Innovative knife identification system for quadraflow hydro cutter

Ensure optimal cutting performance and minimize product loss with a cutting-edge knife identification system specifically designed to enhance precision and quality in high-speed potato processing operations.

Monitors Knife Alignment and Cutting Accuracy

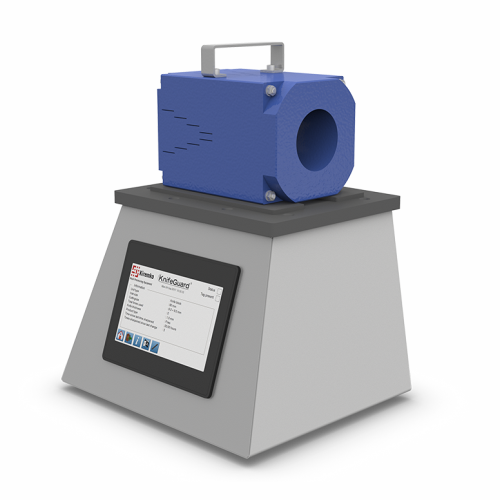

The KnifeGuard system from Kiremko is a sophisticated knife identification solution engineered for the Quadra Invicta hydro cutter. This system ensures precise cutting through real-time monitoring of knife blocks and alignment tubes, reducing miscuts and product waste. It’s specifically designed for continuous, high-speed potato processing, making it ideal for applications such as French fries, hash browns, and pellet snacks. With its integration capability, KnifeGuard seamlessly fits into your production line, enhancing quality and efficiency. The system features easy maintenance, supported by Kiremko’s engineering experts, offering customization to suit specific operational needs.

Benefits

- Minimizes product loss through precise knife alignment and cutting accuracy.

- Enhances production efficiency with continuous, real-time monitoring.

- Integrates seamlessly into existing potato processing lines, supporting high-speed operations.

- Reduces maintenance downtime with durable and easy-to-maintain components.

- Customizable features accommodate specific processing requirements for diverse end products.

- Applications

- Hash brown, Flake line, Pellet snacks, Potato chips, Formed mash, French fries

- End products

- Hash brown patties, Potato flakes, Crinkle-cut fries, Ripple potato chips, Formed mashed potato bites, Barbecue-flavored pellet snacks, Shoestring french fries, Cheese-flavored pellet snacks

- Steps before

- Washing, Peeling, Blanching

- Steps after

- Sorting, Packaging

- Input ingredients

- French fries, wedges, slices, potatoes

- Output ingredients

- French fries, slices, potato wedges, cut potatoes

- Market info

- Kiremko is known for manufacturing industrial equipment for the potato processing industry, specializing in engineered-to-order solutions, with a strong reputation for innovation, quality, and reliability in turnkey processing lines and individual machines.

- Knife Monitoring System

- Live Time Cycle

- Cutting Accuracy

- Optimal Combination of Venturi and Knife Block

- Prevention System

- Prevents Wrongly Cut Products

- Machine Type

- QuadraFlow Hydro Cutter

- Knife monitoring system

- Daily maintenance

- Cutting accuracy

- Optimal venturi and knife block combination

- Real-time monitoring

- Live time cycle of knives

- Product loss prevention

- Prevents wrongly cut products

- Machine footprint

- Depends on system layout

- Discharge method

- Continuous operation

- Control panel type

- Digital interface

- Compact footprint

- Optimized for space

- Control panel type

- Touchscreen/HMI

- Integration possibilities

- With existing QuadraFlow systems

- Knife identification system

- QuadraFlow compatible

- Live time cycle monitoring

- Real-time data acquisition

- Alignment tube customization

- For specific cutting purposes