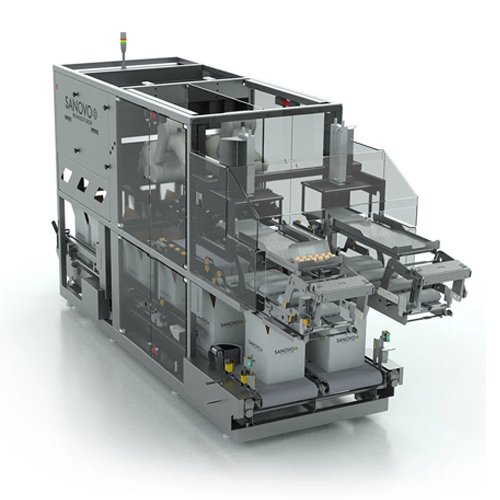

Automatic case packer for egg processing

Streamline your egg processing with high-speed case packing, seamlessly integrating with existing grading systems to enhance operational efficiency and reduce labor costs.

Automates and Streamlines Egg Carton Packing

The Case Packer Twin from SANOVO TECHNOLOGY GROUP is an engineered-to-order solution for automating egg carton packing operations. Designed for rigorous demands of egg producers and food industry specialists, this robotic system operates at speeds up to 160 cases per hour, accommodating up to 57,600 eggs. Its modular design allows seamless integration with existing grading setups, providing flexibility in packing patterns and the potential for traceability software integration like Ovotrack. The open design ensures easy maintenance and cleaning, while its ergonomic construction minimizes operator fatigue. With the option to enhance with an RPC kit for diverse case handling, this machine optimizes resources, reduces labor, and lowers total ownership costs. SANOVO’s Case Packer Twin meets CE, UL, and CSA certifications, ensuring compliance and safety in egg packaging environments.

Benefits

- Maximizes operational efficiency by handling up to 57,600 eggs per hour.

- Reduces labor costs, requiring only one operator for four lanes.

- Enhances production flexibility with customizable packing patterns.

- Minimizes maintenance time with an open, accessible design.

- Lowers total cost of ownership through durable, long-lasting construction.

- Applications

- Biosecurity, Egg grading, Food safety, Fertilized egg handling, Robotic automation, Egg-cultured vaccine production, Egg packaging

- End products

- Vaccine developed eggs, Egg cartons, Egg pallets, Graded eggs, Sanitized egg packages, Carton-packed eggs, Fertilized egg trays

- Steps before

- Egg Grading, Egg Washing, Sorting

- Steps after

- Palletizing, Distribution, Shipping

- Input ingredients

- egg packs, empty cases, RPC cases

- Output ingredients

- packed egg cases, discharged packed cases

- Market info

- Sanovo is renowned for manufacturing ETO industrial equipment, specializing in egg handling, processing, and packaging machinery. They hold a strong market reputation for innovative solutions and reliable, high-quality systems tailored to the food and egg industry.

- Capacity

- 57, 600 eggs/hour

- Case packing capacity

- 160 cases/hour

- Footprint dimensions

- 4, 464 x 1, 247 mm

- Minimum height of ceiling

- 2, 400 mm

- Machine weight

- 1, 650 kg

- Nominal voltage

- 220-240 VAC +N+PE

- Full load current

- 29 A

- Frequency

- 50/60 Hz

- Air pressure

- 6.0 bar

- Air consumption basic machine

- 2, 900 l/hr

- Air consumption with RPC kit

- 4, 090 l/hr

- Automation level

- High (PLC-controlled)

- Batch vs. continuous operation

- Inline Continuous

- Changeover time

- Minimal with modular design

- Cleaning method

- Manual

- Energy efficiency

- Optimized

- Traceability integration

- Compatible with Ovotrack software

- Accessibility for maintenance

- Open design

- Cleanability

- Yes

- Biological compatibility

- Suitable for egg handling

- Corrosive resistance

- Stainless steel construction

- Abrasion resistance

- High durability

- Container Type

- Egg cartons and cases

- Machine footprint

- 4, 464 x 1, 247 mm

- Minimum ceiling height

- 2, 400 mm

- Machine weight

- 1, 650 kg

- Discharge method

- Conveyor system

- Integration with existing systems

- Compatible with common graders

- Base conveyor type

- Common or Split base conveyor

- RPC Kit

- Included for both lanes

- Pass-through conveyor

- Optional for manual packing