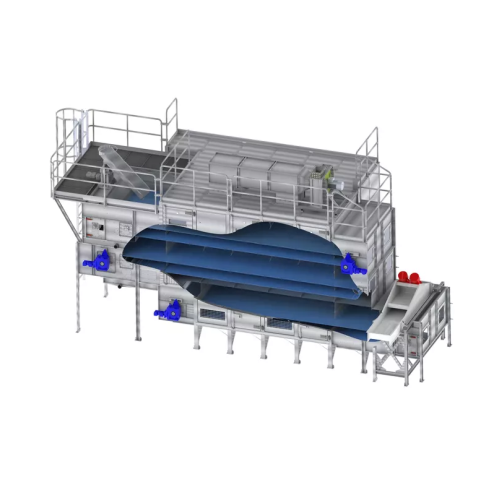

If you are looking to produce french fries or potato chips at scale, it is definitely recommended to opt for a fully automatic potato chips processing line. This potato chips line will incorporate all the necessary processes into one completely automated process. For example, a complete production line would include stainless steel cutters or cutting machines, peeling machines, blanchers, fryers, slicers as well as seasoning and packaging machines.

Processing steps involved in potato chips making

Which potato chips technology do you need?

Industrial tumble dryer for moisture control in snack production

Ensure precise moisture reduction and optimal air circu...

Industrial multi-pass dryer for bakery products

Ensure consistent moisture reduction and quality enhancement in your baker...

Fried snack extruder for potato rings

Efficiently produce a variety of fried snacks, from potato rings to ethnic noodles, w...

Dough thickness reduction system

Achieve precise dough sheet reduction with controlled thickness to enhance consistency and ...

Smart bakery oven zone for flexible heating

Optimize your production with flexible heat transfer options that enhance cont...

Emithermic zone for baking biscuits and cookies

Enhance your baking efficiency and precision with a flexible heat transfer...

Industrial direct drive mixer for dough preparation

Optimize your production line with a robust mixer designed for seamle...

Efficient dough dump station for bakery systems

Streamline your dough handling process with this advanced dumping station,...

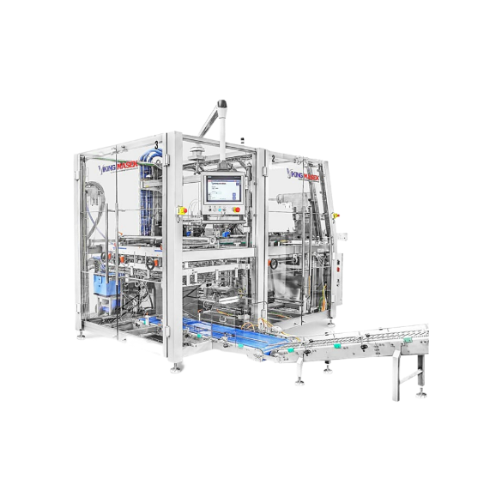

Intermittent motion end load cartoner for baked goods and home care products

Streamline your packaging line with high-...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

Pulsed electric field system for food preservation

Enhance your production line with technology that extends shelf life a...

Open frame mixer for bread and dough applications

Enhance baking productivity with a versatile mixer designed for efficie...

Medium duty mixer for dough preparation

Achieve perfect dough consistency across various products with a versatile medium d...

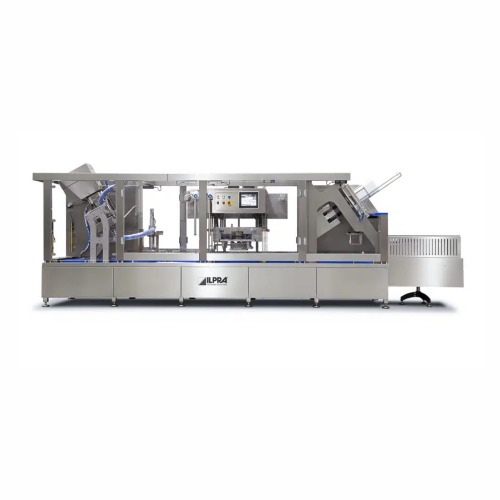

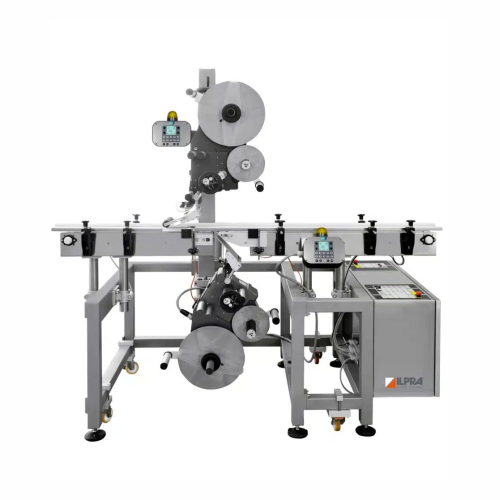

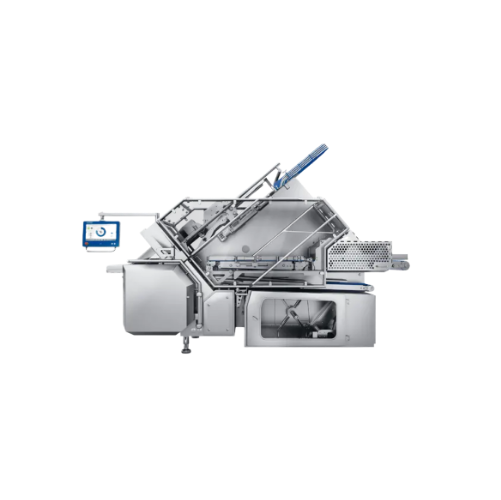

Automatic traysealer for food packaging

Optimize your packaging efficiency with this advanced traysealer, designed to enhan...

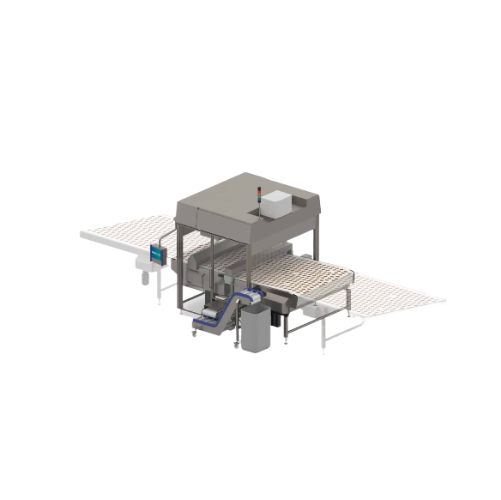

X-ray inspection system for food packaging

Ensure product integrity and safety with advanced detection of foreign bodies i...

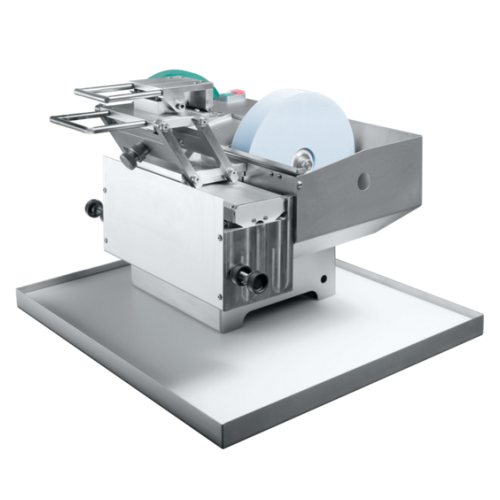

Label dispenser integration for packaging lines

Streamline labeling operations with precision and flexibility, ensuring yo...

Labelling and marking solutions on flowpackers

Achieve unmatched precision and flexibility in packaging with labelling and...

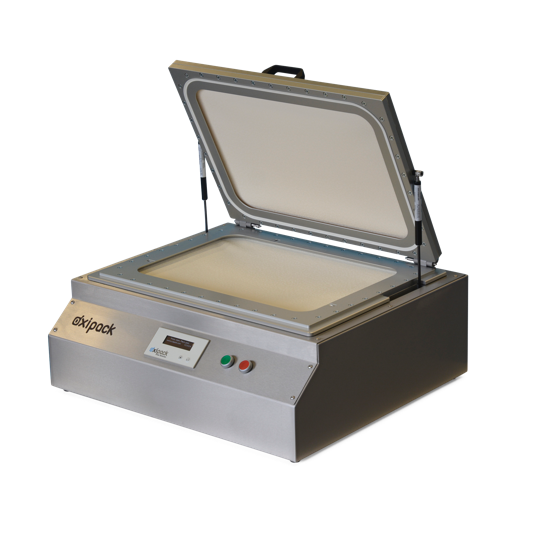

Vacuum packaging chamber for industrial products

Achieve consistent sealing precision and extended shelf life for diverse ...

Industrial shrink and drying units for food products

Ensure optimal product integrity and extended shelf life by seamless...

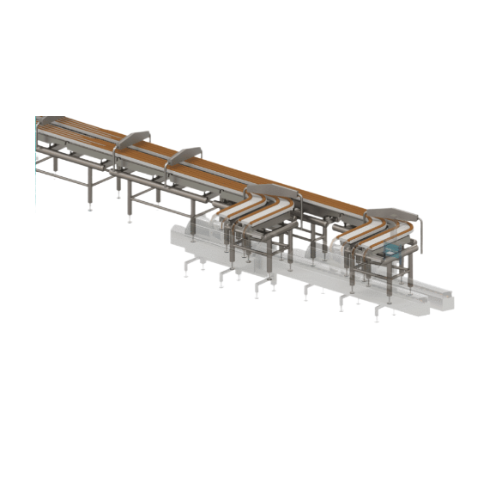

Mbs belt systems for seamless packaging integration

Optimize your packaging line with a system that seamlessly merges mul...

Automated conveyor systems for food packaging lines

Seamlessly integrate high-speed product transport and handling into y...

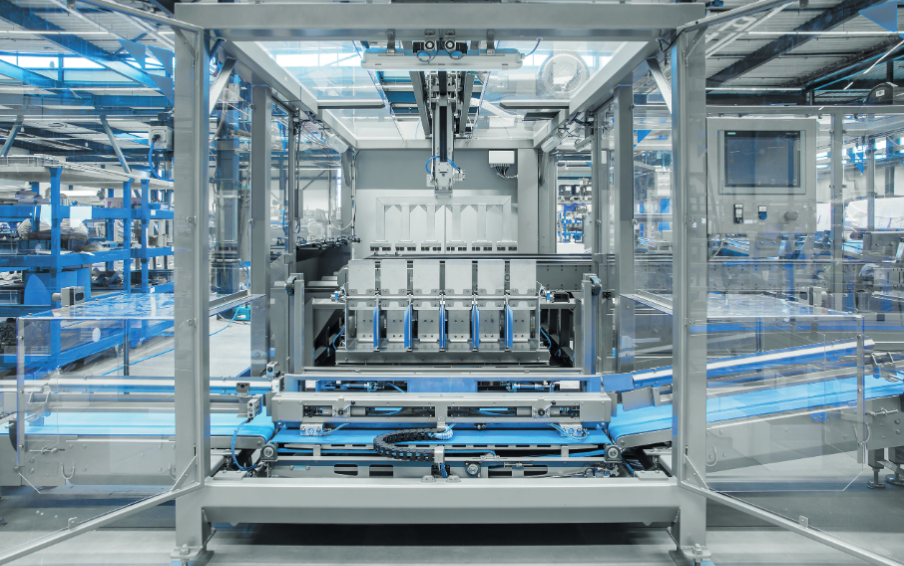

Robotic loading systems for packaging applications

Enhance your production line with versatile robotic loading systems, d...

Automatic checkweighers for precise weight control

Ensure accurate weight compliance and enhance quality control with adv...

