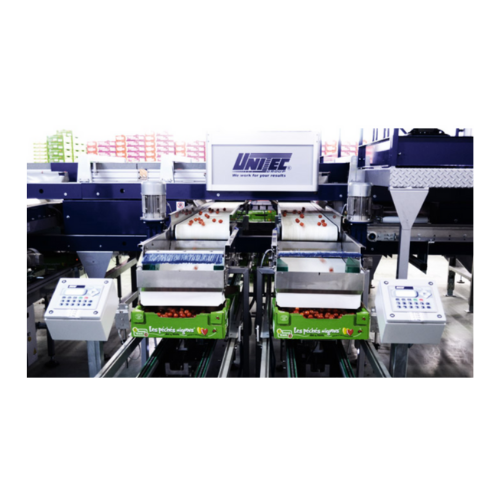

Sorting and grading systems for cherry tomatoes

Ensure uniform quality and size of cherry tomatoes with advanced sorting and grading technology, reducing manual labor and maintaining product integrity for enhanced market appeal.

Sorts and Grades Cherry Tomatoes Efficiently

The CHERRY TOMATO VISION 3 by Unitec is an electronic sorter designed specifically for cherry tomato and small fruit processing, offering precision in sorting based on size, color, and defects. This high-capacity system uses advanced vision technology for non-destructive quality assessment, ensuring optimal product appearance and integrity. It is ideal for producing cherry tomato salads, salsas, and fresh produce packs. The equipment operates continuously at high speeds, integrating seamlessly into automated production lines to enhance throughput and reduce manual labor. Constructed with AISI 304 stainless steel, it ensures durability and corrosion resistance. Customizable to adapt to varying plant needs, Unitec supports engineering modifications to optimize processing efficiency.

Benefits

- Enhances product quality with precise non-destructive sorting.

- Reduces labor costs through automated defect detection.

- Increases profitability by optimizing production efficiency.

- Meets exacting market standards with superior color and quality selection.

- Customizable design tailored to specific operational needs.

- Applications

- Small fruits, Tomatoes, Fruits, Cherry tomatoes, Produce, Vegetables

- End products

- Fresh produce packs, Tomato salsas, Fruit salads, Vegetable medleys, Tomato sauces, Cherry tomato salads, Pre-packaged cherry tomatoes

- Steps before

- Harvesting, Transporting, Receiving

- Steps after

- Packing, Distribution, Exporting

- Input ingredients

- cherry tomatoes

- Output ingredients

- sorted cherry tomatoes, graded cherry tomatoes, packed cherry tomatoes

- Market info

- Automation

- PLC-controlled

- Capacity

- Ultra-high capacity

- Accuracy

- Precision sorting based on size, colour, defects

- Detection type

- Non-destructive internal and external quality detection

- Material

- AISI 304 stainless steel

- Sorting speed

- High-speed alignment and sorting

- Automation Level

- PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning Method

- CIP / Manual

- Energy Efficiency

- High / Optimized

- AISI 304 stainless steel

- Corrosive resistance

- Durability

- High

- Biological compatibility

- Yes

- Cleanability

- Easy

- Non-destructive testing compatibility

- Yes

- Customization

- Available to suit specific needs

- Integrated technology

- CHERRY TOMATO VISION 3 Unitec Technology

- Ultrahigh capacity sorters

- UNICAL 200

- Control panel type

- Customizable

- Integration possibilities

- Plant specific

- Customization options

- Product and market requirement specific

- System modules

- Modular