Food Packaging Equipment

Find production technology for food packaging, and connect directly with leading machine manufacturers worldwide.

The food packing process is the final and essential step of the production process. This process prepares the products for shipment and allows them to be stored and protected safely. Choosing the best packaging technology depends on the nature of the product, its end-use, and your production process. It is important to identify which type of industrial packaging your food products need since each product has particular packaging requirements.

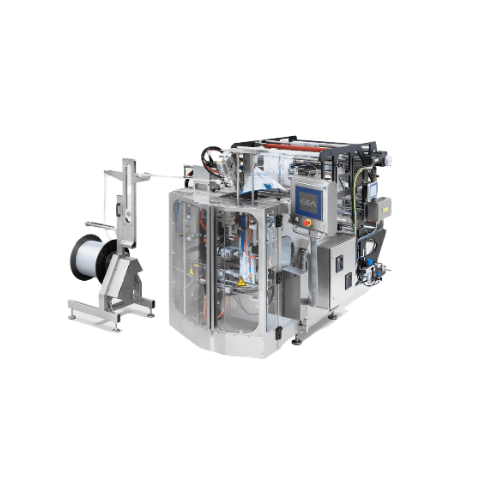

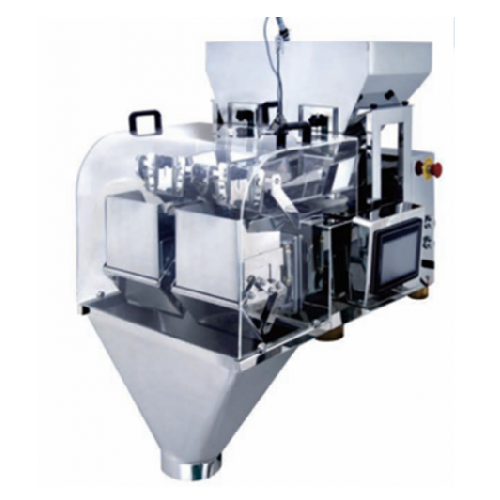

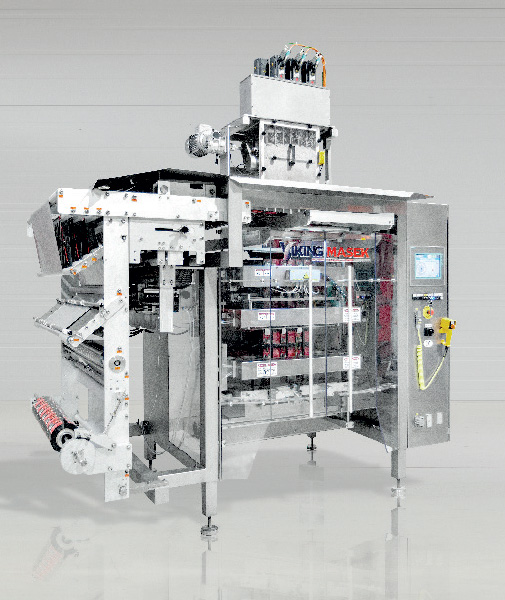

Put those snacks in the bags!

Is your food product fresh produce, soup, or chips? Depending on the state of matter, the packaging material, form, and technology will change drastically. Snacks like potato chips and grains like rice can be packed in bags. Here, bagging equipment can be employed. You measure out parts of a product and place them into bags during this procedure. By bagging your goods, you can prevent them from going bad, make them easy and safe to carry and keep them protected from tampering and theft. The mass or volume per bag, the product’s flow characteristics, and the structure and design of the bag all factor into the choice of bagging equipment. Bags come in a range of sizes, from tiny sachets to large, flexible containers.

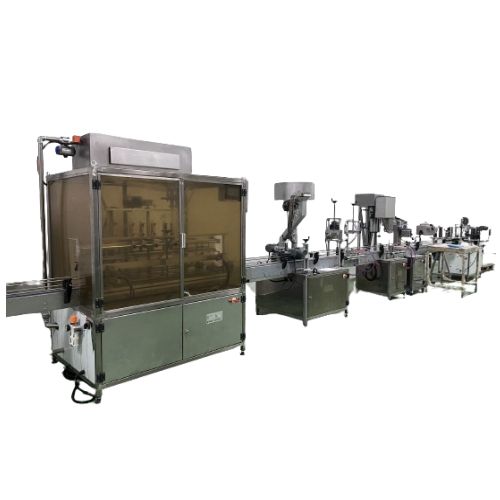

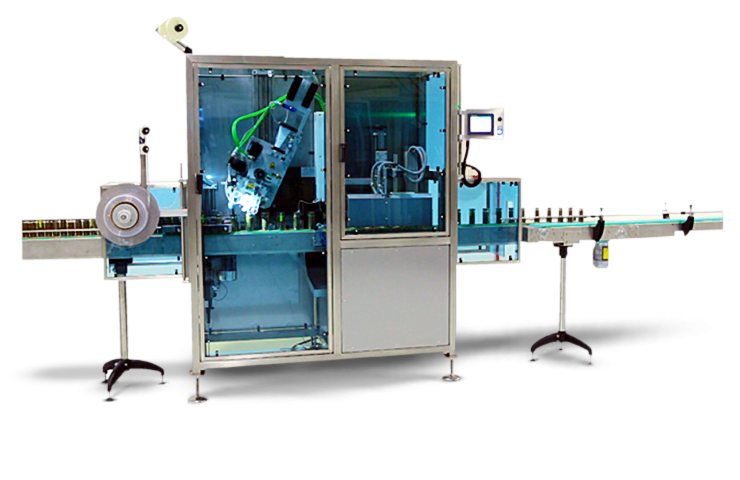

Bottle your beverages away!

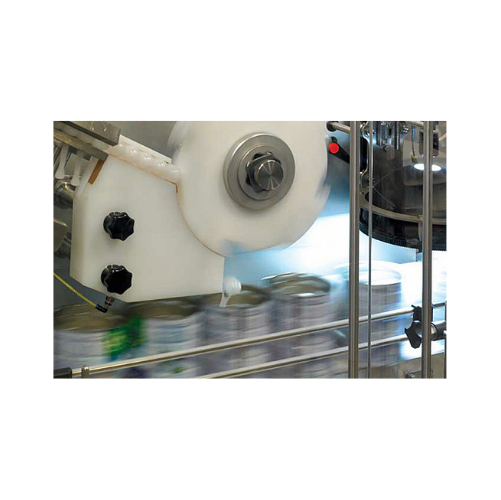

Beverages like soda, beer, and fruit juices can be bottled, capped, and packed in cartons. You must inspect, cap, label, and seal the bottles for distribution after bottling the liquid. Depending on your production volume, product format, and regulatory requirements, different bottling solutions with different product metering systems, levels of sterilization, container types, and sealing systems are employed. As an alternative to bottling, you can pack your liquid product in aluminum cans, like soups, beans, corn, and prepared fish like tuna and salmon.

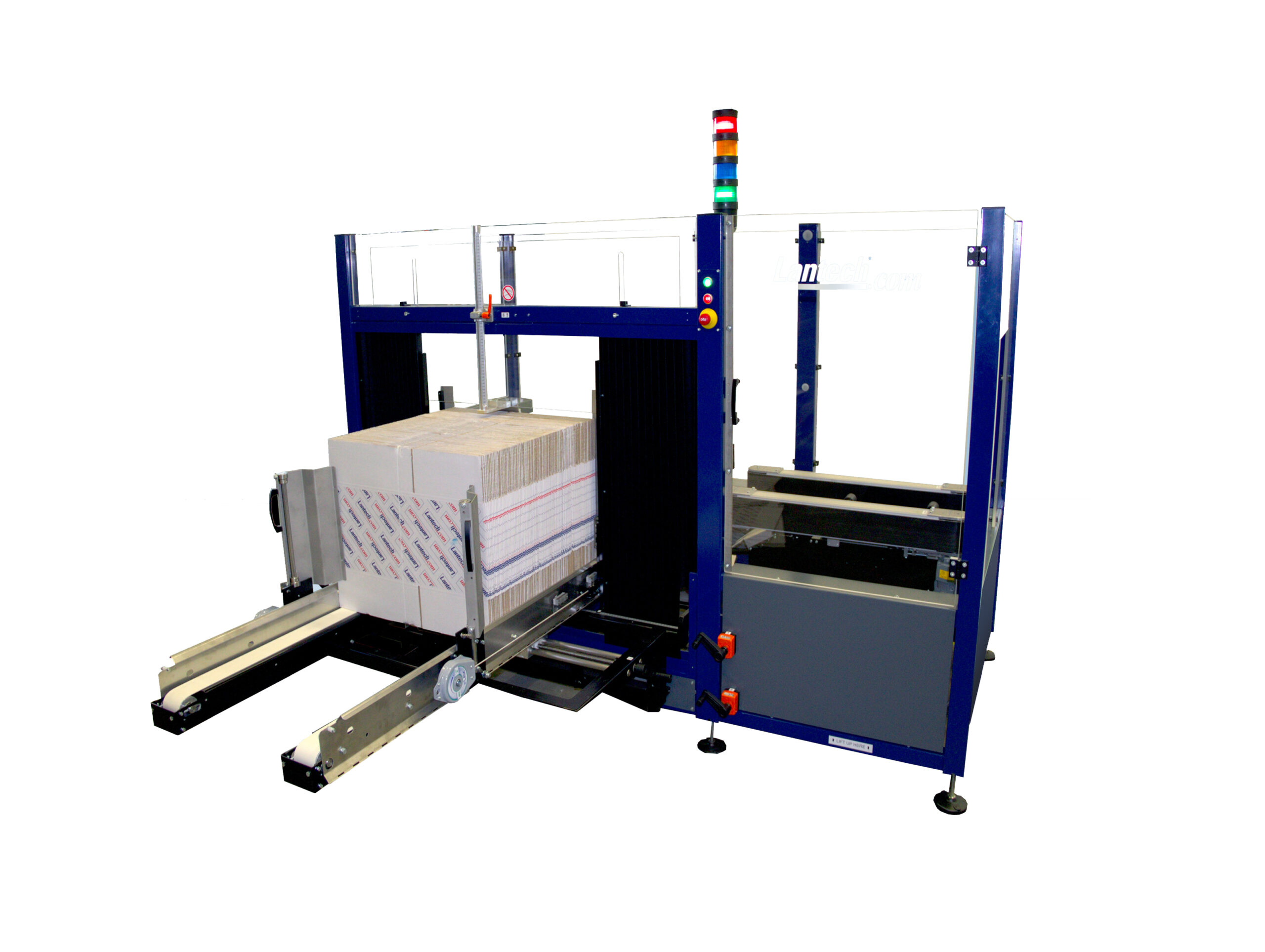

It all comes down to cartoning in the end

When you are packing your products in cartons, utilize forming, filling, sealing, and cartoning equipment. When you are packing your products in cartons, utilize forming, filling, sealing, and cartoning equipment. In the process of cartoning, a folded carton is constructed, the product is placed inside, the flaps are closed, and a lid is applied and sealed with glue or adhesive tape. When choosing the type of cartoning equipment, take into account the primary packaging type, the production volume, the size and number of the products in a carton, and the required level of automation. Depending on the size of the product you intend to pack and design or the carton, you can choose either horizontal or vertical cartoning machines.

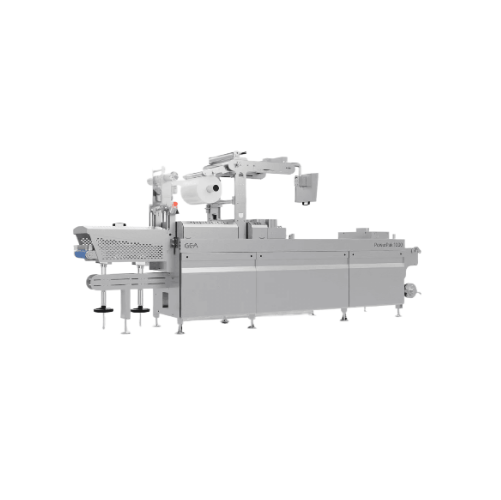

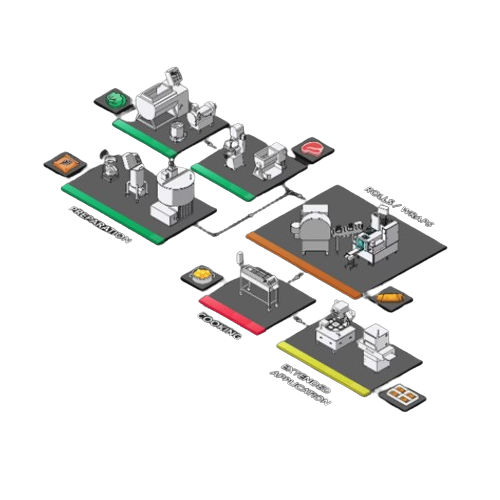

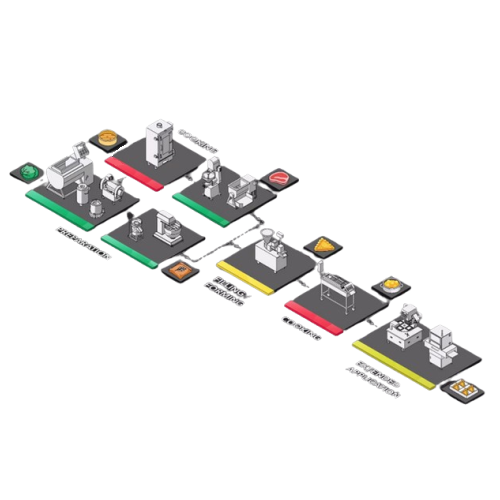

Identify the type of food product you are producing to select the ideal packaging solutions!

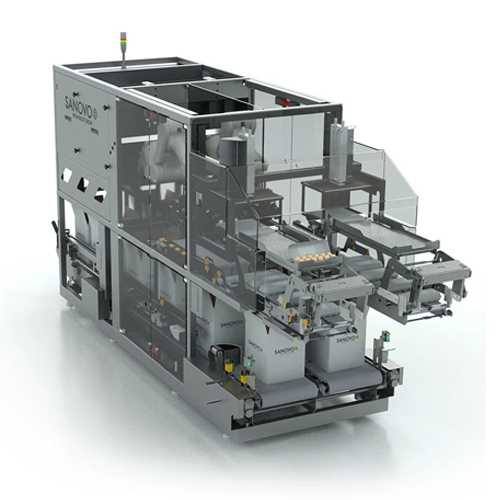

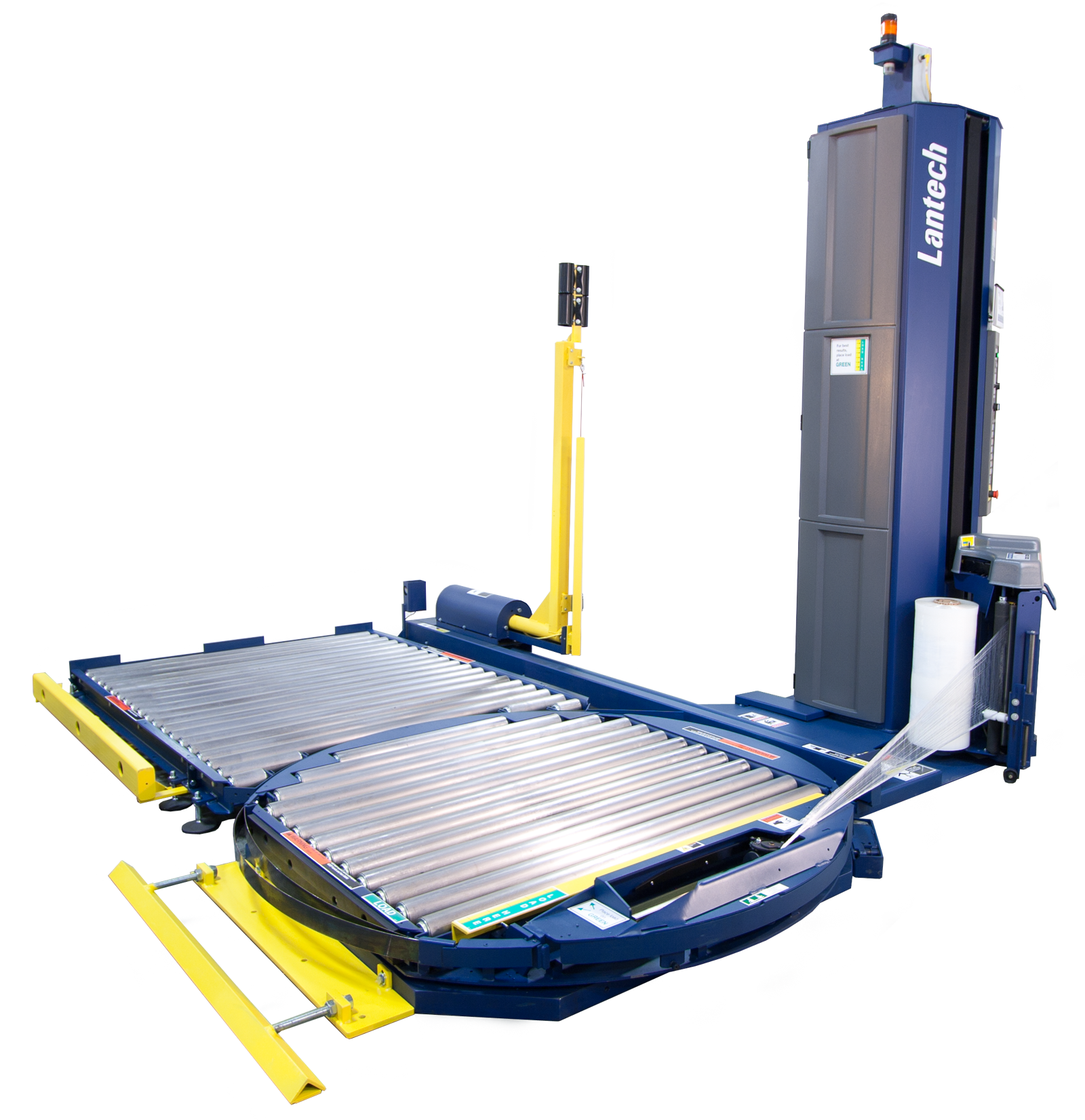

If your product is an egg or dairy product, you need to use aseptic packaging and sterilizing equipment. Since dairy and egg products can go bad easily if they are exposed to bacteria, an aseptic process and multi-layer packaging may be needed for your product. Fresh produce like vegetables and fruits, and fish can be packed in polymer or biopolymer trays. Salad mixes and candies like gummies and chocolates can be packed with flexible packagings such as polymer or biopolymer bags. Also, for fresh meat or dried meat, you can employ vacuum packing or shrink-wrapping equipment.