Automatic onion peeler for industrial food processing

Optimize your vegetable preparation process with this machine that ...

Intermittent pick and place solution for stackable items

Optimize your production line with high-speed, intermittent oper...

Root crop peeler for high-volume processing

For efficient root crop processing, this robust peeler, washer, and scrubber e...

Root crop peeler and scrubber

Achieve efficient peeling and scrubbing of root crops while maximizing product recovery, makin...

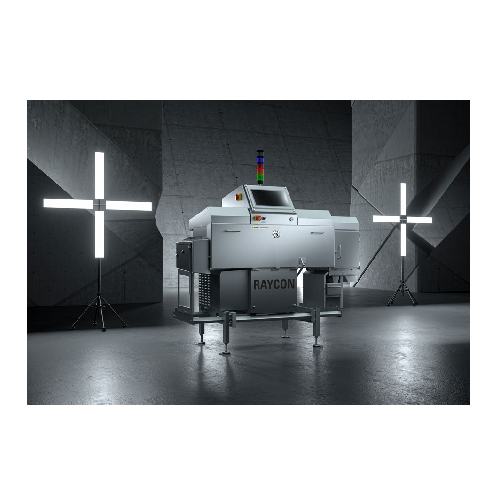

X-ray inspection system for large bulk products

Ensure consumer safety and product quality by efficiently detecting contam...

Industrial metal detector for food production lines

Ensure product safety and compliance by seamlessly detecting metal co...

Conveyorized food metal detector for high-care environments

Ensure food safety with advanced metal detection tailored fo...

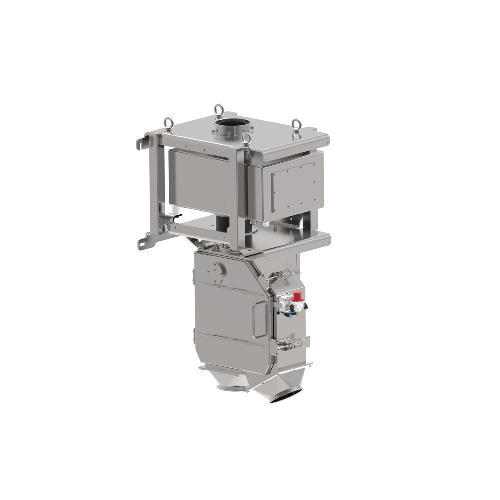

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

X-ray food inspection system for loose products

Ensure contaminant-free loose products by integrating a versatile inspecti...

Curtainless x-ray inspection for small lightweight packaged food products

Eliminate product damage and false rejects w...

Compact x-ray inspection system for food safety

Enhance food product safety with advanced x-ray inspection, targeting both...

Metal detector checkweigher combination system for food products

Simultaneously detect metal contaminants while ensuring...

Metal detector conveyor system for food safety

Ensure product integrity across high-speed production lines with robust met...

Cryogenic chilling system for meat processing

Ensure uniform temperature control in meat production lines to maintain prod...

Commercial vegetable peeler for potatoes and carrots

Efficiently integrate peeling and polishing vegetables into your pro...

Receiving hopper for jumbo boxes

Efficiently unload and handle bulk agricultural products with ease, streamlining your pre-p...

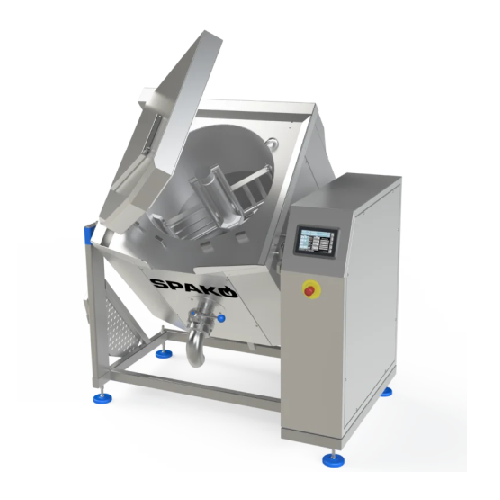

Industrial food mixer for vegetables and powder mixing

Enhance your production efficiency with a versatile mixer designed...

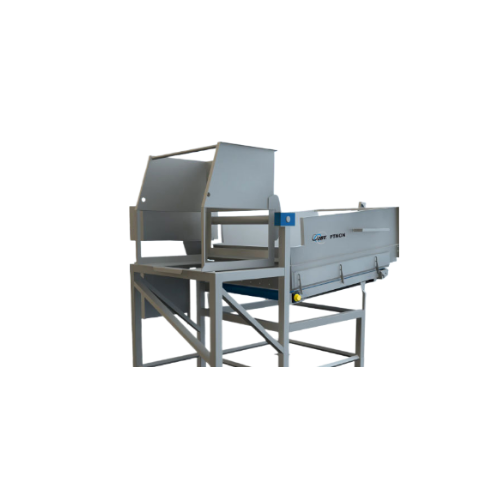

Inspection table for vegetables and fruits

Streamline your quality control with an efficient inspection table designed for...

Potato processing line for tubers

For food processors seeking efficiency, this semi-automatic line streamlines peeling, cut...

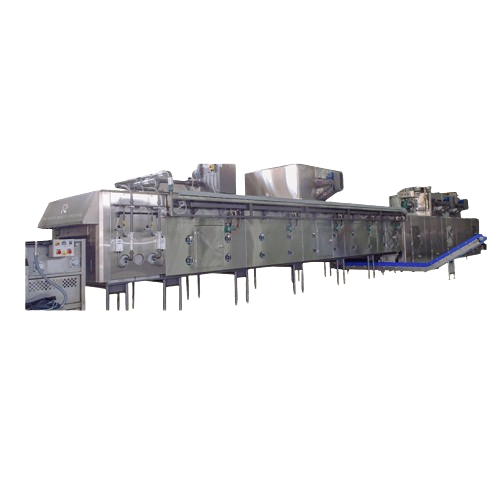

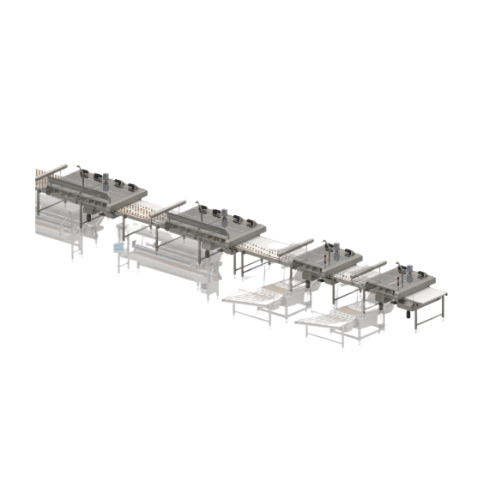

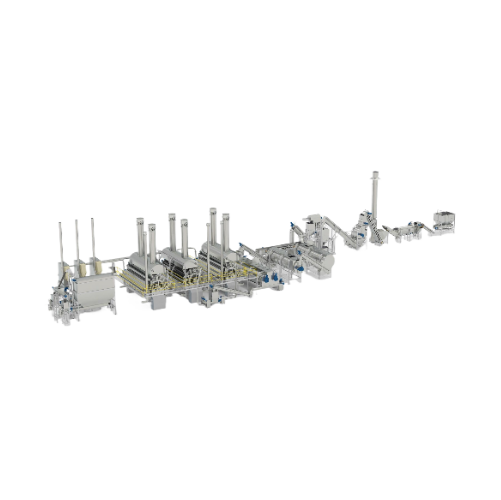

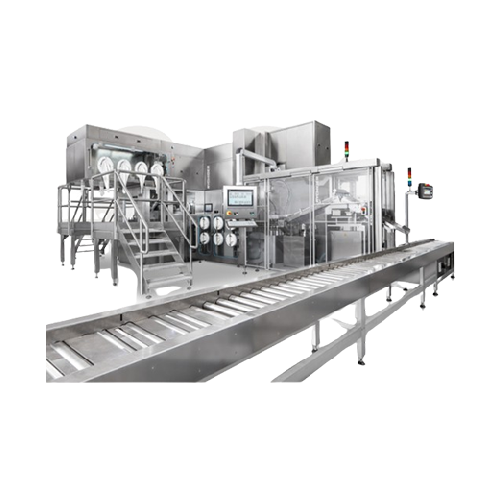

Potato chip production line

Achieve consistent, high-quality potato chips with a seamlessly integrated line that optimizes e...

Optical measuring and weighing instrument for peeled potatoes

Enhance your potato processing efficiency by precisely det...

Potato diameter sorter

Efficiently sort and pre-grade peeled potatoes by diameter to streamline your processing line and enha...

Industrial potato cutting system

Optimize your potato processing with precision slicing and cutting solutions designed for a...

Screw type blancher for potato products

Achieve precise temperature control and even water circulation to enhance your pota...

Steam peeling system for potatoes

Enhance your potato processing efficiency by reducing peeling time up to 25% while minimi...

Industrial potato flake production line

Maximize yield and quality in potato processing by integrating advanced pre-cleanin...

Formed mash processing line for potato products

Optimize your potato processing with this versatile line, designed for hig...

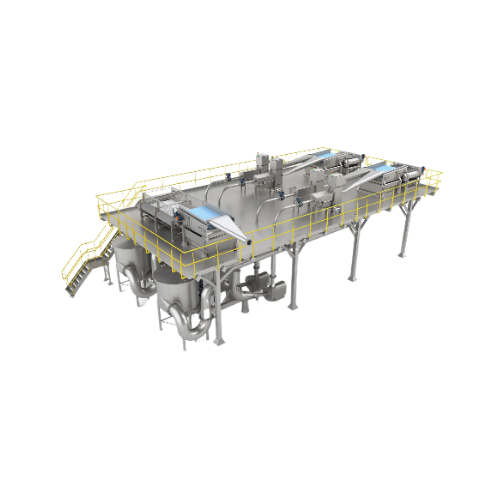

French fry and coated french fry processing line

Optimize every potato’s potential from pre-cleaning to frying with ...

Hash brown production line for formed potato products

Optimize potato processing with this advanced production line, tran...

Industrial cutting solution for potato products

Optimize your potato and vegetable processing with a versatile cutting mac...

Cyclone destoner for removing stones and clods

Ensure optimal pre-cleaning by removing stones and clods from potatoes effi...

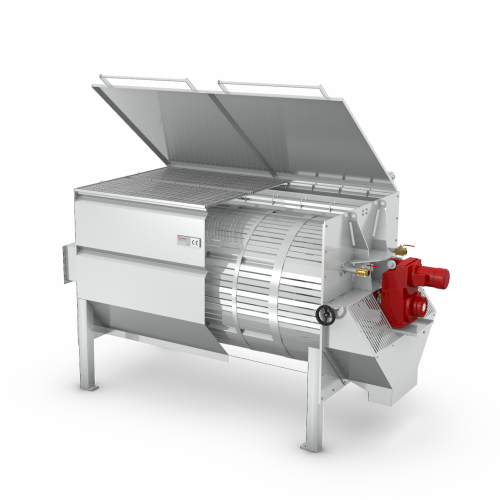

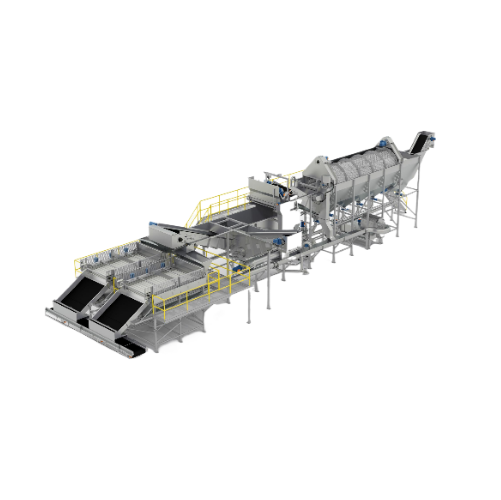

Potato drum washer for soil, clay, and sand removal

Ensure your potato processing line efficiently removes soil, clay, an...

