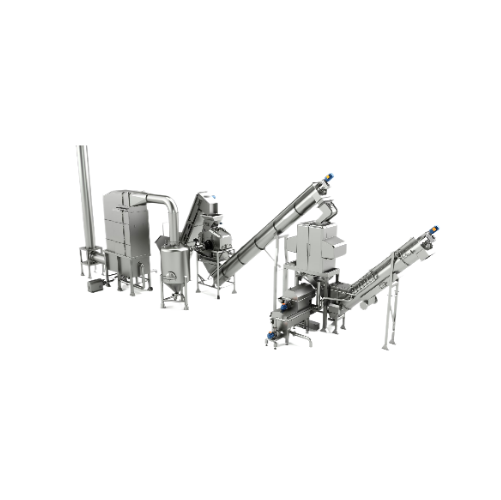

Potato peeling line

Optimize your peeling process with precision steam technology that reduces peel loss and enhances product quality for seamless integration into your food processing line.

Peels, Brushes, and Washes Potatoes Efficiently

The Tummers Peeling Line is engineered for food processing companies seeking efficient potato and vegetable processing. This line excels with its steam peeling system that reduces peel loss while ensuring optimal yield through minimal maintenance and low steam consumption. The process begins with precise potato weighing and continues through steam and dry brushing stages, utilizing the Tummers Steam Peeler followed by either a U-Brusher or innovative ZicZac-Brusher, depending on capacity needs. The manufacturing spectrum spans peeled potatoes to animal feed-ready dried peels. The system’s after washers implement continuous filtering and reuse of water to minimize consumption and boost sustainability. Each unit seamlessly integrates into existing production lines, with automation features facilitating continuous high-speed operations. Customization options and engineering support are available to meet specific production requirements.

Benefits

- Enhances product yield with minimal peel loss, improving overall efficiency.

- Lowers operational costs through reduced steam and water consumption.

- Supports sustainability goals by enabling resource reuse and reducing emissions.

- Simplifies maintenance with a low-failure rate and minimal downtime.

- Integrates seamlessly into existing production lines for streamlined processing.

- Applications

- Animal feed, Snacks, Potatoes, Processed vegetables, French fries

- End products

- Peeled and processed vegetables, Potato-based snacks, Potato chips, Peeled potatoes, Dried potato peels for animal feed

- Steps before

- Washing, Weighing

- Steps after

- Cutting, Final Washing, Starch Removal, After Washing

- Input ingredients

- potatoes

- Output ingredients

- peeled potatoes, potato peel, residual starch, clean potatoes

- Market info

- Tummers is known for its expertise in manufacturing industrial engineered-to-order equipment, particularly for the potato processing industry, including peeling, cutting, and frying systems. They are reputed for innovation, quality, and customized solutions in food processing technology.

- Steam Peeling Efficiency

- Minimal steam consumption

- Peeling Drum Speed

- High speed

- Peeling Yield

- Optimal yield

- Dry Peeling Method

- Brushing Machine

- Brusher Type

- U-Brusher / ZicZac-Brusher

- After Washing Type

- Drum washers / Washing screw conveyors

- Water Temperature

- Above 100°C

- Water Recycling

- Filtered and reused

- Automation

- Accurate control of filling weight

- Sustainability Features

- Sustainable, emissions-free

- Turnkey delivery

- Yes

- Working mechanism

- Steam and dry peeling

- Integrated steps

- Supply, Steam Peeling, Dry Peeling, After Washing

- CIP/SIP

- Manual

- Batch vs. continuous operation

- Inline Continuous

- Energy efficiency

- Designed for low steam consumption

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product type

- Potatoes

- Discharge method

- Discharge screw

- Control panel type

- PLC-controlled

- Customization for different peeling needs

- U-Brusher / ZicZac-Brusher

- Integration possibilities

- Turnkey delivery