Which food packaging technology do you need?

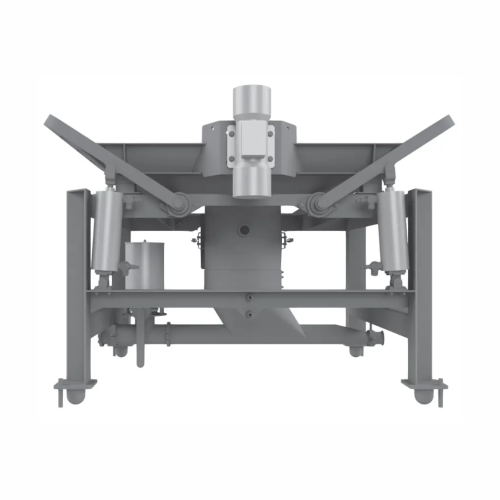

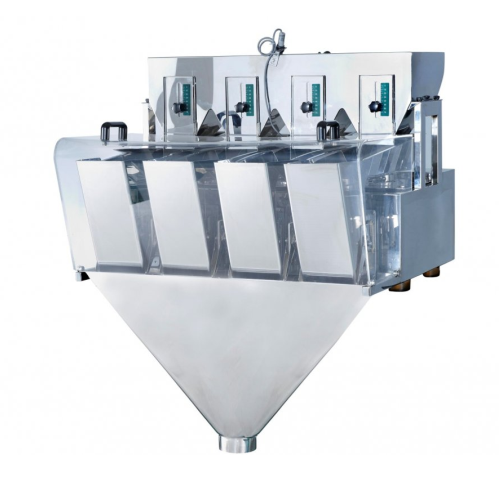

Linear vibratory weigh filler for fragile food products

Achieve precise and gentle filling of fragile food products with ...

Crown cork sealer for liquid food packaging

Ensure reliable sealing for bottled beverages and dairy with a compact, table-...

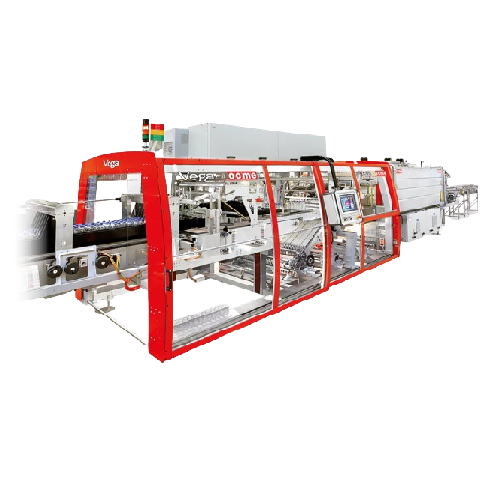

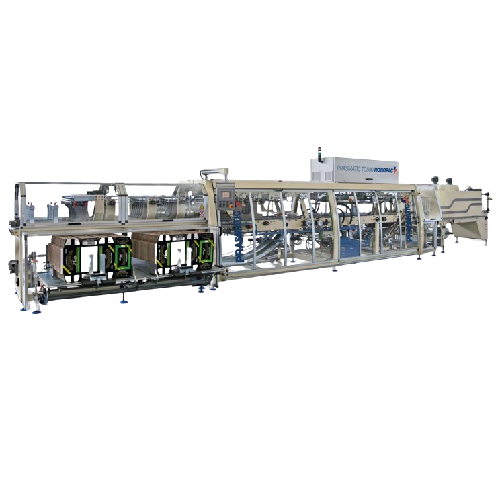

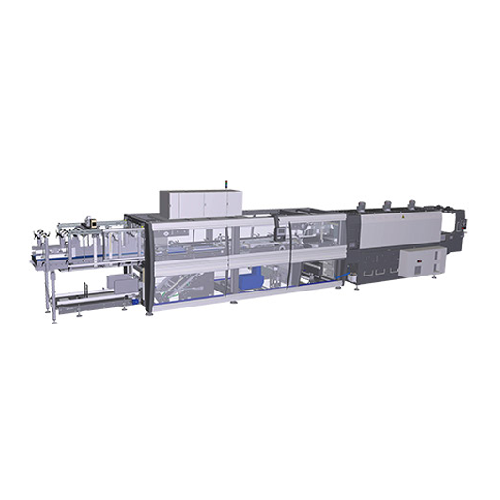

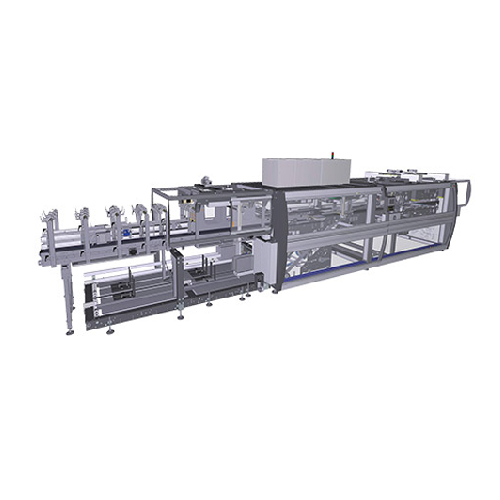

Shrink wrap packer for beverage and food industries

Optimize your production line efficiency with a versatile packer capa...

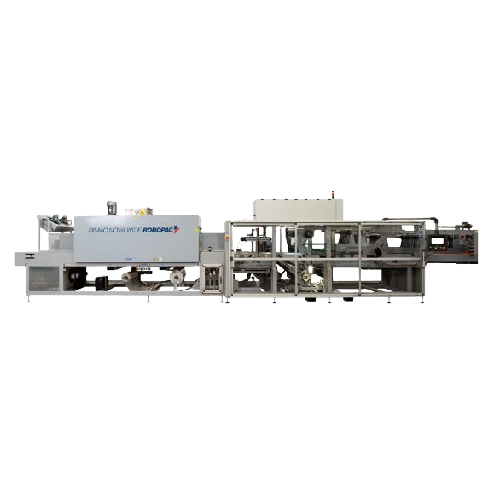

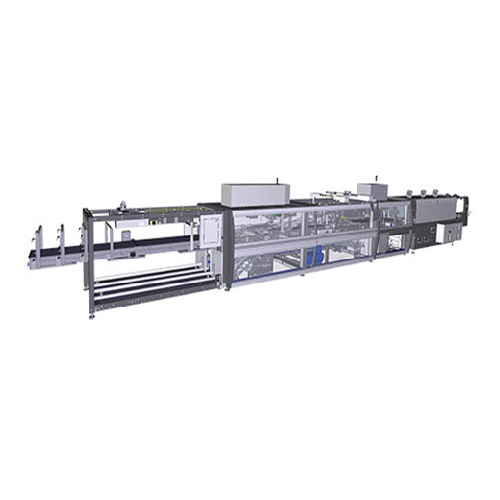

Medium-speed shrink wrapper and case packer for food industry

Optimize your packaging line with a combined solution that...

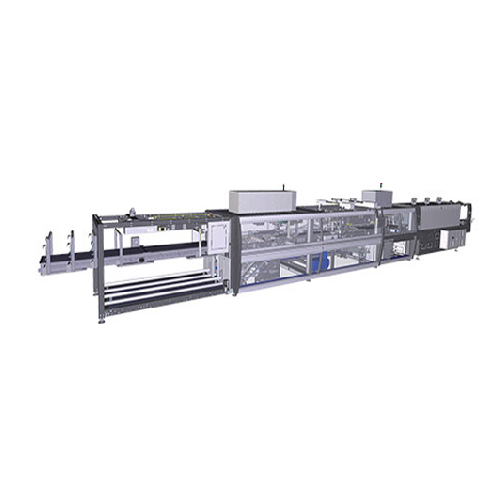

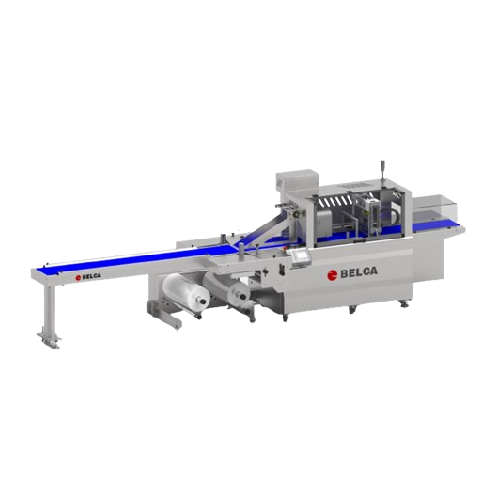

Medium-speed automatic shrink wrapping systems for food and dairy

Optimize your packaging line with this flexible shrin...

Medium-speed wrap around case packer for food and dairy industries

Optimize your end-of-line efficiency with a reliable...

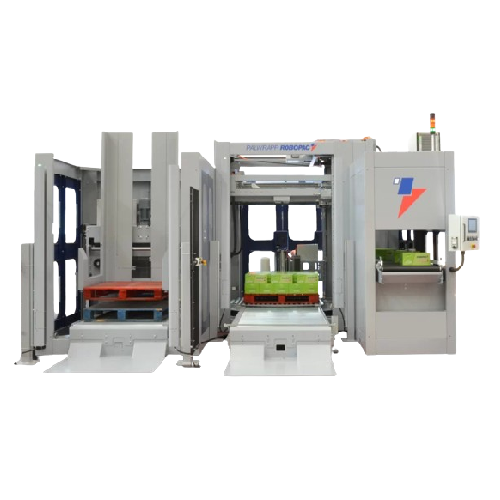

Compact and modular palletizer for food industry

Optimize your end-of-line efficiency with this modular palletizing soluti...

Horizontal stretch-film wrapping system for frozen food

Optimize your packaging line with a high-speed solution that secu...

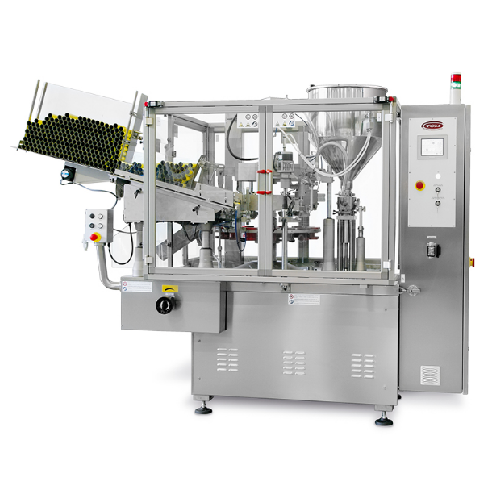

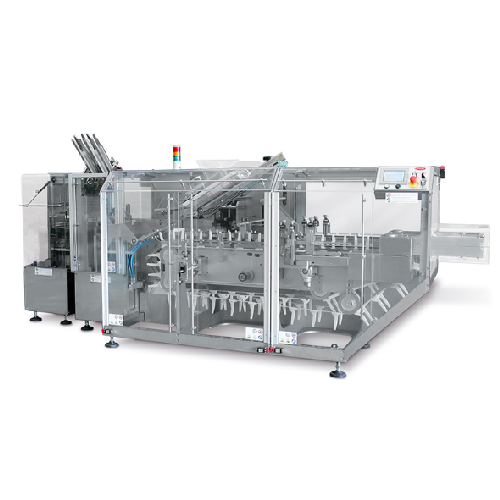

Tube filling machine for cosmetics and food products

Achieve precise and efficient packaging with this advanced twin-head...

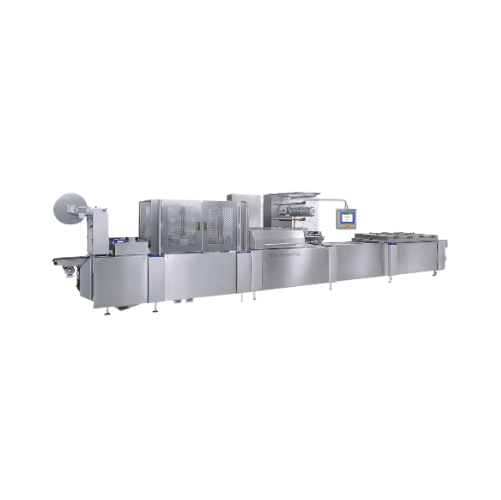

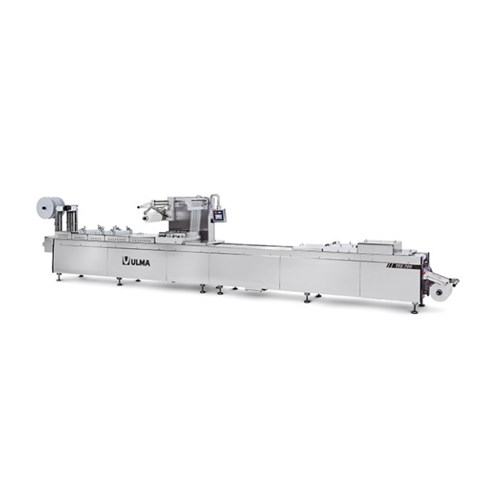

Automatic traysealer for food packaging

Optimize your packaging efficiency with this advanced traysealer, designed to enhan...

Flowpackers for efficient food packaging

Achieve seamless packaging with flowpackers designed for high-speed, sustainable o...

Belt loaders for automated food packaging

Streamline your packaging line with precision-engineered belt loaders, designed ...

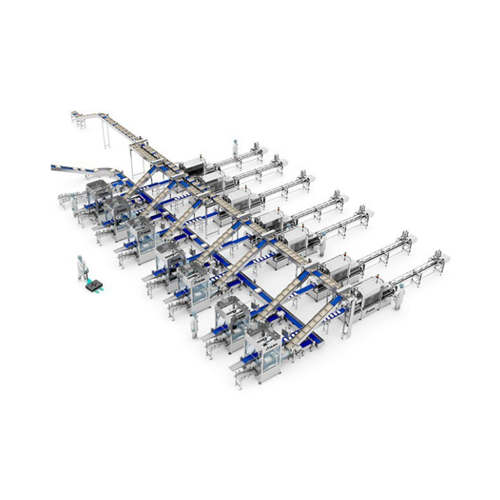

Automated conveyor systems for food packaging lines

Seamlessly integrate high-speed product transport and handling into y...

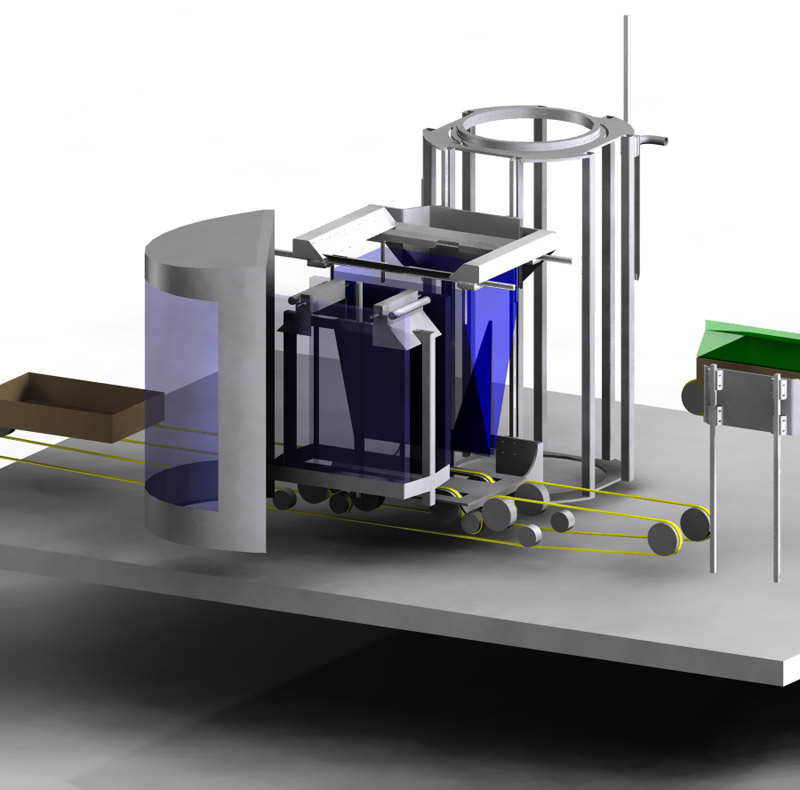

Accurate batching system for prepared foods

Streamline your food production with high-accuracy batching, minimizing rework...

