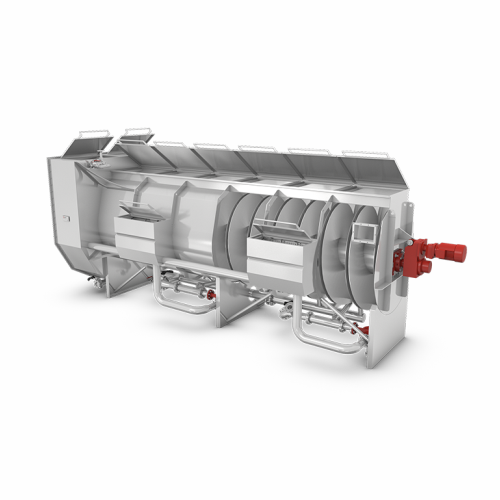

Screw type blancher for potato products

Achieve precise temperature control and even water circulation to enhance your potato processing line with a screw type blancher, ensuring optimal product quality for a range of potato-based foods.

Blanches and Heats Potatoes with Precision

The Screw Type Blancher from Kiremko is designed for precise temperature management and uniform water circulation, crucial for optimal potato processing. This versatile machine supports the production of frozen French fries, potato flakes, and snack foods. Its continuous operation and high-speed processing ensure efficiency and consistency across applications like flake lines and hash browns. With multiple discharge options, the blancher integrates seamlessly into your processing line, enhancing product quality while reducing energy consumption. Built with durable materials, it withstands harsh processing conditions, and its easy-maintenance design minimizes downtime, meeting food industry standards and providing robust engineering support for custom configurations.

Benefits

- Enhances product quality with precise temperature and water control.

- Increases efficiency through continuous, high-speed processing.

- Reduces energy consumption with optimized motor control.

- Seamlessly integrates into diverse potato processing lines.

- Minimizes maintenance downtime with easy-access design.

- Applications

- Hash brown, Flake line, Pellet snacks, Potato processing, Potato chips, Formed mash, French fries

- End products

- Diced potatoes for processing, Potato flakes, Ridged potato chips, Mashed potato powder, Frozen french fries, Hash browns patties, Cheese-flavored potato snacks

- Steps before

- Sorting, Washing, Slicing

- Steps after

- Drying, Cooling, Packaging

- Input ingredients

- potato slices, raw potatoes

- Output ingredients

- blanched potato slices

- Market info

- Kiremko is known for manufacturing industrial equipment for the potato processing industry, specializing in engineered-to-order solutions, with a strong reputation for innovation, quality, and reliability in turnkey processing lines and individual machines.

- Temperature Control

- Even distribution throughout the machine

- Automation

- Yes

- Flow Type

- Even product flow

- Discharge Execution

- Multiple options available

- Temperature control

- Even temperature distribution

- Product flow

- Stable flow

- Batch vs. continuous operation

- Continuous

- Density/particle size

- 0.5–2.5 g/cm³

- Discharge method

- Multiple discharge executions

- Even temperature distribution

- Yes

- Versatile machine

- Utilized in different product lines

- Discharge method

- Multiple discharge executions

- Temperature control

- Even temperature distribution

- Product flow control

- Versatile applicability in different product lines