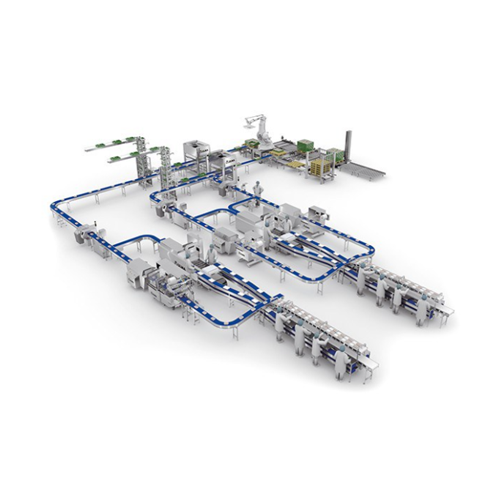

Chicken breast packaging system

Streamline your poultry packaging line with a solution that ensures precise loading, wrapping, and vacuum sealing, enhancing product shelf life and presentation.

Packages and Palletizes Poultry Products Efficiently

The ULMA Packaging system offers a fully automated solution for poultry and meat processing operations. This comprehensive system integrates flow pack and thermoforming technology to deliver high-speed packaging for products such as chicken breasts and marinated drumsticks. Capable of handling various packaging modes—flow pack for modified atmosphere packaging and vacuum sealing via thermoforming—the system ensures extended shelf life and excellent product presentation. With a process capacity that supports continuous, high-speed throughput, it is ideal for large-scale operations. ULMA’s solution incorporates metal detection for quality assurance and employs robotic cells for case packing and palletizing, facilitating seamless integration into existing production lines. Designed for energy efficiency, the system also includes customizable options and remote monitoring capabilities to enhance operational control and maintenance ease.

Benefits

- Enhances production efficiency by automating all stages from loading to palletizing.

- Ensures product integrity with reliable vacuum and MAP packaging options.

- Minimizes operational costs through energy-efficient design.

- Reduces contamination risk with integrated metal detection systems.

- Facilitates seamless integration with existing production lines for uninterrupted workflow.

- Applications

- Meat, Poultry

- End products

- Chicken breasts, Vacuum-sealed chicken wings, Sliced turkey, Packaged chicken thighs, Marinated chicken drumsticks

- Steps before

- Product preparation, Manual loading, Tray loading

- Steps after

- Inspection, Case packing, Robotized palletizing, Film bundling for storage, Transport

- Input ingredients

- chicken breasts, preformed trays, shrink barrier film, flexible film

- Output ingredients

- packaged chicken breasts, flow pack wrapped trays, vacuum packaged chicken breasts, plastic crates

- Market info

- ULMA Packaging Spain is renowned for designing and manufacturing innovative, customized packaging solutions for the food, pharmaceutical, and non-food industries, emphasizing advanced automation technology, sustainability, and high-quality service.

- Automation

- Fully automated

- Packaging Type

- Flow pack, thermoforming, vacuum packaging

- Film Type

- Shrink barrier film

- Inspection Method

- Metal detectors

- Robotic Palletizing

- Anthropomorphic robot

- Working Mechanism

- Flow pack wrapping, thermoforming, vacuum packaging

- Integrated Steps

- Product preparation, packaging, inspection, case packing, palletizing

- Automation Level

- Fully automated with robotic cells for case packing and palletizing

- Inspection Technology

- Metal detectors

- Batch vs. Continuous Operation

- Inline Continuous

- Packaging Method

- Modified atmosphere packaging (MAP), shrink film, vacuum

- Palletizing Method

- Anthropomorphic robot

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Poultry products

- Chicken breasts

- Machine footprint

- Compact

- Tray shape

- Preformed

- Film type

- Shrink barrier film

- Discharge method

- Plastic crates

- Palletizing method

- Robotized palletizing

- Flow pack wrapping

- Modified atmosphere (MAP)

- Thermoforming film type

- Flexible film

- Control panel type

- Touchscreen / Push-button

- Integration possibilities

- Robotic cells / Automation systems

- Packaging technology

- Flow pack / Thermoforming

- Loading method

- Manual / Automated

- Palletizing method

- Anthropomorphic robot

- Film type

- Shrink barrier / Flexible