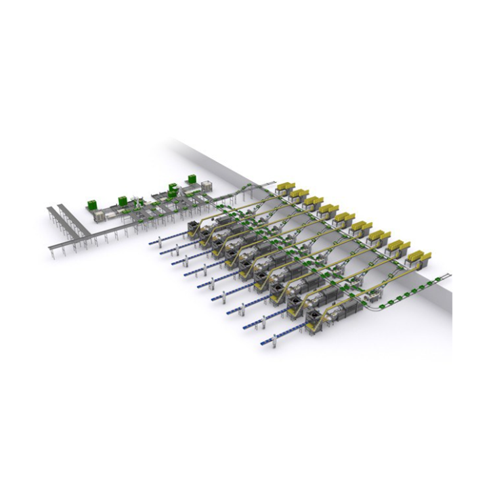

Traysealing system for chicken breasts packaging

Streamline your poultry packaging with a fully automated traysealing solution designed for high-speed operations, ensuring secure sealing, efficient product handling, and robust inspection to meet rigorous quality standards.

Seals, Inspects, and Palletizes Chicken Breasts

The industrial traysealer and palletizing system, integrated with ULMA Packaging’s engineering expertise, revolutionizes chicken breast packaging operations. It features fully automated processes, from robotic loading and tray sealing under modified atmosphere conditions to inspection, labeling, and palletizing. Ideal for poultry and meat industries, this system excels in high-speed, continuous production environments, ensuring each tray meets quality standards with its advanced metal detection. The nine-line setup offers flexibility and scalability, handling large throughput with ease. Flexible for food distribution centers, it incorporates PLC controls for seamless integration into existing lines. Its energy-efficient operation and robust materials ensure reliability, compliance, and long-term durability, meeting industry certifications.

Benefits

- Enhances production efficiency with fully automated loading, sealing, and palletizing.

- Ensures product safety and quality with integrated metal detection and MAP sealing.

- Reduces labor costs through robotic automation and efficient distribution systems.

- Provides scalability for large production volumes with nine parallel processing lines.

- Facilitates easy integration and operational monitoring with PLC-controlled systems.

- Applications

- Meat, Poultry

- End products

- Tray-sealed poultry products, Chicken breasts

- Steps before

- Distribution of trays, Warehouse management, Product loading by robots

- Steps after

- Inspection with metal detector, Labeling, Manual case packing, Palletizing

- Input ingredients

- chicken breasts, trays, plastic crates

- Output ingredients

- sealed trays, labeled trays, palletized boxes

- Market info

- ULMA Packaging Spain is renowned for designing and manufacturing innovative, customized packaging solutions for the food, pharmaceutical, and non-food industries, emphasizing advanced automation technology, sustainability, and high-quality service.

- Automation

- Fully automated

- Traysealing lines

- 9 lines

- Palletizing cells

- 2 cells

- Packaging method

- Traysealing with MAP

- Inspection system

- Metal detector

- Automation level

- Fully automated

- Batch vs. continuous operation

- Inline Continuous

- Product loading method

- Automatic robotic loading

- Tray sealing type

- Modified Atmosphere Packaging (MAP)

- Inspection system

- Metal detector

- Labeling process

- Automated

- Case packing method

- Manual

- Palletizing method

- Anthropomorphic robot

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Not specified

- Traysealing lines

- 9 lines

- Palletizing cells

- 2 cells

- Robot loading

- Automatic

- Tray distribution

- Fully automated

- Plastic crate distribution

- Fully automated

- Loading method

- Automatic by robots

- Inspection system

- Metal detector

- Palletizing method

- Anthropomorphic robots

- Packaging atmosphere

- Modified Atmosphere Packaging (MAP)

- Control panel type

- Touchscreen HMI

- Integration possibilities

- Robotic integration

- Automation level

- Fully automated