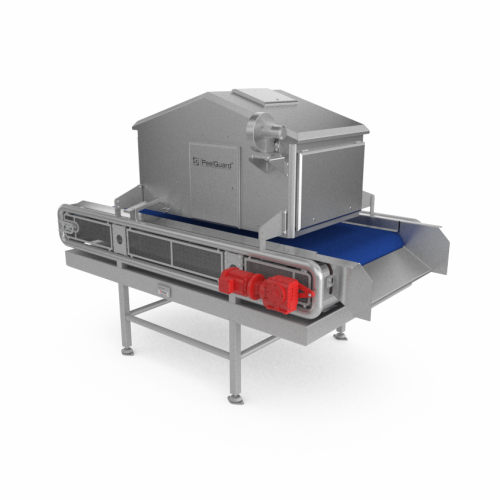

Optical measuring and weighing instrument for peeled potatoes

Enhance your potato processing efficiency by precisely detecting residual peels and defects like dark or green spots, ensuring optimal peeling and higher product yield.

Detects and Analyzes Residual Peels and Defects

The PeelGuard from Kiremko is an optical measuring and weighing instrument, pivotal in optimizing the peeling process for potato products like French fries and hash browns. It accurately detects residual peels and blemishes by integrating advanced optical sensors and statistical analysis. This technology allows potato processing plants to enhance product yield and quality by providing precise control over steam peeling operations. The PeelGuard’s integration into continuous production lines ensures high-speed operation and minimal downtime. Its robust design suits food processing environments, offering reliable performance with minimal maintenance. Additionally, its compatibility with existing systems simplifies integration, making it an invaluable asset for efficient potato processing.

Benefits

- Enhances product quality by precisely detecting and correcting peeling inefficiencies.

- Increases yield through accurate measurement and analysis, optimizing steam peeler performance.

- Reduces waste by identifying and removing defective areas in potato products.

- Integrates seamlessly into high-speed, continuous production lines.

- Minimizes maintenance costs with robust design suited for demanding food processing environments.

- Applications

- Pellet snack, Hash brown, Flake line, Potato chips, Formed mash, French fries

- End products

- Hash browns, Potato flakes, Pellet snacks, Formed mashed potatoes

- Steps before

- Purification, Sorting, Washing, Trimming

- Steps after

- Inspection, Quality Control, Processing, Packaging

- Input ingredients

- potato

- Output ingredients

- peeled potato

- Market info

- Kiremko is known for manufacturing industrial equipment for the potato processing industry, specializing in engineered-to-order solutions, with a strong reputation for innovation, quality, and reliability in turnkey processing lines and individual machines.

- Detection type

- Optical measuring

- Automation

- Automatic control

- Statistical analysis

- Potato dimensions

- Net product yield

- Enlarging

- Cycle time

- Shortest cycle time

- Capacity

- High capacity

- Peeling detection

- Optical measurement

- Defect detection

- Dark, green, or black spots

- Automation level

- Integration with steam peeler

- Data collection

- Full data on potato dimensions

- Yield enhancement

- Increases net product yield

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Weight measurement capability

- Accurate

- Optical measurement capability

- Detects residual peels and spots

- Compatibility with peeling systems

- Steam peeler control

- Data collection capability

- Full data of peeled potato

- Control panel type

- Touchscreen / HMI

- Integration possibilities

- SCADA / PLC Systems

- Material handling customization

- Options for different potato sizes and conditions