Dry brush system for potatoes after steam peeling

Optimize your potato processing by ensuring consistent peel removal aft...

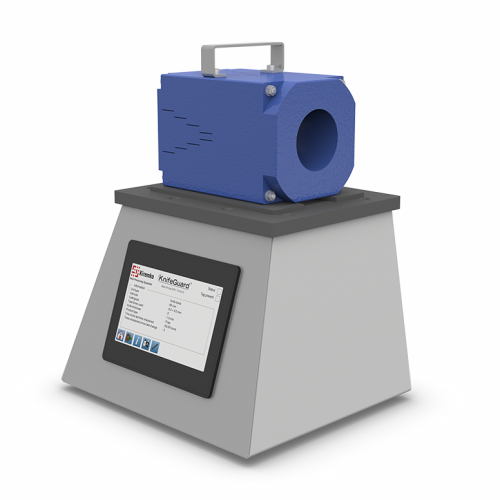

Innovative knife identification system for quadraflow hydro cutter

Ensure optimal cutting performance and minimize prod...

French fry length grader

Efficiently sort and standardize your potato products by length, optimizing your french fry producti...

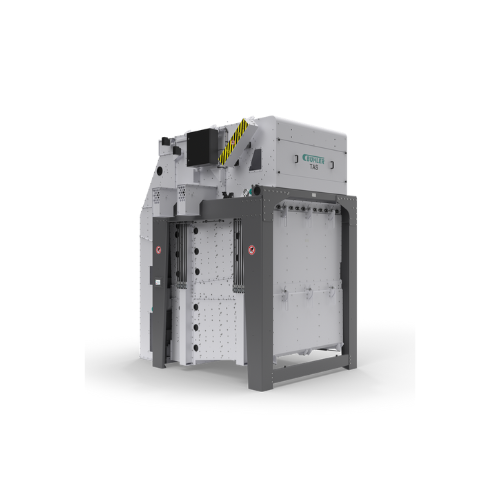

Rotary size grader for food processing

Enhance your production line by efficiently sorting and classifying produce to ensur...

Small piece remover for food processors

When handling diverse food products, ensuring consistent product sizing is vital. T...

Tote bin dumper for bulk product transfer

Streamline your bulk product handling with a solution that efficiently transfers...

High-performance food processing and sorting solutions

Optimize your production line with integrated processing, conveyin...

Food processing mixing system for vegetables

Tackle complex product mixing challenges with a system that seamlessly integr...

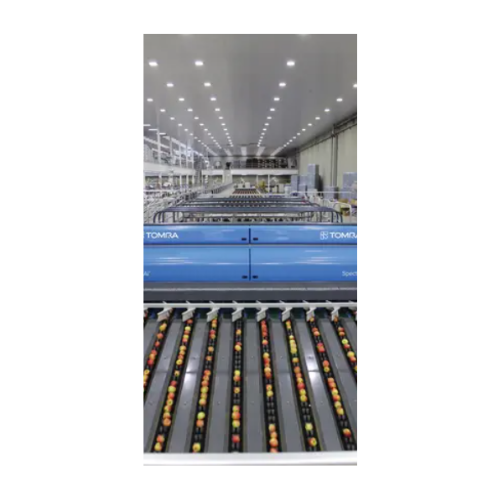

Optical sorting platform for food processing

For manufacturers aiming to enhance quality control, this platform offers pre...

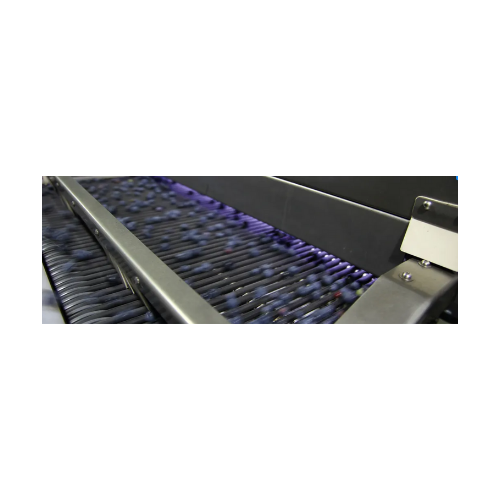

Optical sorter for blueberries

Enhance product quality and yield by precisely sorting blueberries, ensuring only optimal fru...

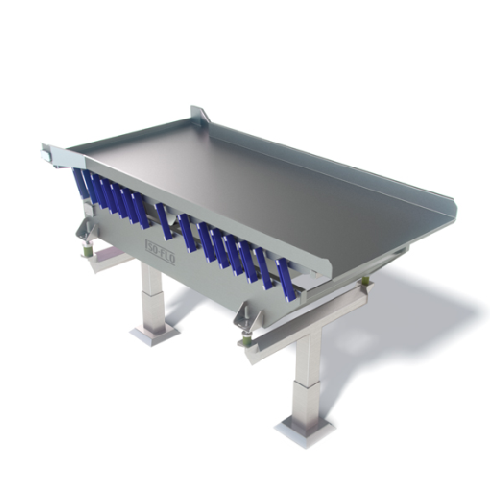

Large capacity horizontal motion conveyor for fragile products

Achieve gentle handling and minimize product damage with ...

Optical sorter for food processing

Enhance your production line with advanced sorting technology that meticulously inspects...

Distribution conveyor systems for food processing

Streamline your food processing pipeline with precision-engineered dist...

Feed conveyors for efficient product presentation

Optimize your production line with feed conveyors designed to streamlin...

Hydro-flo food processing pump for vegetable transfer

Optimize food handling with a gentle, space-saving pump that protec...

Industrial food grading system for vegetables

Optimize your production line with a versatile food grading system, ensuring...

High-capacity optical sorter for food processing

Optimize your production line with precise sorting and separation, enhanc...

Optical potato sorter

Ensure precise sorting with advanced optical technology that identifies and separates defects in a wide...

Optical sorting solution for food processing

Achieve precise sorting and maximize yield with a cutting-edge optical soluti...

Sorting system for blueberries

Streamline diverse food processing tasks by efficiently conveying, processing, and sorting pr...

Vibratory conveyor for efficient bulk material transportation

Optimize your processing line with robust vibratory convey...

Versatile cone mill for uniform size reduction

Achieve precise particle size consistency and gentle deagglomeration across...

Automatic defect removal for french fries

Maximize yield and enhance quality in potato strip production with precision cut...

Inspection systems for poultry and seafood processing

Enhance the quality control of your food production with cutting-ed...

Industrial air cleaner for food processors

Optimize your production line with high-speed air separation, effectively remov...

Collection conveyors for food processing

Optimize your production line by efficiently collecting and conveying solid produc...

Industrial cooking kettle for food processing

Achieve seamless integration of cutting, mixing, and cooking processes to cr...

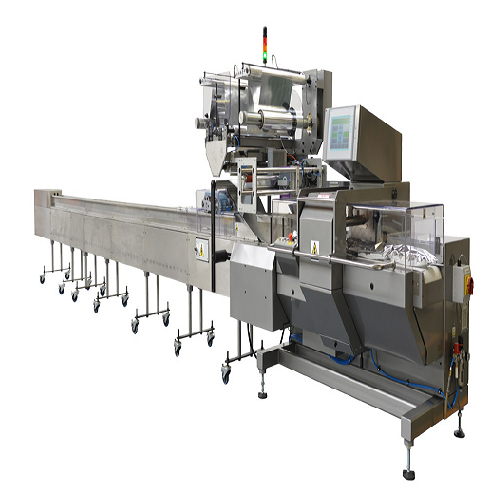

Entry-level flow wrapping machine for small and medium products

Optimize your packaging line with a high-speed flow wrap...

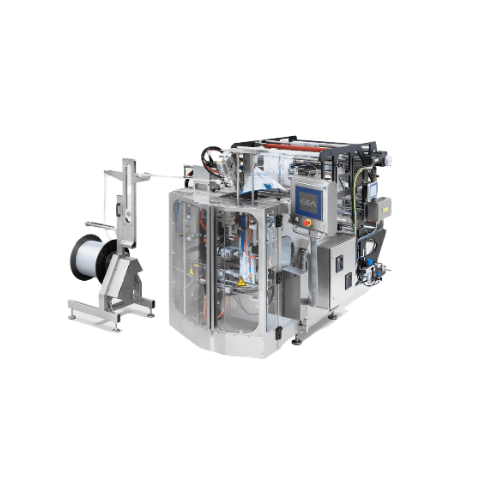

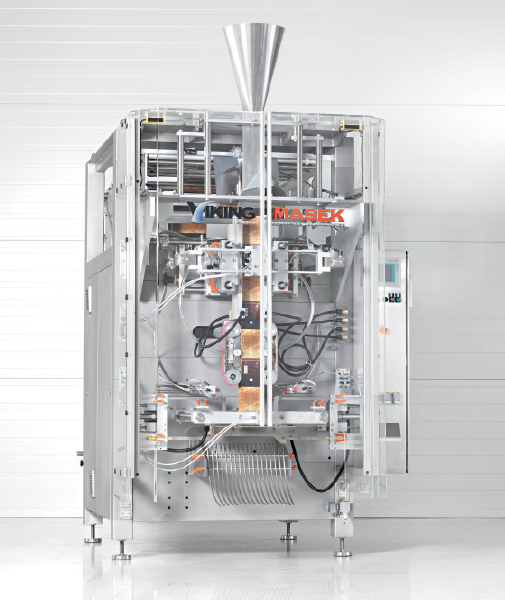

Vertical bagging system for heat sealing films and Lpde

Achieve unparalleled flexibility with a versatile vertical baggin...

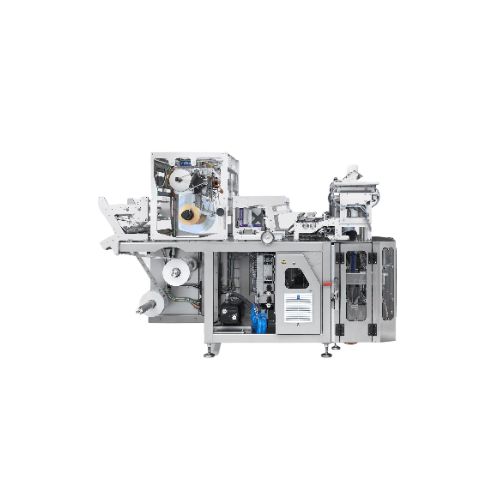

Horizontal form fill and seal for biscuits on edge

Optimize your packaging line with a machine that streamlines wrapping ...

Flexible flow wrapping solution for small and medium products

Enhance your production line with a versatile flow wrappin...

Flow wrapping solution for fresh produce and food products

Optimize packaging efficiency for irregular products with a v...

Continuous vertical form fill seal packaging solution

Experience unrivaled accessibility and efficiency in packaging fres...

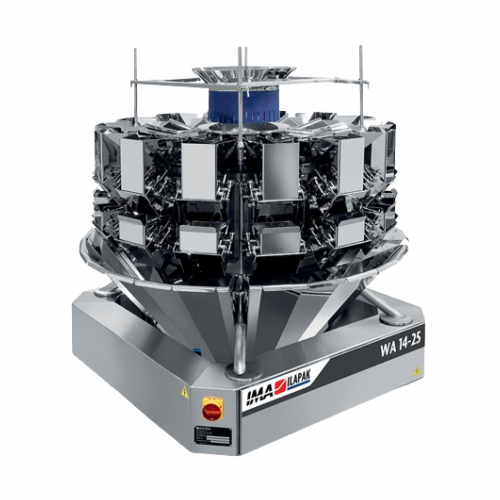

High precision multihead weigher for confectionery production

Achieve precise weighing and counting for varied product c...