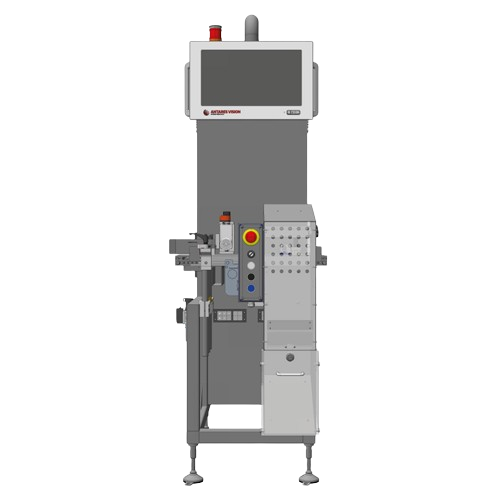

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

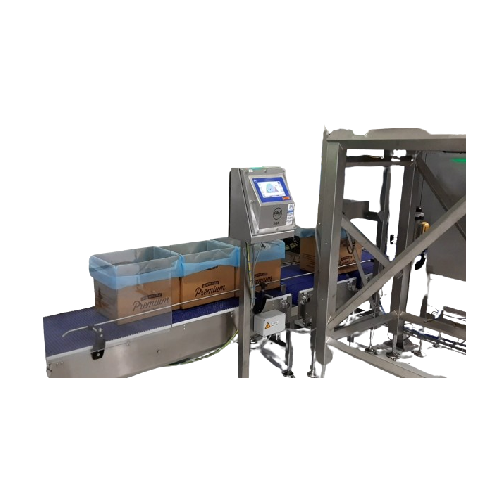

Checkweigher for high-care food environments

For facilities needing precision and hygiene, this high-care checkweigher ens...

Hygienic design robot for food industry

Optimize your production line with a high-speed, hygienic design robot engineered f...

Entry-level food packaging machine for pillow bags

Achieve space-saving packaging versatility with a machine designed for...

Continuous packaging solution for free-flowing food products

Streamline your production with a high-speed packaging mach...

Flexible packaging solution for large food volumes

For high-volume food packaging, achieving consistent bag sizes and red...

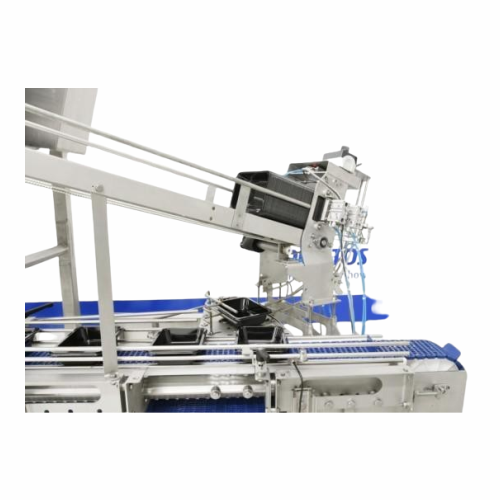

Tray handling equipment for food packaging

Optimize your food production with adaptable tray handling units that streamlin...

Twin-column palletizer for beverage and food packaging

Achieve seamless operation with a flexible twin-column design that...

Flow wrapping solution for fresh produce and food products

Optimize packaging efficiency for irregular products with a v...

Map flow wrapper for chilled food packaging

Optimize your chilled food packaging with a flow wrapping solution that easily...

Tray sealer for food packaging buckets

Enhance your packaging efficiency with a highly adaptable tray sealer, designed for ...

Tray sealer for packaged food products

Optimize your food packaging with precise sealing and advanced Modified Atmosphere P...

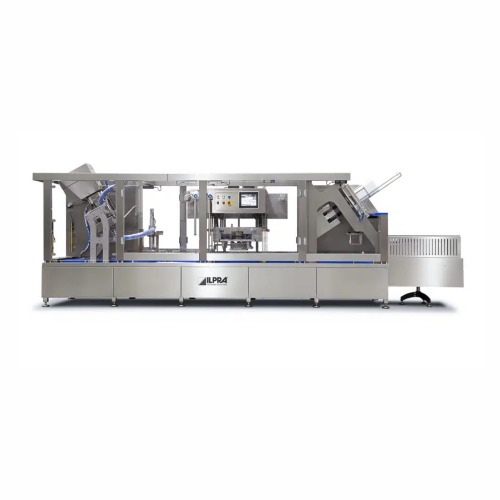

Traysealer for modified atmosphere packaging - food products

Optimize your packaging line with this semi-automatic trays...

Compact thermoforming packaging system for food industry

Revolutionize your packaging line with a space-saving solution t...

Traysealer for small scale food packaging

Improve your production efficiency with a compact traysealer designed for versat...

Traysealer for food packaging with rotating table

Enhance your packaging line efficiency with a traysealer that simultane...

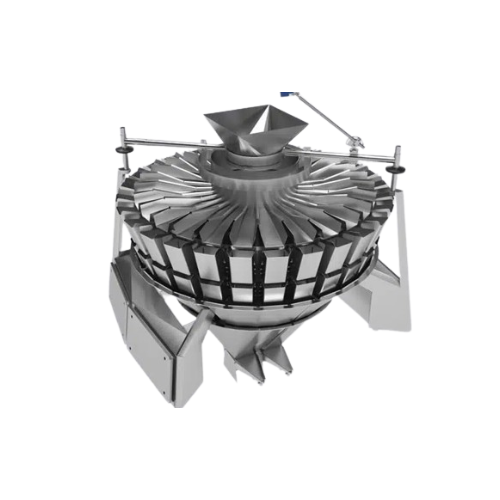

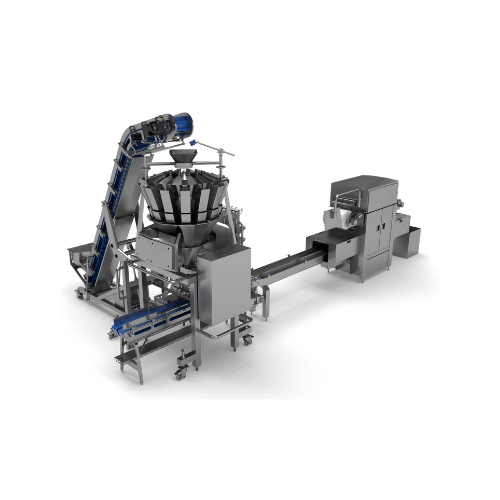

Multihead weigher for food processing

Enhance production efficiency and accuracy with multihead weighing technology, offeri...

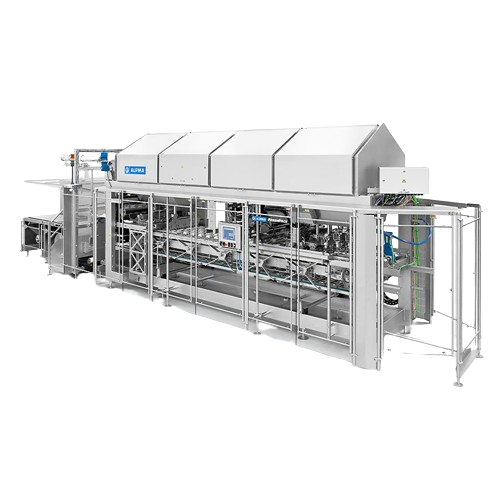

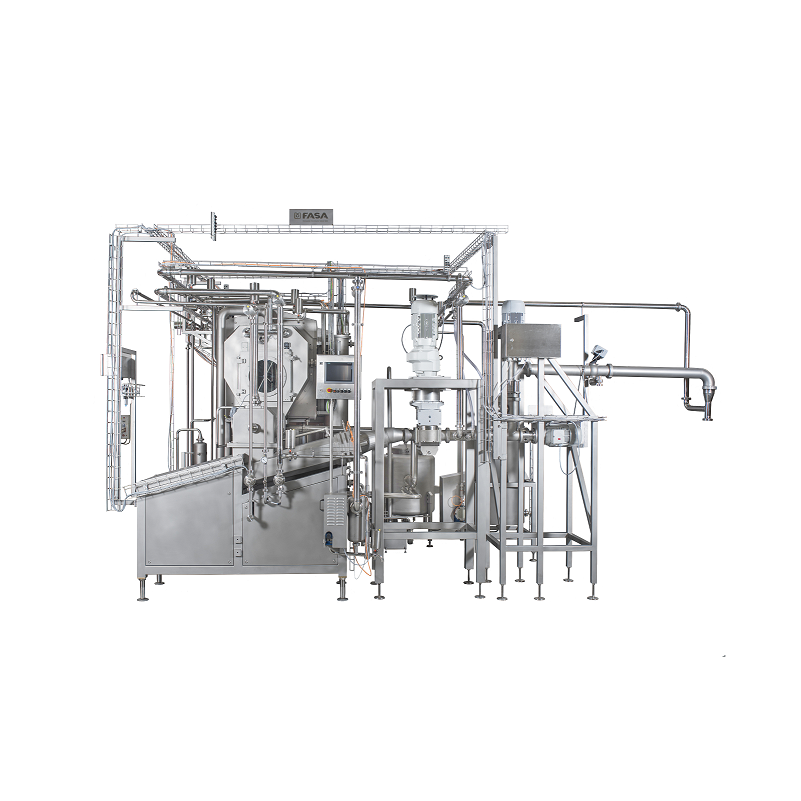

Industrial aseptic fillers for food processing

Ensure sterile packaging with advanced aseptic fillers, designed for precis...

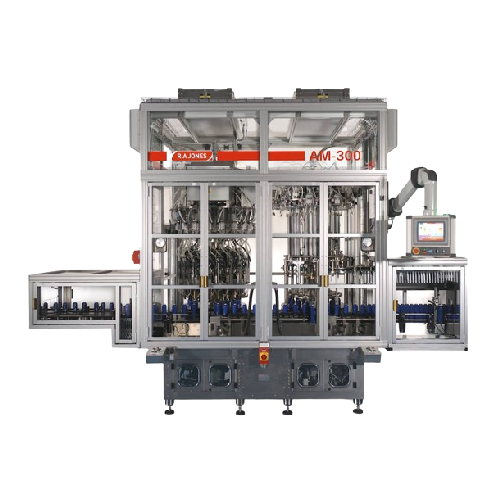

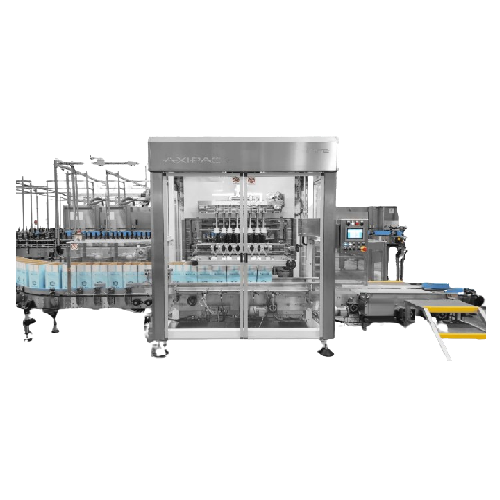

Liquid food filling solutions

Maximize efficiency in your packaging line with versatile filling machines designed for precis...

Multilane wrapping solution for food and confectionery products

Enhance your packaging line efficiency with high-speed m...

Horizontal case-packer for medium-sized shipping cases in pharma and food

Streamline your packaging line with a versat...

Intermittent motion overwrapper for cosmetic and food products

Achieve flawless packaging with precision wrapping and se...

Vibratory rotary filler for accurate filling in food packaging

Achieve precise and efficient filling of diverse solid pr...

Horizontal load carton erector for food production

Enhance your production line with precise carton erecting, loading, an...

Automatic top sealing for frozen food packaging

Streamline your food packaging operations with a top sealing machine desig...

High speed horizontal flow wrapper for food products

Achieve precise, high-speed packaging for snacks with this versatile...

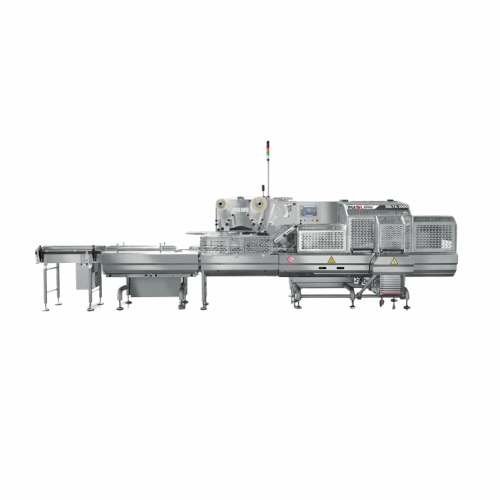

Automatic tray sealer for high-speed food packaging

Optimize your production line with a high-capacity tray sealing solut...

High-speed tray sealer for food packaging

Streamline your packaging process with high-speed tray sealing, reducing labor c...

Hand operated tray sealer for small-scale food production

Optimize your packaging process with this compact tray sealing...

High-capacity tray sealer for poultry, meat & seafood

Optimize your high-speed packaging line with this large-capacity tr...

Vertical packaging system for short-cut pasta and dry granular food

Streamline your packaging operations with a high-sp...

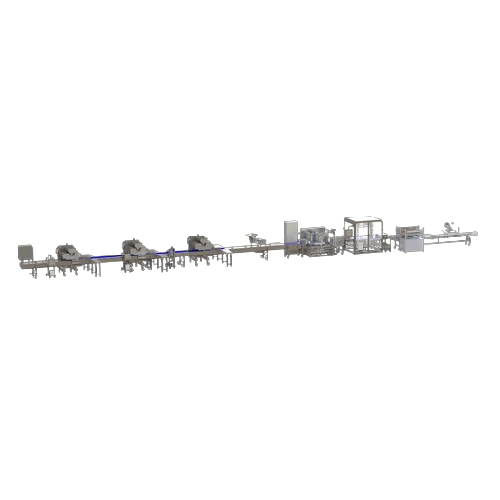

Packaging system for short-cut pasta and dry granular food

Streamline your packaging process with a versatile system des...

Vertical packaging system for fragile food products

Handle delicate food items like pasta nests and bakery products with ...

Intermittent motion packaging system for dry granular food

Achieve precision packaging for dry foods with an advanced sy...

Vertical pouch packaging system for food products

Achieve high-speed, precise packaging with our vertical pouch system, i...

Vertical form fill sealer for food packaging

Achieve high-capacity, flexible packaging for diverse food products with a ro...

Entry-level thermoforming packaging system for food products

Streamline your packaging process with a versatile thermofo...

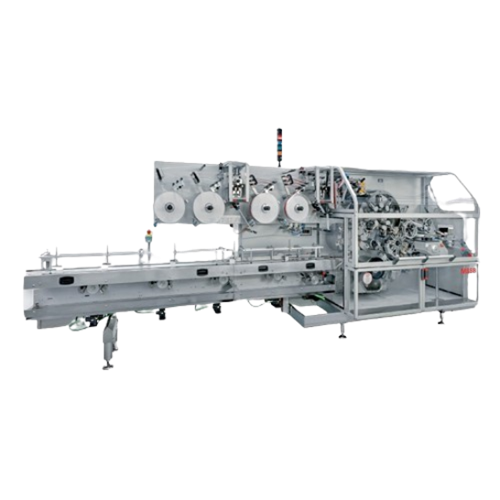

High-speed cross-web labeling for food packaging

Streamline your packaging process with a high-speed labeling system desig...

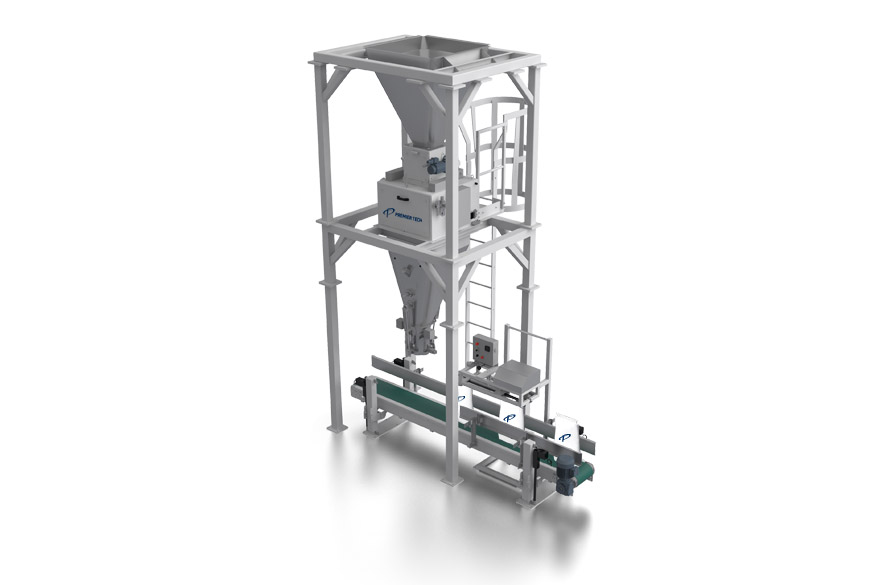

Bulk powder filler for food, dairy, and nutraceuticals

Optimize your bulk powder filling process with a system designed t...

Inline automatic powder fillers for food and nutraceuticals

Ensure precise and efficient filling of sensitive powders in...

Semi-automatic powder filling system for food products

Achieve precise and flexible filling for food powders and granules...

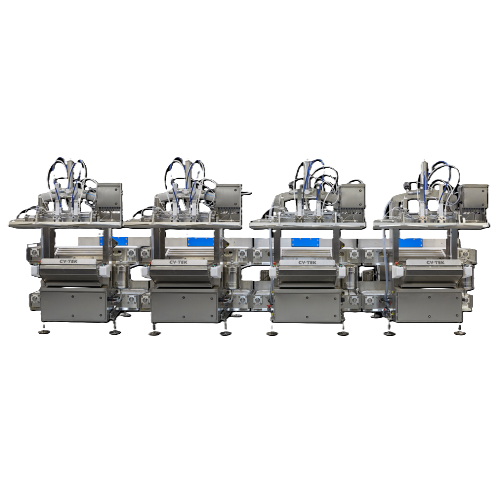

Handpack fillers for diverse food products

Streamline your canned food production by efficiently filling a wide range of c...

