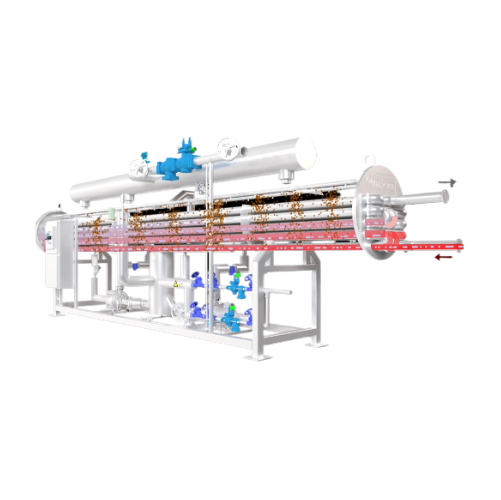

Efficient industrial re-chiller for poultry and seafood cooling

Enhance your production line’s efficiency by maintaining precise temperature regulation for your meat, poultry, and seafood with this high-speed, continuous re-chilling solution designed to ensure optimal product quality and safety.

Regulates Temperature for Continuous Processing

The C.A.T. Re-Chiller from Cooling & Applied Technologies is a robust solution for precise temperature regulation in poultry, meat, and seafood processing. This re-chiller stands out with its dual hermetically sealed ammonia pumps, providing 100% operational backup. It utilizes a unique patented “U” bend design that ensures leak-free performance, enhancing reliability. The C.A.T. Re-Chiller handles heavy cooling and refrigeration demands across various end products, such as chicken breasts, sausage, and salmon fillets, supporting continuous, high-speed, automated processes. Equipped with state-of-the-art PLC control packages, it offers seamless integration into existing production lines, optimizing energy efficiency with minimized consumption. Constructed from ASME-rated stainless steel components, it promises durability and corrosion resistance while adhering to stringent industry standards. Each unit is pre-piped, pre-wired, and insulated for ease of installation, ensuring minimal downtime and simplified maintenance with all necessary valves and pressure gauges included.

Benefits

- Ensures reliable operation with dual ammonia pumps providing 100% backup.

- Enhances operational efficiency with leak-free, patented “U” bend technology.

- Minimizes installation and maintenance time through pre-wired and pre-piped construction.

- Optimizes energy usage with state-of-the-art PLC-controlled systems.

- Delivers durability and corrosion resistance with ASME-rated stainless steel components.

- Applications

- Seafood, Meat, Poultry

- End products

- Salmon fillets, Pork chops, Sausage, Chicken breast, Shrimp, Turkey slices, Ground beef, Bacon, Lobster tails, Crab meat

- Steps before

- Injection, Marination, Grinding

- Steps after

- Freezing, Chilling, Packing

- Input ingredients

- ammonia, refrigerant

- Output ingredients

- chilled products, refrigerated meats, refrigerated seafood, chilled poultry

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Pressure Rating

- 250 psi (ASME rated)

- Automation

- PLC-controlled

- Pump Type

- Hermetically sealed ammonia pumps

- Refrigerant Type

- Ammonia

- Capacity (Models)

- 100 – 300 TR

- Piping

- Pre-piped including all refrigerant valves

- Insulation

- Pre-insulated

- Isolation Valves

- Included

- Pressure Gauges

- Included

- Bend Type

- Unique patented “U” bends

- Working mechanism

- Hermetically sealed ammonia pumps

- Cooling method

- Ammonia-based refrigeration

- Backup system

- 100% backup ammonia pump

- Automation level

- PLC control

- System integration

- Pre-wired, pre-insulated, and pre-piped

- Pressure rating

- ASME rated at 250 psi

- Corrosive resistance

- High resistance to ammonia

- Abrasion resistance

- Stainless steel

- Cleanability

- Stainless steel, easy to clean

- Biological compatibility

- Suitable for food processing environments

- ASME Pressure Vessel Certification

- 250PSI

- Frame Material

- Stainless Steel

- Components Material

- Stainless Steel

- Frame Pressure Rating

- ASME 250 psi

- Piping

- Pre-piped with all refrigerant valves

- Insulation

- Pre-insulated

- Valve Type

- Isolation valves included

- U-bend Design

- Patented, leak-proof

- Pump Type

- Hermetically sealed ammonia pumps

- Control panel type

- PLC control package