High-speed multi-head weigher for confectionery products

Achieve precise measurements and minimize waste in high-speed fo...

Rotary doypack for granules, liquids, and powders

Enhance your packaging line with a rotary doypack system designed to ef...

Tray sealing machine for buckets

Ensure efficient sealing and preservation with high-speed tray sealing for various food pro...

Tray sealer for food packaging buckets

Enhance your packaging efficiency with a highly adaptable tray sealer, designed for ...

Tray sealer for packaged food products

Optimize your food packaging with precise sealing and advanced Modified Atmosphere P...

Traysealer for medium production

Streamline your packaging process with high-speed traysealing, ensuring freshness and exten...

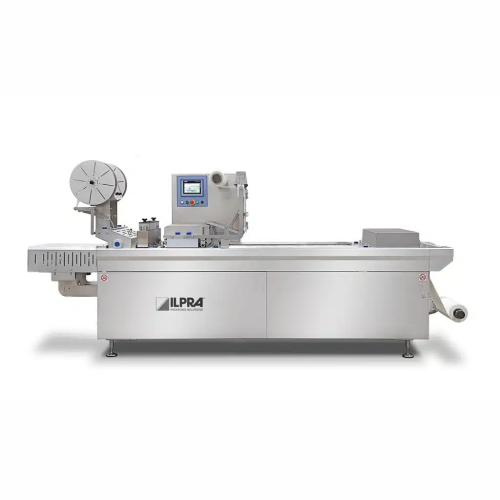

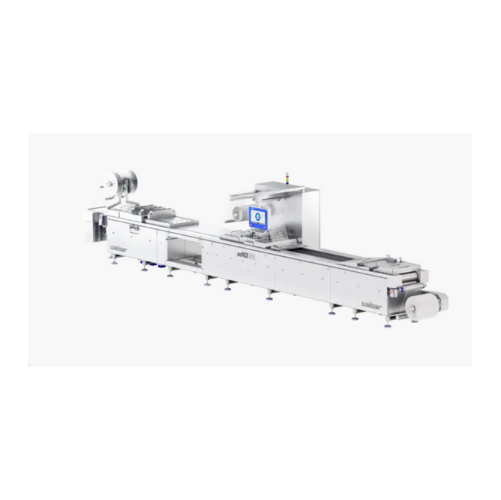

Thermoforming packaging solution for food and medical applications

Enhance your packaging line with a solution designed...

Compact thermoforming packaging system for food industry

Revolutionize your packaging line with a space-saving solution t...

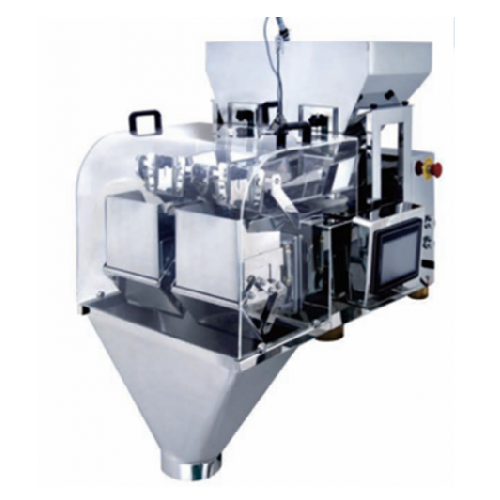

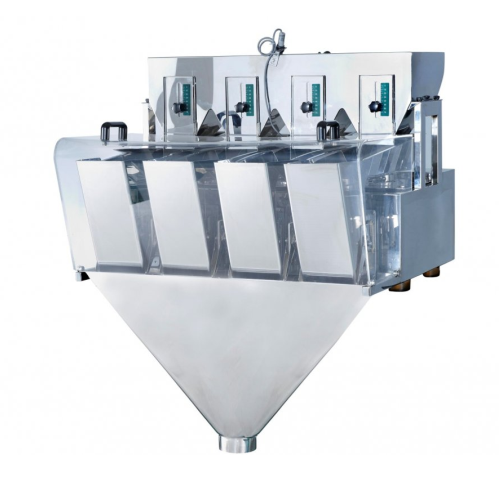

Linear and auger weighing systems for non-free-flowing products

Optimize your production line with precise weighing and ...

Metal detector for small to medium-sized products

Ensure product integrity and compliance by seamlessly integrating metal...

Multi head weigher for precise portioning

Ensure consistent product portions with our multi head weigher, ideal for high-s...

Vertical form fill seal for small to medium production runs

Ideal for scaling production, this compact packaging solutio...

Automatic c-wrap labelling for packaged products

Enhance your production line with precise C-wrap labelling, seamlessly in...

Automatic top & bottom labelling system

Enhance your packaging line efficiency by applying precise top and bottom labels to...

Top loading case packer for automated box sealing

Streamline your packaging line with a top-loading case packer that effi...

Industrial check-weigher for accurate product weight verification

Ensure precise weight compliance and reduce waste wit...

Rotary filler for optimized production processes

Streamline your fill and seal process with precise timing control and enh...

Entry-level in-line traysealer for ready-to-eat meals

Streamline your ready meal packaging with a compact traysealer that...

Semi-automatic tray sealer for skin packaging

Optimize your small-scale food packaging with a compact tray sealer designed...

Industrial pick and place system for packaging

Streamline your packaging line with precise robotic pick and place operatio...

High-speed continuous rotating packaging solution

Transform your packaging efficiency with versatile operations, accommod...

Traysealer for food packaging with rotating table

Enhance your packaging line efficiency with a traysealer that simultane...

Industrial metal detector for gravity feed applications

Ensure the purity of your products by detecting and removing both...

Ferrous-in-foil metal detection system

Enhance quality control for foil-packaged goods with precise ferrous metal detection...

Kettle chip fryer

Achieve consistent frying results and prevent chip clusters in kettle-style potato chips production with th...

Compact continuous fryer for food service applications

Streamline your frying operations with a compact continuous soluti...

Heavy-duty batch fryer for snack and prepared foods

Effortlessly transform diverse ingredients into high-quality fried pr...

Batch fryer for kettle-style potato chips

Achieve uniform kettle-style chips with our compact batch fryer, designed to opt...

Kettle fryer for batch potato chips

Ensure consistent quality and precise frying for your kettle-cooked chips with this the...

X-ray inspection system for contaminant detection

Detect and eliminate foreign contaminants in a wide range of food produ...

Metal detection and weight verification system

Optimize space and boost inspection accuracy by combining metal detection a...

In-line seal checker for high-speed snack packaging

Ensure flawless package integrity with in-line leak detection, enhanc...

Checkweigher for packaged goods inspection

Ensure precision and compliance with this high-speed checkweigher, perfect for ...

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

Truck dumping system for unloading bulk potatoes

Optimize unloading with precision-tilted truck dumping, reducing product ...

Vacuum fryer for high-sugar snacks

Eliminate the need for an external vacuum chamber while achieving perfect texture and re...

Universal fryer system for snack foods

Optimize your snack production with customizable frying modules that allow precise c...

Bucket conveyor for wet and dry free-flowing products

Seamlessly elevate, lower, or convey free-flowing products without ...

Vertical screw elevator for potato processing

Efficiently elevate and separate your produce while minimizing space with ou...

Multi-lane checkweigher for mixed-application production lines

Achieve precise weight verification across multiple lanes...

X-ray inspection system for identifying foreign bodies in food products

Ensure precise detection of foreign materials i...

X-ray inspection system for detecting foreign objects in food products

Ensure product safety and quality by detecting e...

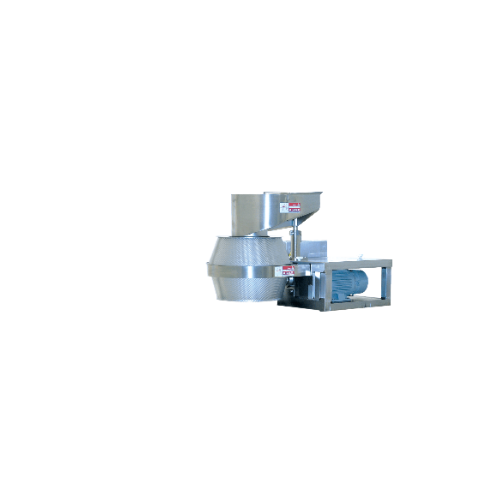

Rotary chip sizer for potato chips

Optimize your snack production with precise grading, ensuring consistent chip size while...

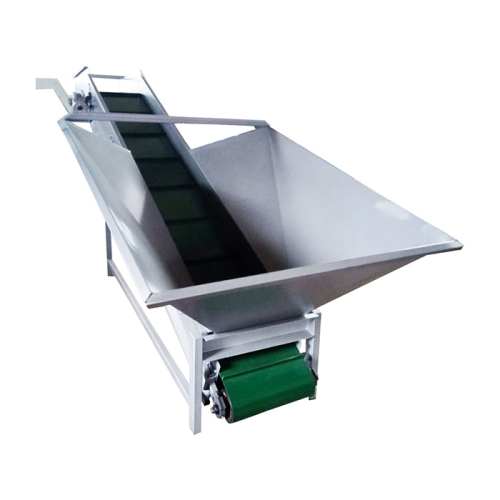

Potato chip production slicer feeder

Ensure optimal slicing and consistent chip quality with a feeder that delivers a stead...

Spiral oven for meat and poultry cooking

Experience even cooking and reduced processing times with a high-speed spiral oven...

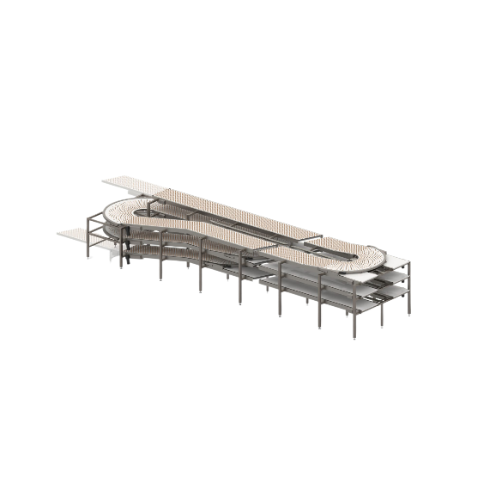

Accumulation conveyor for snacking industry

Optimize your production line with a space-saving accumulation conveyor that r...

Potato product surface oil removal system

Efficiently remove excess surface oil from fried potato products, enhancing prod...