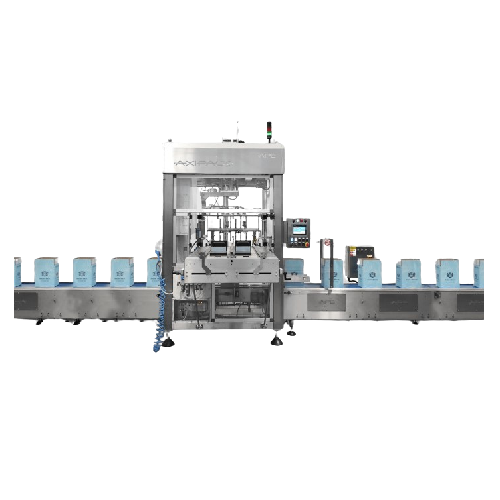

Complete filling and closing line for food containers

Optimize your production line with a versatile solution that ensure...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

Industrial tray sealer for food packaging

Optimize your packaging operations with precise tray handling and versatile seal...

High-speed Map packaging for fresh food products

Ensure product freshness and safety with robust, high-speed packaging tha...

Advanced horizontal flow wrapper for food packaging

Achieve seamless high-speed packaging for diverse food products with ...

Brick forming and wrapping system for food products

Optimize your production line with seamless forming and wrapping of v...

Portable vacuum sealer for food packing

Simplify your food storage and preparation with a compact vacuum sealer designed to...

Portable vacuum sealer for food preservation

Experience effortless food preservation with a compact vacuum sealing solutio...

Multihead weighers for food production

Optimize your food production line with precision and speed by integrating advanced ...

Linear weigher for accurate food portioning

Ensure precise weight control for snacks and confectioneries with our advanced...

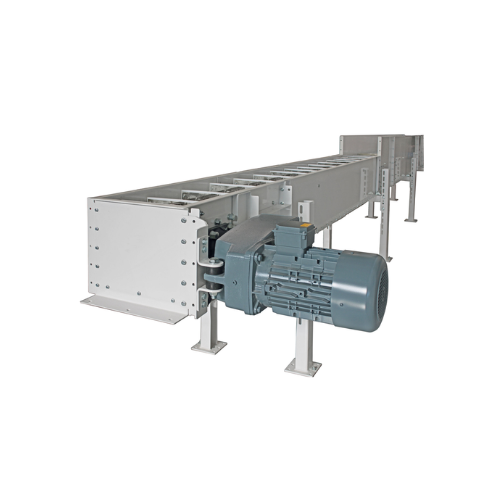

Food production conveyors for efficient material handling

Streamline your food production with versatile conveyors desig...

Vertical package accumulator for food and beverage production

Ensure seamless flow and precise order tracking of package...

Horizontal flow wrapper for food packaging

Simplify your packaging process with our high-speed horizontal flow wrapper tha...

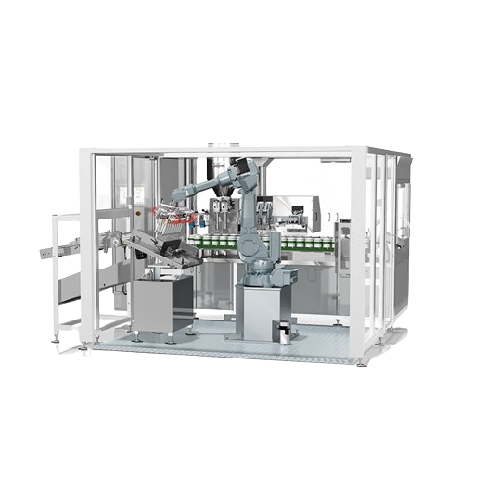

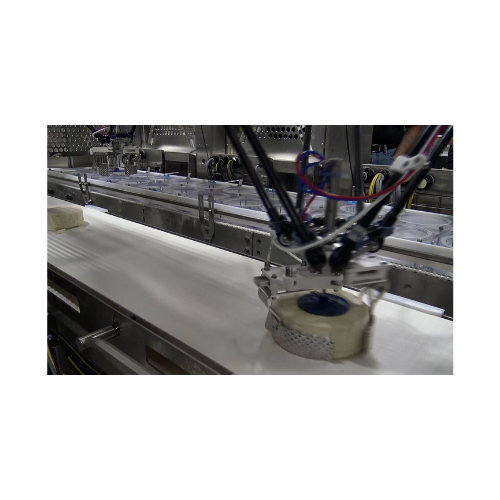

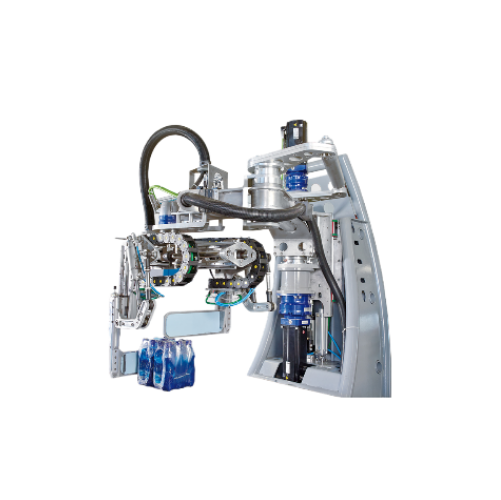

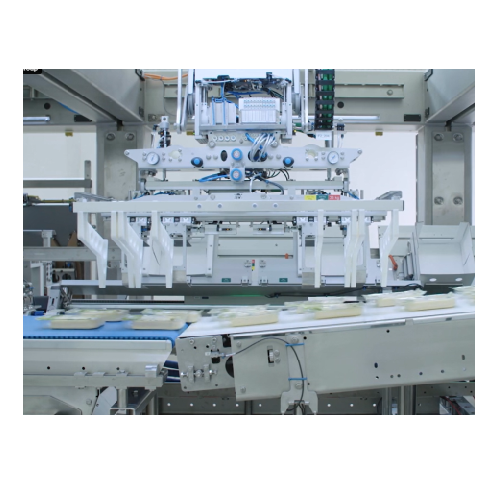

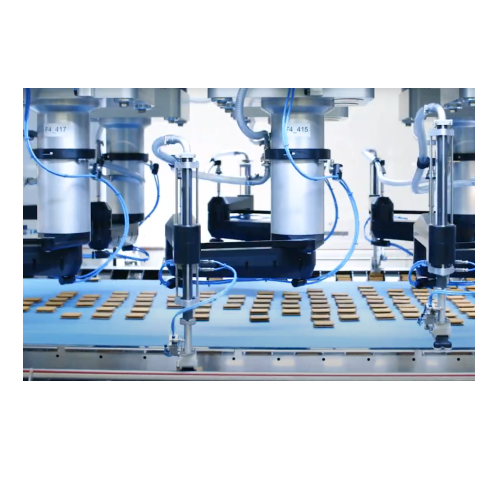

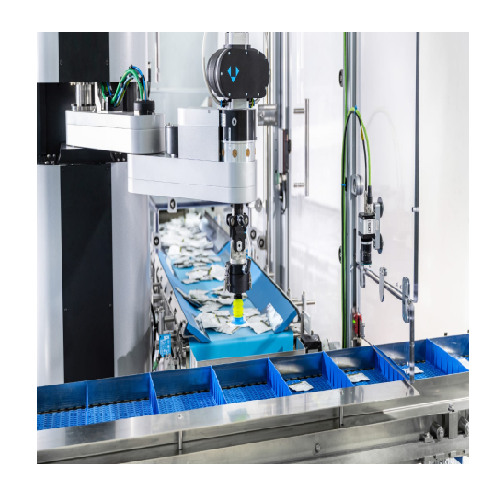

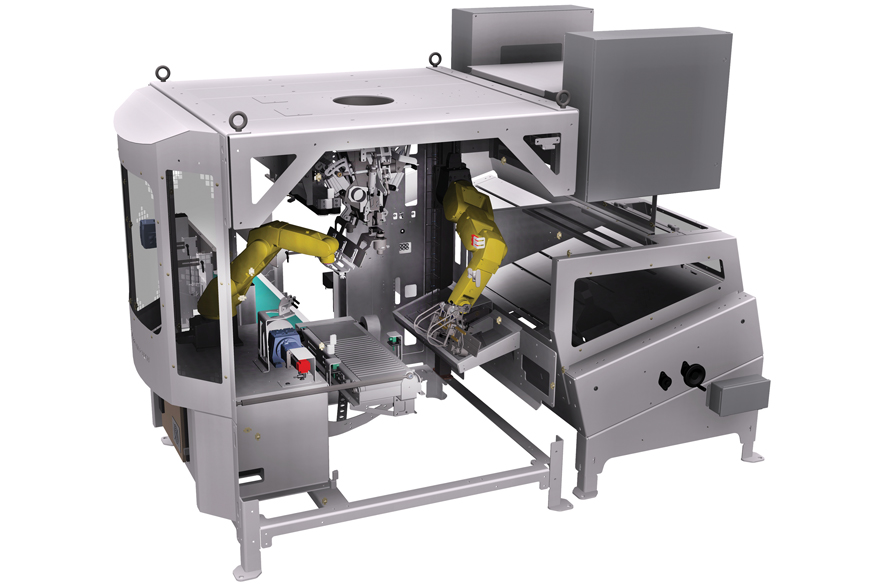

Robotic pick and place platform for food packaging

Enhance your packaging efficiency and product quality with a scalable ...

Industrial bag sealing solution for medical and food applications

Enhance your packaging line with reliable and versati...

Case packer for diverse food products

Optimize your packaging line with this versatile case packer, capable of handling a w...

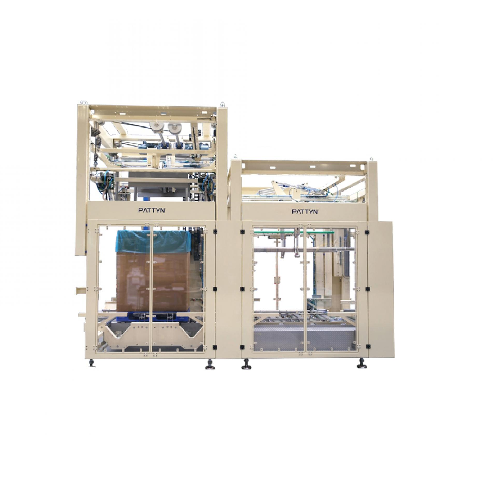

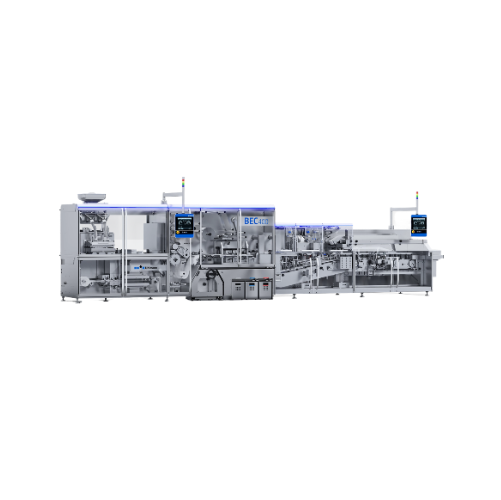

Cartoning solutions for beverage and food industries

Optimize your packaging line with a versatile range of cartoning sys...

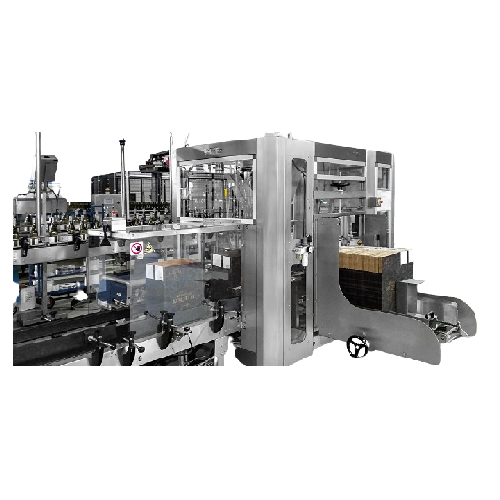

Side Load Case Packer For Packaged Food

Accuracy is a primary concern for case-packing pre-packaged foods such as milk or p...

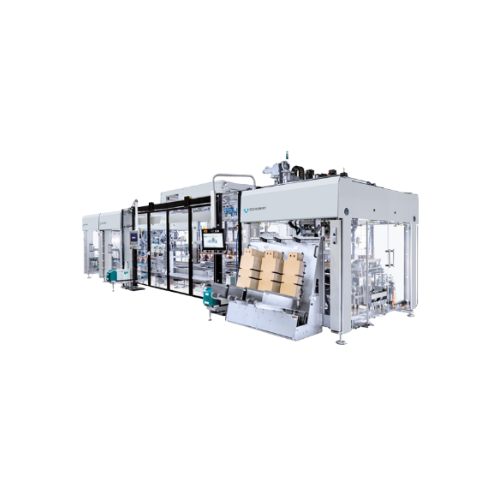

Intelligent Continuous Food Cartoner

Fully automated robotic packing solutions enable larger-scale food producers to pack a...

Washdown Cartoner For Frozen Foods

When packing frozen foods into cartons, your packaging system should be cleaned by wash-...

Tray sealer for food production

Companies in food industry know how essential packaging is in keeping food fresh and ensurin...

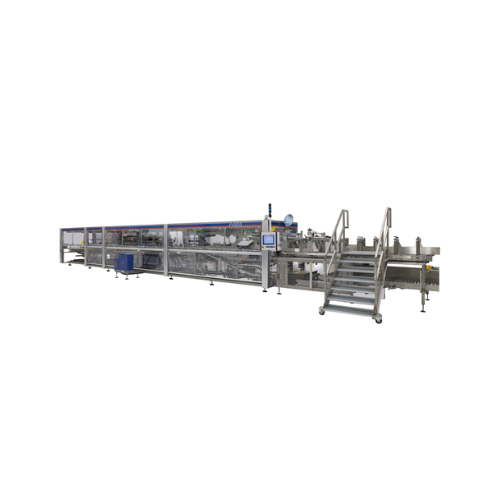

Frozen food automatic case packer

Adequately packaged frozen fries retain their original color, taste, and texture. And bec...

Machine for packing canned pet food

Most packaging applications require different types of packaging machines, some need wr...

Filling and weight checking machine for food cans

Making sure the right quantity of product is in the packaging can be a ...

Horizontal cartoner for food products

Depending on the primary product packages, food products like confectionery (biscuits...

Entry-level vertical cartoner for frozen food

When it comes to frozen food, selecting quality packaging is fundamental for...

Industrial thermoformer for food production

The primary purpose and aim of food packaging are to protect all food products...

Industrial food vacuum packaging machine

Compact and clean vacuum sealers help increase the value and quality of food produ...

Baguette cutting and sauce filling system

Optimize your bakery production with an innovative system that seamlessly cuts a...

Intermittent motion end load cartoner for baked goods and home care products

Streamline your packaging line with high-...

Intermittent end load cartoner for baked goods and snacks

Optimize your packaging line with an efficient, space-saving c...

Rotary indexing sealer for cup filling

Streamline your production line with precise cup filling and sealing, ideal for a wi...

High-speed aerosol filling system for personal care products

Streamline your aerosol production with a multi-functional ...

Tailor-made transport systems for confectionery production

Optimize your confectionery production line with customizable...

Semi-liquid weigh filler for edible oils & fats

Achieve precise weigh filling of semi-liquids while minimizing product was...

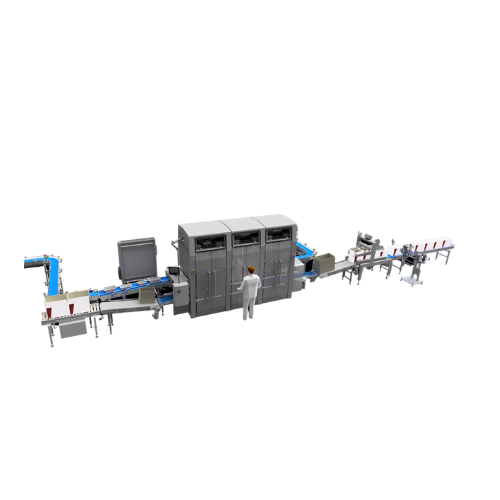

Industrial vision robot for optimized packing

Optimize your bakery production line with a system designed to efficiently p...

Linear belt vibratory weigh filler for solid chocolate

Optimize your chocolate production by minimizing product giveaway ...

Automatic bag inserter for various containers

Optimize your packaging process with a high-speed bag inserter that perfectl...

Combined case erector with bag inserter for packaging lines

Streamline your packaging process by integrating case erecti...

Hermetic bag sealer for extended shelf life

Achieve superior product protection and extended shelf life with precision her...

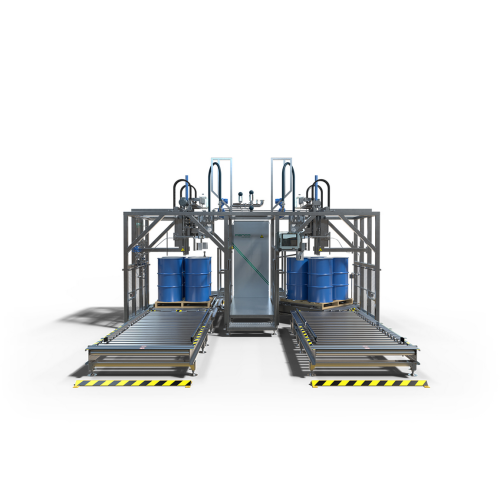

Industrial Xl bag sealer for large pallet containers

Eliminate manual handling and ensure perfect seals for bulk packagin...

