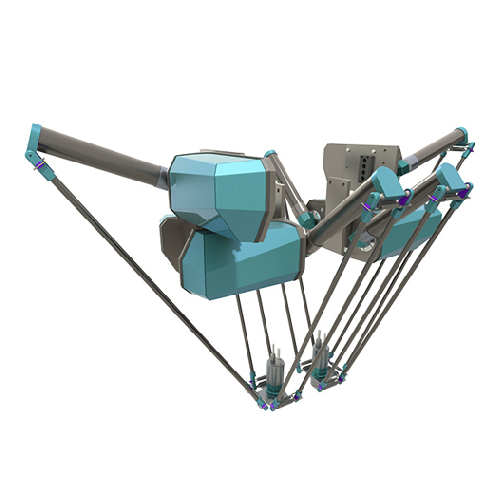

Dual-axis delta robot for high-capacity packaging lines

Enhance your production line’s efficiency with a dual-axis delta robot designed for rapid and precise packaging, loading, and handling, enabling seamless integration for high-speed, continuous operations.

Performs High-Speed Packaging and Handling Operations

The ABIflexx Wide Delta Robot series is engineered by ABI to revolutionize high-speed packaging and handling tasks. Featuring a dual-axis design with a perpendicular third axis, these robots deliver enhanced rigidity, light weight, and speed, making them ideal for double robot configurations in limited spaces. Tailored for the packaging, horticulture, and semiconductor industries, among others, these robots seamlessly handle products ranging from snack packages to semiconductor wafers. The ABIflexx models, including the WD3 and WD4 series, operate with continuous, automated precision, accommodating high-capacity lines. Integration is streamlined with advanced PLC controls, ensuring smooth connection upstream and downstream in your production line. Constructed to endure, these robots can be customized with materials suited for varied industrial applications and adhere to relevant industry standards, promoting reliability and compliance.

Benefits

- Enhances productivity with high-speed, simultaneous loading capabilities.

- Saves valuable floor space with compact double robot configurations.

- Easily integrates into existing production lines with seamless PLC control.

- Minimizes maintenance downtime with robust and durable construction.

- Adaptable for diverse industrial applications through configurable options.

- Applications

- Semiconductor industry, Bulk packaging, Food industry, Packaging industry, Automotive technology, Consumer packaging, Access technology, Horticulture, Graphic industry, Production automation, Medical industry

- End products

- Printed materials, Bulk food containers, Automotive components, Medical device packaging, Pharmaceutical blister packs, Snack packages, Semiconductor wafers, Cereal boxes, Flower pots, Electronic devices

- Steps before

- Product Feeding, Material Sorting

- Steps after

- Packaging, Bulk Handling

- Input ingredients

- consumer packaging, bulk packaging

- Output ingredients

- loaded consumer packaging, loaded bulk packaging

- Market info

- Robot Type

- Wide Delta

- Number of Axes

- 3 (two parallel, one perpendicular)

- Capacity

- High-capacity lines

- Weight

- Lighter construction

- Stiffness

- High stiffness

- Space Utilization

- Compact

- Speed

- High speed

- Load Handling

- Consumer and bulk packaging

- Model

- ABIflexx WD3-1000, WD3-1250, WD3-1580, WD4-1000, WD4-1250, WD4-1580

- Working Mechanism

- Wide Delta Configuration

- Automation Level

- PLC-controlled

- Batch vs. Continuous Operation

- Batch

- Speed

- High-speed capability

- Load Capacity

- Double robot combination capability

- Flexibility

- Consumer and bulk packaging

- Stiffness

- Enhanced rigidity

- Compactness

- Space-saving design

- Changeover Time

- Quick adjustments possible

- Application

- Consumer and bulk packaging

- Integration possibilities

- Multiple robots in one space

- Compact footprint

- Wide-Delta design for compact solutions

- Control panel type

- Compatible with KEBA controllers

- Mechanische engineering

- Custom mechanical design available

- Elektrische engineering

- Custom electrical design available