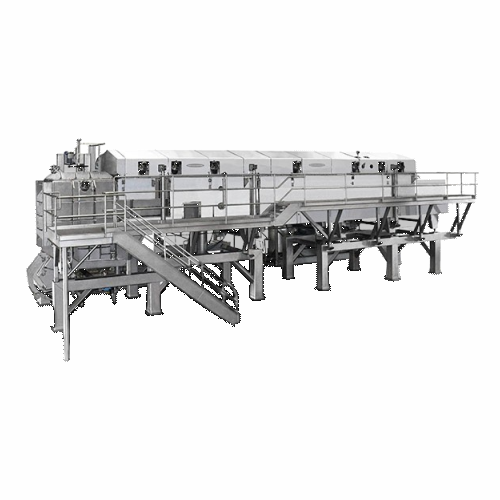

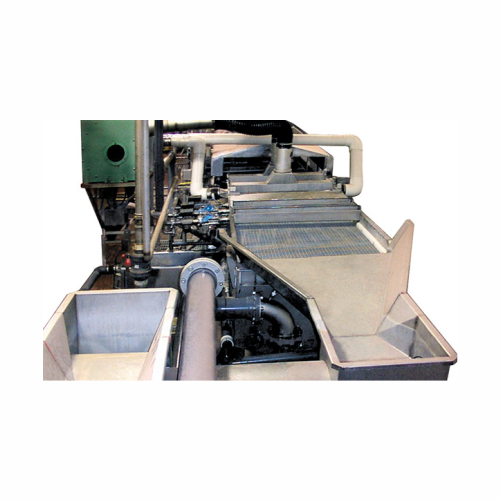

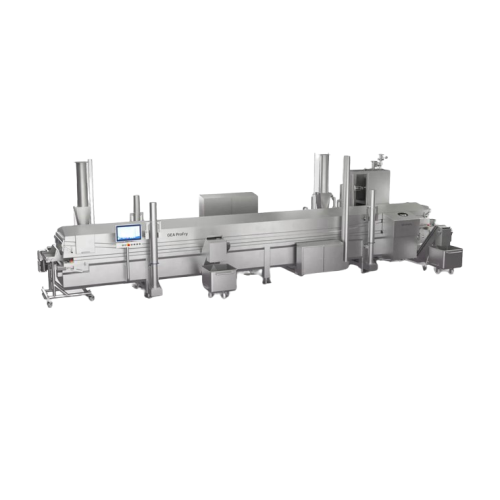

Industrial potato chip fryer

Enhance your snack food production with the Industrial Potato Chip Fryer, expertly designed for...

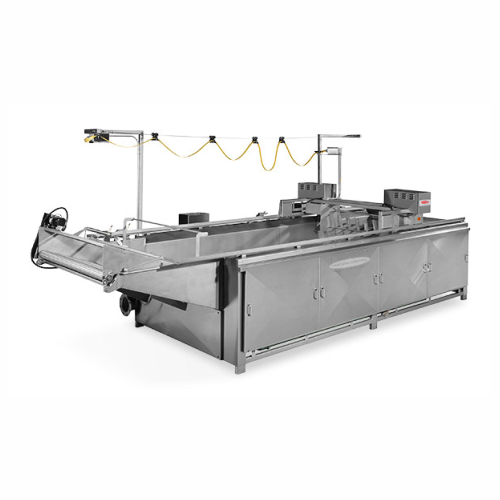

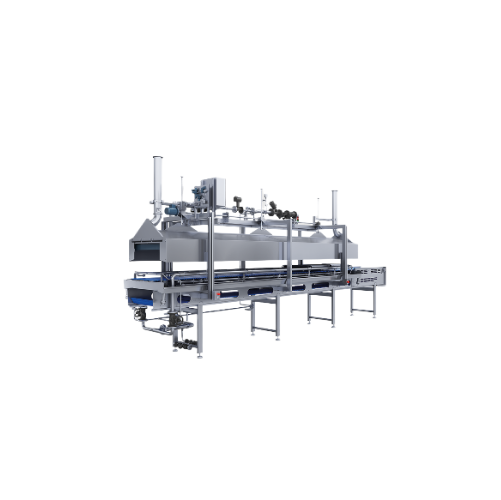

Potato slice speed washer for potato chips

Enhance your chip production line with a solution that efficiently removes star...

Potato slice washer conditioner

Ensure consistent texture and color in your potato chips by precisely controlling washing an...

On-machine seasoning system for potato chips

Achieve uniform seasoning coverage for various snack foods with minimal wasta...

Oil cooling module for industrial fryers

Quickly cool frying oil to prevent thermal shock and maintain oil quality, allowin...

Industrial oil mist eliminator

Optimize your frying operations with efficient oil mist control, minimizing emissions and vir...

Continuous french fry fryer

Achieve optimal frying conditions with precise temperature control and rapid load adjustments, e...

Gentle-flo storage and handling system for fresh produce

Ensure gentle handling and precise control of fresh produce stor...

Potato slice washer for surface starch and fines removal

Ensure optimal cleaning and dewatering of potato slices while si...

Industrial heat recovery system

Transform exhaust heat from fryers into usable energy, reducing operational costs and boosti...

Incline transfer conveyors for dry, fresh, and frozen food products

Efficiently transfer a variety of solid and granule...

Inspection conveyor for potatoes and vegetables

Streamline your defect removal and trimming process with a conveyor system...

High-efficiency heat exchanger for fryer systems

Optimize your frying line’s efficiency and environmental impact by ...

Crate dumper for potatoes and fresh produce

Ensure consistent produce flow with a robust hydraulic tilt system that stream...

Flexible fryer for various snack products

Optimize your snack production with a fryer that adapts to varied product requir...

Electroporation system for potato products

Optimize your potato and snack food production with an electroporation system t...

Energy recovery heat exchanger for fried food production

Harness otherwise wasted energy from your frying process to pre-...

Fabricated chip fryer

Achieve uniformity in stackable snack chips with a fryer that precisely controls temperature and oil le...

Slicer infeed conveyor for potato products

Enhance slicing efficiency by smoothly feeding potatoes into multiple slicers, ...

Multihead weigher for precise bulk product weighing

Optimize your weighing operations with highly accurate multihead tech...

Multihead weigher for food processing

Enhance production efficiency and accuracy with multihead weighing technology, offeri...

Industrial water removal system for food preparation

Enhance your production line with advanced surface water and starch ...

Automatic centrifuge for oil reduction in batch fried products

Optimize your batch frying process by effectively reducin...

Batch frying system for kettle-style potato chips

Achieve consistent, high-quality kettle-style potato chips with a syste...

Batch peeler for potatoes and root vegetables

Optimize your vegetable processing with precise peeling and polishing, ensur...

Batch-operated chamber dryer for surface drying

Enhance production efficiency with precise, low-temperature drying and coo...

Batch drying solution for industrial applications

Achieve precise and gentle moisture control in diverse production proce...

Rotary drum dryer for robust food products

Achieve uniform and gentle drying for sensitive and robust products alike with ...

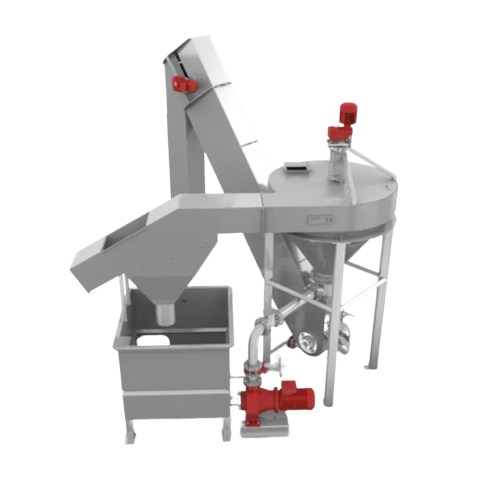

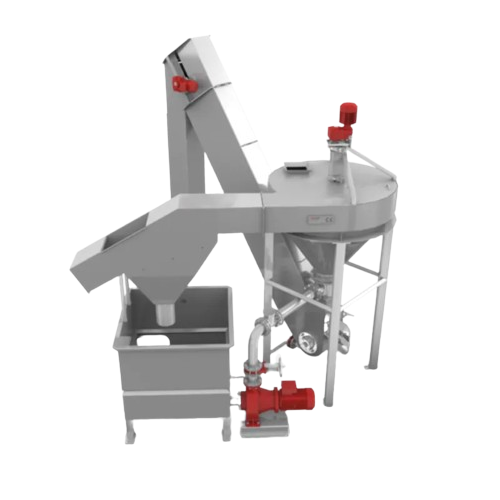

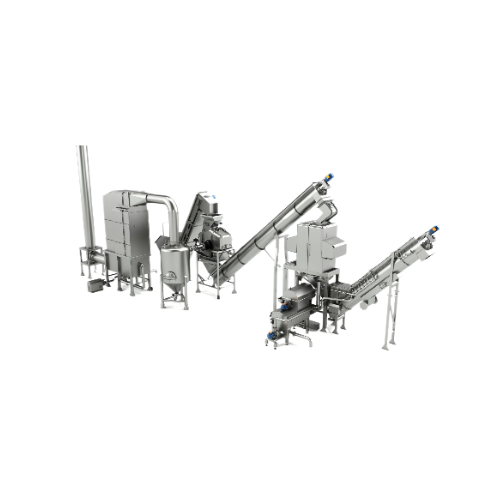

Additive mixing and dosing system for potato flakes

Achieve precise flavor and texture in potato flakes with this system,...

Drum dicer for french fry processors

Achieve precision in cutting fresh and frozen produce, maintaining optimal shape and s...

V-belt slicer for meat and fish

Achieve uniform, high-quality slices with minimal waste for any long- or oblong-shaped produ...

Vegetable and fruit dicer

Achieve uniform cuts and reduce waste in your food processing line with a versatile dicer designed...

Knife honing equipment for industrial use

Enhance blade precision with minimal effort and cost, ensuring your cutting tool...

Flat-belt slicer for fruits and vegetables

Optimize your slicing process with a solution that delivers precision cuts whil...

Honing tool for hydrocutting blades

Maintain the sharpness and precision of your hydrocutting blades effortlessly with this...

V-belt slicer for larger diameter leafy vegetables

Optimize your slicing operations with high-speed, precision cutting fo...

Potato slicer with dual rotation technology

Revolutionize your slicing process with dual rotation technology, ensuring gen...

Centrifugal shredder and slicer for vegetables and fruits

Achieve precise slicing and shredding with reduced waste and e...

Vegetable and fruit centrifugal slicer and shredder

Enhance your food processing with high-capacity slicing and shredding...

High-capacity shredder for cheese processing

Achieve impeccable cut accuracy and consistent shred dimensions for high-volu...

Cheese shredder for high-volume applications

Streamline your cheese processing with a high-capacity shredder designed to d...

Screen changer for extrusion lines

Prevent clogs and maintain quality with this screen changer, designed to filter out soli...

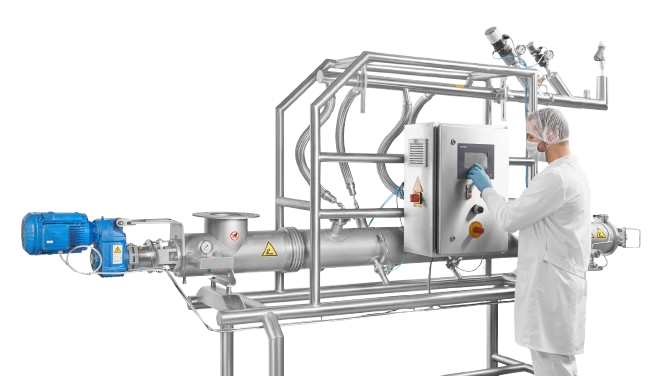

Pulsed electric field treatment for roots, tubers, and fruits

Enhance your production line with advanced pulsed electric...

Cell disintegration measurement tool for food products

Ensure precise measurement of cell disintegration across food prod...