Bag inserter for drums

Effortlessly streamline your packaging process by automatically inserting custom-made bags into drums,...

Vertical bagging system for four corner seal bags

Optimize your coffee pod and capsule production with a high-speed, cont...

Automated case erector for Rsc cartonboard

Streamline your packaging line with an innovative solution that efficiently for...

Automatic case erector for Rsc-american cartonboard

Streamline your packaging process with precise and efficient setup by...

Automatic case erector for cartonboard with hot-melt glue binding

Streamline your packaging line with efficient case er...

Automated carton former for Rsc american boxes

Streamline your packaging line with high-speed carton forming that combines...

Automated carton forming for bottles

Optimize your bottling line with an integrated carton forming solution that combines s...

Automated bottle packaging solution for breweries

Streamline your packaging process with a compact unit that combines bas...

Automated case erector for high-speed packaging lines

Streamline your packaging line with this solution that forms and se...

Bottle repacking system for return cartons

Optimize your bottle repacking efficiency with a system designed specifically f...

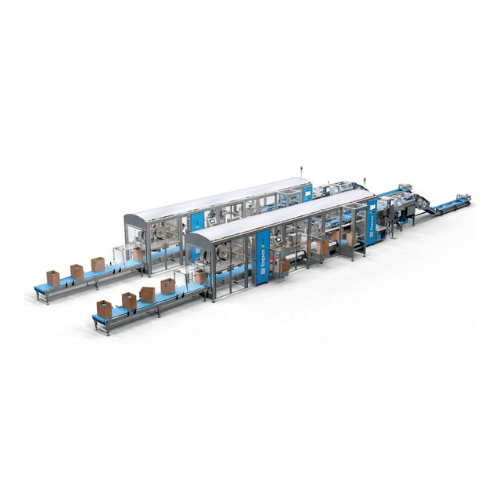

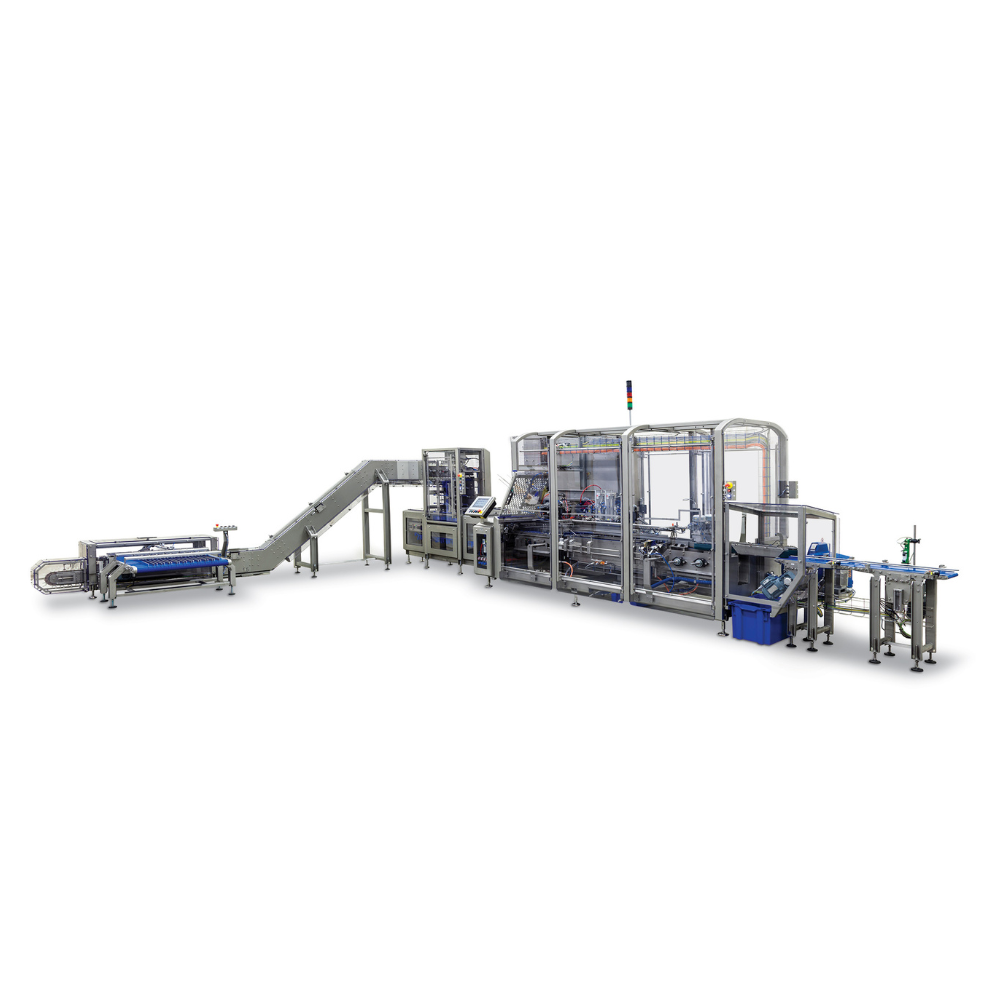

Automated packaging line for bottling industry

Streamline your packaging operations with a fully automated solution design...

Automated case erector for american cases

Streamline your packaging line by efficiently erecting American-style cases with...

Automatic bag-in-box packaging system

Optimize your liquid packaging with a precise and seamless workflow, ensuring efficie...

High infeed palletizer for varied product types

Optimize your production line with high infeed palletizers, ensuring seaml...

Wrapping system with intermittent motion for high-speed packaging

Optimize packaging speed and efficiency for diverse p...

Pick and place cartoning solution for Hdpe bottles

Streamline your packaging process with precise HDPE bottle handling an...

Automatic case packer for soft pillow bags

Streamline your packaging process with a case packer designed to efficiently ha...

High-speed in-line palletizer for beverage industry

Effortlessly streamline your palletizing processes with a compact, hi...

Conventional palletizer with 90° infeed

Optimize your palletizing efficiency with high-speed, energy-saving operations that...

Basket packer for fully recyclable packaging

Achieve high-speed, plastic-free packaging for diverse solid products with op...

Combined shrink-wrapper and case packer for medium to high-speed productions

Optimize your end-line packaging process ...

Medium to high-speed carton packing solution

Optimize your packaging operations with a versatile solution capable of handl...

Industrial shrink wrapper for beverage packaging

Maximize packaging efficiency with this flexible shrink wrapper, designed...

Shrink wrapping solution for high capacity beverage and dairy bundles

This modular shrink wrapping and tray forming sol...

Compact shrink wrapper for medium-speed productions

Optimize your packaging line with this compact shrink wrapper, design...

Robotic crating and decrating solution for returnable glass bottles

Streamline your bottling line by efficiently handli...

Shrink wrapping solution for low-speed packaging

Achieve seamless low-speed packaging with a shrink wrapping solution desi...

Fully automatic rotary ring wrapper

Achieve superior load stability and efficiency with this rotary ring technology, ideal ...

High-speed automatic rotary ring wrapper for stretch wrapping

Optimize your packaging line with a fully automated high-s...

Fully automatic rotary ring wrapping solution

Optimize your packaging line with this advanced wrapping technology that enh...

Automatic rotary ring wrapper for high-speed pallet wrapping

Achieve optimal load stability and reduce material usage wi...

Automatic horizontal banding system for label application

Optimize your end-of-line operations with a high-speed horizon...

Fully automatic horizontal banding solution for labeling

Optimize your packaging line with a sophisticated banding system...

High-speed wrap-around case packer for beverage industry

Optimize your packaging line with a high-speed case packer that ...

Tube filling solution for plastic and laminate tubes

Ensure precise tube filling and sealing with quick changeovers, enha...

Tube filling solution for plastic, laminate, and aluminum tubes

Optimize your production line with a versatile tube fill...

Hig Speed Tube Cartoner

Achieve seamless integration into your high-speed packaging line with a cartoning solution that ensur...

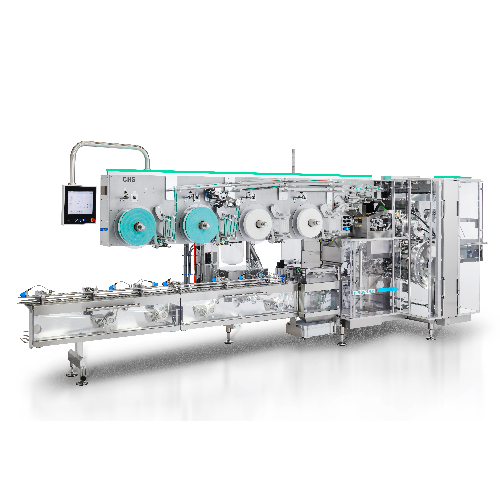

Cartoning solution for tube applications

Streamline your cartoning operations with a machine designed for flexible size cha...

Tube filling station for plastic, laminate, and aluminum tubes

Efficiently seal and fill various tube materials, ensurin...

Linear weigh filler for accurate box packaging

Ensure precise weight-based filling for a variety of solid products, from d...

Accurate powder filling solution

When precision is paramount, this solution offers exceptional accuracy, filling powders up ...

High-precision batch counting solution

Achieve precise product alignment and counting with advanced vibration and photocell...

Thermoforming packaging for high-output segment

Enhance your production efficiency with advanced thermoforming technology,...

Labelling solution for thermoformed packaging

Ensure flawless labeling integration with high-speed, continuous production....

Marking solutions for traysealers

Ensure precise labeling and data printing on tray-sealed packages with integrated solutio...

Mbs belt systems for seamless packaging integration

Optimize your packaging line with a system that seamlessly merges mul...

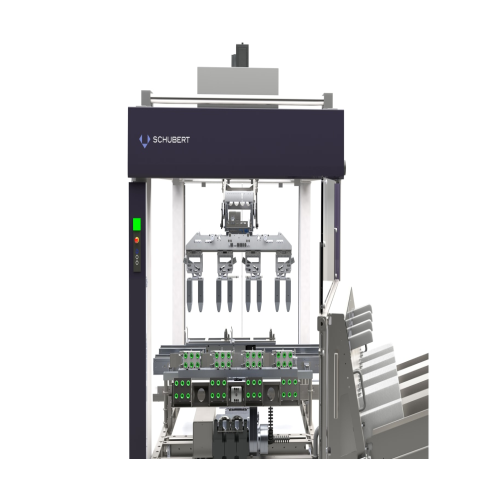

Robotic loading systems for packaging applications

Enhance your production line with versatile robotic loading systems, d...

Vacuum preservation system for professional packaging needs

Enhance your food product longevity and quality with precise...

Intermittent pick and place solution for stackable items

Optimize your production line with high-speed, intermittent oper...

Horizontal continuous motion cartoner

Streamline your packaging process with a high-speed cartoning solution that ensures p...

Valves for bulk powder flow control

Ensure efficient and controlled discharge of diverse powder forms while minimizing flow...

Tray diverter for packaging line efficiency

Optimize your packaging line with an advanced tray diverter designed to stream...

High-pressure forming solution for plant-based and meat products

Experience precision forming with versatile application...

Low pressure forming for plant-based products

Achieve precise shape and weight consistency in plant-based products with lo...

Low-pressure forming solution for plant-based products

Achieve a handcrafted look and precise texture retention for plant...

Multihead weigher for frozen products

Achieve precise fixed-weight batching and minimize product giveaway with high-speed, ...

Compact grader for poultry and meat processing

Streamline your production line with this precise grading solution, designe...

Top-loading cartoner for bar and confectionery packaging

Optimize your high-speed packaging operations with a flexible ca...

Horizontal flow wrap solution for chocolate bars

Achieve high-speed precision in packaging with a machine designed to hand...

Fold wrapping solution for round pharma tablets

Ensure precise and gentle packaging of round tablets with our innovative f...

Volumetric filling and capping solution for liquids and viscous products

Effortlessly integrate high-precision filling ...

Semi-automatic packaging system for sauerkraut and vegetables

Efficiently tackle the challenge of packing sticky product...

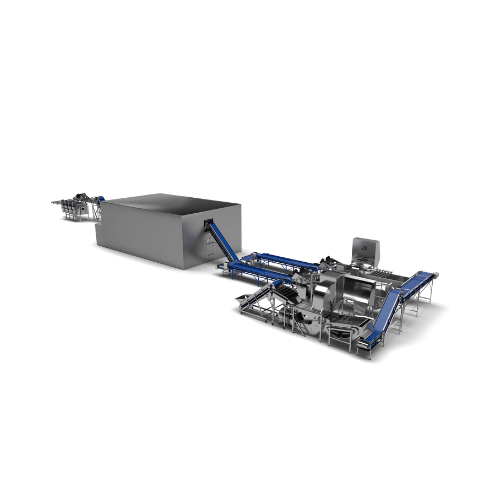

Automatic dosing and packing system for cabbage and sauerkraut

Streamline your vegetable processing line with a robust, ...

Flexible packaging line for beverage production

Streamline your beverage production with a flexible system capable of hand...

Paper packaging machine for agricultural products

Streamlining your packaging process, this machine efficiently seals foo...

Packaging solution for bulk vegetables and fruits

Ensure precise, high-speed packaging for diverse product sizes with a f...

Dense phase vacuum conveying for fragile powders

Efficiently convey fragile powders without compromising their integrity, ...

25kg powder packaging system for sanitary applications

Achieve high accuracy and hygiene in powder packaging with a syste...

Bag break station for pneumatic conveying systems

Efficiently manage powder feeding and dust control in your production l...

Sanitary bulk bag unloader for powdered products

Efficiently manage powder discharge with enhanced dust control and stream...

Flexible packaging system for beverage containers

Streamline your packaging process with a modular system that adapts sea...

Twin-column palletizer for flexible packaging feed

Optimize your production line with flexible and high-speed palletizing...

High-performance distribution and combining system

Streamline your packaging operations with a versatile system designed ...

Gentle container conveyor for bottles and cans

Achieve seamless container flow with minimal noise and enhanced precision, ...

Wrap-around packer for cartons and trays

Effortlessly streamline your packaging process with a high-speed solution designed...

Fully automatic wrap-around shrink packer

Ensure maximum pack stability and energy efficiency with this high-performance s...

Automated end-of-line packaging for diverse products

Streamline your packaging line with this automated solution, designe...

Vertical packaging for leafy greens

Optimize your packaging line with high-speed vertical systems designed for precise pack...

Sleeving system for leafy greens and cut fruits

Enhance your packaging line with seamless tray sleeving, enabling high-spe...

Vertical packaging for fresh produce

Streamline your fresh produce packaging with high-speed vertical form fill seal machin...

Intermittent motion cartoner for pharma packaging

Streamline your packaging line with versatile cartoning solutions that ...

Top loading cartoner for variable box sizes

Achieve precision packaging with a versatile top-loading cartoner that adapts ...

High-speed side loading case packer for small dimensions

Optimize your packaging line with a high-speed solution designed...

Automatic biscuit sandwiching equipment for high-volume production

Optimize your biscuit production line with high-spee...

Entry-level flow wrapping machine for small and medium products

Optimize your packaging line with a high-speed flow wrap...

Semi-automatic tray packing for soup cubes

Effortlessly package soup cubes into organized, stratified layers, optimizing y...

Vertical bagging system for heat sealing films and Lpde

Achieve unparalleled flexibility with a versatile vertical baggin...

Horizontal form fill and seal for biscuits on edge

Optimize your packaging line with a machine that streamlines wrapping ...

Flexible flow wrapping solution for small and medium products

Enhance your production line with a versatile flow wrappin...

Horizontal flow wrapper for medium performance level

Offering high-speed, continuous flow wrapping, this versatile machin...

Stick pack forming, filling, and sealing solution

Enhance packaging efficiency with a high-speed solution designed for pr...

Automatic sandwich biscuit production system

Elevate your biscuit production line with high-speed sandwiching capabilities...

Filling and sealing system for pre-formed cups

Experience seamless integration of hygienic filling and sealing with adapta...

Stand-up pouch making system

Efficiently transform pre-printed reels into customizable stand-up pouches with precise unwindi...

Filling and wrapping system for pasty products

Achieve precise dosing and flexible wrapping of diverse pasty products, ens...

Rotary filling and sealing system for pasty products

Efficiently streamline your cup and tub packaging process with a ver...

Flow wrapper for processed meat and cheese

Optimize wrapping efficiency and hygiene in your meat and cheese packaging line...

Top loading case packer for loose or bundled bottles

Effortlessly handle and pack both standard and uniquely shaped bottl...

Cartoning solution for soup cubes

Optimize your soup cube packaging process with a compact, high-speed wrap-around solution...

Intermittent vertical form fill seal for confectionery packaging

Optimize your packaging operations with this versatile ...

Continuous vertical form fill seal packaging solution

Experience unrivaled accessibility and efficiency in packaging fres...

High-speed multi-head weigher for confectionery products

Achieve precise measurements and minimize waste in high-speed fo...

Rotary doypack for granules, liquids, and powders

Enhance your packaging line with a rotary doypack system designed to ef...

Packaging solution for small bottles and jars

Effortlessly seal and fill non-stackable containers, ensuring precision for ...

Vertical stick pack sachet packaging solution

Ideal for mid-scale operations, this vertical stick pack machine streamlines...

Linear and auger weighing systems for non-free-flowing products

Optimize your production line with precise weighing and ...

