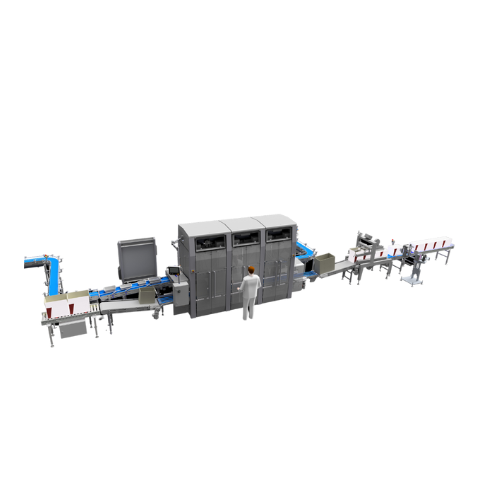

Automated end-of-line packaging for diverse products

Streamline your packaging line with this automated solution, designed to efficiently handle a variety of product types while ensuring precision and speed in packing, labeling, and loading processes. Ideal for businesses focused on enhancing throughput without compromising product integrity.

Automates Packing, Labeling, and Loading

The JASA End of Line Packaging System is designed for seamless integration into food packaging lines, offering an automated solution to enhance efficiency and accuracy. Leveraging high-speed robotics, it manages the packing, labeling, and loading of a variety of products ranging from leafy greens to meat and fish. With its capacity to process solid and semi-solid items, it produces end-products such as mixed salad bags, fruit salad cups, and frozen fish fillets. This system operates continuously and fully automatically, making it ideal for high-throughput scenarios found in food manufacturing and agricultural businesses.

Equipped with advanced pick and place robots, the system minimizes human error, achieves precise label application, and further increases process consistency. The unit’s menu control feature ensures quick changeovers, enhancing operational flexibility. Constructed from durable materials to withstand demanding conditions, it is an investment in longevity and reliability. Additionally, customizable options and engineering support are available to adapt the system to specific packaging requirements.

Benefits

- Increases production efficiency by automating packing, labeling, and loading processes.

- Enhances operational flexibility with quick changeovers via menu control.

- Maintains product integrity through precise handling of delicate items.

- Reduces manual labor and associated costs with continuous, automated operation.

- Adapts to various product types, supporting diverse packaging needs.

- Applications

- Avocados, Tomatoes, Potatoes, Onions, Pome fruits, Kiwis, Tapas, Leafy greens, Meat (plant-based) and fish, Citrus, Cut fruits, Carrots

- End products

- Baby carrot snacks, Tomato salsa jars, Avocado halves packages, Pre-chopped onions, Citrus fruit baskets, Frozen fish fillets, Plant-based meat packages, Pear and apple slices, Mashed potato packs, Tapas snack trays, Kiwi fruit tubs, Mixed salad bags, Fruit salad cups

- Steps before

- Sorting, Washing, Inspection, Cutting

- Steps after

- Labeling, Crating, Boxing, Shipping

- Input ingredients

- leafy greens, cut fruits, tapas, meat (plant-based) and fish, potatoes, carrots, onions, tomatoes, citrus, avocados, pome fruits, kiwis, solid products, semi-solid products, flex products

- Output ingredients

- crates, boxes, trays, packaging patterns

- Market info

- JASA Packaging is known for its innovative, sustainable packaging solutions, particularly in the design and manufacture of high-speed packaging machinery for food products, emphasizing flexibility and eco-friendly processes.

- Automation

- Fully automatic

- Speed

- High throughput

- Product rotation option

- Yes

- Packaging pattern variety

- Wide range

- Menu control

- Fast change-over

- Precision

- High

- Automation level

- Fully automatic

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Fast

- CIP/SIP

- Not applicable

- Cleaning method

- Manual

- Energy efficiency

- N/A

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Footprint

- Compact design

- Infeed system

- Rotating option

- Product placement

- Vertical in carrier

- Product handling type

- Automatic loading

- Control method

- Menu control

- Control panel type

- Menu control

- Integration possibilities

- Pick, Place Robots

- Product infeed system

- Rotating or non-rotating

- Packaging pattern customization

- Wide range