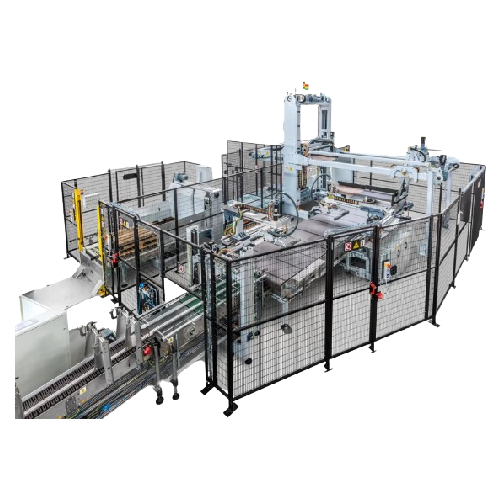

Conventional palletizer with 90° infeed

Optimize your palletizing efficiency with high-speed, energy-saving operations that seamlessly integrate into your production line, ensuring robust handling and stable stacking of various product types from drums to tissue rolls.

Optimizes Palletizing and Depalletizing Operations

The Perseus Series by OCME offers meticulously engineered palletizing solutions, featuring fully automatic operations and 90° infeed configurations. These robust machines are tailored to efficiently manage diverse product formats, from 60 L and 200 L drums to carton boxes and tissue rolls, providing seamless integration into packaging and transport departments across the beverage, food, personal care, and paper industries. With high-speed capabilities, these machines handle up to 510 layers per hour, optimizing your end-of-line efficiency. Equipped with advanced layer forming systems and robotic grippers, the Perseus Series ensures precise layer pad insertion and product handling. These palletizers are Industry 4.0 ready, featuring centralized PLC control and remote monitoring for enhanced operational oversight. Designed for durability and minimal maintenance, they incorporate brushless motors, reducing energy consumption while maintaining optimal torque control. Customizable configurations and engineering support guarantee that the Perseus Series meets your specific production needs, from compact setups to varied infeed levels.

Benefits

- Enhances operational efficiency with high-speed palletizing up to 510 layers per hour.

- Reduces labor costs through fully automatic, Industry 4.0-ready integration.

- Minimizes energy usage with brushless motors, ensuring optimal torque and control.

- Increases production flexibility with customizable configurations for diverse product formats.

- Improves safety and precision in handling with advanced robotic grippers and layer forming systems.

- Applications

- Food, Personal care, Paper and tissue, Beverage, Lubricants, Home

- End products

- Bundle packages, 60 l drums, 200 l drums, Tissue rolls, Carton boxes

- Steps before

- Product sorting, Layer forming, Pack rotating

- Steps after

- Stretch wrapping, Internal logistics, Shipping

- Input ingredients

- tissue products, package with bundle, cases, cartons, 60 L drums, 200 L drums

- Output ingredients

- palletized layers, pallets with interlayer pads, stacked products

- Market info

- OCME, part of Aetna Group Italy, is renowned for manufacturing innovative, high-quality packaging and material handling solutions, including filling, palletizing, and conveying systems, with a strong reputation for reliability and technological advancement in industrial sectors.

- Speed (Perseus F)

- 480 drums/hour

- Speed (Perseus N,HM-N variant)

- 510 layers/hour

- Speed (Perseus N,low level infeed)

- 300 layers/hour

- Speed (Perseus Z)

- 150 layers/hour

- Automation

- Fully automatic

- Energy Efficiency

- High energy saving

- Compact Design

- Extremely compact and sturdy

- Control System

- HMI user friendly

- Motor Type

- Brushless motors

- Automation level

- Fully automatic

- Batch vs. continuous operation

- Continuous

- Cleaning method

- Manual

- Energy efficiency

- High energy saving

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Processed products

- Tissue products, bundles, cases, cartons

- Machine footprint

- Extremely compact

- Infeed method

- 90° infeed

- Pallet type

- Steady / Moving

- Pallet height

- Low or high product infeed level

- Pad insertion system

- Automatic feeding for layer-pads

- Layer forming system

- MIZAR Layer Forming System

- Manipulator types

- Cartesian, robot, or gantry

- Gripping mechanism

- Brushless motorised gripping heads

- Product type compatibility

- Various types of packs

- Control panel type

- HMI user friendly

- Integration possibilities

- Industry 4.0 ready

- Pallet infeed level

- Low or High

- Palletizing variants

- Steady or Moving pallet

- Product compatibility

- Various types of packs

- Motors type

- Brushless motors