Multi head weigher for precise portioning

Ensure consistent product portions with our multi head weigher, ideal for high-s...

Vertical form fill seal for small to medium production runs

Ideal for scaling production, this compact packaging solutio...

Top loading case packer for automated box sealing

Streamline your packaging line with a top-loading case packer that effi...

Rotary filler and sealer for dairy products

Optimize your filling and sealing needs with a compact solution designed for c...

Industrial pick and place system for packaging

Streamline your packaging line with precise robotic pick and place operatio...

Continuous powder agglomeration system

Enhance product solubility and flowability while minimizing energy consumption with ...

Cheese packaging system for mixed cheese types

Optimize your cheese production line by seamlessly integrating a system des...

Automatic salad filler for preformed trays

Streamline your salad packaging process with this high-speed solution, ensuring...

Valve bag filling system for cement and chemicals

Optimize your material handling with precision filling and sealing, ens...

Stationary entry packaging system for valve bags

Optimize your packaging workflow with a high-speed, modular filling syste...

Fully automatic bag applicator for valve bags

Maximize your packaging line efficiency with a high-speed system that seamle...

Packaging system for gummy products

Optimize your gummy production with a flexible packaging system that safeguards product...

Multi-lane ice cream wrapping system

Optimize your production line with a high-speed, multi-lane wrapping system designed t...

High-capacity ice cream cartonizing solution

Effortlessly handle complex ice cream production with a cartonizing solution ...

Automatic bag closing with metallic clipband

Ensure secure and efficient bag sealing for bakery products at high speeds wi...

Continuous flow-wrapping system for high productivity

Optimize your packing line with a high-speed flow-wrapping system d...

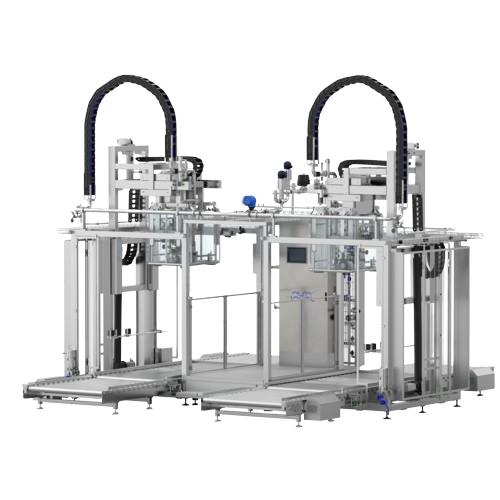

Automatic cartoning solution for 3-20l aseptic bags

Streamline your aseptic packaging with an integrated cartoning soluti...

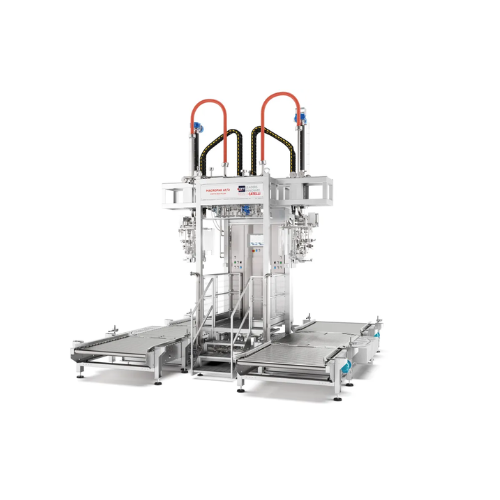

Aseptic filler for large bags

Ensure safe and sterile packaging of liquid and slurry products in large formats with this ase...

Rotary hot melt labeller for pre-cut labels

Achieve precise high-speed labelling of diverse containers with enhanced adhes...

Automatic mechanical line for rigid set-up boxes

Elevate your packaging precision with a high-speed mechanical system tail...

Automatic mechanical line for small-size rigid cardboard boxes

Optimize your packaging line with a solution tailored for...

High-care big bag filling system for hygienic environments

Ensure precise hygienic filling of Big Bags in high-care envi...

Bag-in-box filling system for packaging efficiency

Streamline your packaging process by integrating filling and boxing in...

Horizontal flow pack packaging solution

Achieve seamless packaging with versatile flow pack machines, designed to efficient...

Horizontal flow pack packaging system for flexible materials

Enhance your packaging line efficiency with a system design...

Horizontal flow pack packaging machine for multi-format packaging

Streamline your packaging process with a versatile ho...

Flow pack packaging system for flexible wrapping material

Achieve seamless, high-speed packaging of solid foods with thr...

Flow pack packaging for flexible wrapping material

Achieve precise and secure packaging with three-sided sealed packages ...

Flow pack packaging for irregularly shaped products

Achieve precise packaging for irregularly shaped and delicate items w...

Horizontal flow-pack solution for flexible wrapping material

Simplify your packaging process with a high-speed, three-si...

Three-side sealing flow pack machine

Optimize packaging efficiency with a high-speed flow pack machine that ensures precise...

Three-side sealing packaging machine

Achieve precise, three-side sealed packaging for both food and non-food products, enha...

Single station modified atmosphere packaging system

Ensure the extended shelf life of sensitive foods with precise gas fl...

Multi-station modified atmosphere packaging system for bulk products

Optimize your packaging efficiency with a system d...

Automated modified atmosphere packaging solution for pre-wrapped trays

Streamline your packaging process with high-spee...

Bigbag filling system for powder and bulk materials

Ensure precise and dust-free bigbag filling with this versatile syste...

Weight filler for small batches in explosive areas

Efficiently handle and weigh small batch products with precision, even...

Robotic case packers for bags and pouches

Efficiently pack a variety of bagged and pouched products with precision handlin...

Robotic handling systems for beverage containers and bins

Streamline your container handling with precision-engineered r...

Aseptic fillers for liquid and viscous products

Ensure sterile and precise filling of liquid and viscous foods with adapta...

High-speed wet glue labelling system

Ensure precise labelling on diverse bottle types with our versatile rotary labelling s...

High-speed packaging system for flow-wrapping

Streamline your packaging operations with a high-speed flow-wrapping solutio...

Rotary filling solutions for ice cream cups and cones

Optimize your ice cream production with customizable rotary filling...

Automatic filling system for continuous bags

Ensure precision in liquid and gas handling with this high-speed system, desi...

Bag-in-box carton erector

Experience seamless carton erection with advanced servomotor technology, enhancing both efficiency...

High-speed horizontal case packer for shipping cases

For high-demand production lines, this modular case packer streamlin...

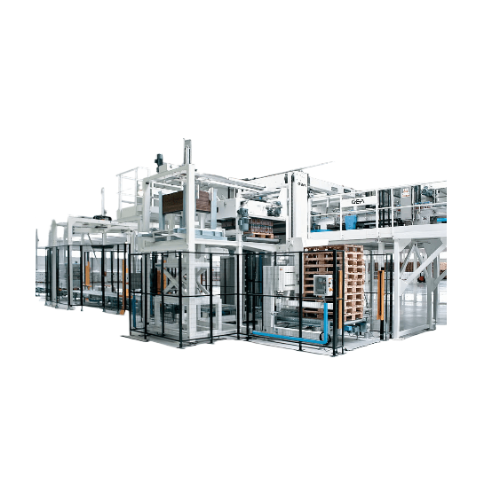

Integrated case-packing and case-palletizing system

Streamline your production line with an all-in-one system that seamle...

High-speed continuous motion overwrapper for thin films

For those needing high-speed, efficient wrapping, this equipment ...

Shrink-sleeve application system for packaging

Enhance your packaging line with efficient, precise shrink-sleeve applicati...

Tray forming machine for packaging solutions

Streamline your packaging operations with precision-engineered tray forming t...

High-speed continuous motion cartoner

Streamline your packaging line with precise cartoning operations, ensuring secure and...

High speed stick packaging solution

Optimize your packaging line with this high-speed vertical solution, designed to effici...

Vertical intermittent motion cartoner for manual or automatic feeding

Optimize your cartoning process with a machine de...

Retail packing solution for Iqf products

Streamline your IQF product packaging with a compact system designed to cut manual...

Automatic sausage depositor

Streamline your production by precisely depositing and aligning sausage portions into trays, ens...

Iqf strawberry processing line

Optimize your strawberry processing with a line designed to ensure gentle handling, precise s...

Marinating line for meat and poultry

Streamline your marinating process with reduced spillage and cleaning time by incorpor...

High-speed weighing system for large batch sizes

Maximize yield and minimize waste with a high-speed batching solution des...

Multihead weigher with vibratory feeding

Experience precise and efficient weighing with a multihead system designed for com...

Flexible weighing and packaging solution for small batch producers

Streamline your packaging line with a mobile solutio...

Tray lid packer & case erector for packaging lines

Efficiently manage packaging lines by seamlessly integrating tray lid ...

Modular end-of-line packaging solution

Enhance your packaging line efficiency with a modular solution engineered to handle ...

Paper inserter for thermoformers and tray sealers

Streamline your packaging line by automating the insertion of materials...

American case packer & case erector for Rsc cartons

Streamline your end-of-line packaging by efficiently erecting and pac...

Case packer for wraparound and tray cartons

Enhance your packaging efficiency by seamlessly integrating flexible and high-...

Carton erector for cup trays

Optimize your packaging line with a high-speed carton erector designed to seamlessly transition...

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

Automatic bagging station for powdery products

Streamline your packaging line with a reliable solution designed for high-s...

Bagging control system for centralized operations

Streamline your bagging operations with a centralized control system, d...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Chain conveyor for grain handling

Optimize your production line with a customizable chain conveyor that ensures efficient, ...

Chestnut processing line for fresh market

Efficiently transform raw chestnuts into polished, fresh market-ready products w...

Chestnut puree production plant

Optimize your chestnut product line with a versatile production plant capable of transformin...

Top load and side load case packer with vision guided robotics

Optimize packing efficiency and flexibility with a versat...

Automatic case packer for frozen potato products

Efficiently pack frozen and delicate products with precision side-loading...

High-speed case packer for flexible bags

Streamline your packaging process with a solution designed for high-speed, error-f...

Vision-guided variety pack solution for confectioneries

Achieve seamless variety pack assembly by dynamically loading var...

Fruit base processing technology for yoghurt and bakery

Ensure the integrity of fruit preparations while maximizing varie...

Cold extraction and enzymatic deactivation for fruit and vegetable purees

Enhance your puree quality with advanced col...

Full production line with depositing and ultrasonic cutting

Streamline your baked goods and dessert production with this...

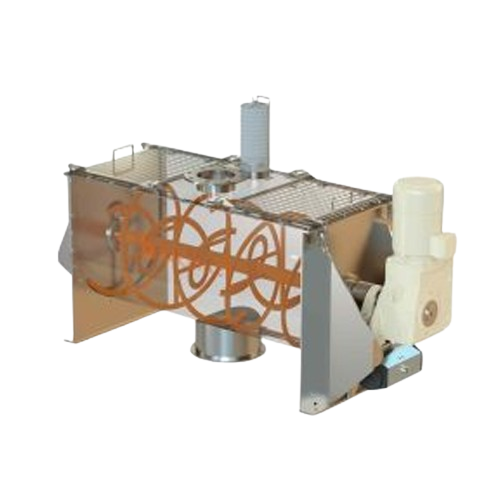

Horizontal ribbon blender for solids and powders

Efficiently achieve uniform blending of bulk solids and powders, ensuring...

Ultra-clean vertical bag filler for viscous and particle-containing products

Streamline your viscous product packaging...

Automatic packaging line for bag-in-box

Streamline your bag-in-box production with a seamless solution that ensures precisi...

Automatic case erector for cartonboard packaging

Streamline your packaging process with precision engineering that simplif...

Automatic case erector for cartonboard packaging

Streamline your packaging process and enhance operational efficiency with...

In-line aggregation module for serialized item management

Optimize your serialization process by seamlessly managing and...

Automatic case erector for american cases

Streamline your packaging line with high-speed case erecting, reducing labor cos...

Special checkweighers for industrial applications

Enhance your production line efficiency by precision weighing your prod...

Industrial checkweighers for medium-large products

Manage large and heavy packagings with precision and efficiency, ensur...

Automatic tortilla production line

Streamline your tortilla production with a fully integrated line that handles pressing, ...

Burrito forming equipment

Streamline your burrito production by automating the delicate tasks of filling, folding, and wrapp...

Automatic wrapping for small products

Achieve precise and efficient packaging of diverse small products with seamless verti...

Automatic boxing system for wrapped products

Streamline your packaging line with precision as this high-speed boxing solut...

Fully automatic packaging solution for butter and pasty products

Streamline your production line with this versatile pac...

Automatic packaging for small cheese products

Effortlessly package a variety of cheese shapes and sizes with quick format ...

Multi-fill powder filling system

Achieve precise and consistent filling for your powdered and granulated products with a mod...

Gravimetric filling solution for inconsistent density products

Achieve precise weight accuracy in your filling processes...

Industrial auger sack filler for large bags

Designed to efficiently fill large bags and sacks, this advanced filling machi...

Vertical form fill seal filling system for auger applications

Effortlessly integrate precise powder and granule filling ...

Flexible bag-in-box filler for liquid and viscous products

Optimized for flexibility and efficiency, this bag-in-box fil...

Thousand-litre aseptic filler

Ensure the aseptic filling of bulk liquid and viscous food products, reducing contamination ri...

Automatic volumetric filler for liquid products

Optimize your production with this high-precision volumetric filler, desig...

Multi-style candy and chocolate wrapper

Achieve high-speed, precision wrapping for diverse confectionery products with vers...

Heat sealer for thermoplastic bags

Ensure airtight seals on thermoplastic bags with precise temperature control and adjusta...

Ultrasonic tube sealer for plastic tubes

Seal plastic tubes with precision and speed using our ultrasonic technology, ensur...

Automatic timed flow volumetric filling machine

Streamline your liquid packaging process with precise volumetric filling o...

Semi-automatic timed flow filler for aqueous solutions

Handle diverse liquid filling needs with precision, from thin oils...

Packaging conveyor for efficient bag handling

Simplify your packaging line with a conveyor designed to efficiently transfe...

Single lane collator for packaging room

Streamline your packaging operations by efficiently collating, counting, and aligni...

Smart pack conveyor systems for packaging room

Efficiently manage the flow of snack and nut products from packaging to dis...

Retractable spiral chute for bulk material handling

Enhance the integrity of your products by gently transferring bulk ma...

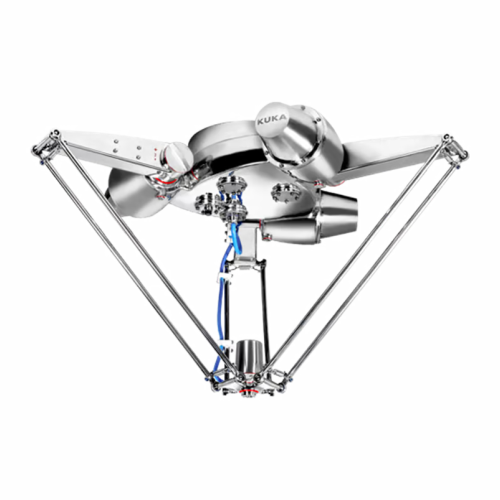

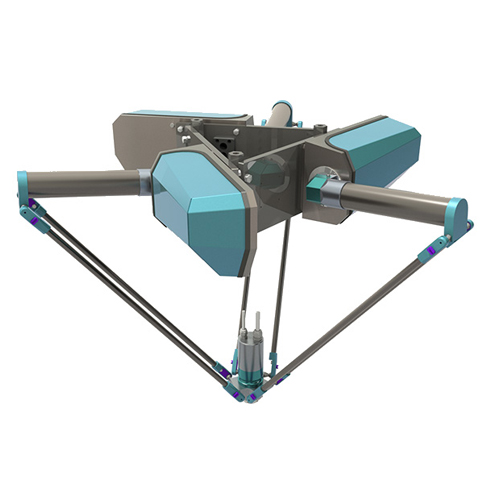

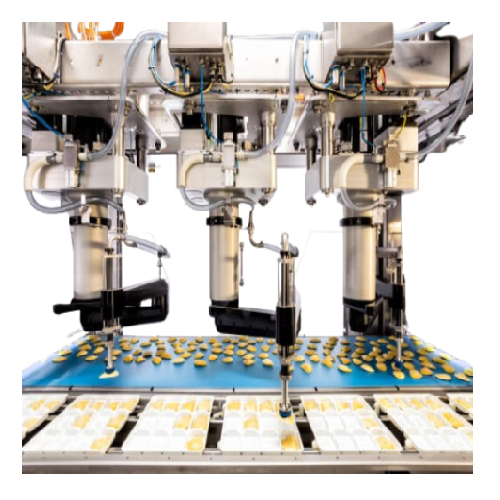

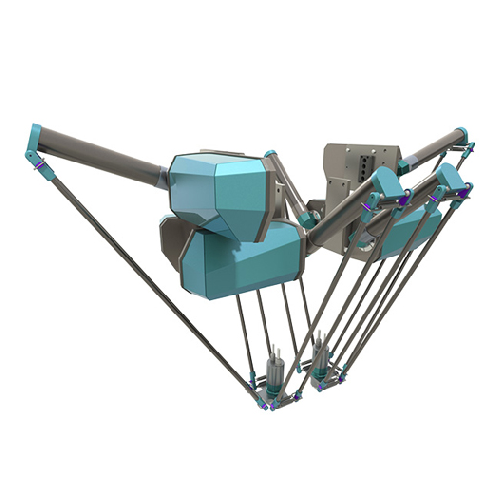

Delta robot for hygienic manufacturing processes

Enhance your processing line with precision and speed, ensuring hygienic ...

