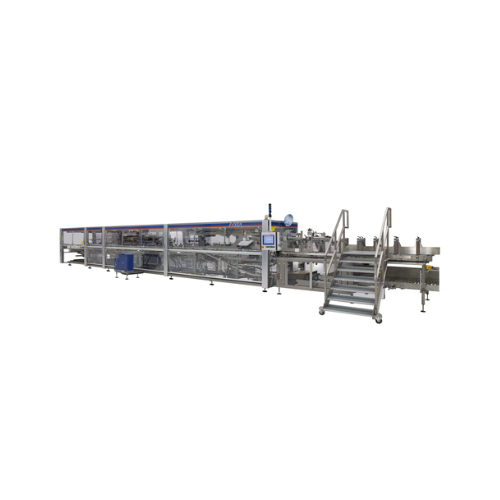

Fully automatic wrap-around shrink packer

Ensure maximum pack stability and energy efficiency with this high-performance solution, featuring versatile wrapping and shrinking capabilities for a wide range of product types.

Wraps and Shrinks Diverse Product Packages

The Innopack Kisters WSP Advanced from KHS Group is a fully automatic wrap-around shrink packer engineered for versatile applications across beverage, food, and non-food industries. This equipment stands out with its modular design, incorporating a film-wrapping module and an optional gas-heated shrink tunnel to optimize energy efficiency and reduce CO2 emissions. Capable of producing up to 6,000 packs per hour, it precisely folds blanks around product groups, ensuring maximum pack stability. The system seamlessly integrates with existing production lines, offering quick format changeovers and a user-friendly interface with an error diagnosis system. Designed for sustainability, it supports film made of 100% recycled material, minimizing carbon footprints without compromising packaging quality. Suitable for packaging various end-products such as bottles, cartons, and trays, the Innopack Kisters WSP Advanced provides high precision and reliability, meeting the demands of diverse production operations.

Benefits

- Enhances production flexibility with quick and simple format changeovers.

- Cuts energy costs by up to 50% using optional gas-heated shrink tunnels.

- Significantly reduces carbon emissions with 100% recycled film options.

- Maintains high machine availability of up to 98% through precise engineering.

- Minimizes spare part expenses by decreasing wear part requirements.

- Applications

- Beverages, Liquid food, Food products, Homecare products, Sanitary items

- End products

- Soda cans, Bottled water, Snack trays, Juice pouches, Milk cartons, Wine bottles, Soap dispensers, Cereal boxes, Shampoo bottles, Detergent bottles

- Steps before

- Bottle blowing, Container design, Filling, Labeling

- Steps after

- Palletizing, Distribution logistics, Quality control, Warehousing

- Input ingredients

- cartons, trays, loose products, packs, beverages, food products, sanitary items

- Output ingredients

- film-wrapped trays, versatile cartons, high-stability packs, recycled material film-wrapped products

- Market info

- KHS is known for manufacturing innovative filling and packaging systems for the beverage, food, and non-food industries, renowned for their engineering expertise, high-quality standards, and sustainable solutions in ensuring efficient production processes.

- Output Capacity

- Up to 6, 000 packs per hour

- Automation

- Fully automatic

- Packaging Types

- Cartons, trays, film-wrapped trays

- Shrink Film Material

- 100% recycled material

- Energy Efficiency

- Gas-heated shrink tunnel reduces energy costs

- CO2 Emissions Reduction

- Up to 65%

- Machine Availability

- Up to 98%

- Film Cutting System

- Integrated high-tech film cutting and feeding

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Continuous

- Changeover time

- Quick and simple format changeovers

- Cleaning method

- Manual

- Energy efficiency

- Reduces energy costs by up to 50% with gas-heated shrink tunnel

- CIP/SIP

- Not specified

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Packaging type

- Cartons, trays, film-wrapped trays

- Machine footprint

- Compact

- Discharge method

- Fully automatic

- Control panel type

- Integrated operator control unit

- Wrap-around capability

- 45° and 90° corners

- Product spectrum

- Cartons, trays, film-wrapped trays

- Film cutting and feeding system

- High-tech, integrated

- Shrink tunnel

- Gas-heated

- Optional

- Control panel type

- Operator control unit with error diagnosis system

- Integration possibilities

- Compatible with various packaging types (cartons, trays, film)

- Shrink tunnel heating option

- Gas-heated or electric

- Shrink film type

- 100% recycled material