Industrial potato cutting system

Optimize your potato processing with precision slicing and cutting solutions designed for a range of applications, from crispy fries to savory snacks, ensuring consistent quality and seamless integration into your production line.

Processes and Slices Potatoes for Snack Production

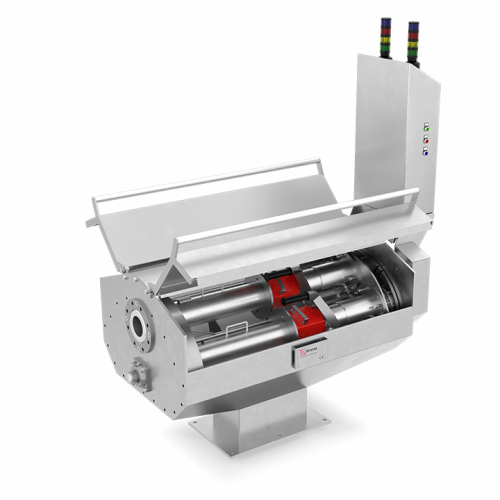

The Quadra Invicta from Kiremko is an innovative cutting machine designed to improve operational performance for potato processing companies and snack manufacturers. This equipment excels with the thinnest knives available, ensuring precise cuts for a variety of potato products including crinkle fries, hash browns, and pellet snacks. Utilizing a state-of-the-art change-over system, it supports continuous operation and maintains high throughput, adapting seamlessly to production lines with user-friendly controls. The machine’s suitability for StrapSlicer® tension operation further optimizes slicing accuracy and consistency. It integrates easily with existing processing infrastructure, saving energy and reducing downtime. Constructed from durable materials, the Quadra Invicta is built for longevity, while its easy-to-clean design minimizes maintenance requirements and ensures compliance with industry standards. Customization options are available to meet specific production needs.

Benefits

- Enhances production efficiency with continuous operation capabilities.

- Minimizes maintenance downtime through easy-to-clean design.

- Optimizes energy use, reducing power consumption in processing lines.

- Ensures precise cuts, maintaining consistent product quality.

- Integrates seamlessly with existing infrastructure for effortless upgrades.

- Applications

- Hash browns, Potato slices, Snacks, Pellet snacks, Mash products, Potato wedges, Potato chips, French fries

- End products

- Thin potato crisps, Chunky potato slices, Crispy hash brown patties, Expanded snack pellets, Diced hash browns, Curly fries, Potato wedges with herbs, Steak fries, Co-extruded snack pellets, Stackable chips, Stuffed hash browns, Waffle fries, Tortilla chips, Traditional hash browns, Paprika chips, Crinkle cut fries, Sweet potato fries, Cheese-flavored chips, Barbecue chips, Flavored mash cups, Mashed potato patties

- Steps before

- Peeling, Sorting

- Steps after

- Packaging

- Input ingredients

- peeled potatoes

- Output ingredients

- French fries, wedges, slices

- Market info

- Kiremko is known for manufacturing industrial equipment for the potato processing industry, specializing in engineered-to-order solutions, with a strong reputation for innovation, quality, and reliability in turnkey processing lines and individual machines.

- Cutting performance

- Excellent

- Knife thickness

- Thinnest on the market

- Operation ease

- Easy to operate

- User-friendliness

- User friendly

- Change-over system

- State-of-the-art

- Continuous operation

- Yes

- Compatibility

- Suitable for StrapSlicer® tension operation

- Cutting performance

- Thinnest knives on the market

- Change-over system

- State-of-the-art for continuous operation

- Operation type

- Easy to operate, user-friendly

- StrapSlicer® compatibility

- Suitable for tension operation

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Cutting type

- French fries, wedges, slices

- Continuous operation

- Yes

- Machine footprint

- Compact

- Knife type

- Thinnest knives on the market

- Change-over system

- State-of-the-art

- Operation method

- Suitable for StrapSlicer® tension operation

- Control panel type

- Easy to operate, user friendly

- Change-over system

- State-of-the-art for continuous operation

- Integration possibilities

- Suitable for StrapSlicer® tension operation