Linear conveyor for sandwich packing

Streamline your sandwich production with a high-speed linear conveyor system, designed...

Semi-automatic tray sealing for ready meals

Achieve versatile packaging with a semi-automatic tray sealing solution design...

Automatic tray sealing system for high-speed packaging

Experience seamless high-speed packaging with this versatile tray ...

Automatic tray sealer for high-speed production

Ensure your product packaging stays fresh and secure with this high-capaci...

Industrial case packing solution for high-speed operations

Optimize your production line with a compact, efficient case ...

Bench mounted tray sealer for small-scale production

Perfect for pilot runs and small batches, this compact tray sealer e...

Bench mounted tray sealer with gas flush

Optimize your production line with a compact tray-sealing machine designed for pre...

In-line tray sealer for high-speed packaging

Optimize your packaging line with a high-speed solution that accommodates mul...

High-capacity tray sealer for vacuum gas packaging

Enhance your production efficiency with a versatile twin-lane tray sea...

In-line tray sealing system

Streamline your packaging line by implementing a high-speed, in-line tray sealing system designe...

Automatic tray sealer for high-speed packaging

Streamline your packaging line with an in-line tray sealer that adapts to t...

Large-capacity automatic tray sealer

Optimize your production line with this tray sealer, designed for high-speed sealing a...

Industrial high speed tray sealer

Enhance your production line efficiency with precision sealing capabilities, accommodatin...

Automatic tray sealer

Maximize throughput and shelf life with our high-speed inline tray sealing solution, ideal for diverse ...

Automatic tray sealing system

Optimize your packaging line with versatile tray sealing technology that accommodates various ...

Automated scoop insertion system for powder containers

Streamline your container filling operations by ensuring precise s...

Automatic tuna can filler

Streamline your high-speed canning operations with precision-engineered fillers that maintain opti...

Aseptic filler for fluids, concentrates, and particulates

Optimize your fluid and concentrate filling process with a hig...

Aseptic filler for juices and beverages

Ensure sterile packaging with precision. This aseptic filler offers high-speed, con...

Poultry bagging system

Enhance your poultry packaging efficiency with a reliable system that ensures leak-proof, ready-to-coo...

Vertical poultry bagger for whole birds packaging

Optimize your packaging efficiency with a vertical bagger designed for ...

Automated clipped netting system for meat packaging

Enhance your packaging line with a system designed for rapid and prec...

Automatic clipper for ready-made casing sections

Streamline your food and pet food packaging with precision clipping for v...

Industrial robot picker for automatic packaging

Streamline your food packaging line with high-speed robotic picking, ensur...

Automatic loader for sliced portions and burgers

Streamline your production line with a flexible loader that efficiently h...

Auger powder sampler for industrial quality control

Ensure precise quality control by integrating an auger powder sampler...

Continuous motion packaging for short-cut pasta

Optimize your packing line with a high-speed solution designed for efficie...

Vertical form-fill-seal packer for frozen vegetables

Efficiently streamline your packaging line with a versatile solution...

High-speed vertical packaging system for candy and snacks

Achieve up to 500 pillow bags per minute with our high-speed p...

Palletizer for high-speed pallet loading

Achieve efficient, high-speed palletizing with a system designed for seamless inte...

Palletizing solution for low to medium production capacity

Optimize your production line with a palletizing solution des...

Multiple feed lane converger system for thermoforming packaging

Efficiently manage high-speed packaging lines by seamles...

Oxygen and leakage detection in Map packaging

Ensure enhanced food safety and reduce waste with precise oxygen and leak de...

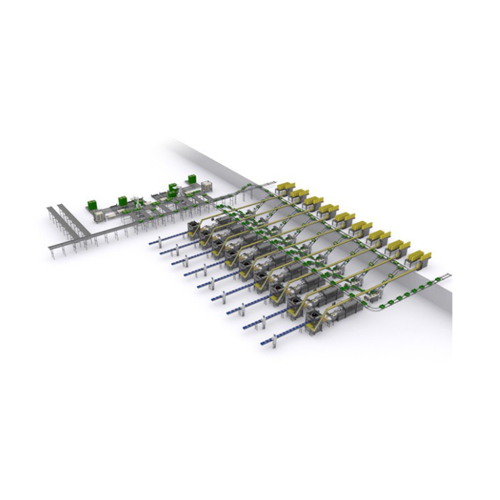

Thermoforming packaging for meat and dairy products

Streamline your packaging process with advanced thermoforming technol...

Thermoforming packaging system for meat products

Enhance your packaging capabilities with a modular thermoforming system d...

Thermoforming packaging for skin applications

Enhance your packaging line’s versatility with a solution designed for...

Vertical form fill sealer for high-speed packaging

Achieve consistent, high-speed packaging with flexible bag styles, per...

Low care bulk powder fillers

Optimize your production efficiency by accurately filling flexible bulk containers with dry pow...

Powdered product shelf-life enhancement through inert gas packing

Extend the shelf life of sensitive powder products by...

Layer preparation system for high-speed palletizing

Optimize your palletizing process with a system that ensures precise ...

High level infeed palletizer system

Optimize your production line with a high-speed palletizing solution that seamlessly in...

Plastic bag sealer for polyethylene bags

Achieve consistent hermetic sealing of polyethylene bags while preserving the inte...

Automated powder bag filling system

Streamline your powder packaging operations with a fully integrated system that automat...

High care bulk powder fillers

Ensure hygienic packaging for your bulk powders with a system designed to enhance filling accu...

Volumetric loading system for biscuits and crackers

Streamline your snack production with efficient volumetric loading, d...

Robot for picking and placing cookies in wrappers

Boost efficiency and flexibility in your bakery production line with vi...

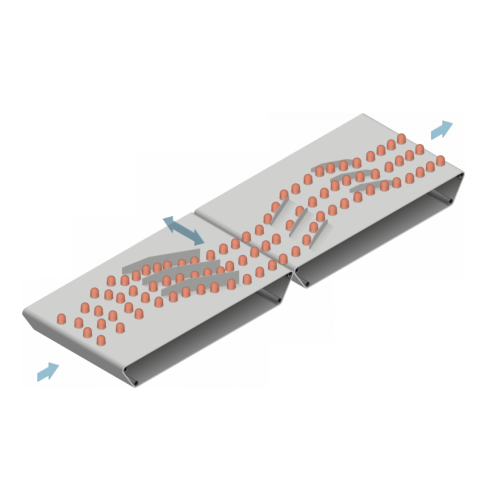

Chicane system for portion pack flowrapper

Streamline your packaging process with a system that ensures precise portioning...

Industrial fruit juice extractor

Maximize juice yield from a wide range of fruits and vegetables with precise extraction and...

Industrial citrus juice extraction system

Streamline your juice production with a versatile system that efficiently extrac...

Bag in box bottling system for fruit and vegetable juice

Streamline your juice production with precise filling and packag...

Industrial multifiller for fruit and vegetable salads

Need to efficiently fill diverse containers with fruit and vegetabl...

Thermoforming packaging system for medium production volumes

Optimize your food packaging with high-speed, continuous op...

Manual Fibc bag filling station

Achieve dust-free filling of bulk bags with an efficient system designed to handle compacted...

Omnidirectional inspection system for bottles and vials

Ensure precise serialization and aggregation with a 360° inspecti...

Stand-up pouch filling and sealing system

For packaging lines that demand quick, efficient, and flexible pouching, this hi...

Stand-up pouch packaging for various products

For manufacturers seeking versatile packaging solutions, this machine delive...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Horizontal flat pouching for top-cap pouches

For manufacturers aiming to streamline pouching operations, this high-speed h...

Horizontal flat pouching system for up to 180ml capacity

Optimize your packaging process with a high-speed solution desig...

Continuous stand-up pouching solution for up to 1000ml

Maximize efficiency in high-speed production lines with precise st...

Horizontal stand-up pouching system for liquids and solids

For producers aiming to optimize efficiency and precision, th...

High-capacity stick pack packaging solution

Enhance your production efficiency by packaging diverse products like powders ...

Stick pack packaging for powders and liquids

Streamline your packing process with high-speed, servo-driven stick pack mach...

Continuous motion liquid packaging system

Achieve precise and clean liquid packaging with advanced servo-driven squeegee s...

Continuous motion vertical form fill seal packaging system

Achieve high-speed, consistent packaging for diverse products...

High-speed vertical form fill seal packaging machine

Optimize your packaging line with this high-speed vertical form fill...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

High-speed vertical form fill seal for various packaging needs

Streamline your packaging process with an advanced vertic...

Vertical form fill seal for large bag packaging

For operations requiring precise, large bag packaging, this equipment ensu...

Vertical form fill seal for bulk bag packaging

Streamline your bulk bag packaging with efficiency and precision, ideal for...

Endload automatic cartoning solution

Streamline your packaging line with this versatile cartoning solution, perfect for eff...

Topload cartoning system for efficient product packaging

Streamline your packaging line with this compact system that com...

Topload cartoner for packaging cartons

Efficient flap closing for diverse carton sizes, ensuring gentle handling of sensiti...

Rotary premade pouch filler and sealer

Maximize production efficiency by seamlessly filling and sealing diverse pouch sizes...

Automatic rotary premade pouch filler and sealer

Optimize your production line with high-speed pouch filling and sealing, ...

Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed a...

Modified atmosphere packaging solutions for perishables

Extend the freshness and shelf life of perishable goods with prec...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Robotic packaging integration for automated systems

Enhance your production line efficiency with seamless robotics integr...

Sleeve cartoners for ready meals and salads

Optimize your packaging line with a high-speed sleeve cartoner designed to eff...

Bin fillers for fruit packing

Achieve precise and gentle handling of fruits and vegetables with flexible bin fillers that se...

Plum sorting and grading system

Enhance your fruit processing efficiency with our advanced solution that precisely sorts and...

Pepper sorting and grading technology

Ensure consistent quality and precision in size and color sorting for a wide array of...

Processing, sorting, and grading solutions for eggplants

Optimize eggplant production with advanced processing solutions ...

Apple sorting and grading system

Ensure precision and quality in apple processing with a cutting-edge system designed to opt...

Vertical form fill seal packaging for medium-speed production

Achieve efficient and reliable packaging for diverse food ...

Side seal shrink packaging machine

Achieve seamless and efficient packaging for varied product sizes with continuous side s...

Shrink film sleeve wrapper for packaging

Achieve efficient packaging for diverse products with a versatile sleeve wrapper d...

Thermoforming solution for flexible or rigid packaging

Optimize your packaging efficiency with a high-performance thermof...

Hygienic thermoformer for flexible film packaging

Streamline your packaging process with a hygienic thermoformer, offerin...

Traysealer for modified atmosphere packaging

Enhance your food packaging line with precise traysealing and modified atmosp...

Automatic tray sealer for cut & seal and Map applications

Optimize tray packaging efficiency with a versatile solution f...

Flow pack wrapper for shrink and film wrapping

Optimize your packaging operations with a versatile solution capable of hig...

Horizontal flow wrapper for packaging trays and punnets

Optimize your packaging process with an adaptable flow wrapper, p...

Leakproof flow pack wrapper for meat and poultry

Ensure your meat and poultry products remain fresh and visually appealing...

Horizontal flow wrapper for vacuum packaging

Enhance your food packaging line with a solution designed for precision vacuu...

Flow pack wrapper for frozen fish products

Ensure seamless packaging of frozen fish with high-speed efficiency, minimizing...

Horizontal flow wrapper for irregular products

Streamline your packaging line with a versatile wrapper designed for irregu...

Automatic hamburger packaging solution

Streamline your hamburger production with a fully automated packaging system that en...

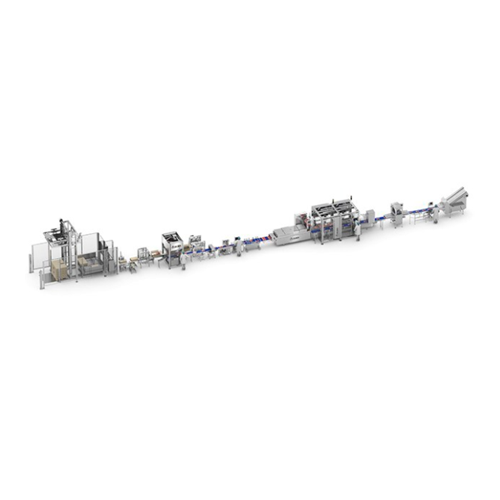

Automated packaging line for meat fillets

Streamline your meat fillet packaging with this fully automated system, designed...

Automated sliced meat packaging solution

Ensure seamless and efficient packaging of sliced meat products with a fully autom...

Complete packaging solution for meat products

Achieve seamless packaging integration with a solution designed to streamlin...

Traysealing system for chicken breasts packaging

Streamline your poultry packaging with a fully automated traysealing solu...

Frozen chicken cut-ups packaging solution

Maximize your poultry packaging efficiency with a solution that seamlessly integ...

Horizontal flow wrapper for medium to high production

Optimize your packaging line with a versatile horizontal flow wrapp...

Biscuit packaging and boxing solution

Streamline your biscuit production line with a fully automated system that ensures pr...

Complete primary and multipack packaging solution for bars

Enhance your bar production efficiency by seamlessly integrat...

Automated packaging and case packing for soft bread & buns

Ensure consistent and high-speed packaging for your bakery go...

Automated packaging line for wafers

Optimize your wafer production with high-speed, fully automated packaging and versatile...

Frozen hamburger packaging solution

Streamline your frozen burger production with a fully automated system that efficiently...

Sustainable biscuit packaging line

Enhance your biscuit production with a fully automated packaging line that leverages sus...

Flour distribution system

Efficiently streamline the regulation and distribution of flours within your production line, ensu...

Automatic packaging machine for open-mouth bags

Optimize your packaging line with precision weighing and high-speed baggin...

French fry production line

Optimize your French fry production with a seamless line that ensures precise cutting, consistent...

Automatic case packer for pharmaceutical industry

Optimize your packaging process with a versatile case packer designed t...

In-line filling and closing system for pre-formed containers

Looking to enhance production efficiency with a solution th...

Aseptic rotary cup filling and closing solution

Maximize your production capacity with this cutting-edge aseptic solution,...

Pre-formed container filling system for multi-layer products

Efficiently handle a diverse range of products with this fl...

Glass jar filling system for processed cheese

Streamline your production line with a robust, high-speed filling solution d...

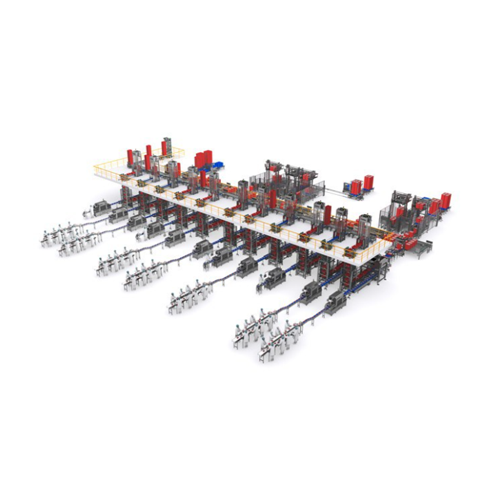

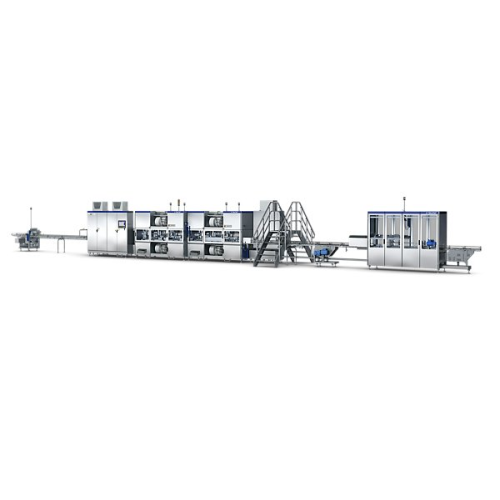

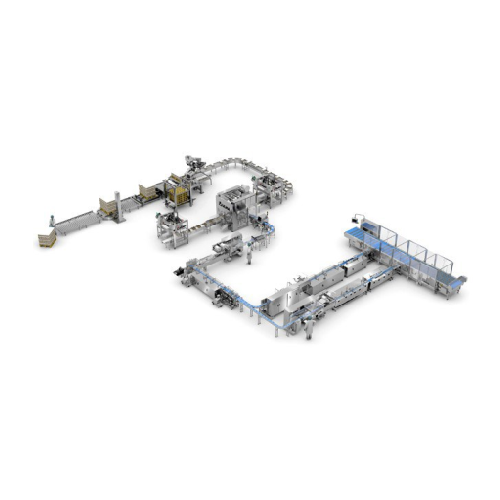

Fully automated packaging lines

Streamline your production with versatile packaging lines designed to handle a range of good...

Automatic pick & place system for product case loading

Achieve high-speed and gentle handling for diverse product types w...

Wrap around sleeving machine for single serve cups

Seamlessly organize and wrap single-serve cups with precision and spee...

Box cartoning solution for single bricks and bar packages

Efficiently collate and seal brick or bar-shaped products into...

Industrial shrink wrapping solution

Optimize your packaging line with a robust shrink wrapping solution, efficiently accomm...

Sweep and gantry robot palletiser

Optimize your packaging line efficiency with a versatile solution capable of seamlessly i...

Vacuum sealer for glass jars with metal lids

Streamline your food preservation process with a versatile vacuum system that...

Single and dual lane sorters for fresh produce

Optimize your food processing line with precision defect detection and vers...

