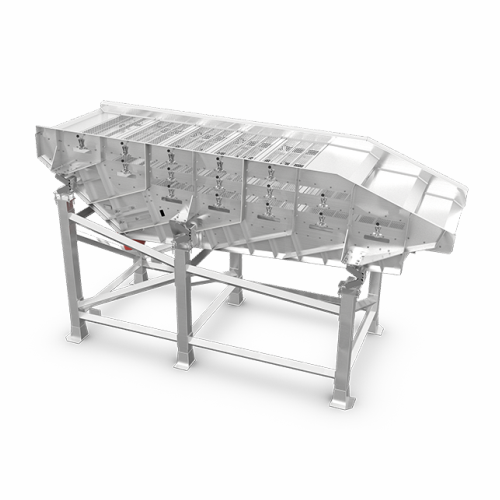

French fry length grader

Efficiently sort and standardize your potato products by length, optimizing your french fry production line for consistency and quality in every batch.

Sorts and Grades Potato Products by Length

The Length Grader from Kiremko optimizes your potato processing line by precisely sorting fries and potato products by length to ensure uniformity. This straightforward but effective machine employs a multi-tier sorting mechanism tailored for high-speed, continuous operations. It seamlessly integrates with upstream processes like cutting and hydro separation, and downstream packaging systems, enhancing overall line efficiency.

Ideal for French fry producers and snack manufacturers, the Length Grader is capable of handling a diverse array of end products, including shoestring fries, crinkle-cut fries, and tater tots. Operating with a simple design, it achieves cost efficiency without sacrificing throughput, processing substantial volumes consistently—making it an essential component in potato processing and snack production lines.

Available options include various construction materials to meet specific processing conditions, with a focus on low energy consumption. Maintenance is simplified via design considerations that allow for easy cleaning and inspection. Kiremko provides detailed engineering support for customization, ensuring the Length Grader fits seamlessly into your production setup.

Benefits

- Enhances product uniformity, ensuring consistent quality in varied end products like fries and snacks.

- Increases operational efficiency with high-speed, continuous processing capabilities.

- Lowers energy consumption through optimized motor control, reducing operational costs.

- Simplifies maintenance with easy-to-clean design, minimizing downtime.

- Customizable to fit specific production line requirements, enhancing integration and flexibility.

- Applications

- Potato products, French fries, Snacks

- End products

- Hash browns, Crinkle-cut fries, Seasoned fries, Potato-based snacks, Potato wedges, Potato chips, Tater tots, Potato croquettes, Kettle chips, Shoestring fries, Puffed potato snacks, Curly fries

- Steps before

- Cutting, Sorting, Washing

- Steps after

- Packing, Inspection

- Input ingredients

- potato products, French fries, cutting residue

- Output ingredients

- sorted French fries, different lengths, reduced cutting residue

- Market info

- Kiremko is known for manufacturing industrial equipment for the potato processing industry, specializing in engineered-to-order solutions, with a strong reputation for innovation, quality, and reliability in turnkey processing lines and individual machines.

- Sorting layers

- One, two, or three layers

- Sorting accuracy

- Different lengths

- Design

- Simple design

- Cost-efficiency

- Cost-efficient

- Residue removal efficiency

- Up to 98%

- Knife identification system

- Innovative KnifeGuard for QuadraFlow hydro cutter

- Visual sorting system

- Visionair

- Working mechanism

- Layer sorting

- Integrated steps

- Length grading

- Cost-efficiency

- High

- Design simplicity

- Yes

- Batch vs. continuous operation

- Continuous

- Compact footprint

- Simple design

- Discharge method

- Arranges French fries in layers

- Customization options

- Sorts fries in one, two, or three layers

- Control panel type

- Touchscreen / Button

- Integration possibilities

- PLC / SCADA

- Layer configuration

- Single / Double / Triple

- Material compatibility

- Food-grade stainless steel

- Sorting configuration

- Adjustable for different lengths