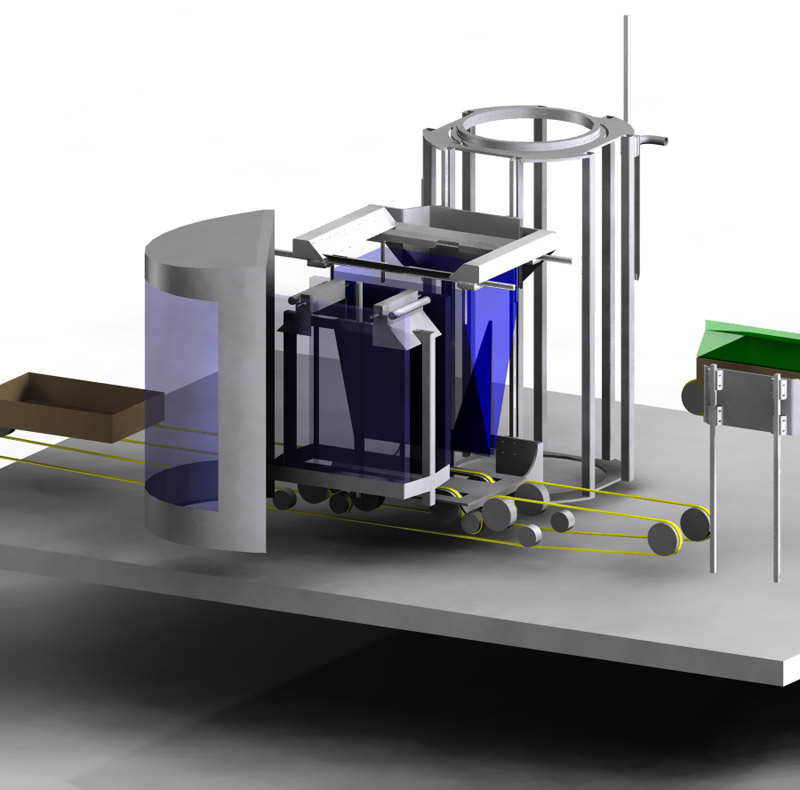

Modular pulsed electric field system for food processing

Enhance your food processing efficiency with a modular system th...

Precision quality control for potato and vegetable cutting

Optimize cutting precision and improve product quality by ins...

Cryogenic screw conveyor for food processing

Enhance your production line with a cryogenic screw conveyor that simultaneou...

Horizontal flow pack packaging solution

Achieve seamless packaging with versatile flow pack machines, designed to efficient...

Flow pack packaging system for flexible wrapping material

Achieve seamless, high-speed packaging of solid foods with thr...

Flow pack packaging for flexible wrapping material

Achieve precise and secure packaging with three-sided sealed packages ...

Three-side sealing packaging machine

Achieve precise, three-side sealed packaging for both food and non-food products, enha...

Electric cooker for preserved food preparation

Efficiently streamline your preserved food production with a multifunction ...

Multi-station modified atmosphere packaging system for bulk products

Optimize your packaging efficiency with a system d...

Vertical form fill seal packaging for high washdown environments

Ensure optimal packaging in demanding environments with...

Horizontal screw loader for food processing

Optimize your production flow with a smooth-loading solution designed to effic...

Inclined screw loader for food processing

Optimize your food processing line with an inclined screw loader, designed for e...

Pallet lift for food processing handling

Enhance your food processing efficiency with a robust pallet lift designed for sea...

Bulk material mixer for high-speed homogenization

Achieve fast and gentle homogenization of bulk materials with a high-sp...

High-speed packaging system for flow-wrapping

Streamline your packaging operations with a high-speed flow-wrapping solutio...

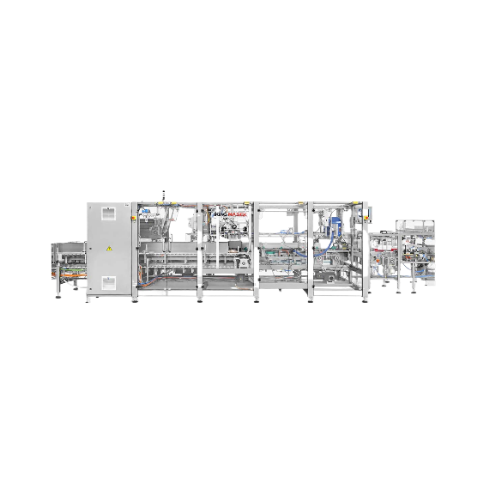

High-speed horizontal case packer for shipping cases

For high-demand production lines, this modular case packer streamlin...

Wafer block spiral cooler

Enhance your confectionery production with a modular spiral cooler that ensures gentle handling an...

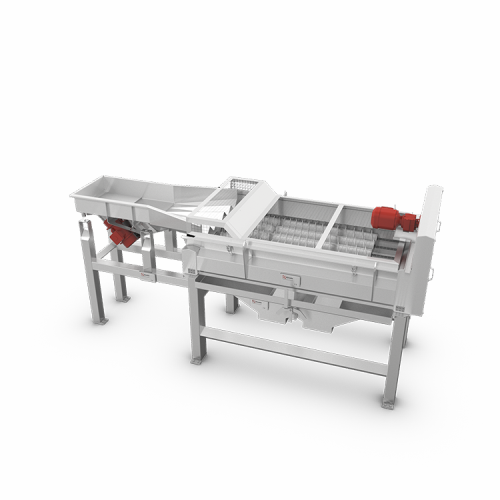

Grain cleaning system for high-quality processing

Optimize your grain processing with a versatile cleaning system designe...

Efficient grain destoning and concentrating system

Optimize your grain processing with a solution that ensures precise se...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Four-roller and eight-roller mill for wheat and grain grinding

Optimize your grinding operations with this versatile rol...

Optical sorter for grains, seeds, and plastics

Enhance sorting efficiency with cutting-edge optical technology that distin...

Premixer for confectionery masses

Achieve consistent ingredient blending with precision-premixing for candy and baked goods...

Sieve tensioning device for milling applications

Achieve precise and consistent tensioning across various sieve frames wit...

Micro loss-in-weight scale for precise dosing

For precise control over micro-component addition, this technology ensures c...

Cooling conveyor for baked goods

Efficiently adapt your baked and confectionery goods to ambient conditions, ensuring optima...

Heavy-duty trough chain conveyor for high throughput applications

Optimized for high-capacity operations, this robust c...

Twin-screw extruder for breakfast cereals production

Enhance your product range with flexible twin-screw extrusion techno...

Four-roller and eight-roller mill for grains

Optimize your grain processing with precise roller configurations, ensuring c...

Discharge station for bags and big bags

Ensure consistent material flow and hygiene in your production line with a versatil...

Control systems for wet grinding industry

Enhance precision and efficiency in your production line with advanced control s...

Digital process service for regulating water in dough preparation

Achieve consistent dough moisture levels with this di...

Vertical conveyor for bulk materials

Optimize your handling of bulk materials with a cost-effective solution that ensures h...

Optical sorter for wheat applications

Effortlessly enhance product purity by eliminating color defects and foreign material...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Industrial plansifter for grain sifting and grading

Optimize your production line with precision grain separation, mainta...

Chain conveyor for grain handling

Optimize your production line with a customizable chain conveyor that ensures efficient, ...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

Ultra-fine pulverizer for aqua feed and pet food

Achieve precise granulation with high efficiency for your feed and food p...

Industrial fine grinding pulverizer

Achieve consistent fine granulation at high capacity with reduced energy consumption, u...

High-capacity horizontal conveyor for bulk storage

Optimize your high-speed bulk material handling with a durable and eff...

Compound rolling unit for dough sheets

Achieve unparalleled precision in dough formation with our high-speed compound rolli...

Lab-scale twin screw extruders for material development

Accelerate your formulation testing and material development with...

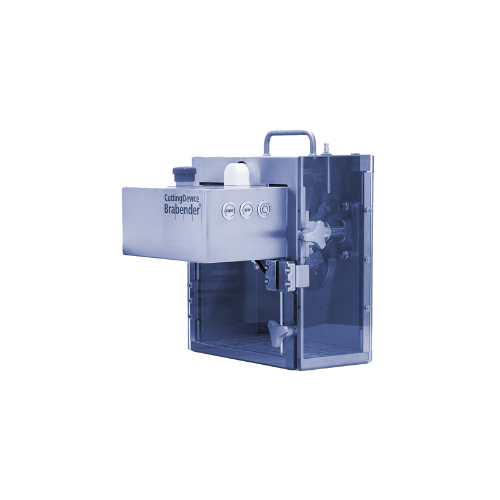

Laboratory cutting device for extrudates

For precise shaping of snack or feed extrudates, this compact cutting solution ens...

Evaporators for fruit and vegetable juices and purees

Optimize your juice and puree production with advanced evaporators ...

Frozen product cleaning and sizing system

Achieve precise cleaning and sizing of frozen goods effortlessly, enhancing prod...

Vibrating tables for dewatering and sizing

Optimize your processing line with versatile vibrating tables designed to effic...

Drum blancher for continuous cooking and blanching

Optimize your production line with a continuous drum blancher, designe...

Gravitational destoner for potatoes

Efficiently remove unwanted stones and debris from your potato and vegetable processing...

Vertical destoner for removing stones from vegetables

Ensure clean and debris-free produce with a high-speed vertical des...

Drum washing system for tubers and roots

Ensure thorough cleaning and desoiling of tubers and root vegetables with a high-e...

Steam peeler for potatoes and fruits

Enhance your processing efficiency with innovative steam peelers designed for high-spe...

Abrasive peeler for potatoes

Efficiently remove peels from potatoes and vegetables with abrasive rollers designed to enhance...

Top load and side load case packer with vision guided robotics

Optimize packing efficiency and flexibility with a versat...

Case packing system for bags and cases

Streamline your secondary packaging process with a compact, fully integrated system ...

Wrap around case packer for horizontal and vertical packing patterns

Optimize your palletizing and distribution with a ...

High-speed case packer for snack bags

Optimize your packaging efficiency with a compact solution designed for seamless vert...

Automated retail ready case closer

Optimize your retail packaging process with a solution that seamlessly seals and closes ...

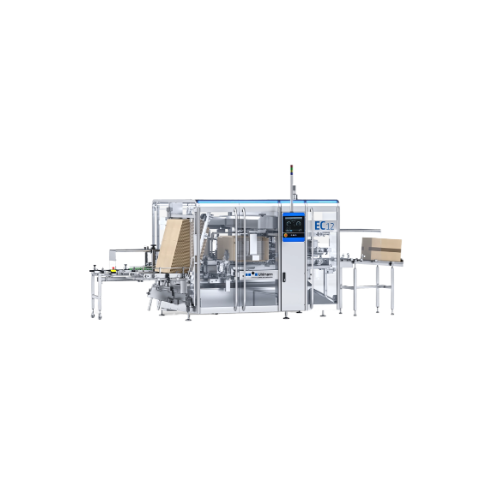

Horizontal load carton erector for food production

Enhance your production line with precise carton erecting, loading, an...

Semi-auto case packer for flexible bag collation

Enhance your manual packing speed and flexibility with a semi-automatic s...

Flexible bag case packer with integrated case erector

Streamline your secondary packaging process with an efficient solut...

High-speed vertical and horizontal case packer

Enhance your packaging line efficiency with a versatile case packing soluti...

High-speed case packer for flexible bags

Streamline your packaging process with a solution designed for high-speed, error-f...

Full Rsc case shaker-compactor-sealer

Streamline your packaging line with a solution that compacts and seals cases to elimi...

Tray erecting system for various tray styles

Effortlessly configure diverse tray styles with an efficient system designed ...

Automatic case forming and sealing solution

Streamline your end-of-line packaging with a solution that forms, folds, and s...

Retail ready packaging system for easy store stocking

Simplify shelf stocking with a sturdily designed packaging system t...

V shape mixer for solids and powders

Ideal for preserving the delicate structures of fragile materials, this mixer ensures ...

Double shaft paddle mixer for solids and powders

Achieve unparalleled mixing precision for fragile and diverse materials w...

Automated quality control for food packaging

Ensure seamless quality control with real-time inspections, serialization, an...

Checkweighers for medium and small products

Ensure precise weight control in high-speed production lines with advanced che...

Contact drum dryer for industrial food and chemical processing

Optimize your drying process with a contact drum dryer th...

Multipack wrapping system for snacks

Streamline your snack packaging process with a machine engineered for high-speed, effi...

4-side seal horizontal form-fill-seal packaging system

Streamline your confectionery and snack packaging with high-speed,...