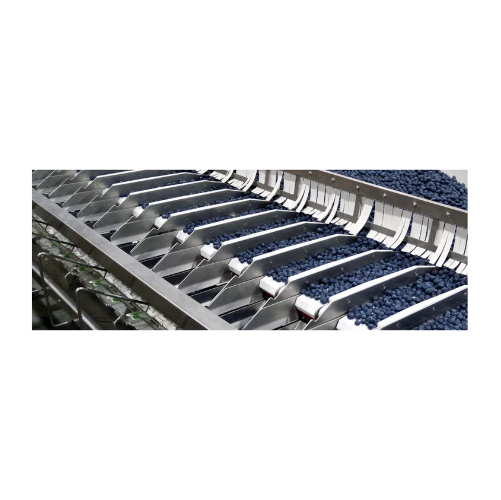

High-speed filling system for cherries and blueberries

Streamline your packaging process with a system designed for rapid...

Heavy duty checkweigher for large packages

Achieve precise in-motion weighing for large packages without halting your prod...

Lane arrangement for efficient product transfer

Optimize your production line’s efficiency with seamless integration...

High speed wrapping solution for pre-formed products

Achieve seamless integration of primary and secondary packaging with...

High-speed wrapping solution for compressed powder products

Efficiently wrap high-volume compressed powder products with...

Bouillon cube wrapping system

Streamline your packaging line with a high-speed system tailored for compact, compressed produ...

High-speed cartoning system for primary wrapped products

Optimize your packaging line with this high-speed cartoning syst...

High-speed chocolate wrapping system

Optimize your confectionery packaging process with a versatile, high-speed wrapping so...

Semi-automatic weigher for irregular products

Efficiently handle and weigh irregular products like whole fruits and meats ...

Spring roll manufacturing line

Optimize your spring roll production with an advanced manufacturing line that ensures consist...

Twin product multihead weighing system for mixing and sorting

Optimize your production line with precision mixing and hi...

Granule filling sachet machine

Ideal for optimizing packing operations, this granule-filling sachet machine ensures precise ...

Sachet powder filling machine

Optimize your packaging line with this efficient solution for precise powder filling, ensuring...

Automatic samosa production system

Optimize your ethnic food production with a machine that seamlessly forms and shapes var...

Modular linear packing system for granular products

Streamline your packing operations with a versatile system that integ...

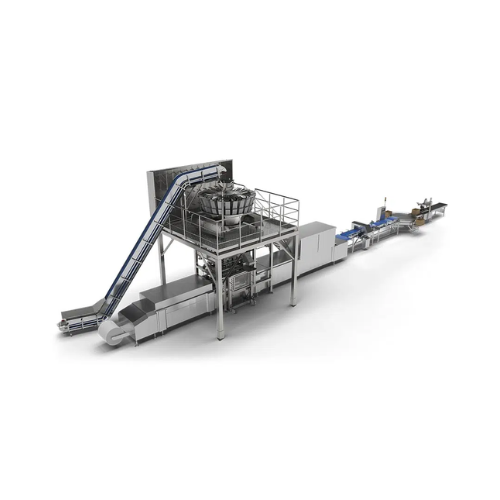

Modular packing system for multihead weighing

Streamline your production with a versatile multihead system designed for pr...

multihead weigher for dry products

Optimize your production line with precise weighing for dry products, ensuring high-spee...

Linear weigher for dry free-flowing products

Optimize your packaging line with precise weighing for snacks, sweets, and gr...

Linear weigher for dry free flowing powder

Optimize your packaging line with precise weighing for free-flowing granular pr...

10 head multihead weigher for dry products

Optimize your weighing and packaging operations with precise and rapid handling...

14 head multihead weigher for dry products

Achieve precise and rapid weighing for a variety of dry, free-flowing products ...

Rotary pouch filling system

Looking to efficiently manage pouch filling for diverse products? This rotary system seamlessly ...

Automatic tube filling solution for medium to high volume production

Boost your production line efficiency with a robus...

Horizontal cartoning machine for medium to high-speed production

Optimize your cartoning process with precise loading an...

Automatic case packer for mid-volume production

Optimize your packaging line with a compact case packer designed to handle...

Modular high-speed flow pack wrapper for preformed products

Eliminate packaging line bottlenecks with a versatile high-s...

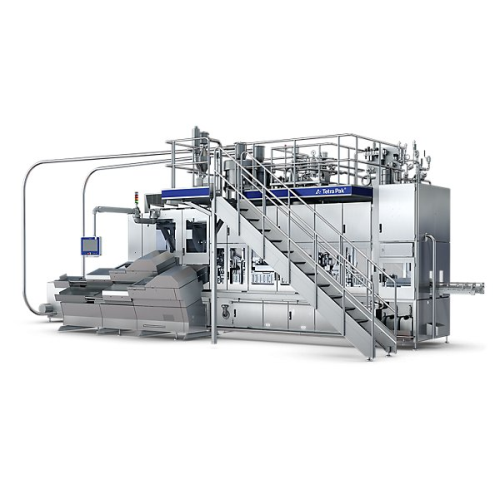

High-speed aseptic carton filling solution

Maximize production efficiency and meet growing demand with this high-output fi...

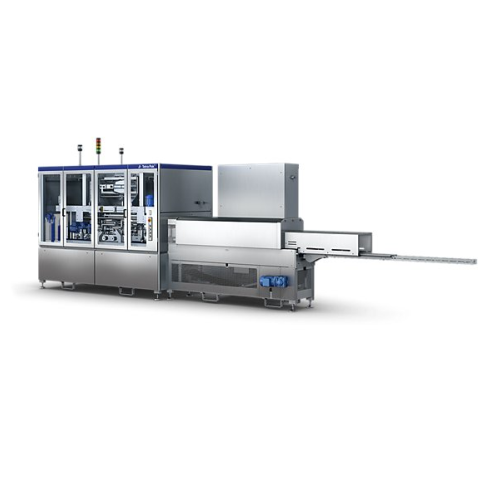

Filling system for gable top cartons chilled products

Achieve precise filling and reliable sealing for chilled beverages ...

Aseptic filling solution for tetra classic packaging

Experience efficient aseptic packaging with high-speed operation, of...

Cardboard packer for secondary packaging

Streamline your packaging process with a high-speed, automated cardboard packer th...

Shrink wrapping system for flex portion packages

Optimize your packaging line with a high-speed shrink wrapping system des...

High-speed shrink wrapping system

Enhance your packaging efficiency with a high-speed shrink wrapping system that ensures s...

Industrial tray shrink wrapper

Optimize your packaging line with rapid, resource-efficient shrink wrapping, accommodating di...

Straw applicator for tetra pak packages

Enhance your packaging efficiency with a high-speed solution that seamlessly attach...

Vegetable salad production line for lettuce processing

Streamline your vegetable processing with an all-in-one solution d...

Commercial mango dehydrator

Optimize your fruit processing with a commercial mango dehydrator that ensures precise moisture ...

Garlic splitting and peeling line

Streamline garlic processing with this high-speed line designed to efficiently split, pee...

Complete fruit and vegetable washing plant

Optimize your production line with efficient fruit and vegetable washing, ensur...

Full-automatic biscuit & cookie production line

Streamline your biscuit and cookie production with a comprehensive solutio...

Complete banana chips production line

Streamline your snack production with a comprehensive line that transforms raw banana...

Vffs packaging solution for diverse bag styles and high hygiene standards

Enhance your packaging operations with high-...

Automatic belt chamber vacuum packing for meat and cheese

Achieve seamless integration into your packaging line with a m...

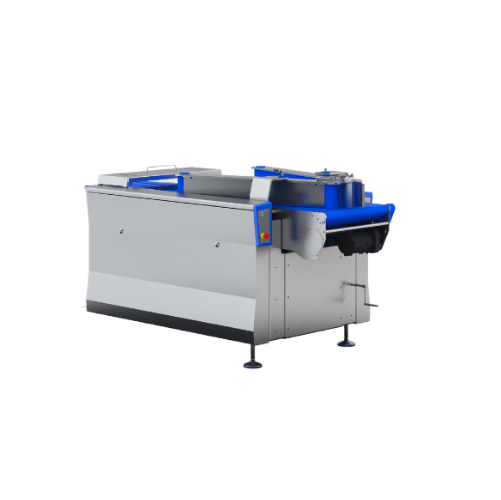

Hot water dip tank for immersion shrinking

Enhance the appearance and seal integrity of vacuum-packaged products with a ro...

Film shrink wrappers with 90° infeed

Easily adapt to compact spaces while efficiently wrapping various container shapes, fr...

Film shrink wrapper with in-line infeed

Streamline your packaging line with advanced shrink wrapping technology designed to...

Combined packers with in-line infeed for plastic and glass containers

Streamline your packaging process with a versatil...

In-line infeed wrap-around case packer

Optimize your secondary packaging process with high-speed wrap-around case packing, ...

Combined packers with in-line infeed for versatile packaging needs

Achieve seamless and efficient packaging with combin...

Flowpacker for packaging products

Achieve seamless packaging with high-speed, automated flowpacking that enhances product p...

High-speed case packer for crates and boxes

Streamline high-speed packaging with advanced robotics, placing over 140 packs...

Steady and moving pallet palletizers

Optimize your packaging line with advanced palletizing solutions designed to handle di...

Ketchup manufacturing line

Streamline your sauce production with precision-engineered efficiency, allowing for seamless reci...

Flowpack packaging machine for chocolate products

Effortlessly wrap and preserve large quantities of chocolate and sweet ...

Flow-wrapping solution for varied packaging needs

Gain unmatched flexibility and sustainability with a cutting-edge flow-...

Case packer for diverse packaging needs

Optimize your production line with this modular case packer, designed to handle div...

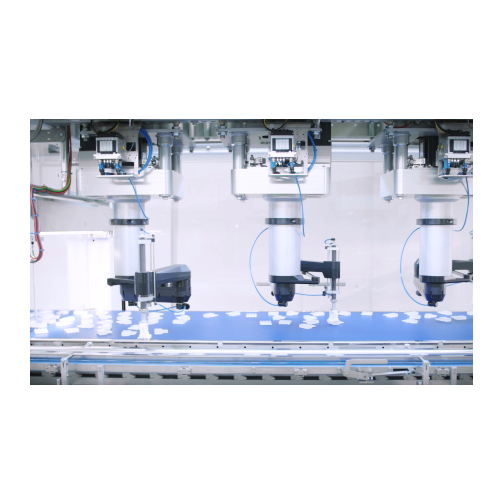

Pick & place robots for industrial packaging

Elevate your production line with advanced automation that ensures precise pa...

Pick and place robots for efficient product handling

Enhance your production line with high-speed pick and place robots c...

Pick & place vision system for packaging quality control

Ensure flawless product packaging with a vision system that enha...

Compact carton packing solution for standardized tasks

Streamline your packaging workflow with a preconfigured solution d...

Ultra-compact case packer for consumer goods

Maximize efficiency on your production floor with a compact case packer desig...

Flowpacker for packaging products in flowpacks

Optimize your flowpack packaging line with a preconfigured solution that ac...

Modular packaging systems for diverse industries

Effortlessly adapt to market demands with versatile packaging systems, de...

Automated pick and place cobot for packaging

Overcome packaging bottlenecks with an advanced cobot designed for high-speed...

Pick and place robotic system for product handling

Enhance your production line with high-speed, flexible pick and place ...

Flow wrapper with quick format change

Streamline your packaging operations with a machine that offers rapid format changeov...

Compact carton blank feeding system

Maximize your production efficiency with a solution designed to streamline carton blank...

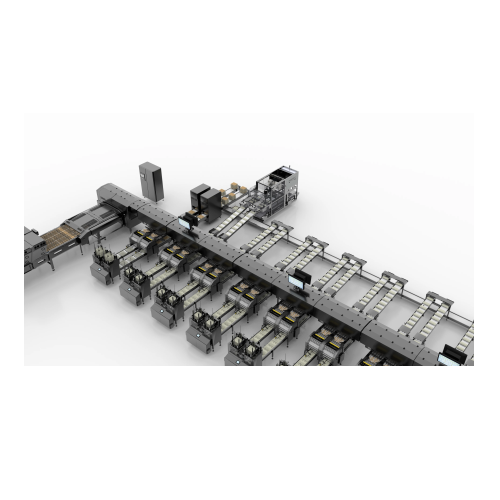

Automatic case packer for egg processing

Streamline your egg processing with high-speed case packing, seamlessly integratin...

Egg tray stacking for small and medium farms

Effortlessly enhance your egg packing operations with a compact tray stacking...

High capacity egg grader for efficient egg processing

Maximize egg quality and safety with this high-capacity grader, des...

Egg packing solution for high volume efficiency

Optimize your egg handling process with seamless packing and stacking effi...

Top-loading delta robot automation solution

For high-speed operations requiring precise product handling, this top-loading...

Top loader robots for precision packaging

Optimize packaging operations with versatile robotic top loaders that achieve hi...

Tray packer for forming, loading, and sealing

Optimize your production line with a versatile tray packer designed to seaml...

Cartoner for pharmaceutical products

Effortlessly streamline your packaging line with compact cartoning capabilities, ensur...

Compact case packer for secondary packaging

Optimize your secondary packaging process with a case packer that operates cle...

Horizontal cartoning system for coffee pods

Enhance your packaging line efficiency with a system designed for gentle handl...

Sequentially automated case packer for small products

Efficiently pack diverse small products into large cases with preci...

Butter Re-packaging Line

Although bulk butter blocks are commonly used in commercial food production, they are heavy and diff...

Big bag discharger

Big bags offer suitable material handling for powder products from pharma and food ingredients to bulk and...

High-speed FFS machine for water cups

Packing water in cup containers, asks for good hygiene in order to avoid contaminatio...

Manual bagger with net weigher

If you are looking for a weigher that is manually controlled for bagging, here it is. It has ...

Seaming machine for infant formula cans

Packaging of food products, but especially those for babies, like infant formula, i...

Robotic case packing machine for snack bags

Automated packing with robotic suction arms can quickly pickup packaged produc...

Confectionery bags case packer for large scale

Mass production lines need faster and more efficient package processing to ...

Grated cheese case packing machine

Large-scale cheese manufacturers process and handle products of different sizes and volu...

Endload cartoning machine

As demand for food production increases, so does that of packaging and sealing the product and mak...

Shrink sleeve labeling machine

Shrink sleeves are new type of full-colour labels that give the opportunity to create a 360-d...

Steam tunnel for shrink sleeve labels

When it comes to the option of applying sleeves or film on a container without wrinkl...

Hot air tunnel for shrink sleeve labels

Sleeves are very popular in food, beverage, Chemical and pharmaceutical industry be...

High-clean FFS machine for butter in mini portions

With the production of dairy products such as butter in mini portions ...

Ultra-clean FFS machine for yoghurt in cups

Dairy products like yoghurt are very susceptible to spoilage. Yeasts and mould...

Standard FFS machine for spreads and sauces in mini portions

In the food industry, from a microbiological point of view,...

Aseptic FFS machine for UHT products

UHT products (ultra high temperature processing) such as sterilized milk, are products...

Double head tray former for punnets

Tray forming machines can be an investment at first and require some technical knowledg...

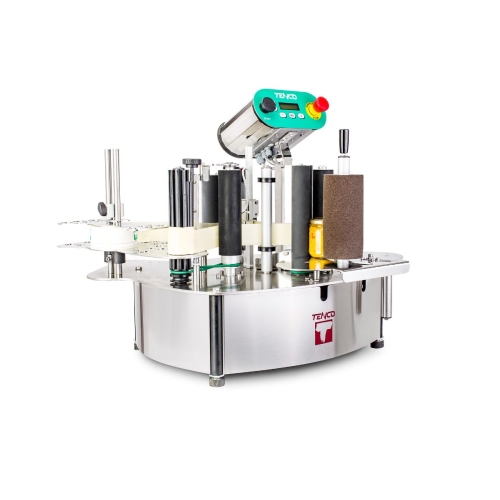

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Linear machine for wraparound label

Wraparound labels allow you to offer detailed information using a small space or fit ex...

Thermoforming vacuum and pressure machine for tray production

Thermoforming is the process of converting a plain plastic...

Industrial cook-in packaging line for cured meat

Industrial cook-in packaging offers numerous advantages for both foodserv...

Form fill seal thermoforming machine

As the name suggests, a Form Fill Seal machine is one that forms, fills, and seals a p...

Skin packaging machine

Skin packaging is when a product is placed on a tray or a paperboard with a thin layer of plastic plac...

Wet Wipes Packaging Machine

Sachet packaging is a convenient and popular wrapping method for a wide range of products in the...

Dairy Packaging Machine

The use of sachets and pouches for powdered or shredded dairy products is an increasingly popular for...

Modular HFFS Machine

A large range of sizes and types is available, with traditional horizontal form fill and seal machines b...

HFFS Machine for Large or Heavy Pouches

Traditional pouch-forming machines can struggle to maintain the position of the pac...

Retort Pouch Packaging Machine

A wide variety of products that were previously canned are now able to be more economically p...

Bag-in-Bag machine

If you are looking for a compact packing machine that packs multiple smaller packs in one master bag; this...

Bagger with servo driven jaw actuation

If you want to accommodate multiple bag designs and dimensions with fast speed and a...

Bagger with rotary jaw drive actuation

If you are looking for a compact packing machine that fits into tight space and tigh...

Shrink sleeve applicator - 400 per minute

Flexible medium to high speed application of shrink sleeveing to containers is u...

Low speed can sleeve applicator

Flexible automatic low speed application of shrink sleeving to cans is used in various indus...

Low speed shrink sleeve applicator

A variety of industries require flexible addition of shrink sleeves to containers on the...

Shrink sleeve applicator - 600 per minute