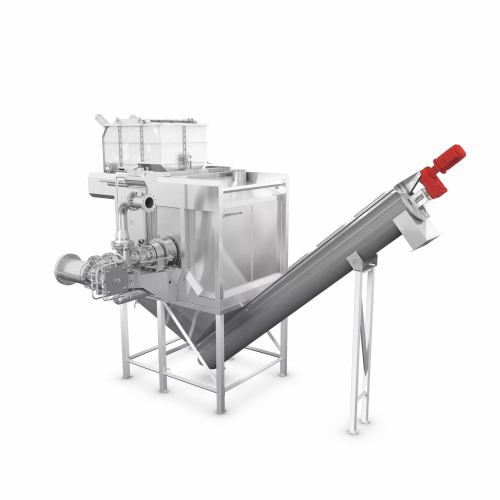

Steam peeling system for potatoes

Enhance your potato processing efficiency by reducing peeling time up to 25% while minimizing waste, thanks to an advanced steam peeling system designed for seamless integration into continuous production lines.

Peels and Calibrates Potatoes for Snack Production

The STRATA Invicta by Kiremko is a cutting-edge steam peeler tailored for potato processing industries, setting a new standard in efficiency and performance. This system excels in offering maximum yields with up to 25% shorter peeling times compared to conventional steam peelers, thanks to its optimized heat transfer via advanced condensate separation. It’s an intelligent system ensuring nearly uniform product feed, minimizing the need for potato buffers and enhancing peel precision. Ideal for producing French fries, hash browns, and snack pellets, the STRATA Invicta seamlessly integrates into high-speed, continuous operations with PLC-controlled automation. Made with special stainless steel, it is equipped with wear-resistant components that lower maintenance demands, such as a robust steam release valve utilizing NASA-grade materials. The built-in weigh hopper calibration system ensures consistent quality by accounting for mechanical deviations, making this peeler an invaluable asset for enhancing production efficiency while reducing waste.

Benefits

- Increases yield efficiency with up to 25% faster peeling times.

- Reduces waste through optimized heat transfer and smaller cooking ring design.

- Lowers maintenance costs with durable, NASA-grade steam release valve materials.

- Minimizes resource use by eliminating the need for inline potato buffers.

- Ensures consistent product quality with precise weigh hopper calibration.

- Applications

- Hash brown, Flake line, Pellet snacks, Potato chips, Formed mash, French fries

- End products

- Hash browns, Potato flakes, Mashed potato, Snack pellets

- Steps before

- Sorting, Washing, Trimming

- Steps after

- Inspection, Quality Control, Packaging

- Input ingredients

- potatoes

- Output ingredients

- peeled potatoes, potato peel waste

- Market info

- Kiremko is known for manufacturing industrial equipment for the potato processing industry, specializing in engineered-to-order solutions, with a strong reputation for innovation, quality, and reliability in turnkey processing lines and individual machines.

- Peeling time

- Up to 25% shorter than standard peelers

- Uniform product feed

- Almost 100%

- Heat transfer

- Advanced condensate separation

- Cooking ring size

- 20% smaller

- Peel waste reduction

- Up to 10%

- Steam release valve material

- NASA quality materials

- Weigh hopper calibration

- Mechanical deviations calibrated

- Maintenance reduction

- Due to special stainless steel

- Total cost of ownership

- Lowest in its class

- Working mechanism

- Steam peeling

- Integrated steps

- Condensate separation

- Batch vs. continuous operation

- Continuous operation

- Automation level

- Intelligent system with controlled interlock restart

- Machine footprint

- Compact

- Cooking ring size

- 20% smaller than standard

- Material structure

- Special stainless steel

- Weight

- Based on built-in weigh hopper system

- Discharge method

- Uniform product feed

- Control panel type

- Intelligent system with controlled interlock restart

- Product feed uniformity

- Almost 100% uniform product feed

- Condensate separation

- Advanced condensate separation for optimal heat transfer

- Material quality

- NASA quality materials for steam release valve

- Maintenance requirement

- Less maintenance due to special stainless steel

- Weigh hopper calibration system

- Built-in calibration for mechanical deviations