Fluidized bed dryers/coolers for bulk material processing

Achieve high-efficiency drying and cooling of bulk materials i...

Turnkey filling lines for packaging solutions

Optimize your production line with our turnkey filling solutions, designed t...

Gravimetric filling solution for inconsistent density products

Achieve precise weight accuracy in your filling processes...

Automatic granular product weighing system

Effortlessly achieve precise fills for dry granular products and powders while ...

Electric bin tipper system for food processing

Achieve consistent product flow and minimize manual handling with this adva...

Industrial oil filter for frying sediment removal

Enhance frying efficiency and product quality by removing fine sediment...

Vibratory spiral elevator for vertical transport

Achieve efficient vertical transport with precise temperature control, su...

Continuous motion packaging for short-cut pasta

Optimize your packing line with a high-speed solution designed for efficie...

Intermittent motion bulk packaging for pasta and granular products

Optimize your production line with precision packagi...

Packaging system for short-cut pasta and dry granular food

Streamline your packaging process with a versatile system des...

Eco-friendly vertical packaging for pasta

Reduce plastic waste and enhance sustainability in pasta packaging with high-spe...

Vertical packaging system for fragile food products

Handle delicate food items like pasta nests and bakery products with ...

Industrial predryer for humidity reduction in food processing

Ensure optimal shelf life and prevent product sticking wit...

Industrial cooling system for packaging temperature control

Achieve precise temperature control and maximize energy effi...

Industrial pasteurizer for efficient bacterial reduction

Ensure your food products are safe with an industrial pasteurize...

Industrial spiral cooler for thermal treatment

Improve your final conditioning and packaging process with a spiral cooler ...

Extruder for short-cut pasta and lasagna production

Achieve seamless pasta and snack production with an extruder designed...

Surface drying system for pasta production

Ensure optimal surface drying of pasta and snacks post-pasteurization, preventi...

Batch standing mixer for dough preparation

Enhance your mixing precision with a batch standing mixer that optimizes paddle...

Water cooker for fresh pasta processing

Enhance cooking precision and product quality with this water cooker, designed to c...

Automatic continuous mixer for dough preparation

Streamline your production line with a mixer that ensures precise dosing ...

Industrial fryer for pork, poultry, and seafood

Enhance your production line with a fryer that ensures consistent, high-qu...

Industrial food processing fryer

Ensure consistent frying quality and enhanced sediment removal for high-volume food product...

Vertical form-fill-seal for pillow bag packaging

Looking to enhance the speed and reliability of your packaging process? T...

Vertical pouch packaging system for food products

Achieve high-speed, precise packaging with our vertical pouch system, i...

High-speed vertical packaging system for candy and snacks

Achieve up to 500 pillow bags per minute with our high-speed p...

Vertical form fill sealer for high-speed packaging

Achieve consistent, high-speed packaging with flexible bag styles, per...

Single-screw extruder for pre-gelatinized materials

Streamline your production of snack pellets and instant noodles with ...

Sterilization of concentrated food products using direct steam

Achieve rapid and efficient sterilization with direct ste...

Cookie arrangement system for packaging

Enhance your packaging efficiency by seamlessly arranging and loading diverse confe...

Vision-based product inspection system for rejecting defective items

Enhance your production line efficiency by ensurin...

Product manipulation and stacking systems

Efficiently transition products from flat to stacked on a conveyor while minimiz...

Vibratory buffer system for line efficiency

Enhance your production line by efficiently managing downstream stoppages and ...

Fifo inflow buffer for efficient production lines

Optimize your production flow with a solution that seamlessly absorbs d...

Tray buffering system for downstream absorption

Handle production line disruptions effortlessly by temporarily absorbing t...

High-volume product distribution system

Efficiently manage high-volume snack and confectionery production flows with a syst...

Conveyor system for ambient product cooling

Ensure precise cooling of baked and confectionery products while maintaining l...

Pv processing vessels for liquid and cream mixing

Optimize your mixing operations with versatile processing vessels desig...

Twin shaft mixers for fragile and high throughput applications

Maximize mixing efficiency and protect delicate materials...

Industrial mixers for hire

Optimize your production line with versatile mixers designed for precision blending, heating, and...

Convection roaster for pet food and delicate food products

Achieve optimal texture and moisture control in delicate food...

High-performance slicer for food processing

Achieve precise and consistent slices for your diverse range of food products ...

High-performance slicer for variety of meat products

Elevate your slicing precision with a high-speed system designed for...

Precise weight determination system for up to four lanes

Achieve consistent portion control and ensure quality standards ...

Automated cold cuts loading system

Optimize your production line with a flexible side loading solution designed for precise...

Automatic infeeder for cold cuts

Ensure seamless integration of portioned products into your packaging line with this compac...

Automatic underlay system for food products

Efficiently placing paper or film underlays beneath food slices optimizes port...

End-of-line converging solution for food packaging

Streamline your food packaging line with compact converging robots tha...

Thermoforming packaging solution for medium production volumes

Optimize your medium-volume packing with a compact thermo...

Automated insertion system for food processing

Streamline your food processing line with this versatile solution, designed...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

Planetary mixers for baking and food industries

Achieve precise mixing and consistency across a range of products with adv...

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

Continuous motion vertical form fill seal packaging system

Achieve high-speed, consistent packaging for diverse products...

High-speed vertical form fill seal packaging machine

Optimize your packaging line with this high-speed vertical form fill...

Vertical form fill seal for large bag packaging

For operations requiring precise, large bag packaging, this equipment ensu...

Endload automatic cartoning solution

Streamline your packaging line with this versatile cartoning solution, perfect for eff...

Top load cartoner for various carton shapes

Optimize your production line with a versatile cartoning solution, perfect for...

Topload cartoner for packaging cartons

Efficient flap closing for diverse carton sizes, ensuring gentle handling of sensiti...

Automatic rotary filler and sealer for premade pouches

Enhance your production line efficiency with a dual-lane system th...

Automatic rotary premade pouch filler for food products

Enhance your packaging line with a high-speed solution designed t...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Support structures for packaging lines

Enhance safety and efficiency in your production line with robust support structures...

Modified atmosphere packaging solutions for perishables

Extend the freshness and shelf life of perishable goods with prec...

Industrial printers and labelers for packaging

Ensure precise package identification and traceability with robust printing...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Robotic packaging integration for automated systems

Enhance your production line efficiency with seamless robotics integr...

Sleeve cartoners for ready meals and salads

Optimize your packaging line with a high-speed sleeve cartoner designed to eff...

High-performance tray erector for packaging

Streamline your packaging process with a versatile tray erecting machine that ...

Segment cutter for potatoes and carrots

Achieve precise cuts on vegetables like carrots and potatoes with minimal featherin...

Slicer for food processing applications

Efficiently achieve precise cuts and textures for a variety of food products, enhan...

Knife honing system for food processing blades

Optimize your slicing and dicing operations with precise edge sharpening, e...

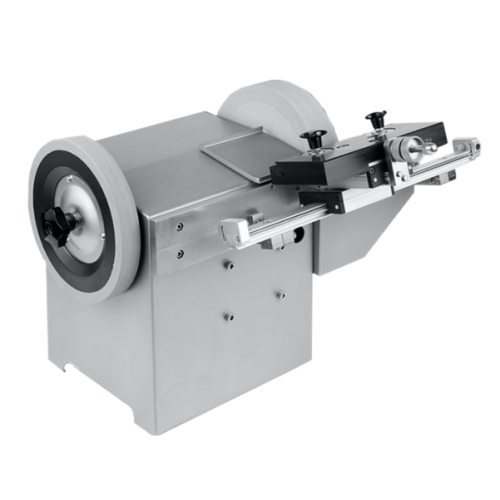

Knife sharpener for urschel slicing and crosscut blades

Extend your knife life and reduce replacement costs with a bench-...

Watergun cutting head for high-volume operations

Optimize your processing line with this precision watergun cutting head, ...

Industrial slicer for precise food cuts

Maximize your food processing efficiency with an industrial slicer that offers unpa...

Industrial dicing solution for food products

Enhance processing efficiency with high-speed dicing and slicing solutions, e...

Single piston food filler

Achieve precise portioning and consistent product flow with a versatile solution perfect for handl...

Vertical packaging system for medium-high speed applications

Optimize your packaging line with a system that delivers pr...

Side seal shrink packaging machine

Achieve seamless and efficient packaging for varied product sizes with continuous side s...

Flow pack wrapper for shrink and film wrapping

Optimize your packaging operations with a versatile solution capable of hig...

Horizontal flow wrapper for bakery and chocolate

Achieve seamless integration in high-speed production lines with a horizo...

Automated feeding and packaging line for crackers

Optimize your cracker production with seamless integration of high-spee...

Potato cutting line for high-quality potato products

Achieve precise cuts and optimized yields in potato processing with ...

Turnkey potato flake processing line

Effortlessly transform raw potatoes into high-quality flakes with this integrated line...

Potato peeling line

Optimize your peeling process with precision steam technology that reduces peel loss and enhances product...

Industrial potato washing line

Optimize your potato processing with a versatile washing line that ensures thorough cleaning,...

Pneumatic potato cutter for precise slicing

Achieve consistent and precise cuts for high-volume potato processing with pne...

Vacuum sealing system for glass jars with metal lids

Efficiently vacuum seal glass jars with metal lids to transform pres...

Professional vegetable cutter for food service industry

Optimize vegetable prep efficiency with a versatile cutter that d...

Optical sorter for nuts, dried fruit, and Iqf

Ensure flawless quality control by efficiently sorting, grading, and ejectin...

Belt sorter for potatoes and leafy vegetables

Enhance the precision and efficiency of your sorting process with a system d...

Optical sorter for nuts and dried fruit

Enhance sorting precision by effortlessly identifying and removing foreign material...

Steam peeler for vegetables and fruits

Optimize your food processing with a versatile steam peeling solution that efficient...

Steam peeler for vegetables

Optimize your peeling process with a versatile steam peeler that minimizes waste and enhances th...

Advanced food sorter for tomatoes and peaches

Achieve precise sorting and defect removal for a variety of food products, e...

Single and dual lane sorters for fresh produce

Optimize your food processing line with precision defect detection and vers...

Intelligent optical fruit sorting and grading system

Enhance product quality and reduce waste with cutting-edge optical s...

Optical sorting solution for root crops

Remove foreign materials from root crops effortlessly while ensuring high throughpu...

Color sorter for small fruits

Optimize your production line with a high-speed color sorting solution that enhances quality c...

Industrial steam peeler for potatoes

Optimize peeling efficiency while minimizing waste and energy usage with this high-spe...

Cherry sorting system with deep learning technology

Boost your fruit processing efficiency by utilizing advanced deep lea...

Blueberry sorting and grading system

Enhance your fruit processing line with a cutting-edge system designed for precision s...

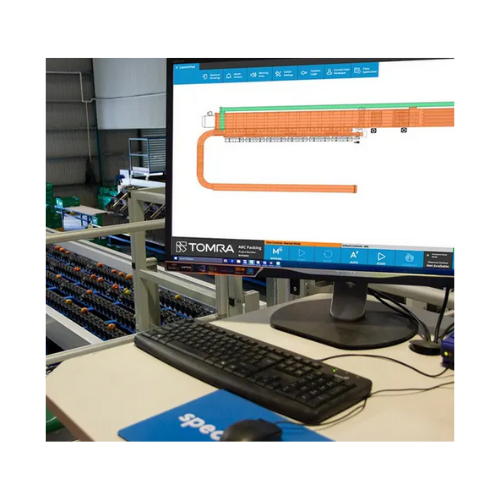

Line control and product tracking systems for post-harvesting

Optimize your production line with precision control and r...

X-ray detection for food inspection

Ensure product integrity in high-speed packaging lines by detecting metallic and non-me...

