Combined shrink-wrapper and case packer for medium to high-speed productions

Optimize your end-line packaging process with a versatile system, capable of handling diverse product forms at medium to high speeds, ensuring seamless integration into existing production lines.

Packs and Wraps Diverse Products Efficiently

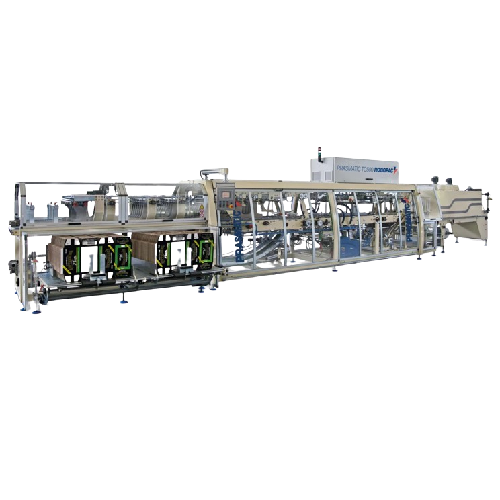

The Prasmatic TC 500/600 Combi from OCME is an engineered solution that integrates high-speed shrink-wrapping and case packing for diverse production lines. This equipment is ideal for sectors such as beverages, food, personal care, and paper products, effectively handling items like milk cartons and shampoo bottles while maintaining continuous operations. The machine’s design offers maximum adaptability, capable of executing secondary packaging solutions with film and wraparound cartons. With processing capabilities reaching up to 65 packages per minute, it ensures efficient throughput. The TC Combi features modular construction, enabling seamless integration into existing lines, and is equipped with brushless servomotors for precise control. Its ergonomic layout includes an external loading system for film reels and a retractable collating plate, simplifying maintenance and format changes. The system also supports automation with options like automatic reel change and electronic format adjustments, enhancing productivity without manual intervention. Available with partial or full stainless-steel execution, the TC Combi suits environments requiring stringent hygiene standards.

Benefits

- Enhances production efficiency with a capacity of up to 65 packages per minute.

- Minimizes manual intervention through automated reel change and format adjustments.

- Features an ergonomic design for easier maintenance and operation access.

- Adapts to diverse packaging needs, from film to wraparound cartons.

- Supports high hygiene standards with stainless steel options.

- Applications

- Food, Personal care, Beverage, Tissue, Lubricants, Paper, Corrugated, Home

- End products

- Packaged rice, Lubricant containers, Bottled motor oil, Milk cartons, Soft drink cans, Tissue paper packages, Glass bottled mineral water, Soap bars, Yogurt containers, Shampoo bottles, Corrugated cardboard boxes, Canned vegetables, Paper towel rolls

- Steps before

- Product Sorting, Primary Packaging

- Steps after

- Palletizing, Distribution

- Input ingredients

- film, carton tray, blanks, reel

- Output ingredients

- shrink-wrapped packs, tray and film packs, wraparound cartons, film only packs, flat pad and film packs, high tray packs

- Market info

- OCME, part of Aetna Group Italy, is renowned for manufacturing innovative, high-quality packaging and material handling solutions, including filling, palletizing, and conveying systems, with a strong reputation for reliability and technological advancement in industrial sectors.

- Packaging Speed

- 55 to 65 packages/min

- Output Capacity

- Up to 65 PPM

- Blanks Magazine Capacity

- 400-1600

- Max Blank Length

- 1250 mm

- Max Blank Width

- 650 mm

- Max Reel Diameter

- 500 mm

- Max Reel Width

- 720 mm

- Max Reel Weight

- 80 Kg

- Average Size Changeover Time

- 10 ÷ 12 min

- Automation

- Brushless Motor Control

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- 10–12 min

- CIP/SIP

- No specific value

- Cleaning method

- Manual / Easy Maintenance

- Energy efficiency

- Not specified

- Cleaning ease

- Sliding doors and led lighting facilitate access

- Modularity

- Highly modular frame

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size

- Various shapes and sizes

- Container type

- Carton, Tray

- Secondary packaging type

- Film, Carton tray, Wraparound Cartons

- Packing speed

- Up to 65 PPM

- Reel positioning

- Various solutions, ergonomic

- Collating plate retractability

- High flexibility for format changes

- Automatic format changing

- Controlled electronically

- Film unit removability

- Quick and efficient maintenance

- Modular design

- Yes

- Ergonomic design

- Yes

- Machine Frame

- Modular with improved access

- External Blank Magazine

- Single/Double version

- Blanks magazine capacity

- 400-1600 according to thickness

- Control panel type

- HMI touchscreen

- Control panel type

- User-friendly touchscreen panel

- Modularity

- High, with various configuration options

- Ergonomics

- Extremely ergonomic design

- Frame material

- Partial or full stainless steel

- Format change

- Automatic format change

- Film unit

- Removable for quick maintenance

- Reel handling

- Automatic reel change