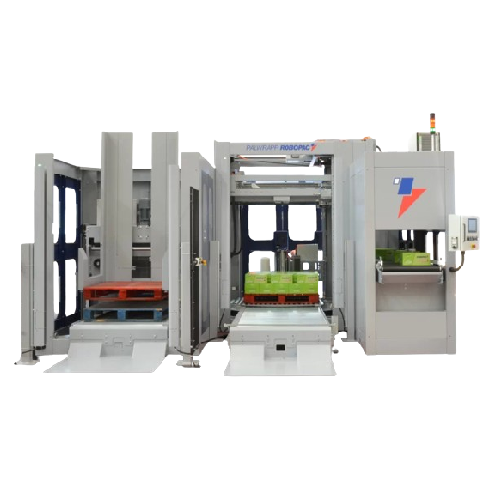

Compact and modular palletizer for food industry

Optimize your end-of-line efficiency with this modular palletizing solution designed for seamless integration, flexibility in handling varied product dimensions, and enhancing safety with top-level electronics and servo-driven components.

Palletizes and Wraps Diverse Product Lines

The PALWRAPP series by Robopac offers a range of compact, modular palletizers and stretch wrappers, engineered for seamless integration into food, beverage, and consumer packaged goods production lines. These units stand out due to their flexible configuration options, accommodating various production needs with models like the PALWRAPP 3 INLINE INFEED, PALWRAPP 2 INLINE INFEED, PALWRAPP 2 SWEEP INFEED, and SEMIAUTOMATIC PALWRAPP. Utilizing servo drives for low energy consumption and high reliability, these machines efficiently handle up to 50 cycles per minute, adapting to different pallet heights and product sizes. The embedded Cube Technology optimizes stretch wrapping, reducing film usage while maintaining load stability. Automation features, such as automatic format changes, ensure minimal downtime, while safety standards meet Category 3 PL (d) requirements. These solutions are particularly suited for operations seeking enhanced throughput and efficient end-of-line handling.

Benefits

- Enhances operational efficiency with automatic format changes, minimizing downtime.

- Reduces material costs through optimized stretch wrapping with Cube Technology.

- Lowers energy consumption via servo-driven components for sustainable operations.

- Ensures operator safety with Category 3 PL (d) safety standards.

- Accommodates diverse production needs with flexible, modular configurations.

- Applications

- Food, Personal care, Consumer packaged goods, Beverage, Tissue, Lubricants, Paper, Corrugated, Home

- End products

- Lubricant containers, Dairy containers, Cardboard boxes, Bottled water, Toilet paper rolls, Paper towels, Soap dispensers, Ready-to-eat meals, Packaged snacks, Canned beverages, Shampoo bottles, Packaged pasta, Detergent bottles

- Steps before

- Infeed preparation, Loading, Product sorting

- Steps after

- Stretch wrapping, Packaging, Logistics handling

- Input ingredients

- flat bottom packs, food industry products, consumer packaged goods

- Output ingredients

- palletized products, packaged goods, wrapped pallets

- Market info

- OCME, part of Aetna Group Italy, is renowned for manufacturing innovative, high-quality packaging and material handling solutions, including filling, palletizing, and conveying systems, with a strong reputation for reliability and technological advancement in industrial sectors.

- Speed

- Up to 50 cpm

- Layer Capacity

- 3 layers/min

- Pallet Height

- Up to 2700 mm (optional 3000 mm)

- Pallet Format

- 1200x1000 mm

- Product Infeed

- 1200x800 mm (800x600 mm optional)

- Product Dimensions

- Min. 150x150x100(h) mm, Max. 600x400x400(h) mm

- Automation

- Automatic and Semi-Automatic Versions

- Servo Drives

- Enabled

- Safety Standard

- 3PL (d) CATEGORY

- Energy Consumption

- Low (Servo Motors)

- Automation level

- Automatic / Semi-automatic / Manual

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Zero downtimes due to automatic format change

- Cleaning method

- Simple and intuitive interface

- Energy efficiency

- Low energy consumption due to servomotors

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact

- Modular structure

- Yes

- Pallet height

- 1400-3000 mm

- Pallet format

- 1200x1000 mm, 1200x800 mm

- Product dimensions (Min)

- 150x150x100 mm

- Product dimensions (Max)

- 600x400x400 mm

- Layer weight

- Up to 350 kg

- Infeed technology

- Inline / Sweep

- Control panel type

- Simple and intuitive interface

- Compact footprint

- Extreme compact machine

- Control panel type

- Simple and intuitive interface

- Integration possibilities

- Concurrent stretch wrapping system integrated

- Modularity

- Compact and modular design

- Format change

- Automatic format change

- Remote assistance

- Available

- Layer weight handling

- Up to 350 KG