Potato cutting line for high-quality potato products

Achieve precise cuts and optimized yields in potato processing with an innovative cutting line that sorts, aligns, and slices potatoes efficiently, ensuring minimal waste and consistent product quality through advanced water recycling and dewatering technology.

Sorts, Cuts, and Recycles Potato Products

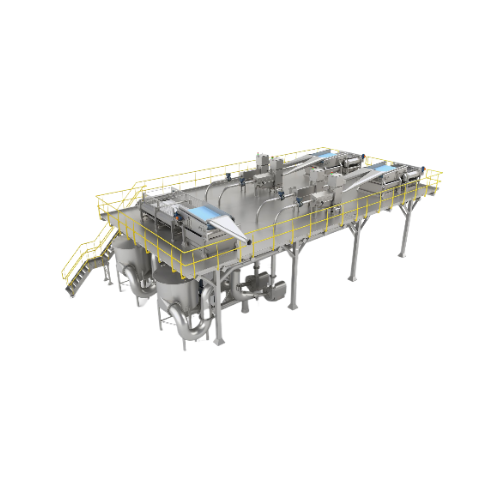

The Tummers Cutting Line from Tummers Food Processing Solutions is a high-precision system designed for efficient potato processing. It expertly sorts and cuts a variety of potato products, including French fries, chips, and potato flakes, ensuring consistent quality and minimizing waste. Utilizing a multi-stage process, the line integrates sorting, cutting, dewatering, sliver removal, and water recycling, with continuous operation tailored for high-speed processing. Capable of processing substantial tonnage, it maintains peak performance with automated control systems that optimize energy use and ensure seamless integration into existing production lines. Constructed with durable materials suitable for rigorous food processing environments, the cutting line requires low maintenance thanks to simple engineering and innovative water recycling features. Custom configurations and engineering support are available, aligning the equipment with diverse operational needs.

Benefits

- Ensures product consistency and quality by precisely sorting and cutting various potato products.

- Minimizes waste and enhances sustainability through efficient water recycling and sliver reuse.

- Increases productivity with high-speed, continuous operation tailored for large-scale processing.

- Reduces maintenance costs with durable construction and low upkeep requirements.

- Lowers energy consumption with optimized system integration and control features.

- Applications

- Potato flakes, Specialty potato products, French fries, Potatoes

- End products

- Hash browns, Potato crisps, Potato wedges, Potato flake powder, Instant mashed potatoes, Potato granules, Potato chips, Potato croquettes

- Steps before

- Washing, Peeling, Sorting

- Steps after

- Dewatering, Sliver Sorting, Water Recycling, Packing

- Input ingredients

- potatoes, raw potatoes, sorted potatoes

- Output ingredients

- cut potatoes, potato slivers, starch, optimal length potatoes

- Market info

- Tummers is known for its expertise in manufacturing industrial engineered-to-order equipment, particularly for the potato processing industry, including peeling, cutting, and frying systems. They are reputed for innovation, quality, and customized solutions in food processing technology.

- Sorting accuracy

- Diameter-based

- Cutting accuracy

- Optimal length alignment

- Capacity

- Based on diameter and tonnage

- Automation

- Patented Fin aligner system

- Water recycling efficiency

- Closed system with balance tank

- Energy efficiency

- Low consumption due to optimized process

- Waste reduction

- Sliver reuse capability

- System Delivery

- Turnkey from A to Z

- Maintenance

- Low maintenance solution

- Failure rate

- Low

- Automation level

- Manual / PLC / Advanced Automation

- Batch vs. continuous operation

- Continuous Inline Process

- Working mechanism

- Sorting, Cutting, Dewatering, Water Recycling

- Changeover time

- Minimal due to streamlined process flow

- Integrated steps

- Sorting, Cutting, Sliver Sorting, Dewatering

- Cleaning method

- CIP / Easy maintenance design

- CIP Principles

- Automated Water Recycling and Starch Removal

- Energy efficiency

- Optimized for low energy consumption

- Sustainability features

- Water Recycling, Low Maintenance

- Damage prevention

- Fin Aligner and Controlled Speed Transport

- Abrasion resistance

- High

- Biological compatibility

- Suitable for food-grade materials

- Cleanability

- Easy to clean (CIP compatible)

- Corrosive resistance

- Stainless steel components

- Density/particle size

- Handles various potato sizes and shapes

- Machine footprint

- Customizable

- Feed method

- Fresh Produce Pump

- Discharge method

- Conveyor belt system

- Control panel type

- PLC interface

- Compact footprint

- Sleek design

- Tank shape and size

- Balance tank

- Control panel type

- PLC-controlled, customizable

- Integration possibilities

- Turnkey delivery, customizable components

- Blade dimensions

- Customizable based on product diameter

- Cutting block options

- Adjustable based on requirements

- Sorting options

- Diameter-based, customizable sorting

- Water recycling system

- Customized closed-loop system