Industrial metal detector for food and beverage applications

Ensure your production line is free from metal contaminants...

Twin product multihead weighing system for mixing and sorting

Optimize your production line with precision mixing and hi...

Modular linear packing system for granular products

Streamline your packing operations with a versatile system that integ...

Modular packing system for multihead weighing

Streamline your production with a versatile multihead system designed for pr...

Multihead weighing system for dry free flowing products

Optimize your packaging line with precise weight measurements for...

Multihead weighers for food production

Optimize your food production line with precision and speed by integrating advanced ...

multihead weigher for dry products

Optimize your production line with precise weighing for dry products, ensuring high-spee...

Linear weigher for accurate food portioning

Ensure precise weight control for snacks and confectioneries with our advanced...

Linear weigher for dry free-flowing products

Optimize your packaging line with precise weighing for snacks, sweets, and gr...

Linear weigher for dry free flowing powder

Optimize your packaging line with precise weighing for free-flowing granular pr...

Food production metal detector for packaged products

Ensure product safety and compliance by detecting metal contaminants...

Industrial metal detector for packaged food products

Ensure the safety and compliance of your packaged food products by d...

Horizontal form-fill-seal systems for pouch packaging

For production lines that demand efficient pouch creation, these hi...

10 head multihead weigher for dry products

Optimize your weighing and packaging operations with precise and rapid handling...

14 head multihead weigher for dry products

Achieve precise and rapid weighing for a variety of dry, free-flowing products ...

Combined metal detector and checkweigher

Ensure compliance and product safety in food production with an integrated system ...

Combined metal detector and checkweigher for food production

Ensure compliance and safety in food production with this i...

Commercial carborundum peeling system

Effortlessly peel a range of root vegetables with precision, optimizing batch process...

Automated cleaning in place system for bakery production lines

Ensure unmatched hygiene and operational efficiency in fo...

Small vegetable food dehydrator

Efficiently remove moisture from your fruits and vegetables with this centrifugal dehydrator...

Vibration sieving machine for removing droplets or oil

Enhance your production line by efficiently removing surface liqui...

Automatic onion peeling system

Efficiently peel and prepare onions with precision using this high-speed, fully automatic sys...

Commercial potato slicer for thin and wavy chip cutting

Achieve precise and consistent slicing of potatoes and other prod...

Fast potato slicer for cutting potato chips

Optimize your potato chip production with this high-speed slicer, designed for...

Root vegetable cutting machine

Enhance your food processing operations with a versatile machine designed to precisely cut an...

Small scale potato chips production line

Optimize your small-scale snack production with a versatile solution that seamless...

Potato grading system for size classification

Efficiently streamline your produce sorting process with a multifunctional s...

Electric potato peeler for mass potato processing

Streamline your potato processing with an electric peeler that efficien...

Complete fruit and vegetable washing plant

Optimize your production line with efficient fruit and vegetable washing, ensur...

Fried food production line

Achieve consistent quality in fried snacks with this integrated production line, streamlining pro...

Semi-automatic frozen french fries production line

Improve efficiency in your production line with a semi-automatic syste...

Small deoiling machine for potato chips production

Enhance your snack production line with rapid deoiling and dewatering,...

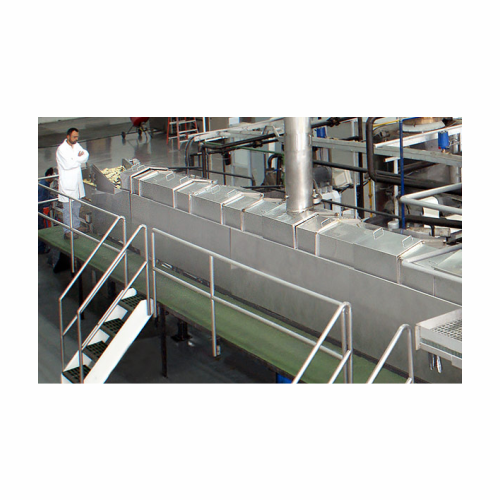

Continuous fryer for high-capacity industrial frying

Achieve consistent high-capacity frying with this continuous mesh be...

Cassava peeling system for efficient garri production

Streamline your tuber processing with high-speed peeling efficiency...

Commercial banana chips slicer

Achieve uniform and precise slicing of fruits and vegetables with this high-speed, continuous...

Complete banana chips production line

Streamline your snack production with a comprehensive line that transforms raw banana...

Small banana slicer for chips

Efficiently transform diverse root vegetables into uniform, smooth slices, ensuring minimal fi...

Horizontal flow wrapper for food packaging

Simplify your packaging process with our high-speed horizontal flow wrapper tha...

Robotic pick and place platform for food packaging

Enhance your packaging efficiency and product quality with a scalable ...

Case packer for diverse food products

Optimize your packaging line with this versatile case packer, capable of handling a w...

Reliable cartoning solution for food and non-food products

Achieve seamless product packaging with a cartoning solution ...

Low-emission belt drying systems for timber industry

Optimize moisture control and energy efficiency in drying processes ...

Layer dryer for food and pet food applications

Optimize drying efficiency with multi-layer technology that minimizes space...

High-force texture analyser for precise measurement

Achieve unparalleled precision in texture analysis for high-force app...

Portable texture analysis for low force applications

Easily perform precision texture measurements on low-force applicati...

Powder flow measurement system

Achieve precise control over powder consistency and prevent process disruptions by assessing ...

Texture analyzer for high force applications

Achieve precise texture measurement across a vast array of products with a so...

Electrostatic drum flavouring system for food industry

Enhance the consistency of your food products with precise flavour...

Electrostatic drum flavoring system for food processing

Enhance your snack production efficiency with a system designed t...

Electrostatic drum flavouring for uniform coating

Achieve precise and uniform flavor distribution on snack products with ...

Industrial cooking kettle for diverse food processing needs

Optimize your food processing with a versatile kettle design...

Storage bunker for potatoes and onions

Optimize storage and feeding efficiency for potatoes, onions, and carrots, while ens...

Wet bunker for potato buffering

Efficiently buffer and rinse pre-peeled potatoes and other potato products using a wet bunke...

Continuous roller peeler for root vegetables

Optimize peeling efficiency with precision-controlled roller systems engineer...

Root crop screw destoner

Efficiently remove stones from root crops with this screw destoner, ensuring clean produce while min...

Spiral roller grader for peeled potatoes

Achieve precise size grading for peeled potatoes with a spiral roller system that ...

Potato halving system

Ensure precise halving of potatoes and root vegetables at high speed with seamless integration into you...

Root crop submersion system

Achieve precise control over submersion times for root crops and vegetables, ensuring uniform so...

High shear mixer for efficient particle size reduction

Achieve rapid and precise blending and particle reduction in your ...

Metal detection system for powders & granules

Ensure product integrity and protect your machinery from metallic contaminan...

In-line metal detector for liquids & pastes

Ensure product safety by seamlessly integrating a metal detection system into ...

In-line metal detector for pneumatic systems

Ensure product purity and operational efficiency with a solution that effecti...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

Metal detector systems for conveyor belts and chutes

Ensure the integrity of your production line by efficiently detectin...

X-ray inspection system for unpackaged bulk products

Ensure product purity and safety in high-speed production lines with...

Process integration for pharma industry

Enhance your production line with seamless process integration, ensuring accurate l...

Flowpacker for packaging products in flowpacks

Optimize your flowpack packaging line with a preconfigured solution that ac...

Flow wrapper with quick format change

Streamline your packaging operations with a machine that offers rapid format changeov...

Batch mixers for raw material preparation in extrusion processes

Optimize your extrusion process with precise raw materi...

Food product extruder for low to high capacity production

Optimize your snack production with versatile extruders that e...

Top-loading delta robot automation solution

For high-speed operations requiring precise product handling, this top-loading...

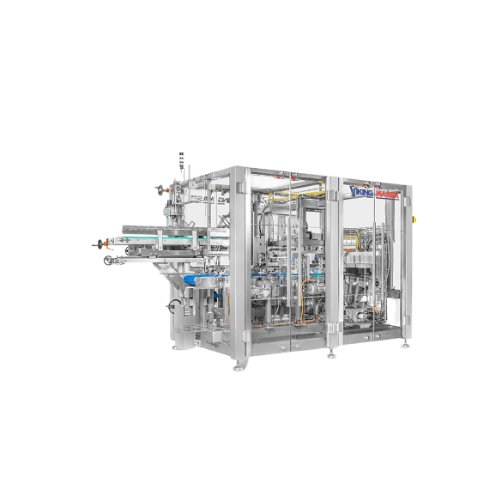

Tray packer for forming, loading, and sealing

Optimize your production line with a versatile tray packer designed to seaml...

Sterile filling platform for pharmaceuticals

Achieve precise, high-speed aseptic filling and packaging with advanced compl...

Compact palletizer for food and beverage products

Optimize your end-of-line operations with a space-saving palletizer tha...

Lab device for testing coffee capsules

Achieve precise testing and reproducibility of coffee capsule parameters crucial for...

Coffee capsule filling and sealing machine

For producers seeking a compact yet powerful machine, this system efficiently f...

Filling solution for powders and liquids in diagnostics

Simplify precision filling of diverse products, from freeze-dried...

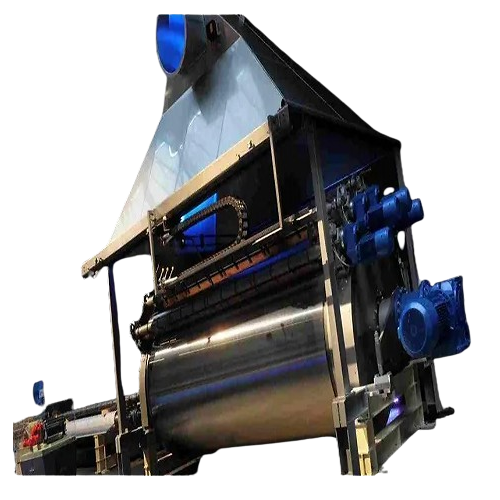

Energy recovery unit for potato chips production line

Manufacturers of French fries and potato chips require a lot of ene...

Top load Case Packer For Food Products

If you want to pack your food cartons, doy packs and pouches into regular cases, a s...

Continuous bagger with twin sealing jaws

If you want to pack into gusseted and pillow style bags and packing speed is impor...

Industrial washing machine for fruits and vegetables

The effective fruit and vegetables’ initial preparation for producti...

Semi-automatic case packer for chip bags

In small to medium scale production units, packing items manually can consume a lo...

Confectionery bags case packer for large scale

Mass production lines need faster and more efficient package processing to ...

Leak tester for pouches and MAP packaging

Nuts are packed with unsaturated fatty acids, which means they are prone to oxid...

Endload cartoning machine

As demand for food production increases, so does that of packaging and sealing the product and mak...

Puffed snack making machine

In the snack food industry, most products are often fried or extruded with a cooker, before bein...

Case packer machine for pouches

Automated case packer machines are a good solution to achieve reliability and to increase th...

Industrial potato washer

Washing potatoes or other vegetables can be a time consuming task for large restaurants or other foo...

Tunnel washer for food containers

With an increase in demand for production across food service and manufacturing companies...

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Standalone metal detector for food

Adding advanced metal detection to existing lines can be difficult and expensive, often ...

Entry-level high volume package seal tester

Manufactured food products need to be packed in gas-filled pouches to ensure t...

Bagger with servo driven jaw actuation

If you want to accommodate multiple bag designs and dimensions with fast speed and a...

Bag-in-box filler

If you want to a complete packaging solution having box erecting, bag placing and box closing technologies,...

Metal detection system

The inspection system automatically determines the best frequencies to maximize sensitivity for both f...